SECTION A-A

SCALE 1:10

DETAIL B

SCALE 1:3

ISOMETRIC VIEW

SCALE 1:25

A

A

B

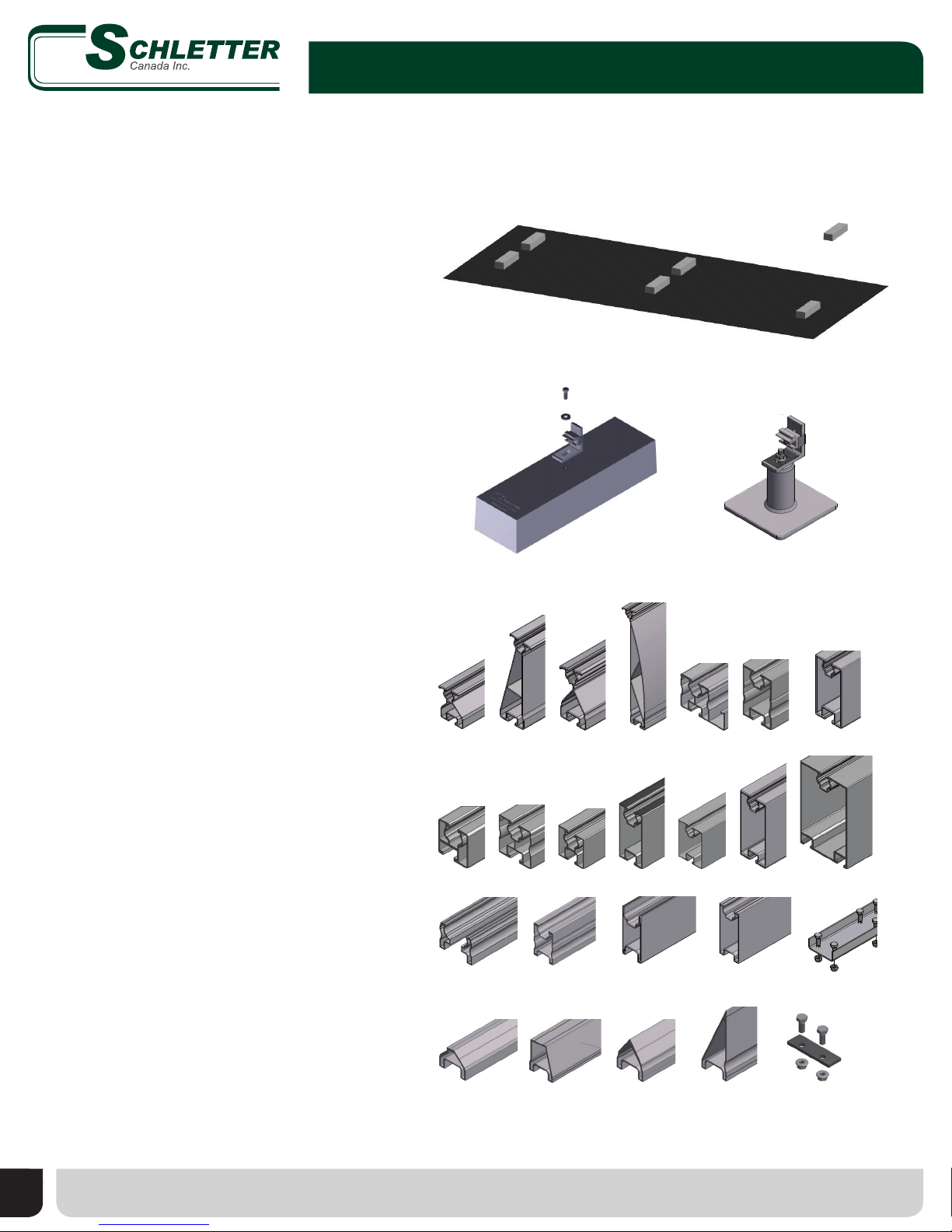

PARTS LIST

DESCRIPTIONPART NUMBERITEM

Block, Ballast, Fix-EZ, Concrete, with Angle, Kit169015-0009

Rail, FixZ-7, Front, Custom

121002-0011

Splice, FixZ-7, Front, Internal, Kit

129071-0002

Rail, FixZ-7, Rear, Custom121001-0016

Splice, FixZ-7, Rear, Internal, Kit129070-000

7

End Clamp, Rapid5K, Grounding, 46mm

135007-14611

Middle Clamp, Rapid5K, Grounding, 40-50mm

135002-00612

1

A

2345678 9 10 11 12 13 14 15 16 17

B

C

D

E

F

G

H

I

J

K

12 3 54 678 9 10 11 12 13 14 15 16 17

A

B

C

D

E

F

I

J

NO. DRAWN: CHECKED: REVIEWED: APPROVED: REVISIONS: Drawing Number:

Sloped Roof Standard FixEZ-7

Standard Racking Structure

Dimensions and Specifications v.01

JOB NUMBER:

SHEET: 1 OF 1

SCALE:

SEE DRAWING VIEWS

ISSUED BY: SCHLETTER INC.

PROPRIETARY AND CONFIDENTIAL

Client: Project Site:

Ballast Block

PRELIMINARY

AND SEALED BY A LICENSED

UNLESS THIS DRAWING IS SIGNED

A PRELIMINARY DESIGN AND SHALL

STRUCTURAL ENGINEER, IT IS

NOT BE USED FOR CONSTRUCTION.

v

0

New Drawing

1001 COMMERCE CENTER DR. | SHELBY, NC 28150

TEL: (704) 595 - 4200 | Fax: ( 704) 595 - 4210

EMAIL: MAIL@SCHLETTER.US

WWW.SCHLETTER.US

DESIGN CRITERIA:

