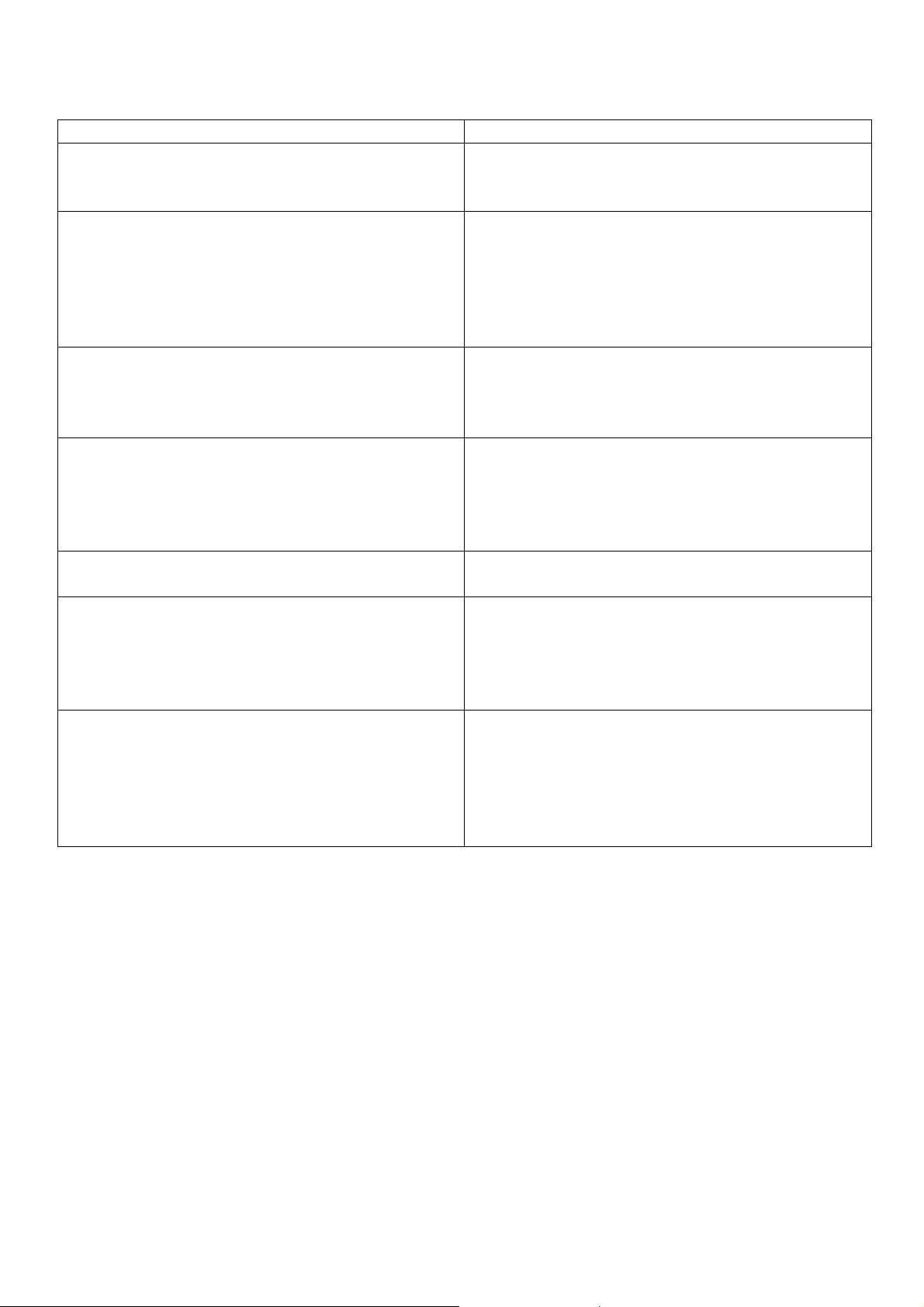

Possible roubleshooting

Malfunction Possible cause / Remedy

It is not possible to switch on the

machine

The power supply to the machine is

interrupted, cause within the machine.,

Contact the after-sales service

The machine is not being filled with

water

The check valve provided by the

customer is closed, the air trap is soiled

– therefore, the level switch does not

work, the inlet valve is soiled or

defective,

Contact the after-sales service

The machine fills up with water and

heats up, but it is not possible to start

the rinsing program

The door contact switch is not in

contact/defective, the fine wire fuse, is

blown

Contact the after-sales service

The machine is not heated up The machine is equipped with 2 safety

thermostats They will switch off the

heating system as soon as the maximum

temperature is being exceeded.

