E - 27200.23101001- 22 February 2017 3:53 PM - Jaga N.V.

Mounting instructions

Knockonwood DBE KNUF

The letters ‘CE’ appear on our products traded on the extended

Single Market in the European Economic Area (EEA). They signify

that products sold in the EEA have been assessed to meet high

safety, health, and environmental protection requirements.

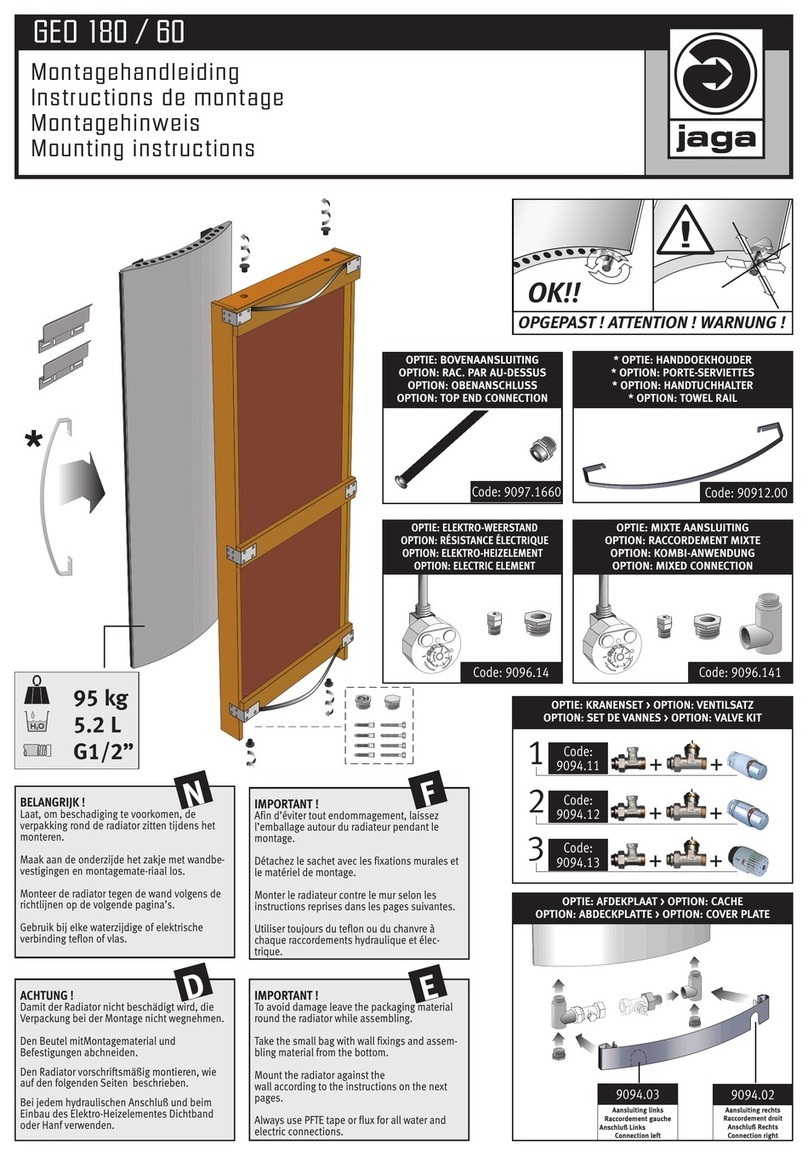

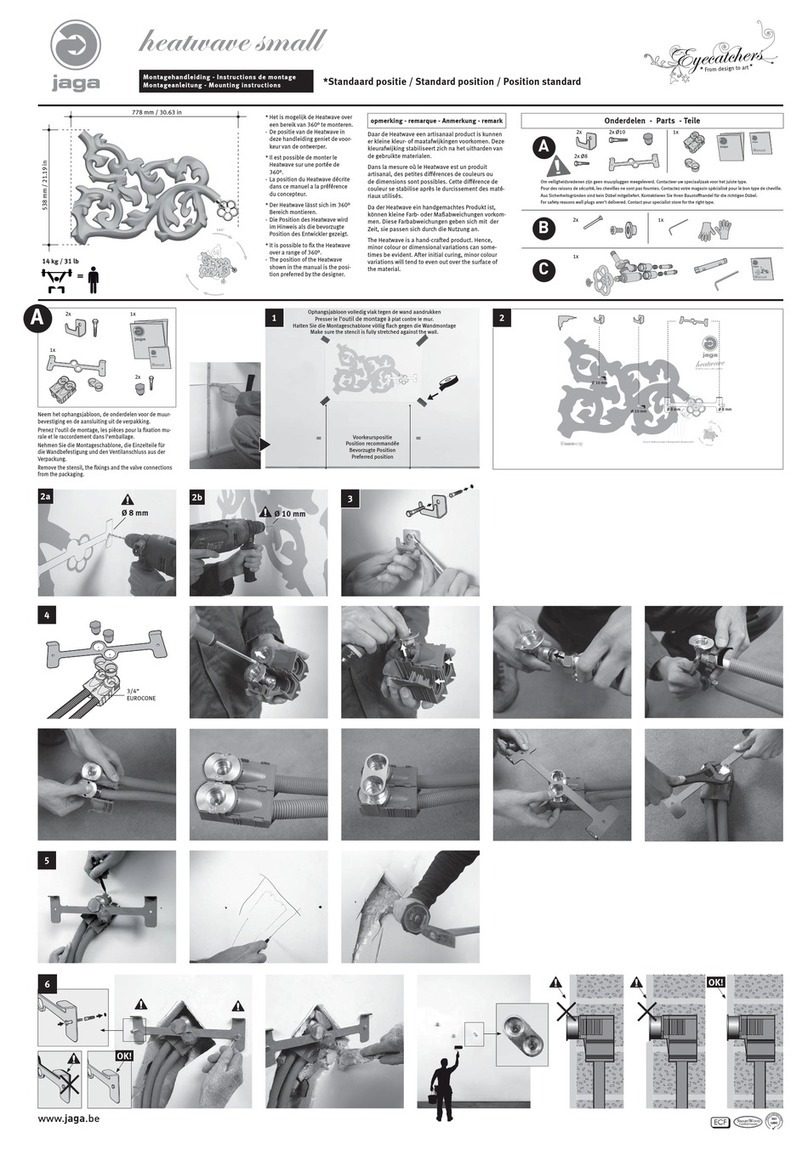

Packaging and components

Follow these instructions to remove the packaging:

• check for any visible damage

• open the packaging

• check if the manuals are in the package

• remove the packaging material and dispose it in the appropriate

collection points or recycling facilities, in compliance with the local

regulations

SAFEGUARD THE ENVIRONMENT

Dispose of the packaging materials in compliance with the national

or local legislation.

Instruction for transport

Handling guidelines:

ATTENTION!

• movement of the unit must be performed with care, in order to

avoid damage to the external structure and to the internal me-

chanical and electrical components

• also make sure that there are no obstacles or people along the

route, in order to prevent the risk of impact, crushing or tipping

the lifting device

• always use personal protective equipment

• all the operations listed below must be carried out in accordance

with current health and safety regulations, with reference to the

equipment used as well as the procedures followed

• if the unit weighs more than 30 kg and is to be handled manually,

this must be carried out by two persons

• packaged units can be stored by stacking a maximum of four on

top of each other and must be stored in a dry area.

The manufacturer is not responsible for:

Modification, change or alteration of the unit, except as expressly

directed in writing by Jaga n.v. Also, the risk analysis should be com-

pletely or partially re-created.

All changes, which could bring adverse change in the strength, sta-

bility, health or safety should be carried out in consultation and with

written approval from the manufacturer. If there are nevertheless

substantial changes are made without consultation mentioned, lia-

bility expires for JAGA N.V.

Before starting up the unit,check if:

Before starting up, make sure the installation and electrical connec-

tions have been carried out in compliance with the instructions in

this manual. Also make sure that there are no unauthorised persons

in the vicinity of the unit during the above operations.

