EC POWER XRGI 15 User manual

INSTALLATION GUIDE

01DOC1043 VERSION 1.0 2018

FOR PROFESSIONALS

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

2

1. DOCUMENTATION INFORMATION 4

1.1 ORIGINAL OPERATING INSTRUCTION 4

1.2 APPLICABLE DOCUMENTS 4

1.3 KEEP THE DOCUMENTS 4

1.4 SYMBOLS USED 4

1.5 RATING PLATE 4

1.6 VALIDITY OF THE GUIDE 5

1.7 CE MARKING 5

2. SYSTEM COMPONENTS 6

2.1 MAIN XRGI® SYSTEM COMPONENTS 6

2.1.1 POWER UNIT 7

2.1.2 iQ-CONTROL PANEL 9

2.1.3 Q-HEAT DISTRIBUTOR 10

2.2 XRGI® SYSTEM ACCESSORIES 11

2.2.1 Q-NETWORK 11

2.2.1.1 STORAGE CONTROL 12

2.2.1.2 FLOW MASTER CONTROL 13

2.2.1.3 FLOW MASTER 14

2.2.1.4 BOILER CONTROL 15

2.2.1.5 VPP GATEWAY 16

2.2.1.6 ELECTRIC HEATER CONTROL 17

2.2.1.7 MODBUS GATEWAY 18

2.2.1.8 STORAGE TANK 19

2.2.1.9 LOAD SHARER S 21

3. SAFETY INSTRUCTION 22

3.1 SAFETY AND WARNING INSTRUCTIONS 22

3.1.1 SAFETY AND WARNING SYMBOLS USED 22

3.2 INTENDED USE 22

3.3 GENERAL SAFETY INSTRUCTIONS 24

3.3.1 HANDLING ENGINE OIL 24

3.3.2 ACTIONS WITH SMELL OF GAS IN BUILDINGS 25

3.3.3 ACTIONS WITH FIRE OR IGRESS OF WATER 25

3.3.4 ACTIONS WITH SMELL OF EXHAUST GAS IN BUILDINGS 25

3.3.5 FROST PROTECTION 26

3.3.6 CONTACT HAZARD 26

3.3.7 EXPLOSIVE AND EASILY FLAMMABLE MATERIALS 26

3.3.8 COMBUSTION AIR SUPPLY 26

3.3.9 MODIFICATIONS TO THE XRGI® SYSTEM COMPOUNDS 27

3.3.10 FILLING AND TOP-UP LIQUID 27

3.3.11 PROPERTY DAMAGE CAUSED BY IMPROPER USE OF AND/OR UNSUITABLE TOOLS 27

3.3.12 MODIFICATIONS IN THE VICINITY OF THE XRGI® SYSTEM 28

3.3.13 OPERATION WITH LIQUID GAS 28

3.3.14 WORKING ON THE ELECTRICAL SYSTEM 28

3.3.15 SAFETY EQUIPMENT ON THE XRGI® SYSTEM 29

3.3.16 SAFETY AND WARNING LABELS ON THE XRGI® SYSTEM 29

3.4 REGULATIONS, STANDARDS AND LAWS 30

3.5 WARRANTY INFORMATION 30

3.5.1 RETURN OBLIGATIONS 30

TABLE OF CONTENTS

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

3

4. ASSEMBLY 32

4.1 SCOPE OF DELIVERY CHECK – XRGI® SYSTEM 32

4.1.1 XRGI® ORIGINAL ACCESSORIES 32

4.2 TRANSPORT AND HANDLING 32

4.3 INSTALLATION ROOM 33

4.3.1 FOUNDATION 33

4.3.2 ROOM TEMPERATURE/DUST 33

4.3.3 NOISE AND VIBRATION 33

4.3.4 CORROSIVE AMBIENT CONDITIONS 34

4.3.5 REQUIRED AIR INLETS 34

4.3.6 REMOTE DATA MONITORING 34

4.4 DIMENSIONS AND CONNECTIONS 35

4.4.1 XRGI® 6/9-SYSTEM 35

4.4.2 XRGI® 15/20-SYSTEM 38

4.5 REQUIRED MINIMUM CLEARANCES – ASSEMBLY & MAINTENANCE CLEARANCES 41

4.5.1 XRGI® 6/9-SYSTEM 41

4.5.2 XRGI® 15/20-SYSTEM 42

4.6 INSTALLATION OF THE XRGI® SYSTEM 44

4.6.1 SOUND INSULATION 44

5. INSTALLATION 45

5.1 HYDRAULIC INSTALLATION 45

5.1.1 EC POWER STANDARD HYDRAULIC SYSTEM 45

5.1.2 INSTALLATION Q-HEAT DISTRIBUTOR – POWER UNIT 49

5.1.2.1 PRIMARY CIRCUIT – FLOW AND RETURN CONNECTION 49

5.1.3 INSTALLATION Q-HEAT DISTRIBUTOR – STORAGE TANK/CONSUMER NETWORK 50

5.1.3.1 SECONDARY CIRCUIT – FLOW AND RETURN CONNECTION 50

5.1.3.2 EC POWER STORAGE TANK 51

5.2 EXHAUST GAS SIDE INSTALLATION 52

5.2.1 EXTERNAL EXHAUST HEAT EXCHANGER 52

5.3 GAS SIDE INSTALLATION 53

5.3.1 GAS HOSE CONNECTION 53

5.4 ELECTRICAL INSTALLATION 54

5.4.1 POWER UNIT 54

5.4.2 Q-HEAT DISTRIBUTOR 54

5.4.3 iQ-CONTROL PANEL 54

5.4.4 POWER FACTOR CORRECTION 56

5.5 NETWORK INSTALLATION 56

5.5.1 STORAGE CONTROL 56

5.5.2 FLOW MASTER CONTROL 57

5.5.3 FLOW MASTER 57

5.5.4 BOILER CONTROL 58

5.5.5 VPP GATEWAY / ELECTRIC HEATER CONTROL 59

5.5.6 MODBUS GATEWAY 59

5.5.7 LOAD SHARER S 60

TABLE OF CONTENTS

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

4

1. DOCUMENTATION INFORMATION

