GE GEI-44233 F User manual

Other GE Industrial Equipment manuals

GE

GE ArcamEBM Spectra H User manual

GE

GE ERESCO MF4 Series User manual

GE

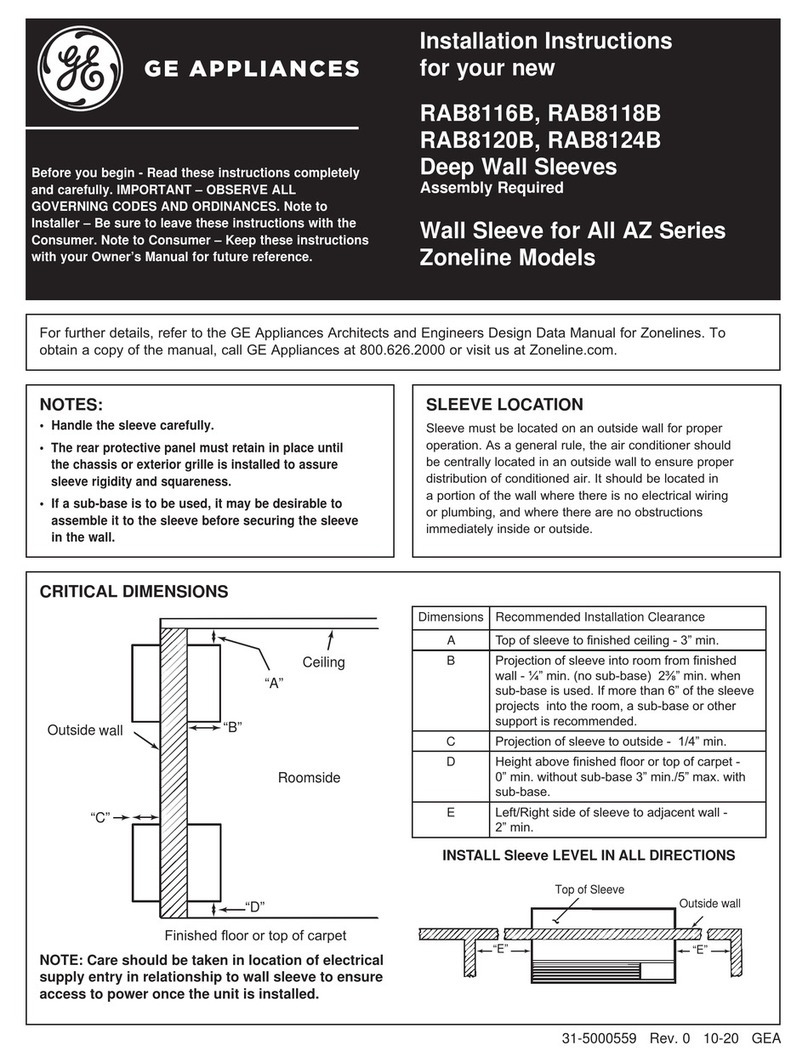

