Eburon 160 User manual

160 / 200

2

CONTENTS:

1 –Safety instructions ...................................................................................... page 3

2 –Control Panel..............................................................................................page 7

3 –Technical data ............................................................................................page 8

4 –Installation...................................................................................................page 8

5 - Functions.....................................................................................................page 9

6 –Errors descriptions......................................................................................page 10

6.1 - Connection to the network ....................................................................... page 10

6.2 - Earth connection ......................................................................................page 10

7 –Electrical diagram ....................................................................................... page 11

7.1 - MMA welding ...........................................................................................page 11

7.2 LIFTIG Wetting ..........................................................................................page 12

8 - Description of the error ...............................................................................page 12

9 - Electrical scheme .......................................................................................page 13

10 - Nomenclature ...........................................................................................page 14

11 - Maintenance .............................................................................................page 15

11.1 - Repairs ..................................................................................................page 15

160 / 200

3

1. SAFETY INSTRUCTIONS

In its conception, specification of parts and production, this machine complies with the regulation in

force, namely the European Standards (EN) and internationals (IEC).

There are applicable the European Directives “Electromagnetic compatibility”, “Low voltage” and

“RoHS”, as well as the standards IEC / EN 60974-1 and IEC / EN 60974-10.

Electric shocks can be deadly.

- This machine must be connected to earthed sockets. Do not touch the live parts of the machine.

- Before any intervention, disconnect the machine from the mains. Only qualified personnel should

intervene in these machines.

- Always check the state of the input power cable.

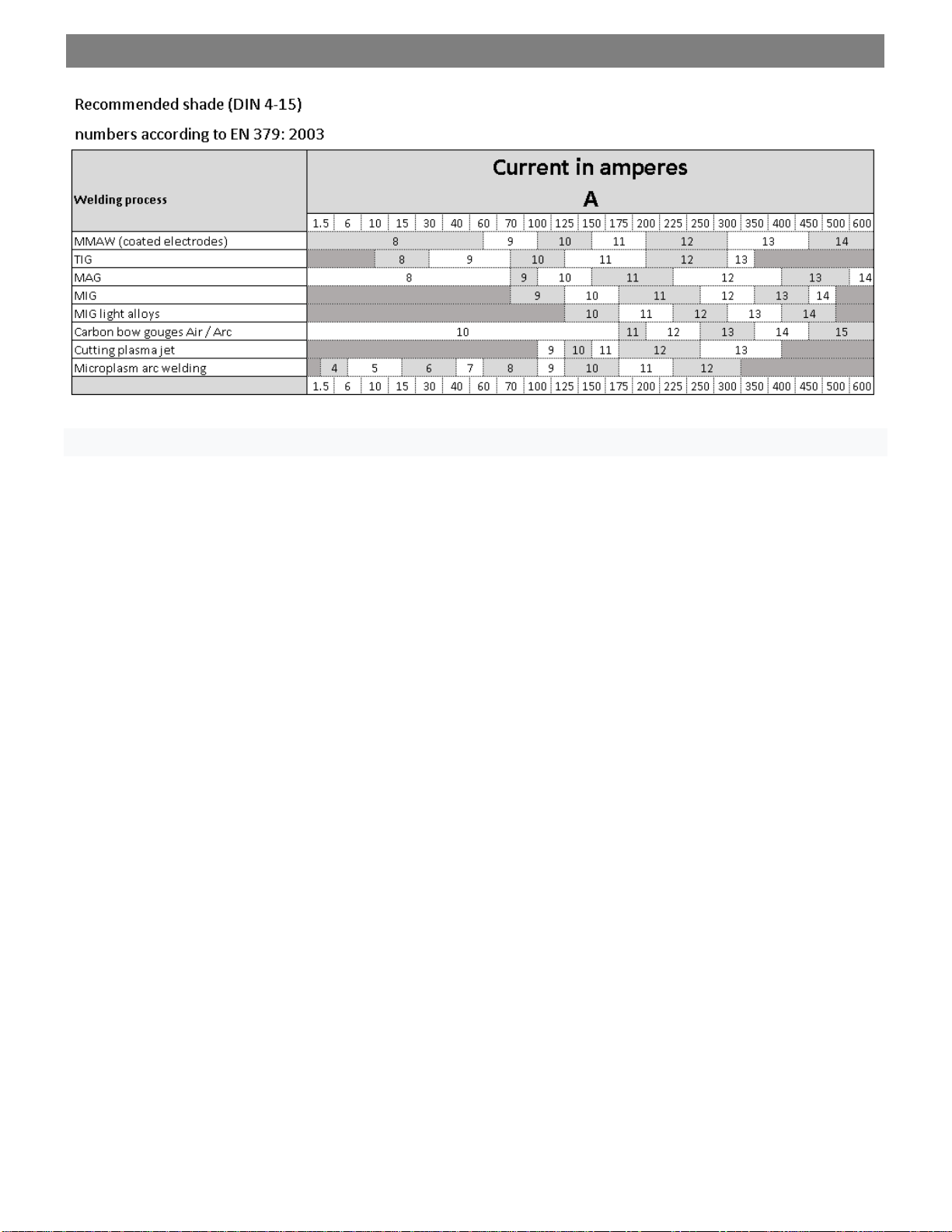

It is essential to protect the eyes against the radiations of the electric arc. Use a welding mask or

helmet with a suitable protective filter.

