II

Contents

1.Important Safety Precautions........................................................................................................... 1

General Information.................................................................................................................... 1

UPS Safety.................................................................................................................................. 1

Battery Safety..............................................................................................................................2

Description of Symbols...............................................................................................................3

2. Product Introduction........................................................................................................................4

2.1 Introduction........................................................................................................................... 4

2.2 System Configuration............................................................................................................4

2.3 Operation Mode.....................................................................................................................4

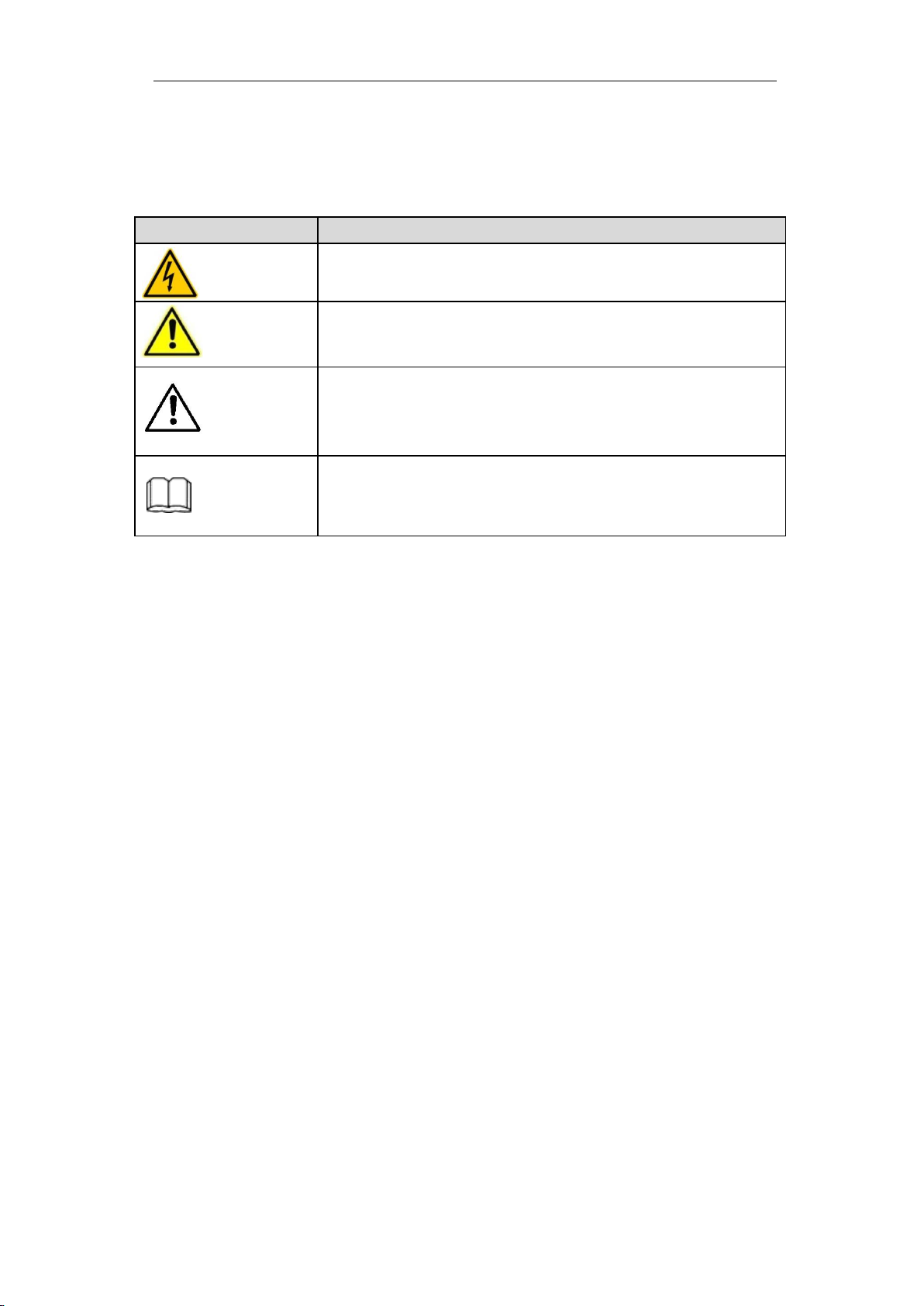

2.3.1 Normal Mode............................................................................................................. 4

2.3.2 Battery Mode..............................................................................................................5