This XRGI® installation guide provides detailed information about the individual XRGI® system components, their functions, assembling

and installation.

It provides important safety instructions that must be complied with when operating the XRGI® system and describes the interplay of

the Power Unit, the Q-Heat Distributor and the iQ-Control Panel as included in the standard scope of delivery. It also describes certain

accessories, the Q-Network modules and the storage tank, which may be required depending in the individual installation.

Please read this XRGI® installation guide carefully before installation and commission.

Only a correct assembling, installation and operation of the XRGI® system according to the specifications from EC POWER ensures proper

functioning and a valid warranty. Please keep this XRGI® installation guide for later reference. EC POWER continuously improves its pro-

ducts and reserves the right to make technical changes and to implement these changes if considered necessary. This means that the

company is not bound to make retrospective changes to already delivered XRGI® systems.

The following information’s are a guide through the entire documentation. In connection with this XRGI® installation guide. In connec-

tion with this XRGI® installation guide, other accompanying documents must be followed. EC POWER cannot take responsibility for any

damages caused by non-compliance with the instructions for the XRGI® system.

1.1 ORIGINAL OPERATING INSTRUCTION

1.2 APPLICABLE DOCUMENTS

1.3 KEEP THE DOCUMENTS

1.4 SYMBOLS USED

1.5 RATING PLATE

This XRGI® installation guide contains original operating instructions in accordance with the Machinery Directive.

When installing the XRGI® system, all installation instructions for additional components and components of the XRGI® system must

be complied with. These installation instructions are attached to the respective components of the XRGI® system and additional

components.

Please note all operating instructions that come with the components of the XRGI® system.

These documents are subject to technical modifications!

Due to the continuous development of the XRGI® systems, illustrations, functional steps and technical data may differ slightly.

Pass on this XRGI® installation guide and all applicable documents to the system operator.

The system operator keeps the XRGI® installation guide and other instructions for future reference so that they are available when

needed.

The following explains the symbols used in the text.

INFO!

Symbol for important and useful information about the issue.

POWER UNIT

The rating plate is located on the back of the Power Unit.

Legend

1Power Unit serial no.

2Type description of the XRGI® system

3Description of the type approval

4Technical data of the Power Unit

5CE marking

1

3

4

2 5

Fig. 1.01 – Power Unit rating plate

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

5

1

3

2 4

1

2

3

4

1

With the CE marking, products comply with the essential requirements of the relevant directives in accordance with the rating plate.

Q-HEAT DISTRIBUTOR

The rating plate is located on the inside of the Q-Heat Distributor

below the electronics box.

Legend

1Q-Heat Distributor serial no.

2Type description of the Q-Heat Distributor

3Technical data of the Q-Heat Distributor

4 CE marking

iQ-CONTROL PANEL

The iQ-Control Panel has two rating plates. These are located on the inside

of the iQ-Control Panel door and on the left side of the iQ-Control Panel,

below the main switch disconnector.