Contact your after-sales service.

The machine is being filled continuously

with water

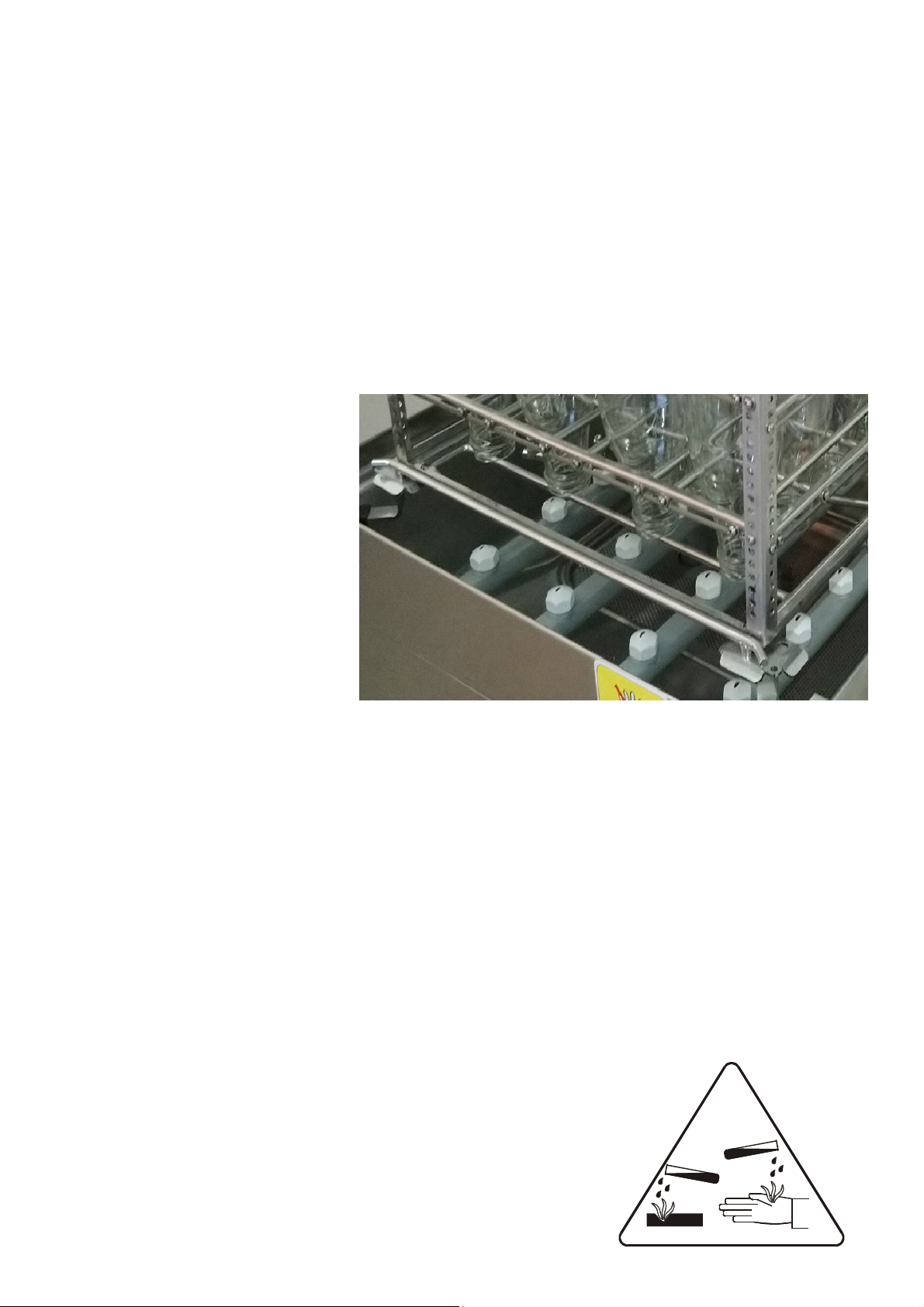

The overflow pipe is not inserted

correctly

The items to be rinsed are not clean The rinsing temperature is too low, is is