2012 EDITION OF THE INTERNATIONAL BUILDING CODE, WITH LOCAL AMENDMENTS.

LOADS:

MODULE DEAD LOAD = 48 LBS PER MODULE

SNOW LOAD = 0 PSF

WIND DESIGN:

DESIGN BASED UPON WIND TUNNEL TEST REPORT # RC 1665/0513-e

BASIC WIND SPEED = 115 MPH (3 SECOND GUST).

EXPOSURE: C

RISK CATEGORY = II

NOTE:

OWNER MUST VERIFY WITH PROFESSIONAL ENGINEER THAT ROOF STRUCTURE AND ITS

COMPONENTS CAN SUPPORT AND TRANSFER POINT LOADS AT EACH CONNECTION LOCATION

RESULTING FROM ADDITION OF SOLAR PANELS AND RACKING. SEE TABLE BELOW

GENERAL:

1. THE STRUCTURAL CONSTRUCTION DOCUMENTS REPRESENT THE FINISHED STRUCTURE.

THEY DONOT INDICATE THE METHOD OR SEQUENCE OF CONSTRUCTION. THE

CONTRACTOR SHALL BE RESPONSIBLE FOR AND PROVIDE ALL MEASURES NECESSARY TO

PROTECT THE STRUCTURE DURING CONSTRUCTION. SUCH MEASURES SHALL INCLUDE,

BUT NOT BE LIMITED TO, BRACING, SHORING FOR LOADS DUE TO CONSTRUCTION

EQUIPMENT, ETC. THE STRUCTURAL ENGINEER SHALL NOT BE RESPONSIBLE FOR THE

CONTRACTOR'S MEANS, METHODS, TECHNIQUES, SEQUENCES FOR PROCEDURE OF

CONSTRUCTION, OR THE SAFETY PRECAUTIONS AND THE PROGRAMS INCIDENT THERE TO

(NOR SHALL OBSERVATION VISITS TO THE SITE INCLUDE INSPECTION OF THESE

ITEMS). THE CONTRACTOR SHALL BE RESPONSIBLE FOR THE DESIGN AND

IMPLEMENTATION OF ALL SCAFFOLDING, BRACING AND SHORING.