• the unit is positioned correctly

• the supply and return pipes of the hydraulic unit are connected and

insulated properly;

• the pipes are clean and bled

• the heat exchanger an DBE units are clean

• the wiring connections are correct

• the screws that secure the conductors are clamped

• the supply voltage is that required

Installation guidelines

Installation must only be carried out by skilled technicians. Always

use personal protective equipment.

ATTENTION!Incorrect installation could cause the unit to run badly,

with a consequent deterioration in performance.

• the unit is only to be installed in domestic or similar environments.

• it is prohibited to insert objects through the air inlet and outlet

vents.

• installing and / or using the Jaga Knockonwood DBE is prohibited

in explosive atmospheres or areas where there is due to gases,

vapours or dust explosion

• when the unit is not used for long periods of time, it must be dis-

connected from the mains by opening the mains switch of the sys-

tem, set in place by the installer.

The unit is not designed to be installed (IEC EN 60335-2-40):

• outside

• in areas exposed to frost

• in wet areas

• in areas where there is due to gases, vapours or dust explosion

Follow these installation guidelines:

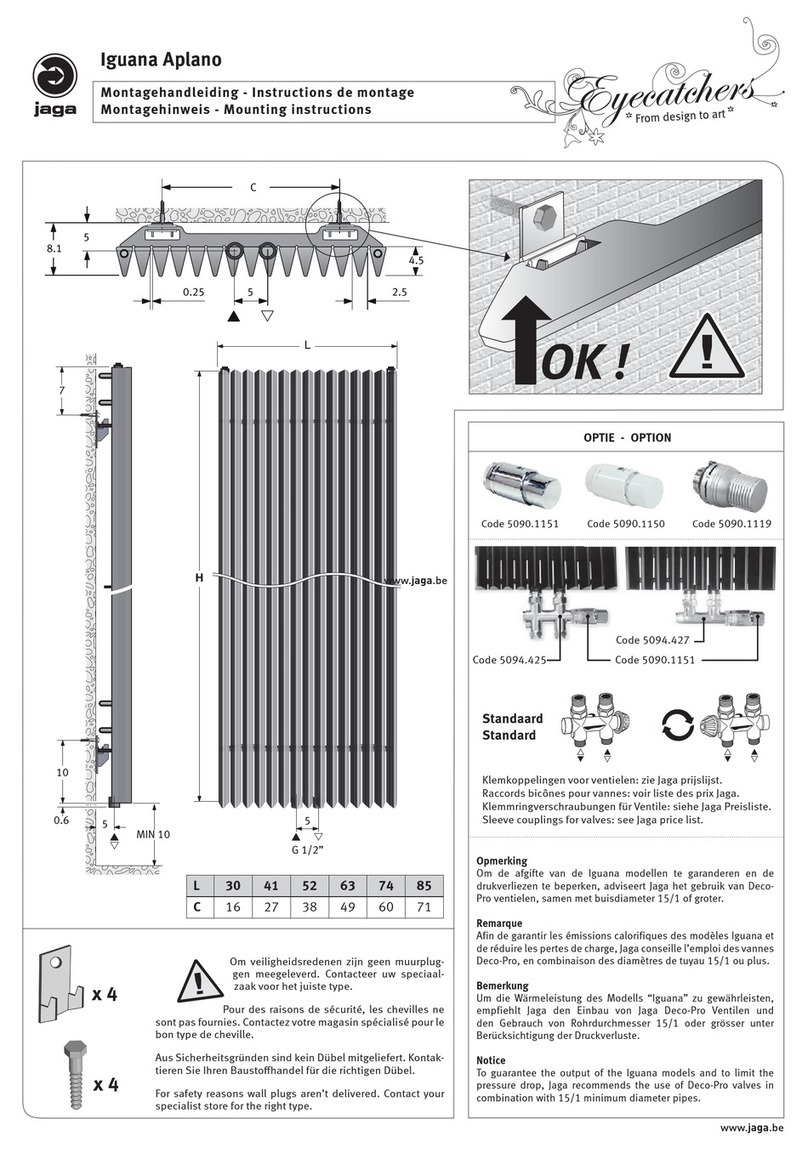

• mark the attachment points on the floor according to the mount-

ing holes of the device. When drilling holes, do not damage hidden

pipes and wiring.