forgotten to fill in the cleaning agent, the

machine does not convey the cleaning

agent, the rinsing agent container is

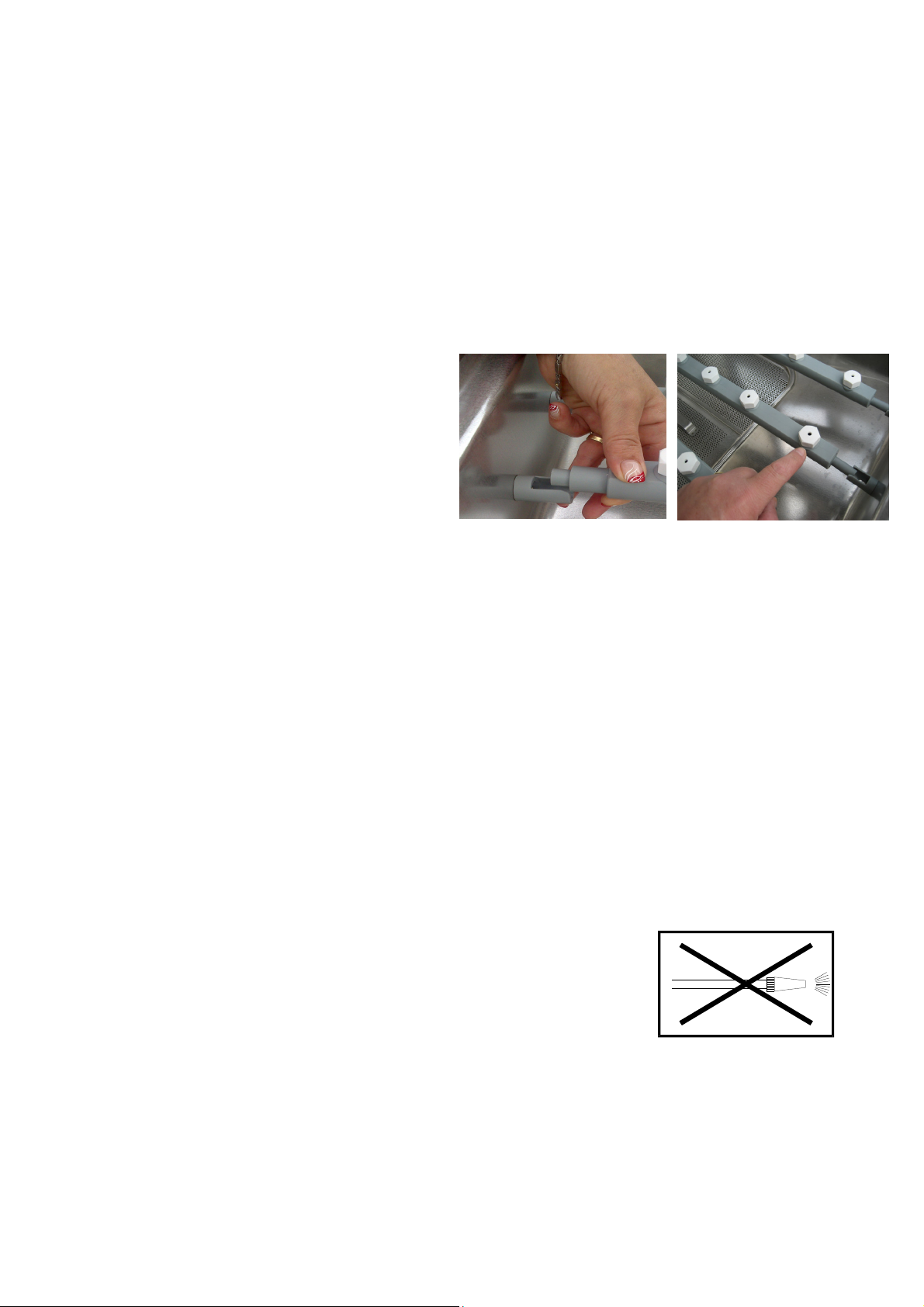

empty, the rinsing nozzles are plugged

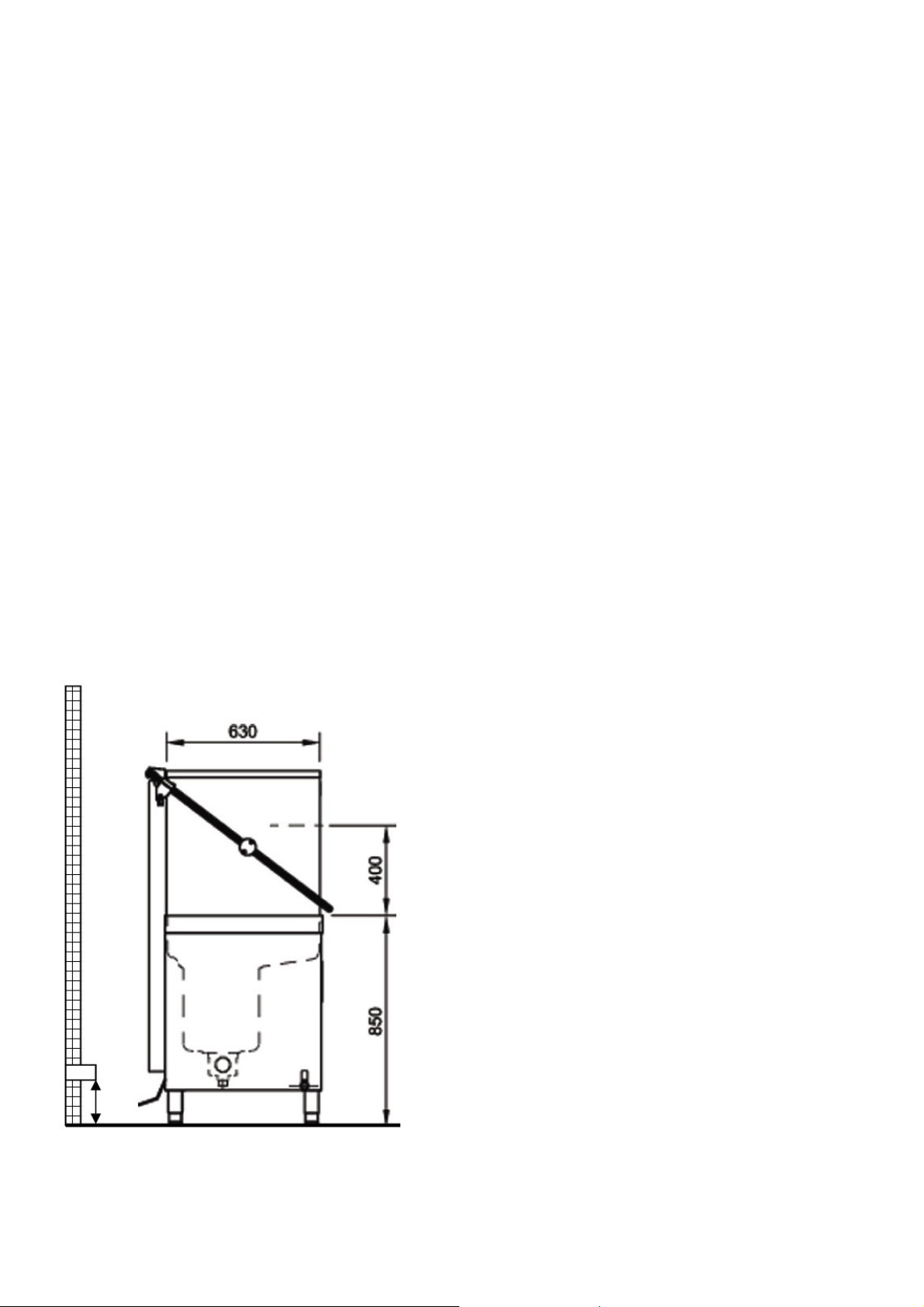

It is not possible to move the hood Check if dirt has accumulated in the

lateral guide rails, remove the dirt, if

applicable.

If there is a defect on the spring system,

do not lift the hood with by force.

Contact the after-sales service.

Seite 9