Contents

Safety .............................................................................................................................7

Explanation of Symbols.................................................................................................8

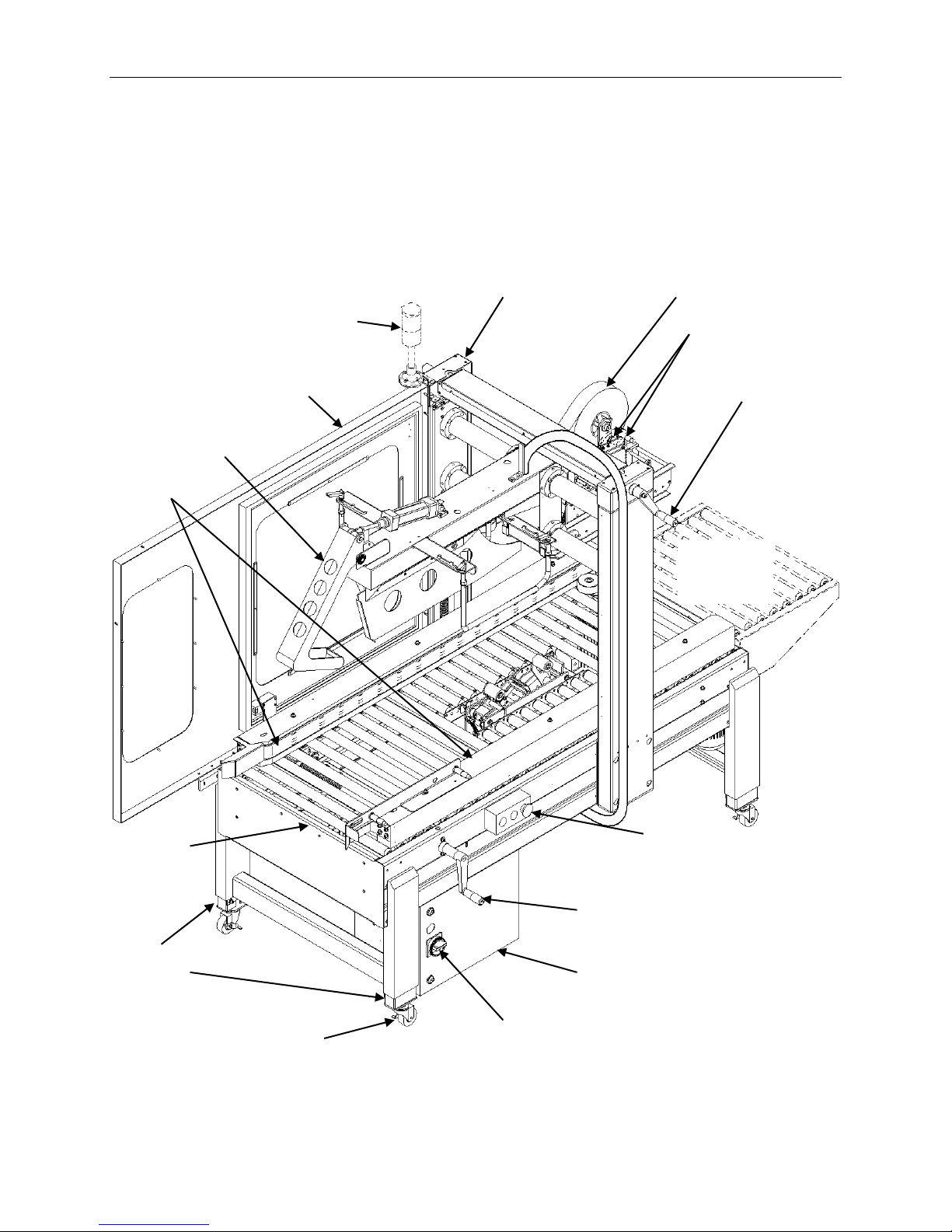

Introduction ...................................................................................................................9

General System Description..........................................................................................9

