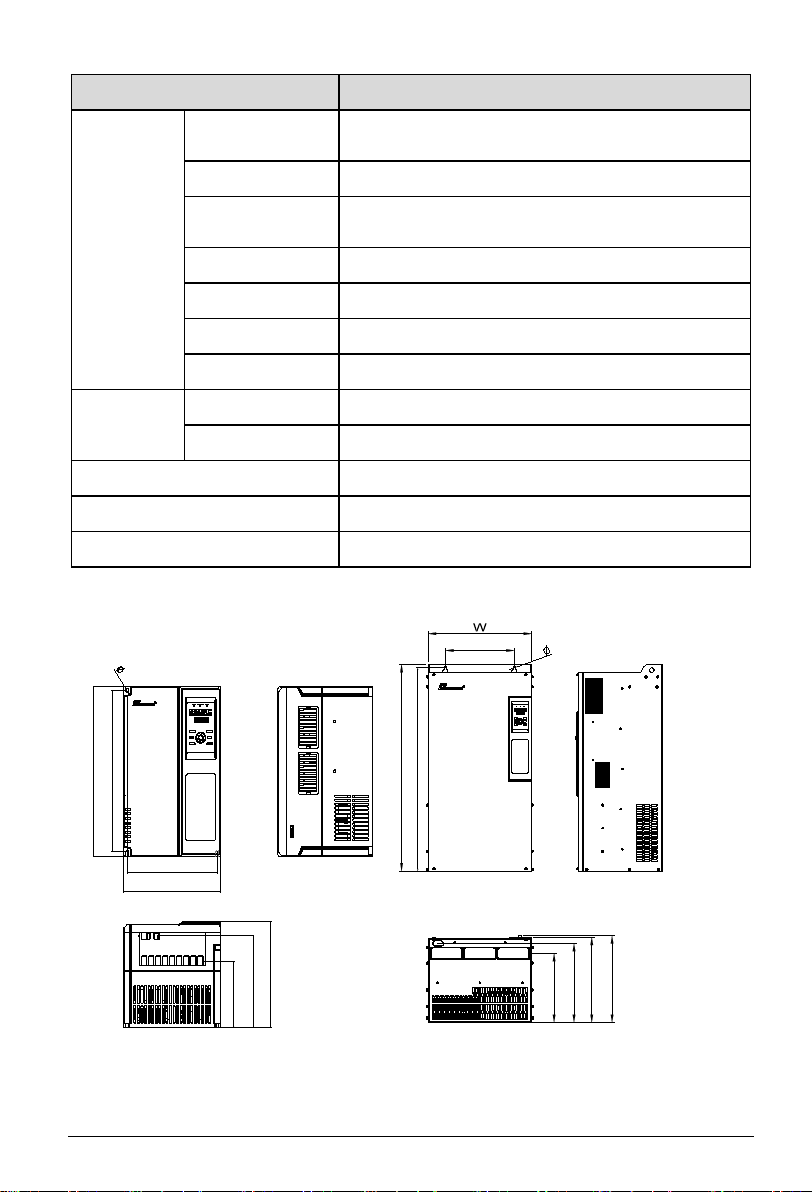

GT200 series general purpose inverter instruction manual

Item Description

Auto energy-saving

running

According to load condition, V/F curve can be

optimized automatically to get the aim of energy-

when rhe voltage of network changes,the output voltage

can be automatically kept constant

During the operation, the current is automatically

limited to prevent frequent flow to falut trip

Auto carrier

According to the load characteristics ,automatically

adjust the carrier frequency

Customized

function

Textile swing frequency control,it can realize the

function of fixed and variable swing frequency

Fixed length control Length reached stop function

Sagging function Applicable to multiple inverters drive one load

stop/non-stop

when power-supply off instantly,it can realize keep

running through control bus voltage

Binding function

Running command channel and frequency given

channal can be binded and change at same time

Running

function

Operation panel,control terminal and communication

port , can be switched through many ways

Frequency given

channel

Digial given, analog voltage given,analog current given,

pulse given,communication port given,can be switched

Auxiliary frequency

given channel

Realize flexible auxiliary frequency fine-turing and

frequency combination operation

~

50KHz pulse square wave signal output,can realize

output setting frequency and output frequency ect.

Analog output

terminal

~

、

~

of physical quantity such as setting frequency and

Operating

panel

Double row LED

display

It can display 20 kinds of parameters such as setting

frequency,output frequency,output voltage,output

Key Locked and

function choose Define the function scope of part of the keys,in case of

mistake operation

protection function

Phase-loss protection(optional),over current

protection,over voltage protection,under voltage

protection,over heat protection,over load

6