2. WHERE REFERENCE IS MADE TO VARIOUS TEST STANDARDS FOR MATERIALS, SUCH

STANDARDS SHALL BE THE LATEST EDITION AND/OR ADDENDA.

ALUMINUM:

1. ALL ALUMINUM SHALL CONFORM WITH THE LATEST ALUMINUM DESIGN HANDBOOK.

2. ALL ALUMINUM SECTIONS SHALL BE:

a. SEMI-HOLLOWS AND HOLLOWS SHALL BE 6105-T5, 6005A-T6, OR 6005-T5

b. SOLIDS SHALL BE 6063-T6

STEEL:

1: ALL BOLTS AND WASHERS SHALL BE 304 STAINLESS STEEL CLASS 2 (A2-70).

2. ALL NUTS SHALL BE 316 STAINLESS STEEL CLASS 2 (A4-70).

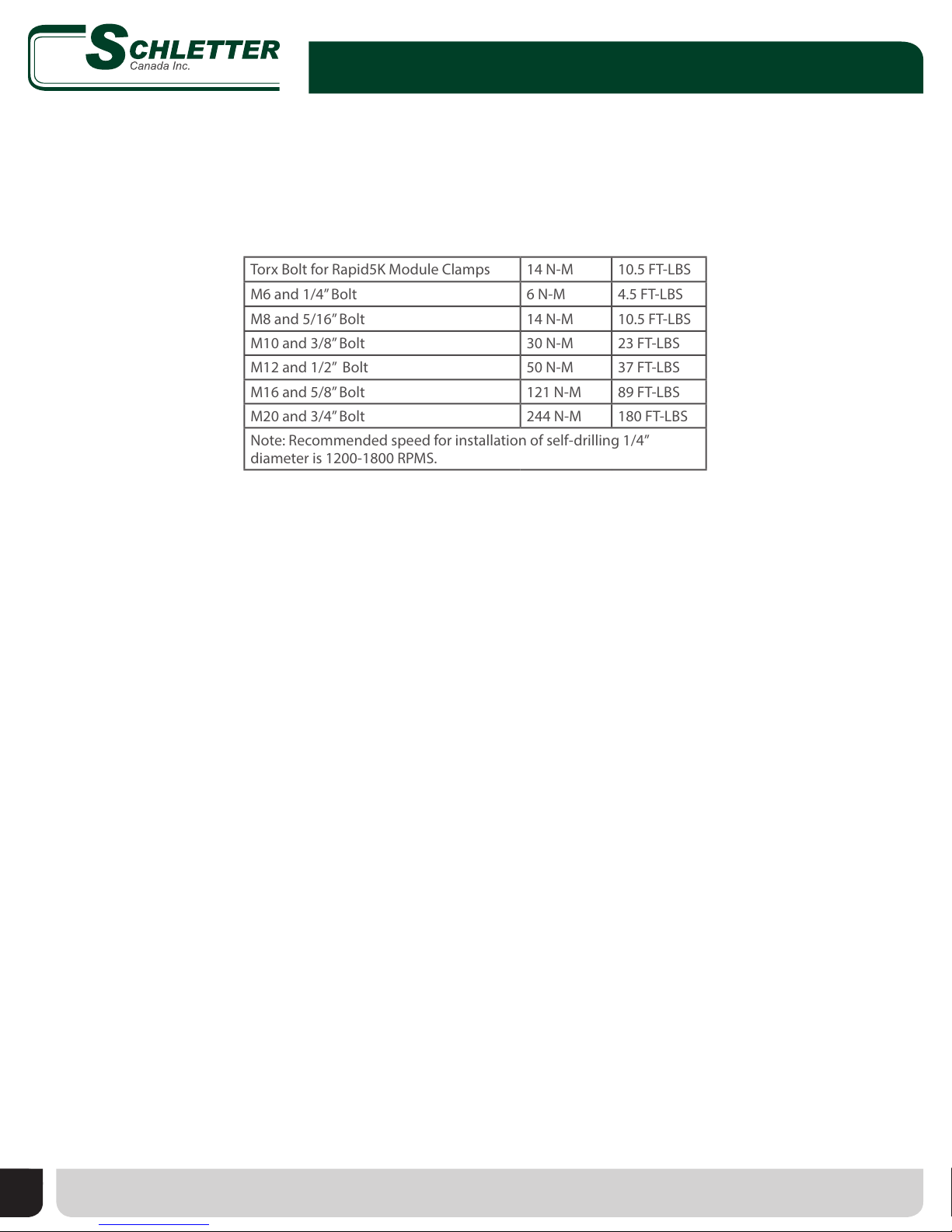

TORQUE:

TORX BOLT FOR RAPID 2+ MODULE CLAMPS IS 14 N-M (10.5 FT-LBS)

M6 AND 1/4" BOLT TORQUE IS 6 N-M (4.5 FT-LBS)

M8 AND 5/16" BOLT TORQUE IS 14 N-M (10.5 FT-LBS)

M10 AND 3/8" BOLT TORQUE IS 30 N-M (23 FT-LBS)

M12 AND 1/2" BOLT TORQUE IS 50 N-M (37 FT-LBS)

M16 AND 5/8" BOLT TORQUE IS 121 N-M (89 FT-LBS)

M20 AND 3/4" BOLT TORQUE IS 244 N-M (180 FT-LBS)

NOTE: RECOMMENDED SPEED FOR INSTALLATION OF SELF-DRILLING 1/4" DIAMETER

SCREWS IS 1200-1800 RPMS.

MODULE SIZE:

RACKING SYSTEM DESIGNED FOR MODULE SIZE: 1600mm x 990mm x 50mm

VERTICAL MODULE GAP: 23 mm

HORIZONTAL MODULE GAP: 5 mm

NOTE:

1. TOTAL RAIL LENGTH NOT TO EXCEED 50 FT WITHOUT EXPANSION JOINT OR PHYSICAL BREAK.

2. SEE LAYOUT FOR MID SPAN SUPPORT LOCATIONS.

3. TO TRANSITION BETWEEN COLOR CODED BALLAST ZONES ONE FULL BALLAST BLOCK

OF A CLOSER SPACING MUST BE CARRIED INTO AN ADJACENT ZONE WITH A GREATER

BALLAST BLOCK SPACING

4. SPLICE CANNOT BE LOCATED ALONG THE LENGTH OF THE CANTILEVER NOR WITHIN 25% OF THE

SPAN LENGTH'S DISTANCE OF AN END SUPPORT AND MUST FALL BETWEEN SUPPORTS.

5. MINIMUM FRICTION COEFFICIENT BETWEEN ROOF AND BALLAST BLOCK IS TOBE 0.42.

VARIES

990 [39 in] TYP

VARIES SPAN TO BE REPEATED FOR LONGER ARRAYS

BASED ON ZONE LAYOUT (SEE NOTES)

VARIES

397[15

5

8

in]

397[15

5

8

in]1191[46

7

8

in]

1985[78

1

8

in]TYP

2500 [98 7

16 in] TYP SHADING DISTANCE

353 [13

7

8

in]

4°

397 [155

8in] 1197 [471

8in] 1303 [51 5

16 in] 1197 [471

8in] 390 [153

8in]