Use closed-in smoke extractor. Smoke and gases can damage the lungs and cause poisoning.

Welding can originate risks of fire or explosion.

- Remove flammable or explosive materials from welding area;

- Always have sufficient firefighting equipment;

- Fire can break out from sparks even several hours after the welding work has been finished.

Hot parts can cause burns. The work piece, the projections and the drops are hot. Use gloves,

aprons, safety shoes and other individual safety equipment.

Electromagnetic fields generated by welding machines can cause interference with other devices.

They can affect cardiac pacemakers.

Gas bottles can explode (MIG or TIG welding). It is essential to comply with all safety regulations

regarding gases.

160 / 200

4

1.1 ELECTROMAGNETIC COMPATIBILITY

The user is responsible for installing and using the arc welding equipment according to the manufacturer’s instructions. If

electromagnetic disturbances are detected, then it shall be the responsibility of the user of the arc welding equipment to

resolve the situation with the technical assistance of the manufacturer. In some cases, this action may be as simple as

connecting to earth the welding circuit. In other cases, it could involve constructing electromagnetic screens enclosing the

welding power source and the work complete with associated input filters. In all cases, electromagnetic disturbances shall

be reduced to the minimum to avoid troubles.

Before installing arc welding equipment, the user shall assess potential electromagnetic problems in the surrounding area.

The following shall be considered:

a) Supply cables, control cables, signalling and telephone cables, above, below and adjacent to the arc welding equipment;

b) Radio and television transmitters and receivers;

c) Computer and other control equipment;

d) Safety critical equipment, e.g. guarding of industrial equipment;

e) The health of the people around, e.g. the use of pacemakers and hearing aids;

f) Equipment used for calibration or measurement;

g) The immunity of other equipment in the environment. The user shall ensure that other equipment being used in the

environment is compatible. This may require additional protection measures;

h) The hour of day when welding or other activities are to be carried out.

1.1.1 Methods of reducing emissions

Connection to mains

Arc welding equipment should be connected to the input supply system according to the manufacturer’s recommendations.

If interference occurs, it may be necessary to take additional precautions such as filtering of the supply system.

Consideration should be given to shielding the supply cable of permanently installed arc welding equipment, in metallic

conduit or equivalent. Shielding should be electrically continuous throughout its length. The shielding should be connected

to the welding power source so that good electrical contact is maintained between the conduit and the welding power

source enclosure.

Welding cables

The welding cables should be kept as short as possible and should be positioned close together, running at or close to the

floor level.

Equipotent bonding

Bonding of all metallic components in the welding installation and adjacent to it should be considered. However, metallic

components bonded to the work piece will increase the risk that the operator could receive an electric shock by touching

these metallic components and the electrode at the same time. The operator should be insulated from all such bonded

metallic components.

Connexion to earth of the work piece

When the work piece is not bonded to earth for electrical safety, nor connected to earth because of its size and position,

e.g. ships hull or building steelwork, a connection bonding the work piece to earth may reduce emissions in some, but not

all instances. Care should be taken to prevent the earthling of the work piece increasing the risk of injury to users, or

damage to other electrical equipment. Where necessary, the connection of the work piece to earth should be made by a

direct connection to the work piece, but in some countries where direct connection is not permitted, the bonding should be

achieved by suitable capacitance, selected according to national regulations.

Screening and shielding

Selective screening and shielding of other cables and equipment in the surrounding area may alleviate problems of

interference. Screening of the entire welding installation may be considered for special applications.

160 / 200

5

1.2 ELECTRICAL SECURITY

1.2.1 Connection to the network

Before connecting your equipment, you must check:

- The safety device against over-currents, and the electrical installation are compatible with the maximum power and the

supply voltage of the welding power source (refer to the instructions plates).

- The connection, either single-phase, or three-phase with earth can be effectuated on a socket compatible with the welding

power source cable plug.

- If the cable is connected to a fixed post, the safety device against electric shocks will never cut the earth.

- The ON/OFF switch located on the welding power source is turned off.

1.2.2 Working area

The use of arc welding implies a strict respect of safety conditions regarding electric currents. It is necessary to check that

no metal piece accessible by the operators and to their assistants can come into direct contact with a phase conductor and

the neutral of the network. In case of uncertainty, this metal part will be connected to the earth with a conductor of at least

equivalent section to the largest phase conductor.

Make sure that all metal pieces that the operator could touch with a non-insulated part of his body (head, hands without

gloves on, naked arms, etc) is properly grounded with a conductor of at least equivalent section to the biggest supply cable

of the ground clamp or welding torch. If more than one metal ground is concerned, they need to be all interlinked in one,

which must be grounded in the same conditions.

Unless very special care has been taken, do not proceed to any arc welding or cutting in conductive enclosures, whether it

is a confined space or the welding machine has to be left outside. Be even more prudent when welding in humid or not

ventilated areas, and if the power source is placed inside (Decree dated 14.12.1988, Art. 4).