GE RAB8116B User manual

GE

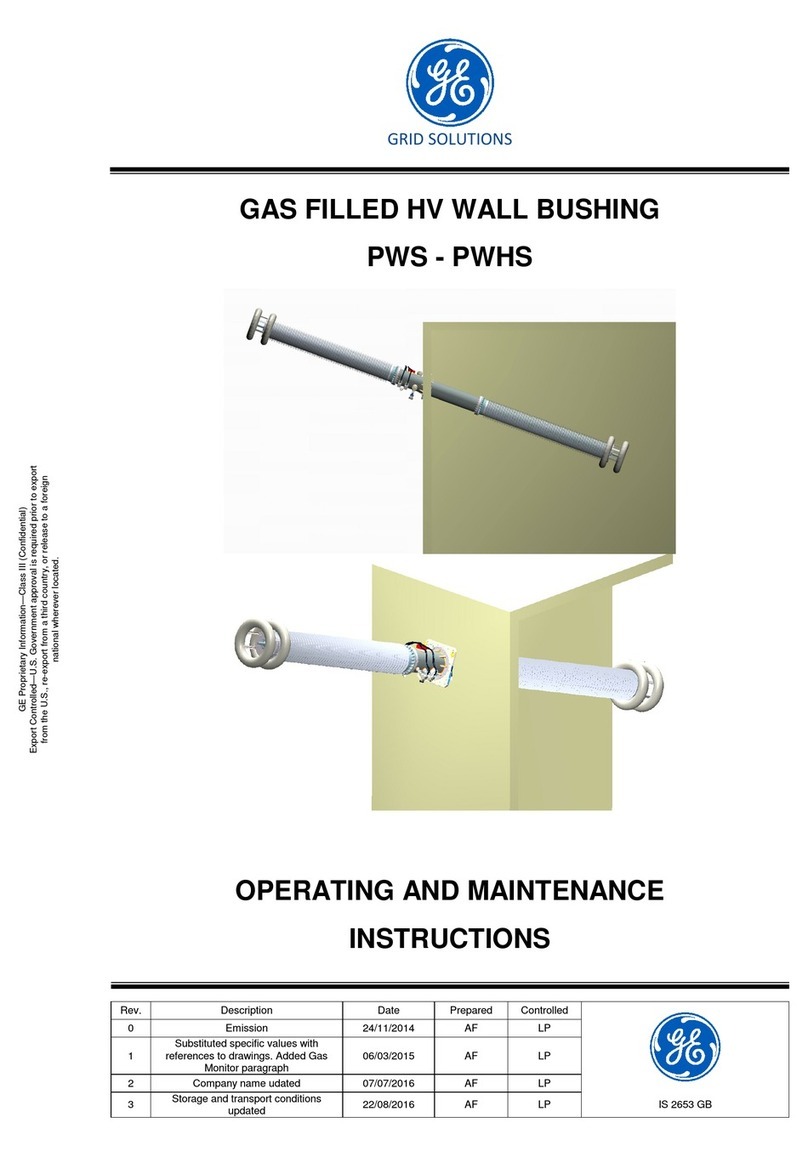

GE PWS Manual

GE

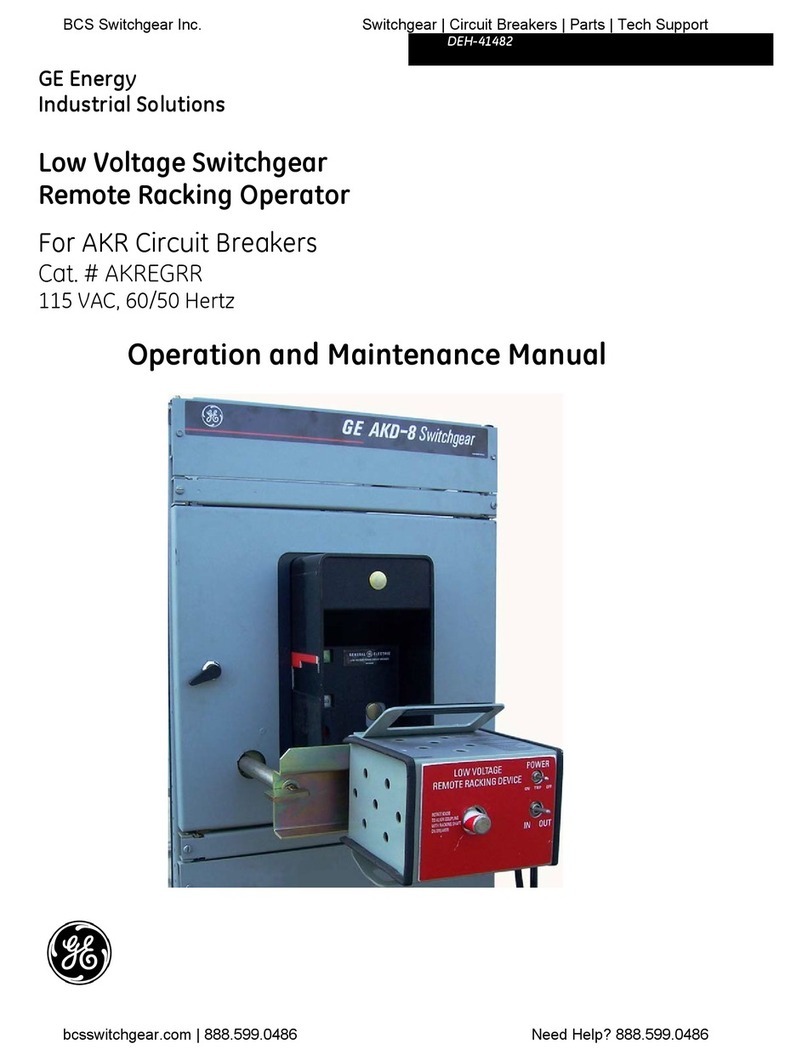

GE AKD-8 User manual

GE

GE ecomagination Profibus DP AF-650 GP User manual