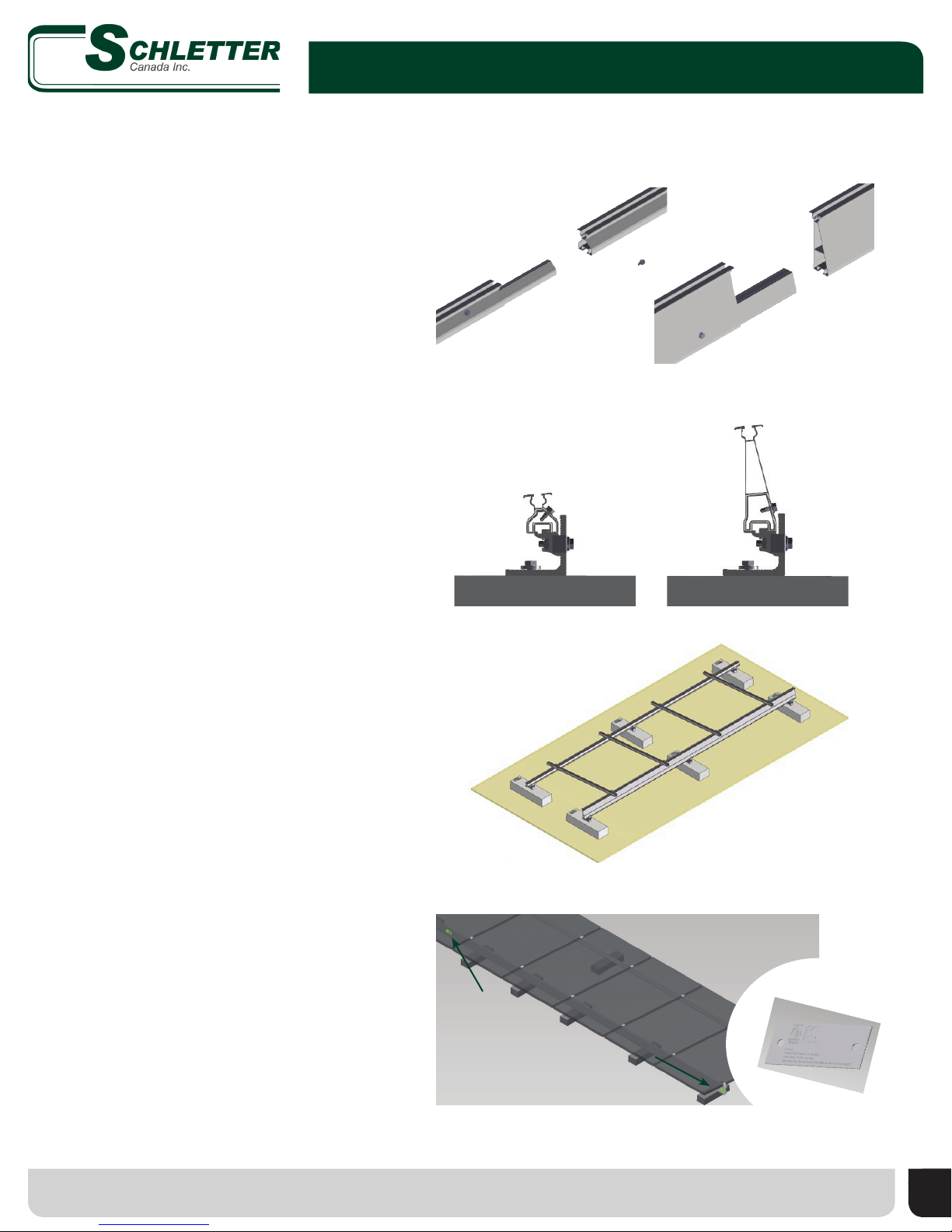

FIXZ-7 FRONT SPLICE DETAIL

SCALE 1 : 5

FIXZ - 7 FRONT RAIL

FIXZ - 7 FRONT SPLICE

FIXZ-7 FRONT RAIL

FIXZ-7 REAR SPLICE DETAIL

SCALE 1 : 5

FIXZ - 7 REAR RAIL

FIXZ - 7 REAR SPLICE

FIXZ - 7 REAR RAIL

FIXZ-7 FRONT EXPANSION JOINT

SCALE 1 : 5

FIXZ-7 FRONT RAIL

FIXZ-7 FRONT SPLICE

(SCREWS ON SAME SIDE)

1" EXPANSION JOINT

BETWEEN RAILS

FIXZ-7 FRONT RAIL

MODULE END CLAMP MODULE END CLAMP

FIXZ-7 REAR EXPANSION JOINT

SCALE 1 : 5

FIXZ-7 REAR RAIL

FIXZ-7 REAR SPLICE

(SCREWS ON SAME SIDE)