1.2.3 Risks of fire and explosion

Welding can originate risks of fire or explosion. You must pay attention to fire safety regulation

- Remove flammable or explosive materials from welding area;

- Always have sufficient fire fighting equipment;

- Fire can break out from sparks even several hours after the welding work has been finished.

1.3 INDIVIDUAL PROTECTION

1.3.1 Risks of external injuries

Arc rays produce very bright ultra violet and infrared beams. They will damage eyes and burn skin if the operator is not

properly protected.

-The welder must be dressed and protected according to the constraints of his works impose to him.

-Operator must insulate himself from the work-pieces and the ground. Make sure that no metal piece, especially those

connected to the network, comes in electrical contact to the operator.

-The welder must always wear an individual insulating protection.

Protective equipment: gloves, aprons, safety shoes that offer the additional advantage to protect the operator against burns

caused by hot pieces, spatters, etc. Check the good state of this equipment and replace them before you are not protected

any more.

- It is absolutely necessary to protect eyes against arc rays.

- Protect hair and face against sparks. The welding shield, with or without headset, must be always equipped with a proper

filter according to the arc welding current. In order to protect shaded filter from impacts and sparks, it is recommended to

add a glass in front of the shield.

160 / 200

6

NOTE: A higher step must be used when welding with low ambient light.

1.3.2 Risk of internal injuries

Gases and fumes

- Gases and fumes produced during the welding process can be dangerous and hazardous to your health. Arc welding

works must be carried out in suitable ventilated areas.

- Ventilation must be adequate to remove gases and fumes during operation. All fumes produced during welding have to be

efficiently removed during its production, and as close as possible from the place they are produced.

- Vapours of chlorinated solvents can form toxic gas phosgene when exposed to ultraviolet radiation from an electric arc.

Safety in the use of gases (welding with TIG or MIG inert gases)

Compressed gas cylinders

Compressed gas cylinders are potentially dangerous. Refer to suppliers for proper handling procedures:

- No impact: secure the cylinders and keep them away from impacts.

- No excess heat (over 50°C)

Pressure relief valve

- Check that the pressure relief screw is slackened off before connecting to the cylinder.

- Check that the union is tight before opening the valve of the cylinder. Open it slowly a fraction of a turn.

- If there is a leak, NEVER tighten a union under pressure, but first close the valve on the cylinder.

- Always check that hoses are in good condition.

160 / 200

7

2. MMA WELDING (coated electrode)

To establish an electric arc, a potential difference is induced between the

electrode and the workpiece. The air between them is ionized and

conductive, so that the circuit is closed and the electric arc is made.

The high temperature of the arc melts the base material and electrode that

is deposited by creating a welding bath. Arc welding is still very common due

to the low purchase cost of equipment and consumables used in this

process.

The metal core of the electrode is covered with a flux material that upon

assembly creates a protective atmosphere that prevents the oxidation of the

molten metal and facilitates the welding operation.

On DC current sources (rectifiers), the polarity of the electrical current

influences the metal transfer mode.

Normally the electrode is connected to the positive (+), although it can be connected in very thin materials

with the negative (-).

Although the horizontal weld position is the most favorable, this process allows use at all positions.

MMA welding parameter table:

Diameter electrode

Welding current

Thickness of sheet metal

2,5 mm

40 –125 A

> 2 mm

3,2 mm

105 –250 A

> 3 mm

4,0 mm

75 –185 A

> 6 mm

5,0 mm

140 –305 A

> 9 mm

6,0 mm

210 –430 A

> 9 mm

8,0 mm

275 –450 A

> 9 mm

3. TIG WELDING (Tungsten inert gas)

It is the process of arc welding under shield gas,

using a torch with a fusible tungsten electrode and

which can be used with or without filler metal in an

inert gas atmosphere such as argon and mixtures

thereof.

This process makes the arc more stable without

splashing, which guarantees a strong mechanical

resistance of the weld connection. This TIG process

replaces with many advantages the oxyacetylene on welding of steel, stainless steel, copper, brass DC, the aluminum

on AC welding and, in various cases, the MMA and Mig welding, especially when the weld seam remains visible.

160 / 200

8

Chemical composition of the electrodes

Code

Composition

Type

Color

Welding

WP

Pure tungstene

W

Green

AC –Aluminium, Magnesium

WT4

0,35-0,55% thorium

Th

Blue

DC

Mild steel, stainless steel, Titanium

Copper

WT10

0,80-1,20% thorium

Yellow

WT20

1,7-2,3% thorium

Red

WT30

2,7-3,3% thorium

Violet

WT40

3,8-4,3% thorium

Orange

WZ3

0,15-0,50% zirconium

Zr

Brown

Stainless steel, Nickel,

Non-ferrous metals

WZ8

0,70-0,10% zirconium

White

WL10

1,0-1,2% lanthanum

La

Black

All TIG applications

WC20

1,9-2,3% cerium

Ce

Grey

All TIG applications

Table of diameters and currents applicable to electrodes

electrode

(mm)

Amp. DC

Amp. AC

Negative (-)

Positive (+)

1,6 mm

40-130 A

10-20 A

45-90 A

2,0 mm

75-180 A

15-25 A

65-125 A

2,5 mm

130-230 A

17-30 A

80-140 A

3,2 mm

160-310 A

20-35 A

150-190 A

4,0 mm

275-450 A

35-50 A

180-260 A

5,0 mm

400-625 A

50-70 A

240-350 A

Shielding gases: The gases used in TIG welding contribute to:

- Wrap the electric arc in an ionizable atmosphere.