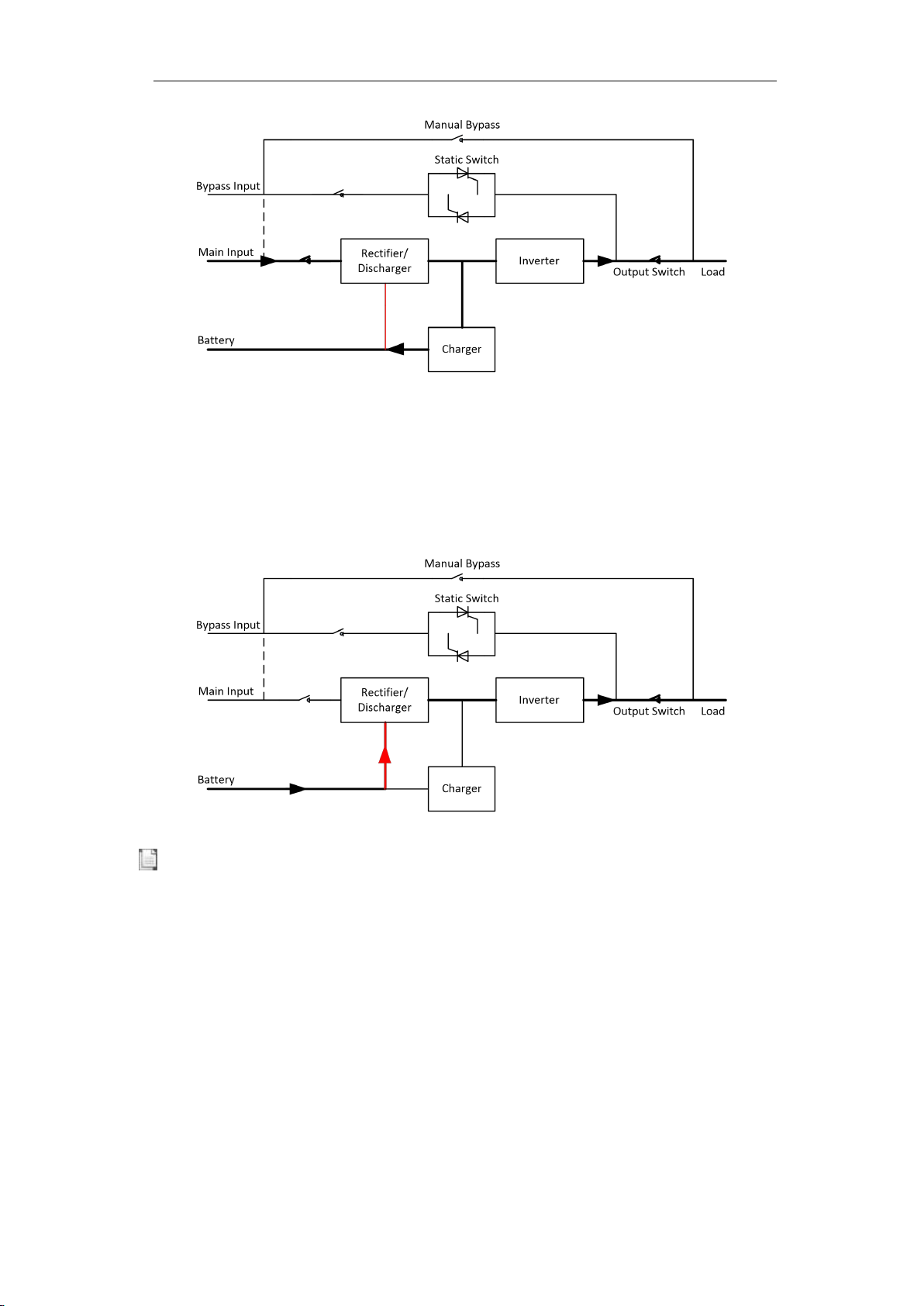

2.3.3 Bypass Mode..............................................................................................................5

2.3.4 Maintenance Mode (Manual Bypass)........................................................................ 6

2.3.5 ECO Mode................................................................................................................. 6

2.3.6 Auto-restart Mode...................................................................................................... 7

2.3.7 Frequency Converter Mode....................................................................................... 7

2.3.8 Self Aging Mode........................................................................................................ 7

2.4 UPS Structure........................................................................................................................8

2.4.1 UPS Configuration.....................................................................................................8

2.4.2 UPS Outlook.............................................................................................................. 8

3. Installation Instruction.................................................................................................................. 10

3.1 Location...............................................................................................................................10

3.1.1 Installation Environment..........................................................................................10

3.1.2 Site Selection............................................................................................................10

3.1.3 Size and Weight....................................................................................................... 10

3.1.4 Installation Tools......................................................................................................11

3.2 Unpacking and Inspection...................................................................................................11

3.2.1 Unpacking of the Cabinet.........................................................................................11

3.3 Main cabinet installation.....................................................................................................12

3.3.1 Tower Installation.....................................................................................................12

3.3.2 Rack Installation...................................................................................................... 13

3.4 Battery................................................................................................................................. 13

3.5 Cable Entry..........................................................................................................................14

3.6 Power Cables.......................................................................................................................15

3.6.1 Specifications........................................................................................................... 15

3.6.2 Specifications for Power Cables Terminal.............................................................. 15

3.6.3 Circuit Breaker.........................................................................................................16

3.6.4 Connecting Power Cables........................................................................................ 16

3.7 Control and Communication Cables...................................................................................17

3.7.1 Dry Contact Interface...............................................................................................18