Contents

I. Installation.............................................................................................................................. 1

1.1 Unpacking and checking.......................................................................................... 1

1.2 Power connection...................................................................................................... 1

1.3 Fuse............................................................................................................................. 1

1.4 Environment............................................................................................................... 1

1.5 Test fixture used.........................................................................................................2

1.6 Preheating and continuous working time.............................................................. 2

1.7 Other features of the instrument............................................................................. 2

II. Introduction to the product................................................................................................. 2

2.1 Main Features............................................................................................................ 3

2.2 Introduction to the front panel..................................................................................4

2.3 Introduction to the back panel................................................................................. 6

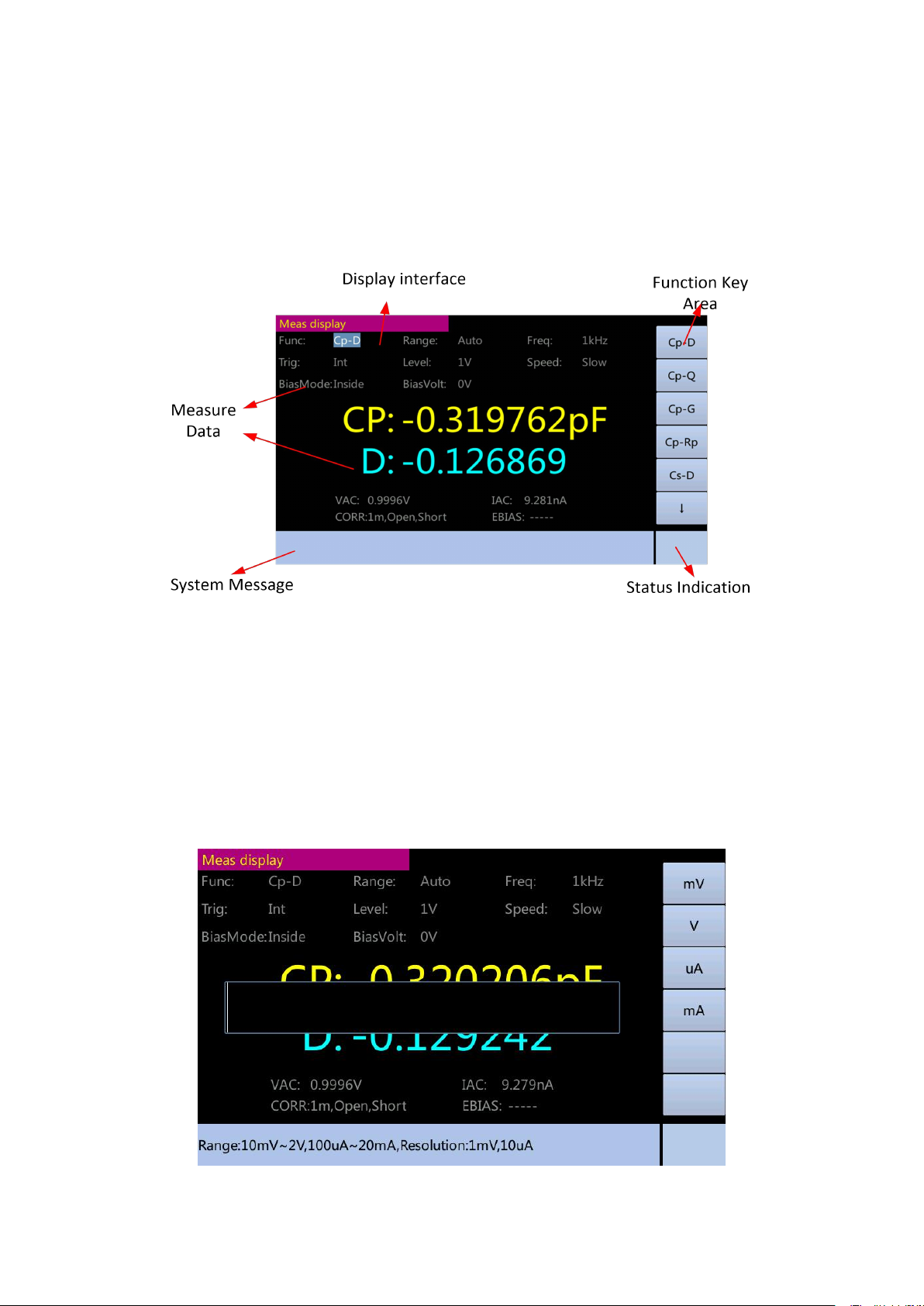

2.4 Screen area................................................................................................................ 7

2.5 Basic Operations....................................................................................................... 8

2.6 Display format............................................................................................................ 8

III. Basic measurement......................................................................................................... 13

3.1 Measurement Setup page..................................................................................... 13

3.2 Correction page....................................................................................................... 27

3.3 Limit table setup display.........................................................................................45

3.4 List Sweep Setup display.......................................................................................53

IV. System configuration....................................................................................................... 57

4.1 System configuration display................................................................................ 57

4.2 System configuration display................................................................................ 59

4.3 System self test....................................................................................................... 69

4.4 System update.........................................................................................................71

4.5 Self correction.......................................................................................................... 73

V. Save / call........................................................................................................................... 75

VI. Technical indicators and performance test.................................................................. 81

6.1 Technical indicators.................................................................................................81

6.2 Components.............................................................................................................93

6.3 General technical requirements............................................................................93

6.4 Performance test..................................................................................................... 94

VII. Instruction on the use of Handler interface................................................................ 97

VIII. Circuit theory and formulas........................................................................................103

IX. Notes and warranty....................................................................................................... 108