- Avoid contamination of the welding bath by oxygen existing in the atmosphere.

- Cool the electrode.

Argon (Ar)

- Is the most common gas and is used with a degree of purity of 99.9%. Helium (He)

- Pure helium is used in welding copper mixed with argon in percentages between 10% and 75%.

Hydrogenated (H) - is an inert gas at ambient temperature and is used especially in copper welding. It is not

recommended to weld in closed spaces because it combines with oxygen by turning the air unbreathable.

160 / 200

9

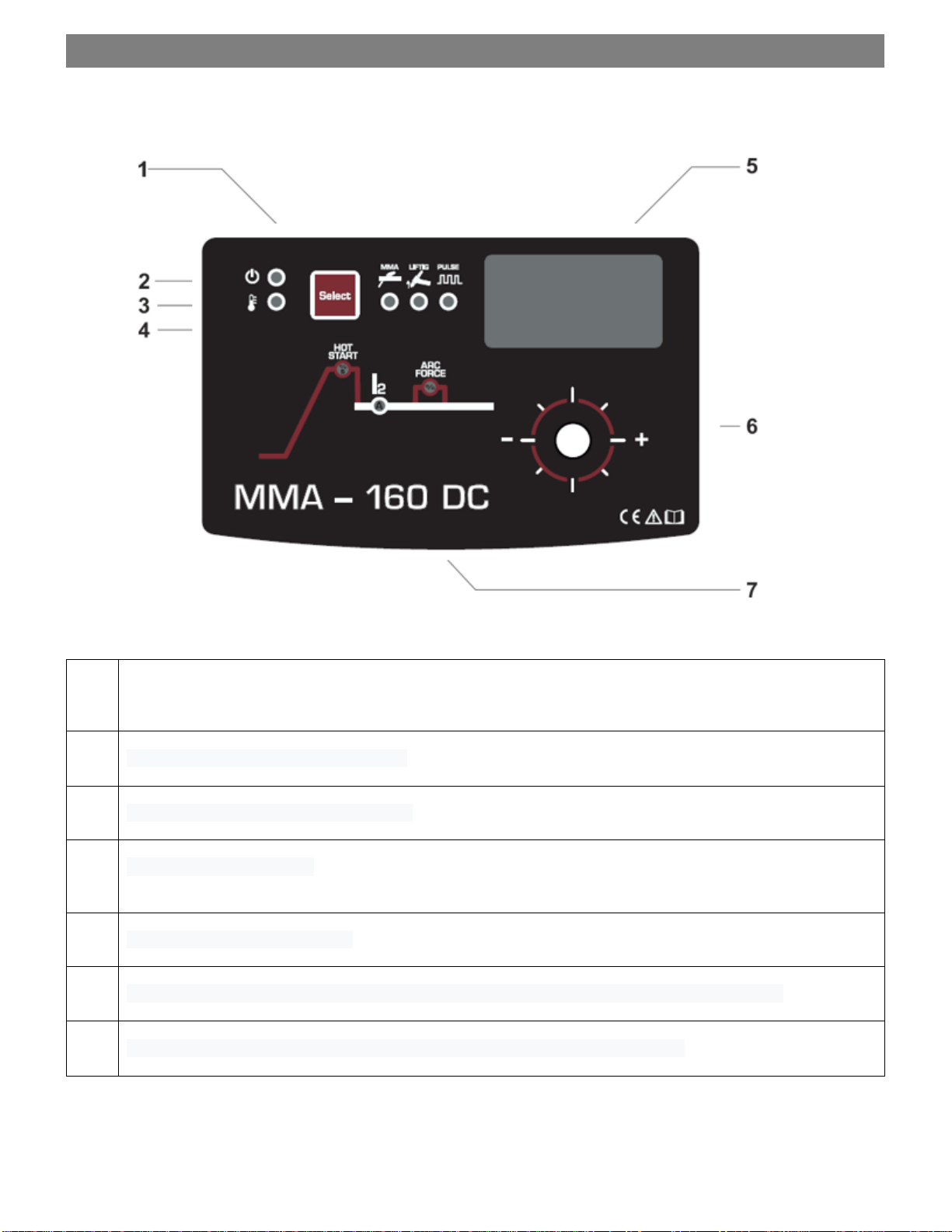

4. CONTROL PANEL

1

Welding process selector: MMA welding, LIFTIG (TIG welding with arc ignition without high frequency) and

PULSE (when lit with another mode also lit, indicates the pulse welding with the respective welding mode)

2

Machine LED connected and powered

3

Overload or overload alarm indicator - Turns off the machine in case of overheating

4

VRD option - MMA VRD - Reduction of secondary voltage for use in environments with increased risk of

electric shock.