• the type of floor determines what type of screw or plug should be

used

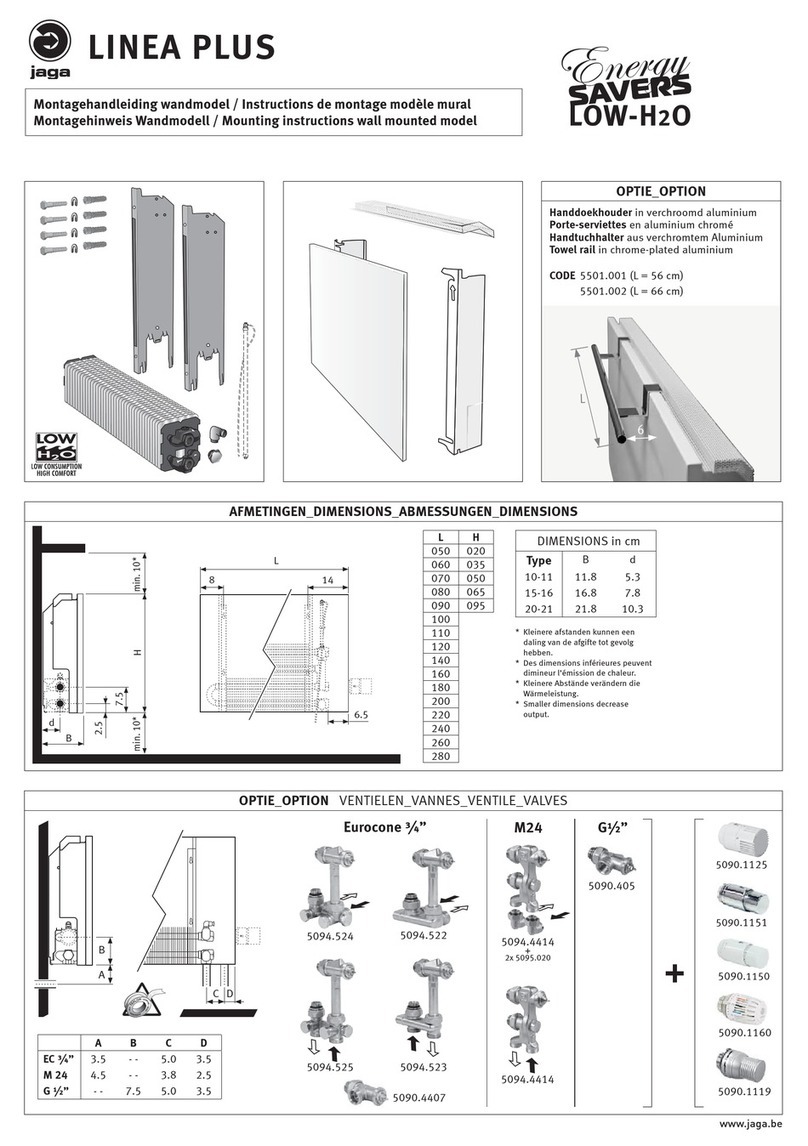

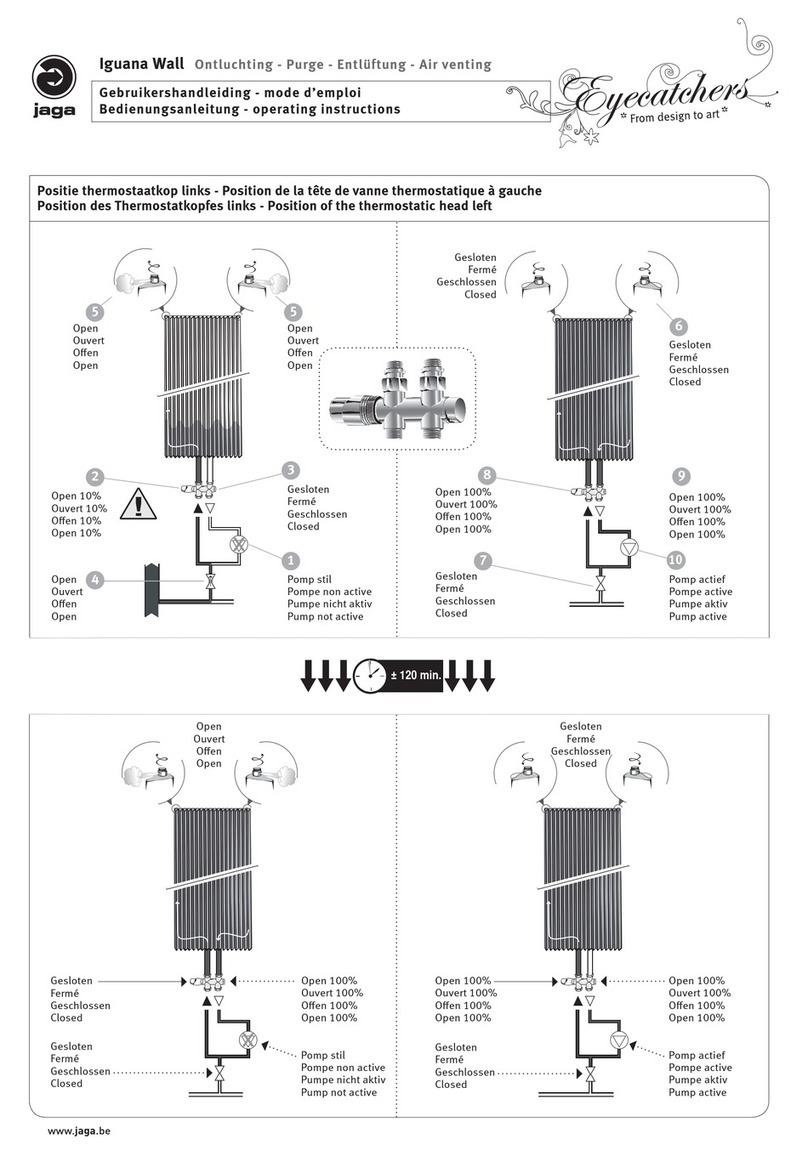

Hydraulic connections:

It is very important for the water connections to be installed with

care by qualified personnel.

• connect the unit to the hydraulic system with the indicated inlet/

outlet connections. Make sure the connections are air tight with a

sealant.

• the heat exchanger is equipped with an air vent

Once installation is complete:

• bleed the air contained in the circuit

• make sure that there are no water leaks. Drain cock, air vent and

valve are tightened up in the Jaga factory by hand. While filling the

installation, control on leaks.

Electrical connections:

The electrical connection of the unit must be carried out by quali-

fied personnel, in compliance with the regulations applicable in the

country where the unit is installed. Non-conforming electrical con-

nections releases Jaga N.V. from liability concerning damage to ob-

jects and persons. Use the supplied Jaga power supply.

• an installation that does not include the recommended free spac-

es, resulting in difficulty in maintenance and reduced perfor-

mance.

Regular maintenance

Maintenance: cleaning at regular interval is important, (at least once

a year), depending on the use and function of the room

Always use the mains switch to isolate the unit from the mains be-

fore carrying out any maintenance work on the unit, !!

• use a vacuum cleaner to clean the heat exchanger and the venti-

lator.

• clean the casing with a soft cloth dampened with water and a little

dish soap. Do not use products based on solvents and detergents.

The wooden casing may be treated with a neutral cleaner. Jaga

recommends using the supplied cleaner „Proterra GR 1900“: more

info, see www.hesse-lignal.de.

• if one fan stops working, the entire DBE unit must be replaced.

Contact your installer.

Checking whether there is air in the water system.

• start the system for a few minutes

• stop the system

• loosen the vent screw on the inlet collector and bleed it

• repeat the operation several times until air is no longer released

from the system.