Contents

1 Basic Introduction........................................................................................................... 1

1.1 Function............................................................................................................... 1

1.2 Summary of Source and Measure Functions....................................................... 1

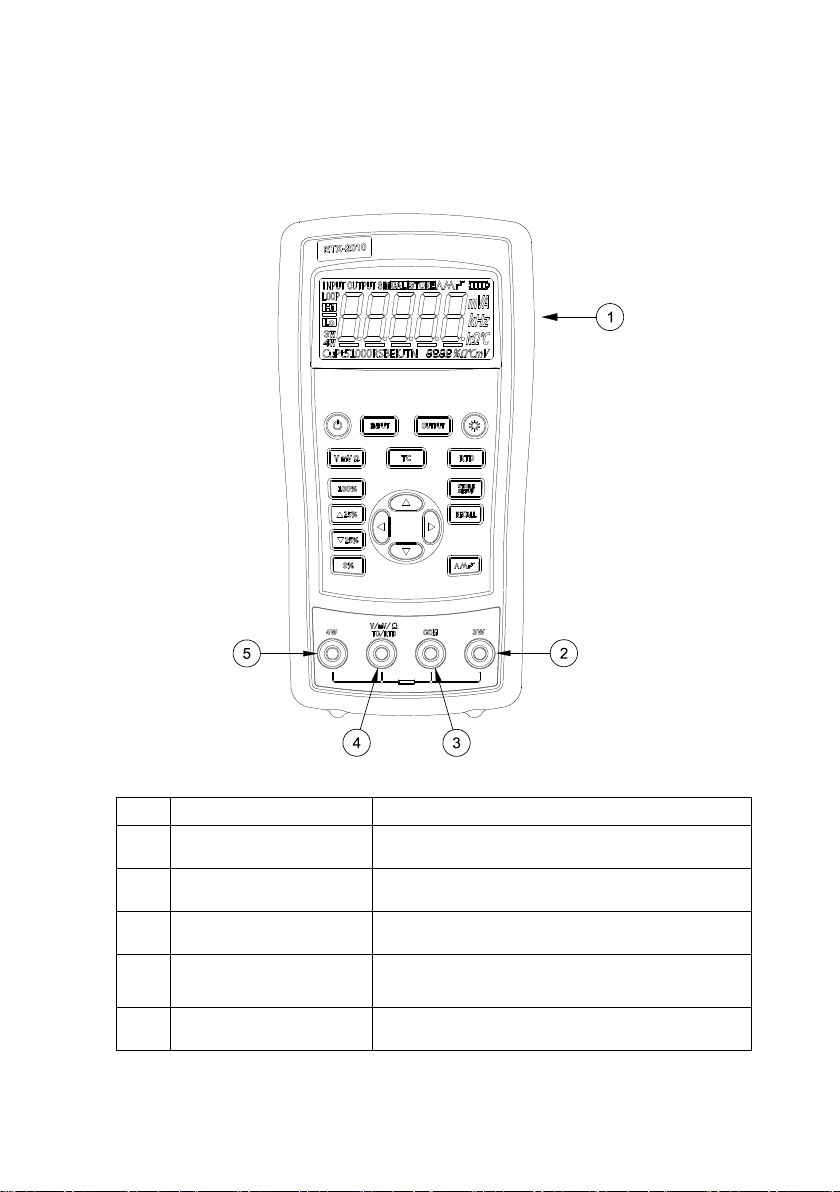

1.3 Terminal Description............................................................................................2

1.4 Key Description................................................................................................... 3

1.5 Display Screen..................................................................................................... 4

2 Basic Operation...............................................................................................................5

