9

GENERAL INSTALLATION PROCEDURES

CHOOSING A SAFE LOCATION

When selecting a suitable mounting location for the heater, it is important to consider the following:

The heater must be installed with a minimum of 7 ft. (2.1 meters) between the floor and the bottom of

the heater in Canada. In the United States it must be installed with a minimum of 8 ft. (2.4 meters)

between the floor and the bottom of the heater, unless the optional protective grill is used, in which case

it may be installed with a minimum of 7 ft. (2.1 meters) between the floor and the bottom of the heater.

(See grill installation procedure, page 16)

The proposed mounting location allows for the minimum required safe distances to combustibles,

including vehicles that may be parked in the building, wood, gasoline and flammable objects, liquids

and vapours that may be stored in the space.

The proposed location will not restrict motion of passageway doors or windows, or the operation of the

overhead garage door.

The proposed location will provide the best coverage of the total area to be heated.

The proposed location will allow the required utilities (i.e. gas, and electric) and venting to be installed

(bearing in mind the minimum and maximum vent length requirements).

Sufficient clearances will exist to allow for maintenance.

Overhead structural members are available, and suitably strong to support the heater assembly.

GENERAL GUIDELINES

Regardless of the vent arrangements that will be connected to the heater, the following general guidelines for

venting must be followed:

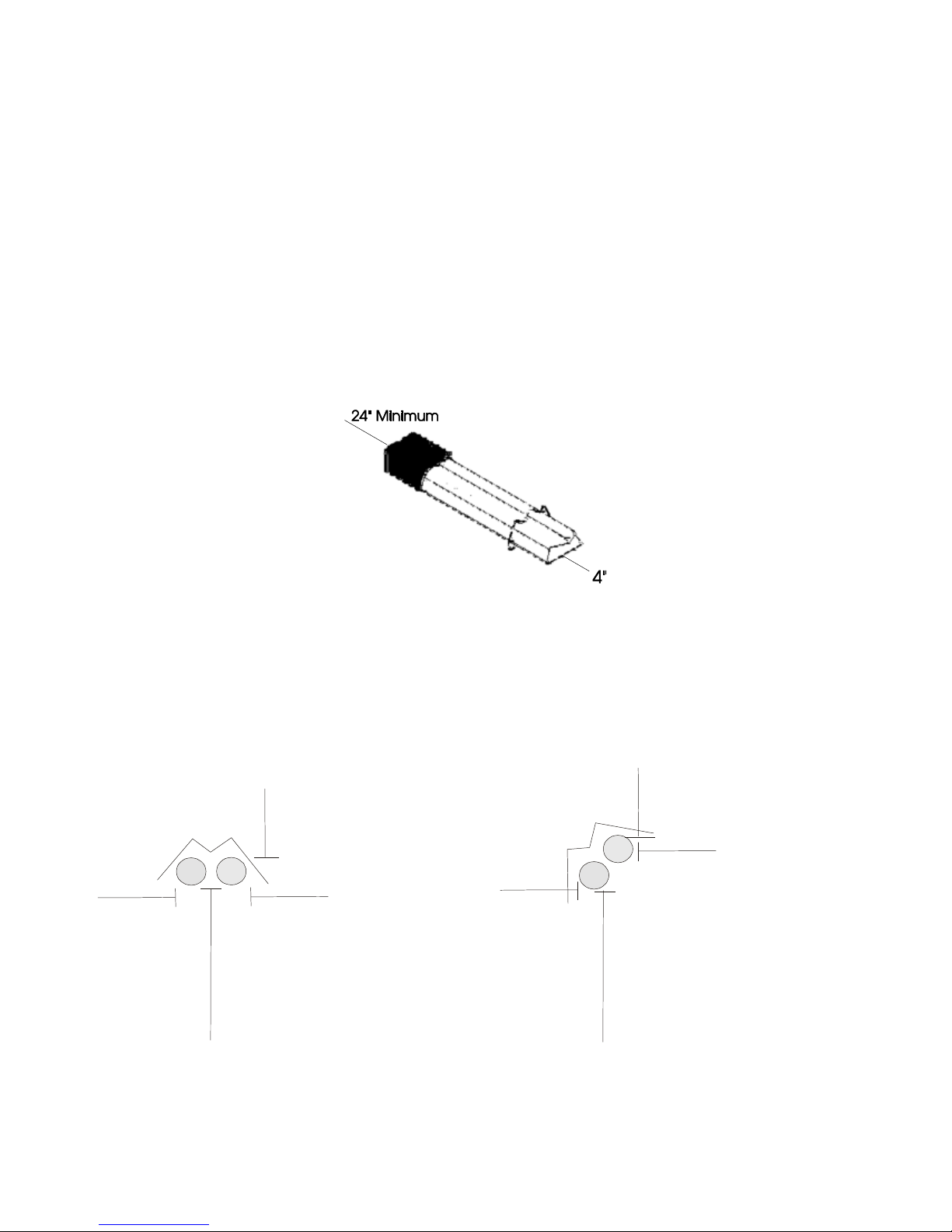

The 3" (7.6 cm) flue pipe must be centered inside the 5" (12.7 cm) air supply pipe using the centering

guides supplied.

IMPORTANT: THE FLUE PIPE AND AIR SUPPLY PIPE MUST BE SECURE. IF NOT SECURE,

THIS WILL CAUSE DAMAGE TO THE HEATER AND VOID WARRANTY.

All horizontal venting sections must slope away from the heater at a rate of 1/4" (6 mm) per foot.

The total length of vent pipe (horizontal and vertical) must not exceed 12 ft. (3.6 meters) and must not

be less than 2 ft. 6 inches (.7 meters)

The vent terminal, mounted outside of the building should not be located above walkways. Condensate

produced during operation of the heater could drip onto the walkway and form ice during cold weather

resulting in a dangerous condition.

Be sure that the venting installation is in accordance with all applicable local codes and

recommendations of the local gas supplier.

DO NOT connect the heater to a separate chimney, and DO NOT common vent with any other fuel-

burning appliance.

Seal all vent pipe connections with high temperature silicone sealant and secure each connection with

three sheet metal screws.