Legend

1iQ-Control Panel serial no.

2 Technical data of the iQ-Control Panel

3Type description of the iQ-Control Panel

4XRGI®-ID of the XRGI® system

1.7 CE MARKING

1.6 VALIDITY OF THE GUIDE

This XRGI® installation guide only applies to XRGI® systems with the following article numbers:

■Without additional accessories

■With additional storage tank

Type Article number

XRGI® 6 X060001 / X060002

XRGI® 9 X090001 / X090002

XRGI® 15 X150001 / X150002

XRGI® 20 X200001 / X200002

Fig. 1.02 – Q--Heat Distributor rating plate

Fig. 1.04 – Rating plate iQ-Control Panel

Fig. 1.03 – iQ-Control Panel rating plate

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

6

An XRGI® system consists of the following three main components:

POWER UNIT

■Heat production

■Power production

■Safety functions

■Power control

IQCONTROL PANEL

■Connection to the grid

■Electrical safety features

■Control of the XRGI® system

■Status and production display

■Remote data transmission

QHEAT DISTRIBUTOR

■Regulation of the temperature of the engine water

■Connection of the XRGI® system to the storage tank and the central

heating system

■Output of high-efficiency pumps regulated according to current demand

■Creation of storage strategies according to current demand

■Service and error messages in the heating system

2. SYSTEM COMPONENTS

2.1 MAIN XRGI® SYSTEM COMPONENTS

An XRGI® system consists of three main components: the Power Unit, the Q-Heat Distributor and the iQ-Control Panel.

The XRGI® system can be expanded with additional XRGI® accessories: Storage Control, Boiler Control, Flow Master Control, Flow

Master, Electric Heater Control, VPP Gateway, Modbus Gateway, storage tank and Load Sharer S.

Construction of the standard XRGI® systems:

XRGI®6 Power Unit XRGI® 6 – Q20-Heat Distributor – iQ10-Control Panel

XRGI®9 Power Unit XRGI® 9 – Q20-Heat Distributor – iQ10-Control Panel

XRGI®15 Power Unit XRGI® 15 – Q80-Heat Distributor – iQ15-Control Panel

XRGI®20 Power Unit XRGI® 20 – Q80-Heat Distributor – iQ20-Control Panel

Fig. 2.01

Fig. 2.02

Fig. 2.03

Fig. 2.04

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

7

A B

C

1 4 52 6

3 7

8/9

10

12

14

13

15

16

18

17

11

Fig. 2.05 - XRGI® 6/9

Fig. 2.06 - XRGI® 6/9

Fig. 2.07 - XRGI® 6/9

2.1.1 POWER UNIT

CONSTRUCTION

Legend:

A Electrical components and safety circuit

B Air filter and mixture control

C Sound- and heat-insulated engine compartment

1 Silencer (integrated)

2 Water-cooled generator

3 Exhaust gas cooler (not visible)

4 Oil sump

5 EC POWER gas engine

6 Oil separator

7 Catalyst (not visible (patented))

8 Primary circuit flow (1“ G)

9 Primary circuit return (1“ G)

10 Electrical connection

11 Exhaust gas connection (twin tube, di = 60 mm, da = 100 mm)

12 Gas connection (½“ G)

13 Air filter

14 Gas safety circuit

15 Cover with gas pressure springs

16 Spark plugs

17 Upright pipe for oil change

18 Oil filter (upright, water-cooled)

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

8

C

A B

15

16

17

18

9

8

10

12

13

14

11

C

A B

15

16

17

18

9

8

10

12

13

14

11

1 2 5 4

3 7

61 2 5 4

3 7

6

CONSTRUCTION

Legend:

A Electrical components and safety circuit

B Air filter and mixture control

C Sound- and heat-insulated engine compartment

1 Silencer (integrated)

2 Water-cooled generator

3 Exhaust gas cooler (not visible)

4 Oil sump

5 EC POWER gas engine

6 Oil separator

7 Catalyst (not visible (patented))

8 Primary circuit flow (1¼“ G)

9 Primary circuit return (1¼“ G)

10 Electrical connection

11 Exhaust gas connection (twin tube, di = 60 mm, da = 100 mm)

12 Gas connection: XRGI® 15: ¾“ G – XRGI® 20: ¾“ G

13 Air filter

14 Gas safety circuit

15 Cover with gas pressure springs

16 Spark plugs

17 Upright pipe for oil change

18 Oil filter (upright, water-cooled)

FUNCTION

CONFIGURATION

The Power Unit contains the following main components:

■Engine control

■Cooling circuit

■Mixture control

■Engine electronics

■Gas safety circuit

■Temperature monitoring relay

Here, gas converts into electricity and heat.