5

Digital welding current display

6

Setting and Parameter Selection - Selects parameter / setting parameters by turning the knob

7

Welding parameters - see the description of these parameters in this user guide

160 / 200

10

5 TECHNICAL DATA

PRIMARY

160

200

Single phased power supply

V

1 x 230 V (-+10%)

1 x 230 V (-+10%)

Frequency

Hz

50/60

50/60

Maximum primary current (MMA)

A

34

43

Maximum primary current (TIG)

A

24

30

Maximum power consumption (MMA)

KVA

7,8

9,9

Maximum power consumption (TIG)

KVA

5,5

6,9

SECONDARY

No-load voltage

V

74

80

Welding current range

A

10 - 160

10 - 200

Welding current at 40 %

A

160

200

Welding current at 60 %

A

135

160

Welding current at 100%

A

105

125

Protection degree

IP 21S

IP 21S

Insulation class

H

H

Norms

IEC / EN 60974-1

IEC / EN 60974-1

Weight

Kg

5,1

5,7

Dimensions

cm

15 x 24 x 32

15 x 24 x 32

6. INSTALLATION

4.1 CONNECTION TO THE MAIN SUPPLY

This unit must be connected to a mono-phase 230V - 50 Hz/60 Hz + ground.

Main supply must be protected by fuses or circuit breaker according to the value I1eff written on the specifications of the

power source.

It is strongly suggested to use a differential protection for the operator’s safety.

4.2 CONNECTION TO EARTH

For the operator's protection, the power source must be correctly grounded (according to the International Protection

Norms).

It is necessary to set a good earth connection with the green/yellow wire of the power cable. This will avoid discharges

caused by accidental contacts with grounded pieces. If no earth connection has been set, a high risk of electric shock

through the chassis of the unit remains possible.

160 / 200

11

7. FUNCTIONS

7.1 MMA WELDING MODE (coated electrode)

- Make the necessary connections to mains and earth as described in “Installation”. Connect the earth and electrode holder

cables to welding plugs + (positive) and –(negative) according to electrode polarity. If necessary, pay attention to electrode

manufacturer instructions.

- Turn the main switch on rear panel to ON position.

- The Power ON indicator lights, indicating that machine is under voltage.

- Select MMA welding (coated electrode) or MMA PULSED welding (both indicators are lit).

- Adjust welding current (Fig.1 - 3), according to the following table:

Electrode diameter (mm)

2,0

2,5

3,2

4,0

5,0

6,0

Adjusting current scope (Amp)