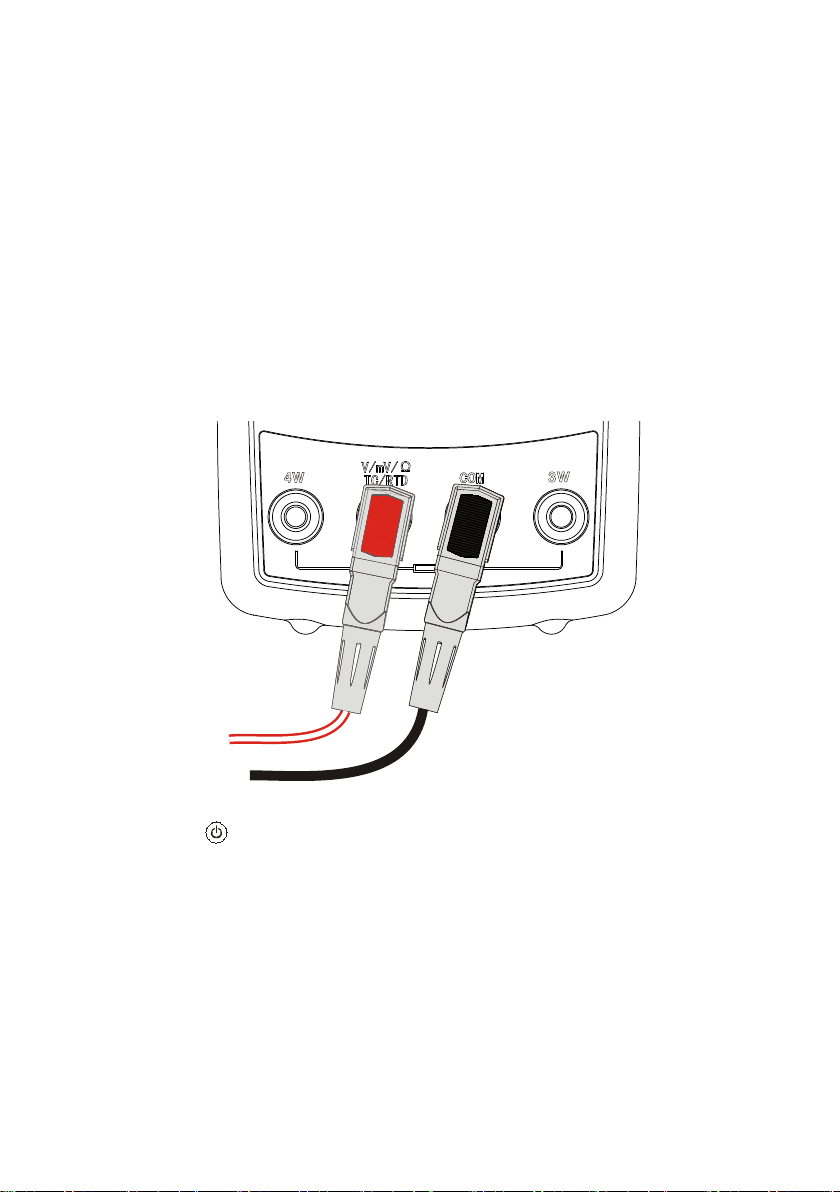

2.1 Measure and Source............................................................................................. 5

2.2 Shutdown Mode................................................................................................... 7

2.3 Backlight Brightness Adjustment.........................................................................8

3 Function Usage............................................................................................................... 9

3.1 DC V Measurement..............................................................................................9

3.2 DC mV Measurement........................................................................................ 10

3.3 Resistance Measurement....................................................................................10

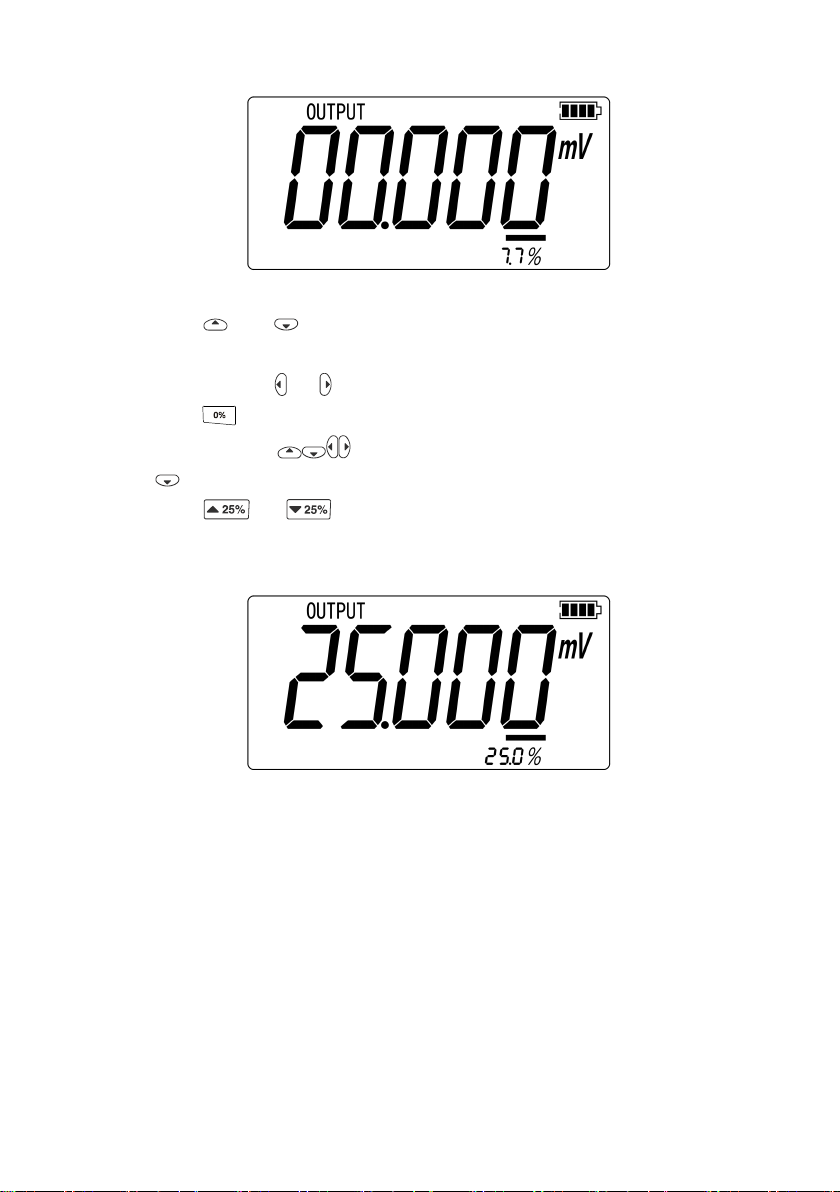

3.4 DC mV Output................................................................................................... 11

3.5 Resistance Output.............................................................................................. 12

4 Temperature Measurement............................................................................................13

4.1 Using Thermocouple (TC)................................................................................. 13

4.2 Using Resistance Thermometer Detector (RTD)............................................... 15

5 Simulation of temperature sensor................................................................................. 18

5.1 Simulating Thermocouples................................................................................ 18

5.2 Application of Resistance Temperature Detector (RTD)................................... 19

6 Advanced Application................................................................................................... 21

6.1 Setting 0 % and 100 % output parameters......................................................... 21

6.2 Auto Ramping the Output.................................................................................. 22

6.3 Factory Reset......................................................................................................22

7 Power............................................................................................................................ 23

7.1 Charge................................................................................................................ 23

8 Specifications................................................................................................................ 24

8.1 DC Voltage Measurement.................................................................................. 24