1" EXPANSION JOINT

BETWEEN RAILS

FIXZ-7 REAR RAIL

MODULE END CLAMP

MODULE END CLAMP

9

1

12

2

11

6

7

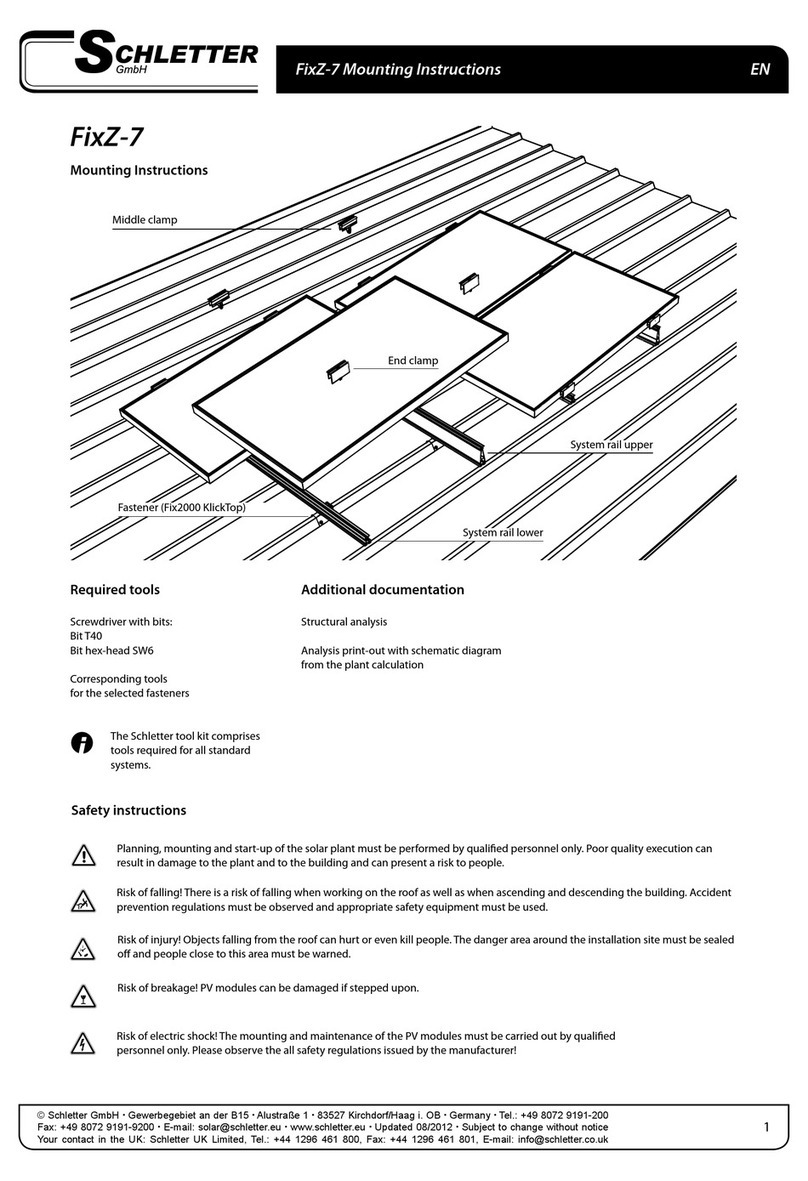

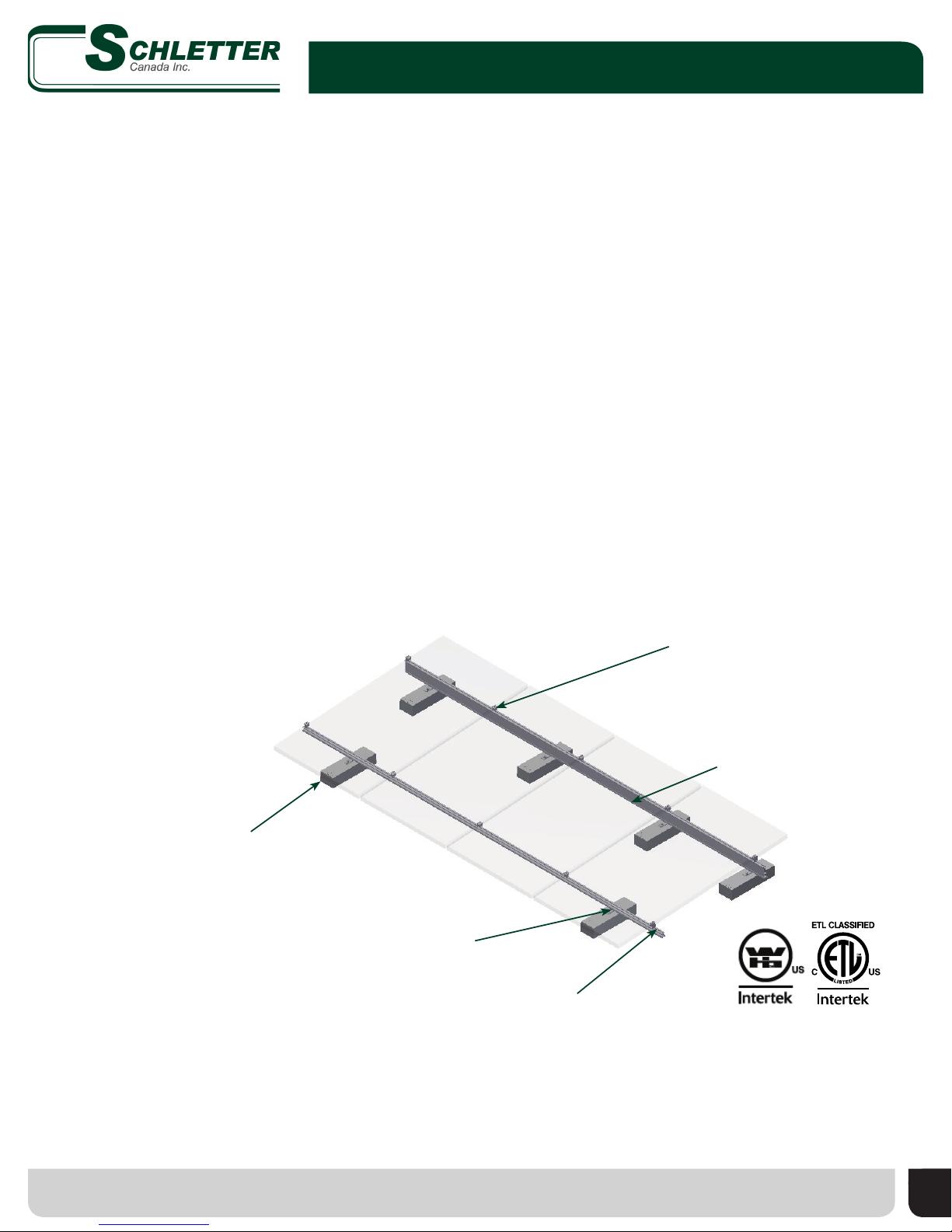

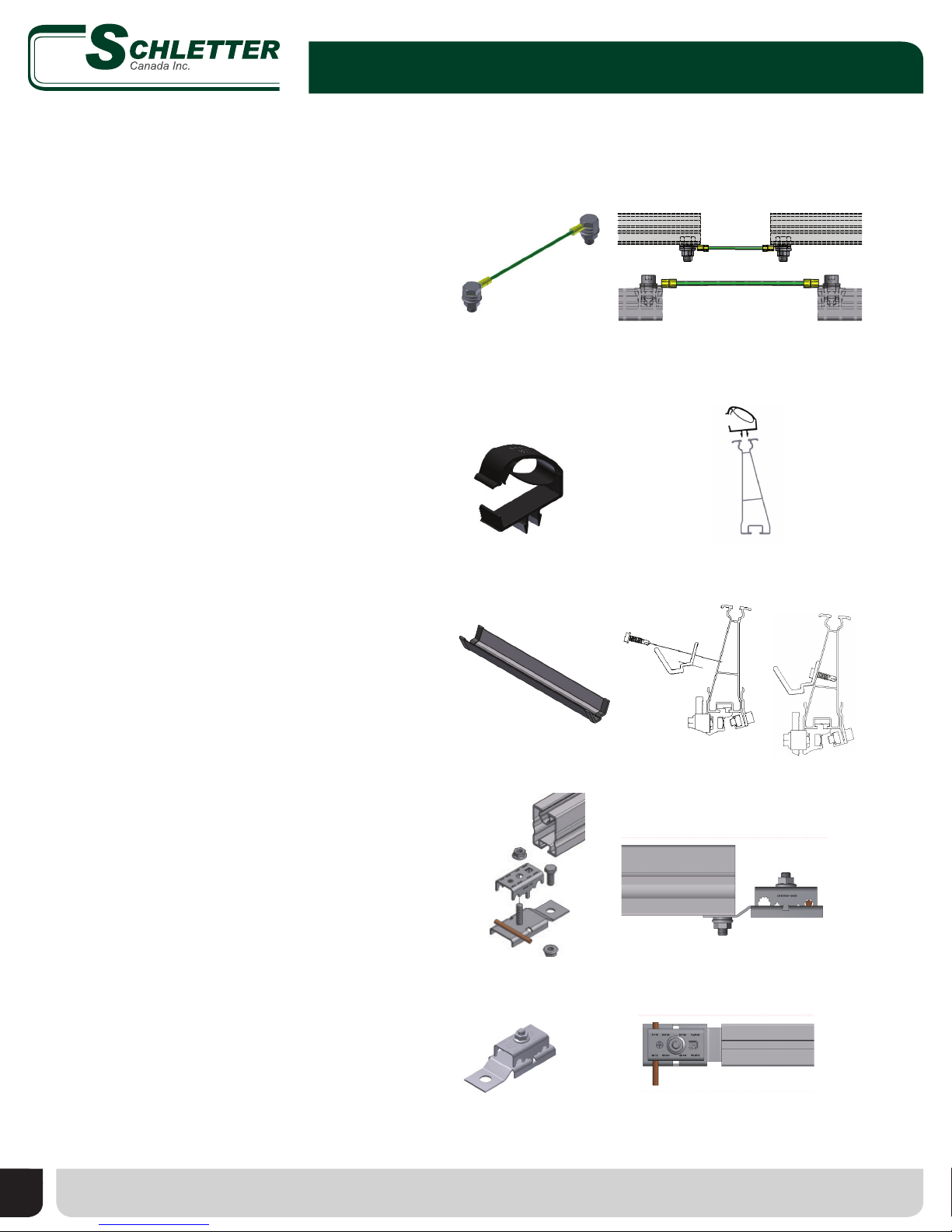

Fix-EZ™ Installation Manual

2/12 MI-018CA

072216

© Schletter Canada Inc. • 3181 Devon Drive • Windsor, Ontario N8X 4L3 • Tel: (519) 946 – 3800 • Fax: (519) 946 – 3805

E-mail: mail@schletter.ca • www.schletter.ca

Sample Drawings

Specic drawings are provided for each project. Key information included on these drawings is as follows:

1. Design Criteria

2. Notes Section

3. Module Dimensions

4. Array Tilt

5. Array Dimensions

6. Ballast Block Spacing

7. Ballast Loads

2

1

3

6

SAMPLE DRAWING ONLY

Row and Ballast Specications

Provided in drawings are locations for ballast blocks and row spacing. Ballast blocks are positioned based on module

manufacturer’s connection specications. Row distance is determined based on shading distance. Ballast requirements and

support spacing will vary. See system/project specic drawings and calculations.

distance according to module height rows according to shading distance

4

5

6

3

7