50 - 70

60 - 100

80 - 150

130 - 200

150 - 260

200 - 360

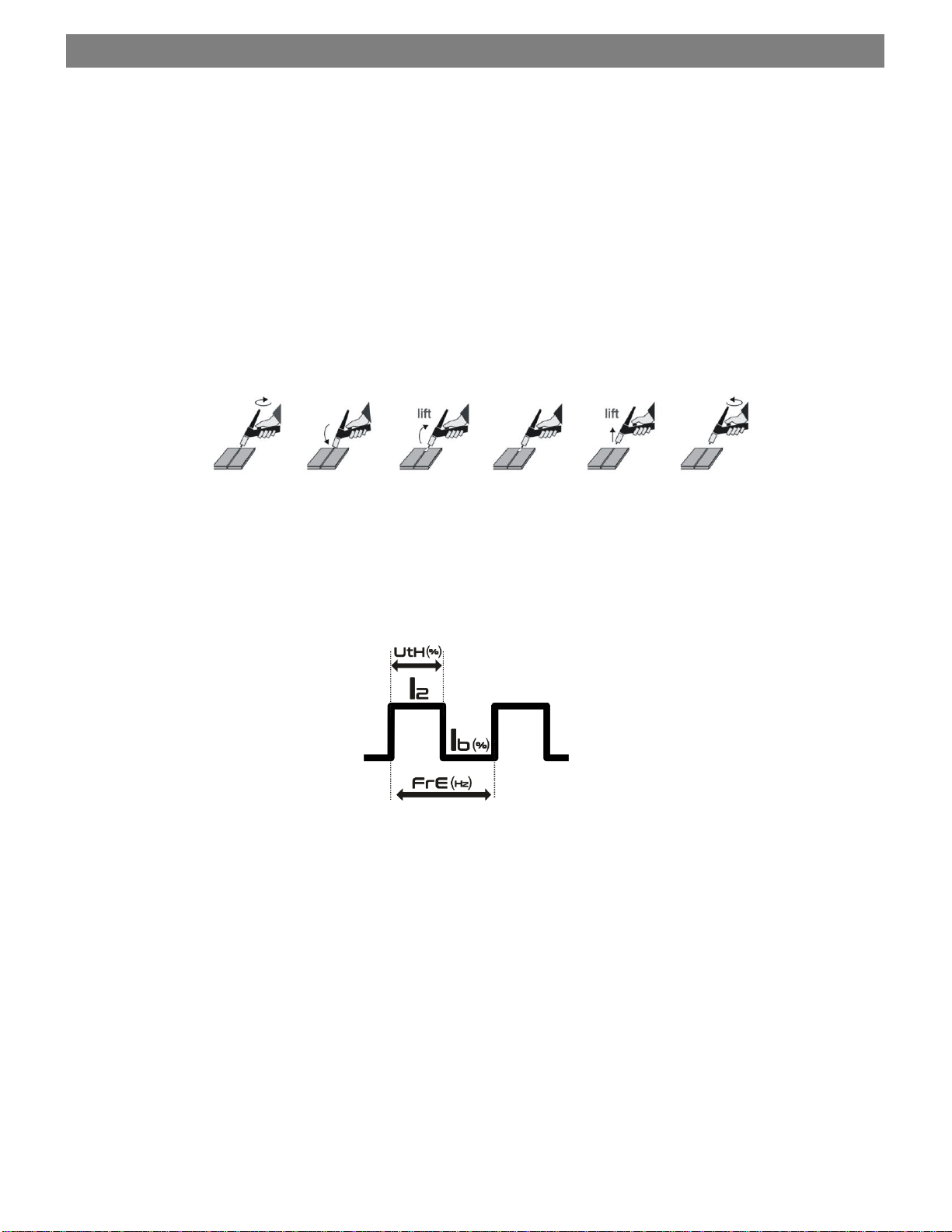

- Hot Start (Fig.1 - 1) - To force arc ignition, adjust hot start percentage of main current and/or time (seconds).

- Arc Force (Fig.1 - 2) - To avoid electrode sticking during welding, adjust arc force current percentage of main current.

Pulsed MMA welding –the welding current oscillates between a high and a low current value allowing less thermal input in thinner

plates and greater arc control in the most demanding positions (vertical ascending).

- Ib - adjust welding base current in percentage of main current (the digital display shows Ib).

- UtH - WIDTH - adjust the time of the peak current (main current) from 10% to 90% (the digital display shows UtH).

- FrE - PULSE FREQUENCY - adjust pulsed current frequency in Hertz (the digital display shows FrE).

- Start welding.

Fig. 1 –MMA parameters

160 / 200

12

1-opengas 2-contact 3-arcignition 4-welding 5-stop 6-closegas

7.2 TIG WELDING MODE

- Make the necessary connections to mains and earth as described in “Installation”.

- Connect earth cable to positive plug by turning it firmly to right to assure a perfect electric contact.

- Connect TIG torch power cable to negative plug by turning it to right to assure a perfect electric contact.

- Connect gas tube to gas bottle. Check the content of gas bottle, and replace it, if necessary.

- Adjust gas flow 6 l/min and 12 l/min according to the value of the current.

- Apply a tungsten electrode on TIG torch. The electrode must be sharpening according the welding method: TIG DC (tip sharpen).

- Turn the main switch on rear panel to ON position.

- The Power ON indicator lights, indicating that machine is under voltage.

- Select LIFTIG* (TIG welding with contact ignition). There is the PULSED welding mode available (both indicators are lit

respectively).

* LIFTIG:

LIFTIG ignition (by contact) should be used when the high frequency radiations could disturb the functioning of electronic devices

near the welding zone (computers, pace-makers, medical tools, etc).

- Adjust welding current (Fig.1 - 3).

Pulsed LIFTIG welding –the welding current oscillates between a high and a low current value allowing less thermal input in

thinner plates and greater arc control.

- Ib - adjust welding base current in percentage of main current (the digital display shows Ib).

- UtH - WIDTH - adjust the time of the peak current (main current) from 10% to 90% (the digital display shows UtH).

- FrE - PULSE FREQUENCY - adjust pulsed current frequency in Hertz (the digital display shows FrE).

- Start welding.