The gas setting must only be carried out by authorised persons. This is described in the commissioning instruction. No further adjust-

ments are needed on the engine.

Fig. 2.08 - XRGI®15

Fig. 2.09 - XRGI®15

Fig. 2.10 - XRGI®15

Fig. 2.12 - XRGI®20

Fig. 2.13 - XRGI®20

Fig. 2.11 - XRGI® 20

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

9

1 9 3 102

84

5

12

7

11 13

6

1 2 3 4

89

5

13

6

12

7

11

10

14

14

Legend:

1 Contactor

2 Residual current breaker (4P 40A 30mA)

3 Miniature circuit breaker

4 Fan

5 Central Control PCB with integrated modem (not visible)

6 Residual current breaker (1P+N 1A C)

7 Motherboard (not visible)

8 RJ45 connector

9 Transient protection

10 Direct power meter

11 Soft starter

12 Main switch disconnector

13 Network monitoring relay

14 Antenna

2.1.2 IQCONTROL PANEL

CONSTRUCTION

CONFIGURATION

FUNCTION

The iQ-Control Panel is used to operate the XRGI® system.

■Main switch disconnector: Main switch connector masters

on/off switch for the iQ-Control Panel and the Power Unit

INFO: The Q-Heat Distributor is powered separately!

■Soft starter: Starts the generator as an engine

■Auxiliary relay: Extra relay for the soft starter

■RCD type A: Fault protection

■Fuses: Overvoltage protection

■Output meter. measures the electricity produced by the

generator

■ENS relay: N/A protection device

■Motherboard power supply: Supplies 12V to the mainboard

■Motherboard: Communication interface with the Power

Unit and the Q-Heat Distributor

■Central Control PCB with integrated modem system

processor: Sends data to the EC POWER service database

via mobile network

The iQ-Control Panel is mainly responsible for the following:

■System control

■Power regulation

■Power meter (production)

■Hardware and software for the operating strategy

■Data collection and analysis

■Communication with the service database

■Interfaces for external connections

The iQ-Control Panel is operated using its front panel and turned on and off using the main switch disconnector on the left side.

Fig. 2.14 - iQ 10

Fig. 2.15 - iQ 15/20

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

10

2

6

5

1

3 4

1

6

5

2

3 4

FUNCTION

CONFIGURATION

The Q-Heat Distributor plays the following role in the XRGI® system:

■Separation of the engine circuit (primary) from the heating

network

■Protection of the primary circuit

■Control of the engine temperature

■Control of the system temperature

■Management of the storage load

■Management of the energy flows

The Q-Heat Distributor separates the engine circuit (Power Unit

cooling water circuit) from the heating system by means of a plate

heat exchanger. In this way, the expansion vessel protects the engine

circuit. The circulation pump for the engine circuit is mounted on the

left of the primary circuit of the Q-Heat Distributor. When the Q-Heat

Distributor is connected to power, the circulation pumps run for 5–10

seconds to check that they are working properly.

The pumps cannot be configured. They start together with the Power

Unit and stop approx. 10–20 minutes after the Power Unit has shut

down. Their power is controlled by the Q-Heat Distributor according

to demand. The storage charge group (on the right of the Q-Heat

Distributor) controls the engine temperature via the mixer and the

speed-controlled circulation pump. The system is designed to maximi-

se the storage charge temperatures (80–85 °C).

The Q-Heat Distributor does not need to be adjusted after assembly.

2.1.3 QHEAT DISTRIBUTOR

Legend:

1Expansion vessel

2RJ45 connector

3Flow and return connection to the Power Unit

4Flow and return connection to the storage tank/consumer network

5Mixer for engine temperature control

6Plate heat exchanger (not visible)

CONSTRUCTION

Fig. 2.16 - Q20

Fig. 2.17 - Q80

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

11

2.2 XRGI® SYSTEM ACCESSORIES

2.2.1 QNETWORK

The XRGI® control system is based on two logical networks:

■Q-net Control (control network)

■Q-net Heat (heat network)

Both systems use the conventional hierarchical master/slave strategy, with the master controller alone being able to access the shared

resources unsolicited. The slave controller cannot access the shared resources of its own accord; it has to wait until it is asked by the

master controller.

