Contents

Safety......................................................................................................7

Explanation of Symbols................................................................................................. 8

Introduction ............................................................................................9

VS1620 L-Sealer and Heat Tunnel Combo................................................................... 9

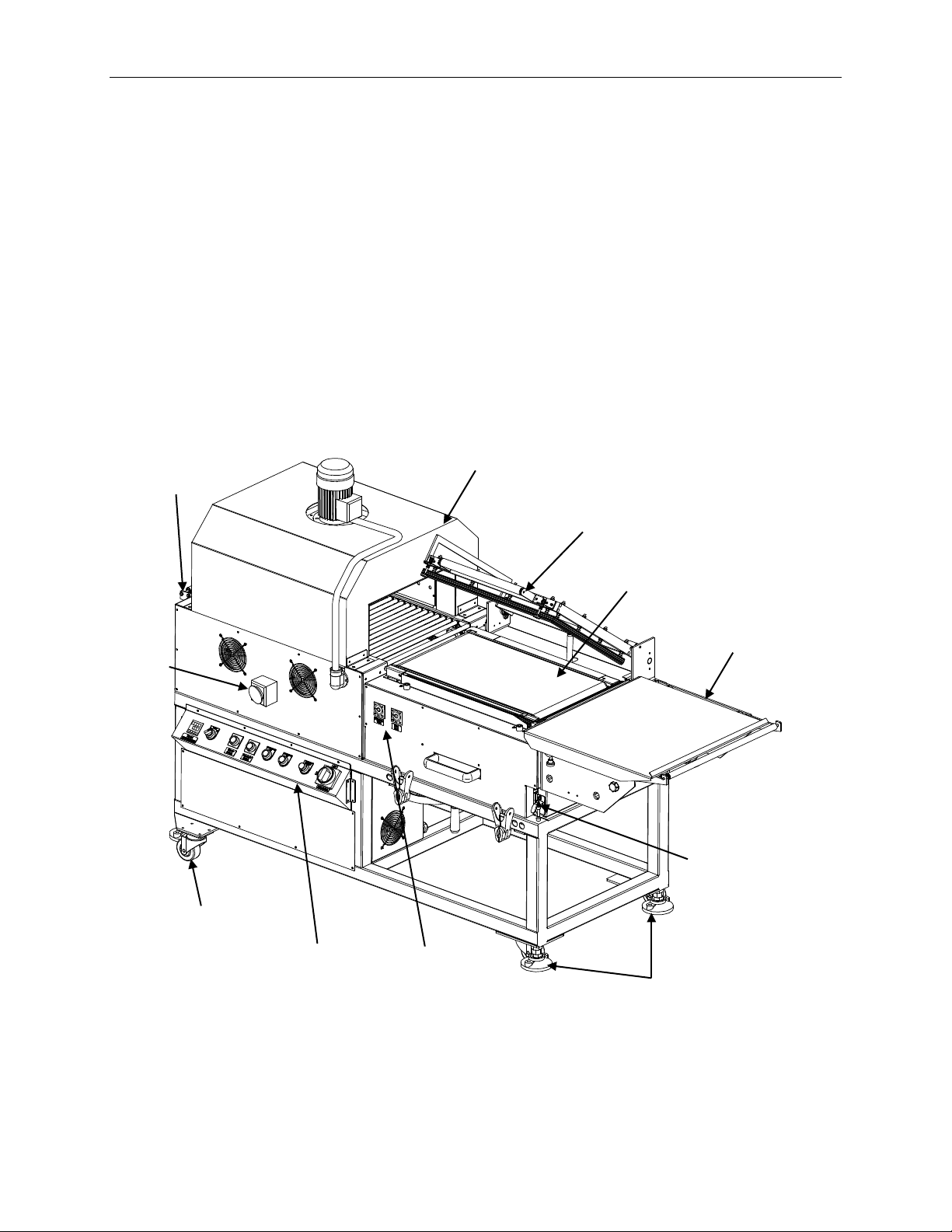

System Components..................................................................................................... 9

Specifications.............................................................................................................. 10

Dimensions............................................................................................................. 11

Installation and Set Up .........................................................................12

Unpacking ................................................................................................................... 12

Assembly .................................................................................................................... 12

Product Tray ........................................................................................................... 12

Power Cord............................................................................................................. 13

Location Requirements ............................................................................................... 13

Aligning the Seal Head Limit Switch and Actuator ...................................................... 14

Loading the Film.......................................................................................................... 14

Threading the Shrink Film ........................................................................................... 16

Aligning the Shrink Tunnel .......................................................................................... 17

Seal Head Height Adjustment ..................................................................................... 18

Operation ..............................................................................................19

Sealer and Tunnel Operation ...................................................................................... 19

Main Power............................................................................................................. 20

Conveyor and Blower.............................................................................................. 20

Tunnel Heater ......................................................................................................... 20

Setting the Tunnel Temperature ............................................................................. 21

Blower Speed ......................................................................................................... 21

Conveyor Speed ..................................................................................................... 21

E-Stop or Emergency Stop ..................................................................................... 22

Sealer Operation......................................................................................................... 22

Seal Time................................................................................................................ 22

Take Away Time ..................................................................................................... 23

Energizing Seal Band Time Adjustment.................................................................. 23

Sealing the Product................................................................................................. 23

Shutting Down............................................................................................................. 24

Special Notes About the Tunnel Shutdown Sequence............................................ 25

Maintenance .........................................................................................26

Sealer.......................................................................................................................... 26

Daily........................................................................................................................ 26

Shrink Tunnel.............................................................................................................. 26

Daily........................................................................................................................ 26

Monthly ................................................................................................................... 26

Cleaning...................................................................................................................... 27

Rollers..................................................................................................................... 27

Replacing the Seal Band, PTFE Tape, or Seal Pads ................................................. 27

Lower Seal Band and Bead Disassembly............................................................... 29