8. ERRORS DESCRIPTION

Er1 - Overheating - Cuts off machine in case of over temperature

160 / 200

13

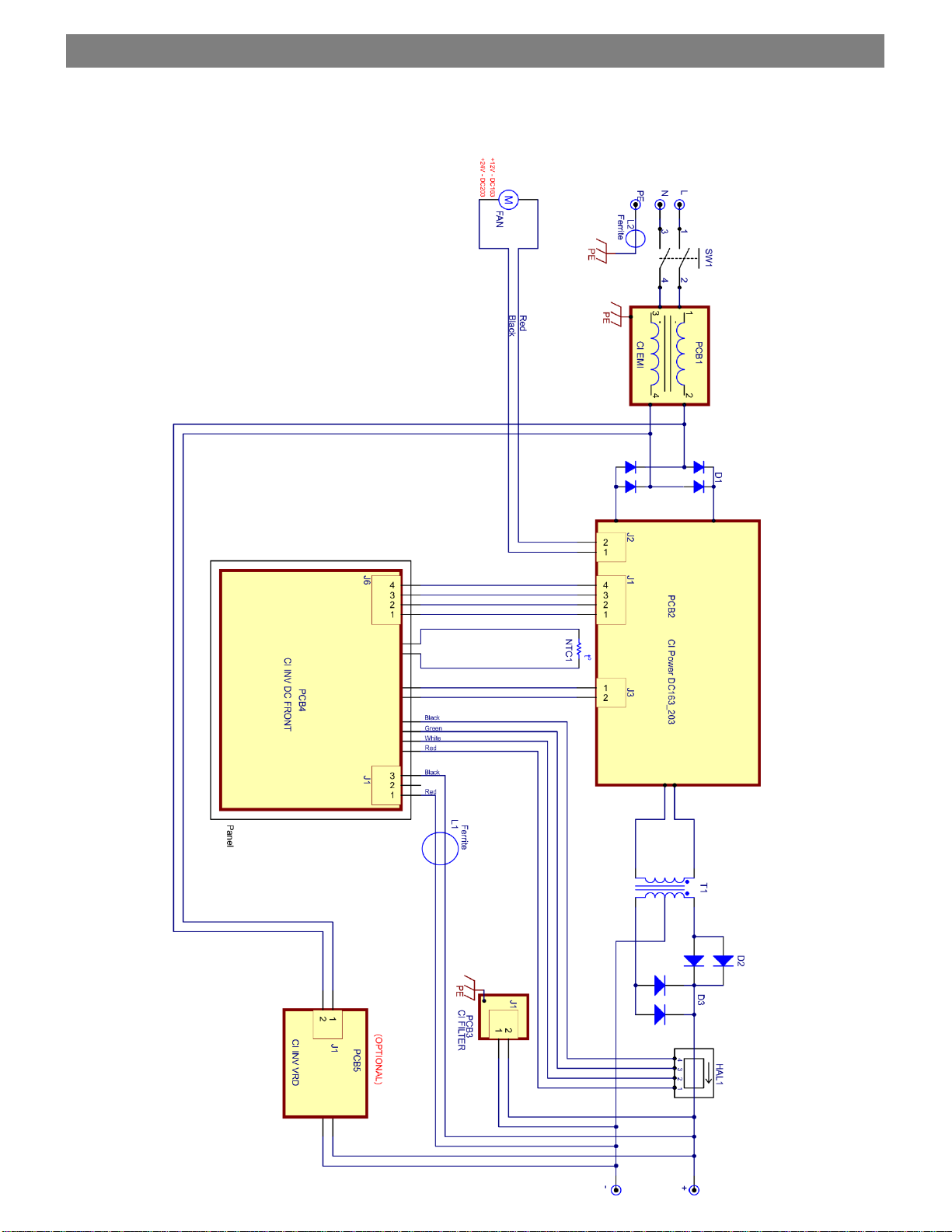

9. ELECTRICAL DIAGRAM

160 / 200

14

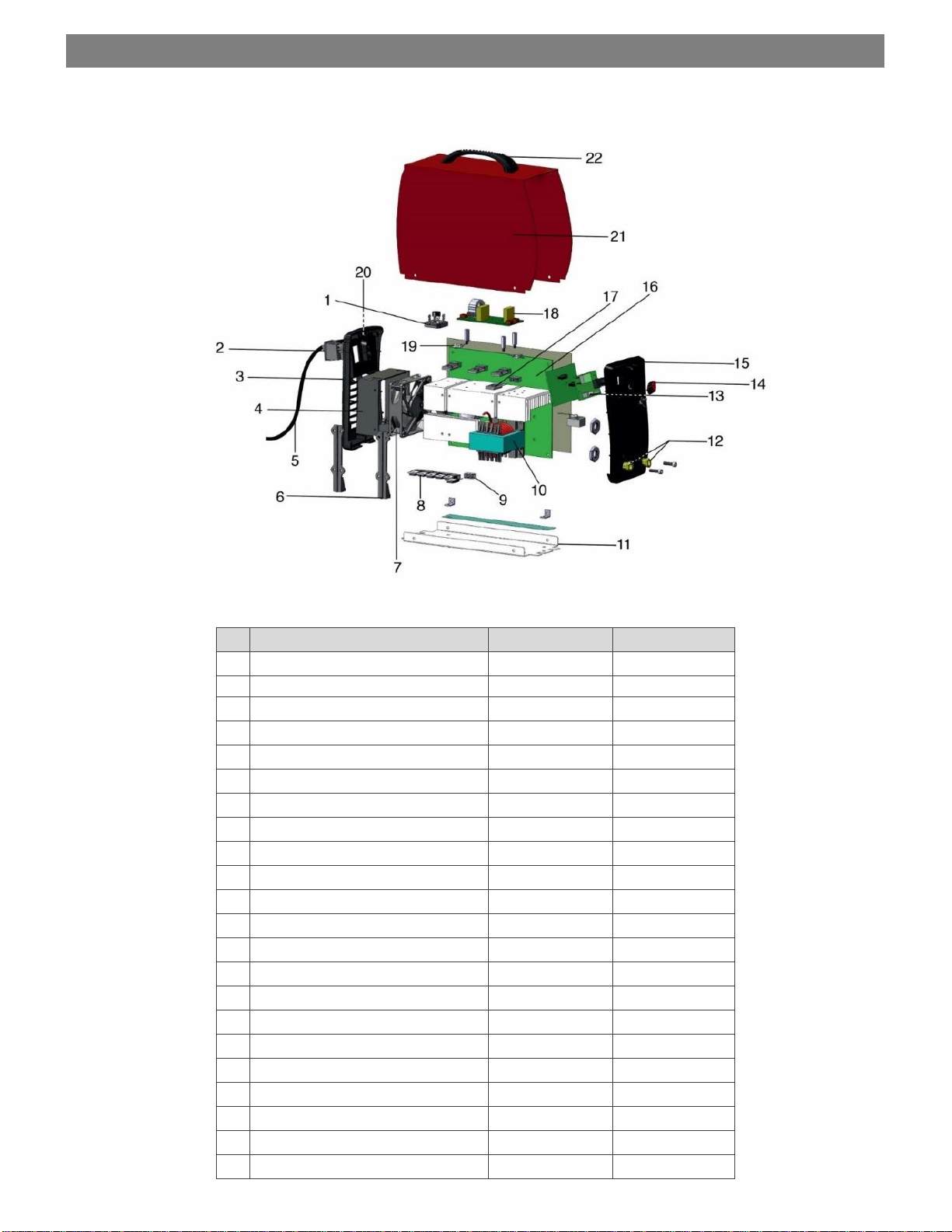

10. SPARE PARTS LIST

Nr.

Description

160

200

1

Rectifier

CO108279

CO108289

2

Main switch

CO109401

CO109401

3

Rear panel

CO9R302G06

CO9R302G06

4

Fan holder

PF109262

PF109262

5

Primary cable

CO2C0252T025B

CO2C0252T025B

6

Support bracket

CO108285

CO108293

7

Fan

CO108284

CO108292

8

Diodes

CO108286

CO108294

9

Diodes isolator

CO98713180

CO98713180

10

Main transformer

CO108276

CO108288

11

Base plate

PF109254

PF109254

12

Quick connections

CO109403

CO109403

13

PCB - Control

PF109645

PF109646

14

Knob

CO109679

CO109679

15

Front panel

CO106610

CO106610

16

PCB - Main control

CO107835

CO107836

17

IGBT module

CO108280

CO108290

18

PCB - EMC

CO108277

CO108277

19

Thermal sensor

CO109397

CO109397

20

Cable clamp connector

CO101584

CO101584

21

Cover

PF109257

PF109257

22

Handle

CO101893

CO101893

160 / 200

15

11. MAINTENANCE

This arc welding equipment should be routinely maintained according to the manufacturers’ recommendations. All access

and service doors and covers should be closed and properly fastened when the arc welding equipment is in operation. The

arc welding equipment should not be modified in any way, except for those changes and adjustments covered in the

manufacturer’s instructions. In particular, the spark gaps of arc striking and stabilising devices should be adjusted and

maintained according to the manufacturer’s recommendations.

Before carrying out any internal checking or repair work, check that the power source has been disconnected from the

electrical installation by locking and guard devices. Ensure and avoid accidental connection of the plug to a socket. Voltages

are high and dangerous inside the machine.

Despite their robustness, ours power sources require some regular maintenance. Each 6 months (more often in dusty