GE

GE Jenbacher JGS 320 GS-L.L Quick start guide

GE

GE J2045J389E User manual

GE

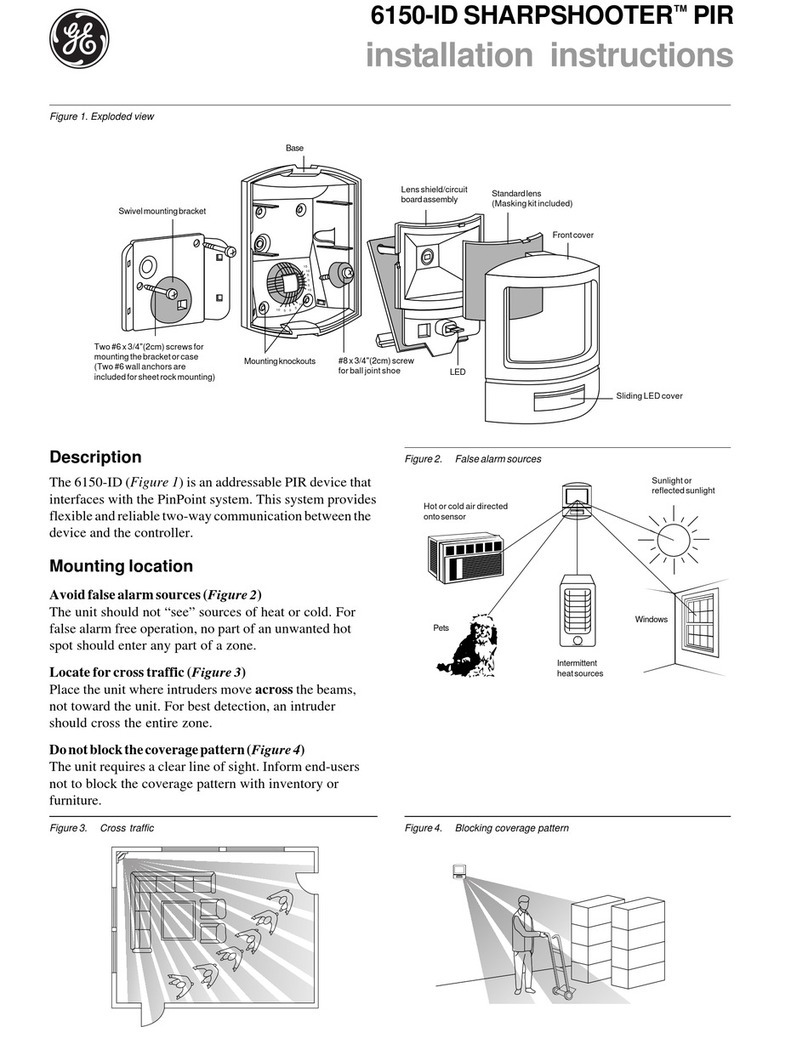

GE SHARPSHOOTER 6150-ID User manual

GE

GE PACSystems* RX3i User manual