All network modules have two RJ45 ports per board. The iQ-Control Panel is the master for the control network and hence for the

Power Unit and the Q-Heat Distributor. The Q-Heat Distributor is the master for the heat network and thus the interface between the

two logical networks. The Q-Heat Distributor therefore has two boards and four ports.

Each RJ45 port has two LEDs (e.g., the Storage Control is shown below):

The LED on the left (orange) indicates the connection status:

■LED off = System off

■LED Continuously on = Connected

■LED Flashing = Communication

The LED on the right (green) indicates the operating status:

■LED green = Everything OK

■LED red = Unit is connected to the wrong network or there is no space for more units

■LED flashing red = Error (refer to relevant product specifications)

The control network consists of the iQ-Control Panel (master), the Q-Heat Distributor and the gas safety circuit (both slaves).

The heat network consists of the Q-Heat Distributor (master) and the downstream members: Storage Control, Flow Master Control

and Boiler Control (all slaves). The members belonging to the network are looped via the Q-Network cable in series (not star-cabled).

Each Q-Heat Distributor can control up to 20 slaves, although there can only be one Flow Master Control in the network, but multiple

Storage Controls. Installations with multiple Power Units have their Q-Network modules linked by a Q-Network cable.

The iQ-Control Panel and Q-Heat Distributor continuously request data from network members every few seconds and update their

functionality. This means that a Storage Control can be added to the network during operation, for example.

Available Q-Network modules:

■Q-Network Storage Control (storage control)

■Q-Network Flow Master Control (discharge control)

■Q-Network Boiler Control (boiler activation)

■Q-Network VPP Control (virtual power plant control)

■Q-Network Electric Heater Control

■Q-Network Modbus Gateway

■Q-Network storage tank with external Storage Control

Fig. 2.18

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

12

2.2.1.1 S T O R A G E C O N T R O L

The Storage Control organises the management of the storage tank (filling and emptying). Each XRGI® system needs at least one

Storage Control.

Temperature sensors determine the separation layer between the cold return and warm flow and from this calculate the required

storage level and/or the required residual heat volume for the selected operating strategy from this.

A clear separation between the cold return and warm flow by the separation layer is crucial for a high capacity in the storage tank and

an optimum operation. This separation is ensured by the EC POWER storage tank.

The storage tank management is based on the following sequence and criteria:

1. Ensure that the XRGI® system runs for a minimum amount of time

Only start up the XRGI® system when the storage tank can accommodate a minimum heat production.

2. Use the XRGI® system to meet the peak heating loads in the building

Start up the XRGI® system when the storage tank is not completely empty. The XRGI® system‘s heat production and the

volume of residual heat from the storage tank reduce the heat production in the boiler and extend the runtime of the XRGI®

system.

3. Enabling a power-controlled operation (either based on electricity need and/or electricity price)

By storing the heat in the storage tank for later consumption, electricity production is ensured, even when no heat is needed

but electricity is.

The reserve capacities determined by the Storage Control vary according to the season

and the extent of the heat demand. In the colder months and/or at times of high demand

for heat, a higher volume of residual heat is retained in the storage tank (to allow for cover-

age of peaks of heat load). A smaller volume of residual heat is maintained in the warmer

months (minimum runtime of XRGI® system, power-controlled operation). The Storage

Control continuously determines the optimum residual heat volume based on demand

and consumer behaviour.

The Storage Control is a self-configuring sensor system. The sequence of the storage tanks

is automatically detected when they are charged for the first time. The sequence of the

sensors within the storage tank is very important: It has to start at the top with sensor 1

and run down to sensor 4.

A Storage Control is needed if no EC POWER storage tank is used.

When using an EC POWER storage tank, the required storage controls are included.

Use a minimum of one Storage Control with four temperature sensors per cubic meter of storage tank volume.

SCOPE OF DELIVERY Modules Storage Control unit, four PT100 sensors, one Q-Network cable

CABLE DIMENSIONS PT100 sensor cable m 3

Q-Network cable m 5

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 130 x 35 x 80

Weight kg 0.165

Fig. 2.19 - Storage Control

Fig. 2.20

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

13

2.2.1.2 F L O W M A S T E R C O N T R O L

The Flow Master Control regulates the heat output from the XRGI® system and the storage tank (temperature level VL between 80

and 85 °C) into the heating system by means of the controllable pump and the valve of the Flow Master so that the required flow

temperature Tf (= setpoint) is reached. The setpoint for Tf is set on the iQ-Control Panel.