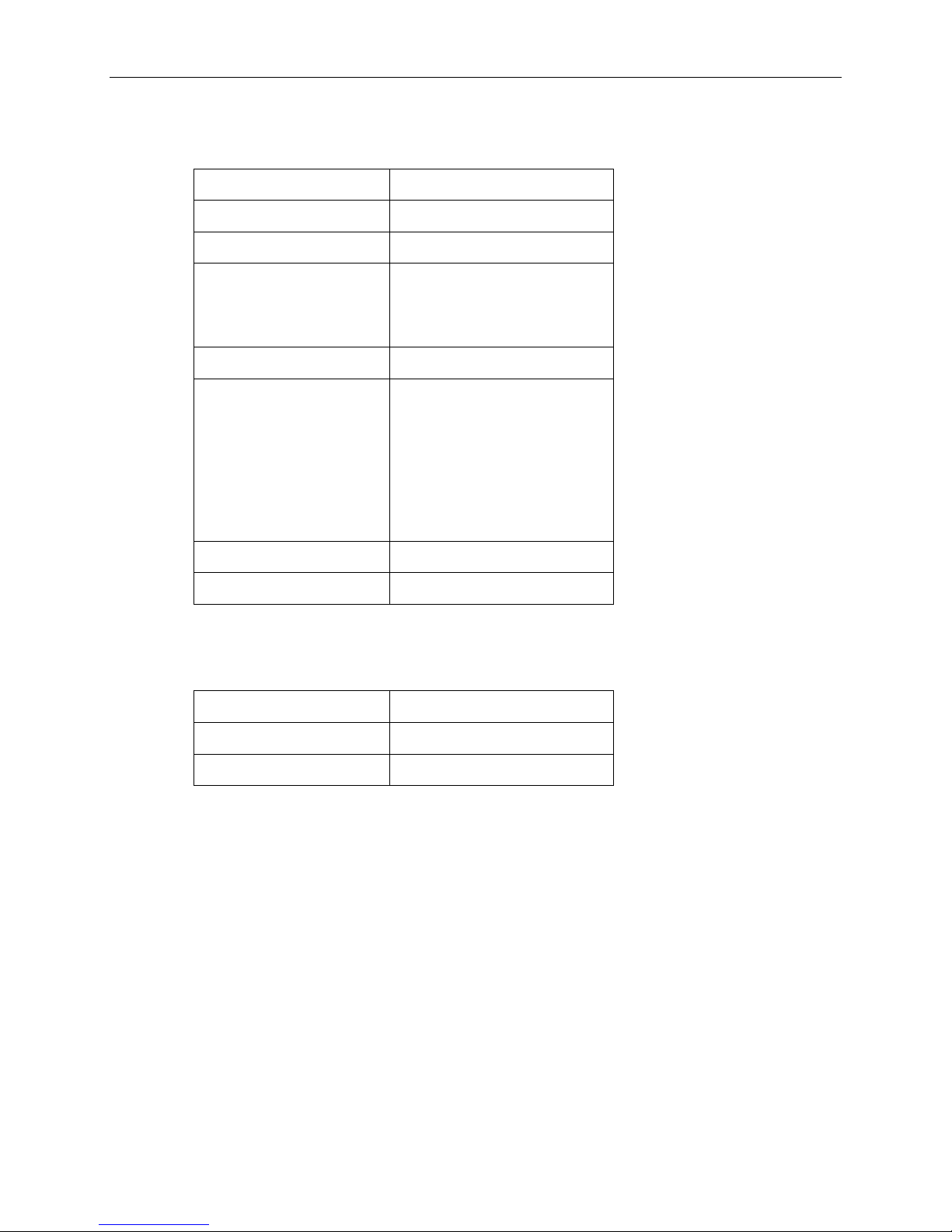

Specifications..............................................................................................................10

Dimensions .................................................................................................................11

Installation ...................................................................................................................13

Location Requirements ...............................................................................................14

Operation.....................................................................................................................15

Loading the Tape Cartridges.......................................................................................15

Check Tension............................................................................................................16

Thread Tape................................................................................................................16

Main Spring.................................................................................................................18

Power..........................................................................................................................19

Control Panel ..............................................................................................................19

Adjustments ................................................................................................................21

Air Pressure unit..........................................................................................................21

Height and Width Adjustment......................................................................................22

Flap Closing Guide Adjustment...................................................................................23

Belt Adjustment...........................................................................................................25

Machine Body Height Adjustment ...............................................................................26

Maintenance ................................................................................................................27

Rollers.........................................................................................................................27

Cutting Knives.............................................................................................................27

Troubleshooting..........................................................................................................28

Parts List......................................................................................................................31

Electrical......................................................................................................................31

Pneumatic Parts..........................................................................................................35

Side Belt......................................................................................................................37

Column........................................................................................................................40

Flap Guide Assembly ..................................................................................................42

Machine Body .............................................................................................................45

Door Guard Assembly.................................................................................................47

Appendix A: Electrical Schematic .............................................................................49

Warranty Statement ....................................................................................................55

Customer Support.......................................................................................................57