surroundings):

- The machine must be blown through with dry, oil free compressed air.

- Check for continuity all electrical connections.

- Check the connection of cables and flat top.

Check the good state, insulation and connection of all the equipment and electrical accessories: plugs and flexible supply

cables, conduits, connectors, extension cables, sockets on the power source, ground clamp and electrode holder. These

connections and mobile accessories are marked according to standards, if consistent with the safety rules. They can either

be controlled by you or by accredited firms.

- Repair or replace all defective accessories

- Check periodically that the electrical connections are tightened and do not heat.

Maintenance works of electrical equipment must be entrusted by qualified people (Section VI, Art. 46).

11.1 TROUBLESHOOTING

POSSIBLE CAUSES

CHECK

DISPLAY OFF = NO SUPPLY

ON/OFF main switch is OFF

Switch it ON

Power supply cable is cut

Check cable and connections

No main supply

Check circuit breaker and fuses

Defective ON/OFF main switch

Replace the switch

THERMAL INDICATOR ON = INPUT VOLTAGE OVER RATED LIMIT

Duty cycle over rated (if ambient > 25°C)

Let the machine cool, it will automatically start again

Insufficient cooling air

Clean the air inlets

Very dusty machine

Open the generator and blow it through

Fan doesn’t start

Replace the fan

IMPROPER WELDING

Wrong electrode polarity

Use the right polarity according to the indications of

electrode’s manufacturer

Dirtiness in the weld parts

Clean and eventually degrease the weld parts

160 / 200

16

160 / 200

17

160 / 200

18

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

PSC

PSC XANTRA VV ADVANCED Installation and operating instructions

Cotek

Cotek SK120 Series user manual

Kaco

Kaco Powador 30.0 TL3 M/X operating instructions

Sunny Boy

Sunny Boy 700 Technical description

Huawei

Huawei SUN2000-4.6KTL-L1 quick guide

Turbo Energy

Turbo Energy HYBRID 48V 5.0 Series instruction manual