Please note:

Once the actual temperature Tf falls below the setpoint, the controllable pump in the Flow Master will start and the control valve will

open. 85 °C hot water from the XRGI® system and/or storage tank will be mixed into in the heating network until the setpoint Tf is

reached.The discharge from the storage tank will be maximised with the power that is possible according to the installed Flow Master.

The temperature sensor Tb ensures that not too much 85 °C warm water is injected into the heating network by the adjustable pump

(to prevent backflow). The temperature sensor Tr detects the temperature of the return water in the system. If the temperature of the

system‘s return water is too high for engine cooling, the Flow Master will stop the injection and the return heating water will bypass

the XRGI® system.

When the storage tank is empty (because of continuously higher heat demand to the heating network than the heat production in

the XRGI® system), the discharge from the storage tank will sometimes stop in order to fill the storage tank. In this case, the heat supply

is automatically supplied by the boiler (the boiler will be activated if the temperature falls below the flow temperature at setpoint

VL in the boiler). While the storage tank is being refilled, the boiler as the sole source of heat in the system prevents the boiler from

constantly switching on and off and, in this way, saves energy.

When the storage tank is sufficiently refilled, it automatically begins to discharge heat into the system again and boiler operation

stops, but only if the heat in the XRGI® system and the storage tank with the installed Flow Master is sufficient to meet demand.

Tf is set to a maximum of 79.9 °C and should always be higher than the maximum boiler temperature so that the

XRGI® system can deliver the base heat load (∆ 5 K is sufficient).

SCOPE OF DELIVERY Modules Flow Master Control unit, four PT100 sensors, one Q-Network cable

CABLE DIMENSIONS PT100 sensor cable m 3

Q-Network cable m 5

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 180 x 60 x 130

Weight kg 0.5

Fig. 2.21 - Flow Master Control

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

14

The Flow Master feeds the heat from the XRGI® system and from the storage tank into the consumer circuit. In the short term, this

allows significantly higher heating capacity on the consumer side than with the installed XRGI® heating line. With this, heat demand

peaks can be handled by the XRGI® system, thus extending its production time and increasing heating capacity.

Four models are currently available that can operate at a ∆T of 20 K with a heat output of 50, 150, 250 or 350 kW. The desired flow

temperatures (up to a maximum of 79.9 °C) are constantly available. The injectable heat output is adjusted automatically depending

on the return temperature from the property‘s network. The decision about which Flow Master to be used with Flow Master Control

is determined according to the building conditions and the consumption habits.

When using a Flow Master with a Flow Master Control, the instructions on the temperature sensors, the injection line and the sizing

of the heating pipes are to be complied with to ensure correct operation.

SCOPE OF DELIVERY FM type (temperature controller, class II = 2 %) FM 50 FM 150 FM 250 FM 350

Modules Flow Master, Flow Master Control Unit, four PT100 sensors, one Q-Network cable,

one valve control cable, one pump control cable and one power cable

DATA Pump UPM3

15-75 130

UPMXL GEO

25-125 180

Magna3

50-60 F 220

Magna3

50-60 F 240

Flow connection G¾" 1 ¼" 1 ½" 2"

Temperature sensor PT100 (5 x 40 mm) PT100 (5 x 40 mm) PT100 (5 x 40 mm) PT100 (5 x 40 mm)

Maximum flow volume m3/h 2.2 6.5 10.8 15.1

Thermal capacity kW 50 150 250 350

∆T (with a return of 60–65 °C) °C 20 20 20 20

CABLE DIMENSIONS PT100 sensor cable m 3

Valve control cable m 1.8

Pump control cable m 1.8

Power cable m1.8

Q-Network cable m 5

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 157 x 120 x 323 181 x 196 x 411 297 x 221 x 483 407 x 273 x 512

Weight kg 2.9 5.4 17.2 27.1

2.2.1.3 F L O W M A S T E R

Fig. 2.22 - Flow Master

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

15

2.2.1.4 B O I L E R C O N T R O L

The Boiler Control ensures the optimum operation of the XRGI® system and the peak load boiler when the XRGI® system is operated

hydraulically via the storage tank parallel to the boiler.

The boiler control activates the boiler to produce heat via a potential free contact if the consumption is larger than the heat producti-

on of the XRGI® system and the storage tank is almost empty.The boiler is disabled as soon as the heat production in the XRGI® system

exceeds the consumption.

If the heat consumption is higher than the heat generation in the XRGI® system in the long term, the top storage sensor S1 will

become cold. Then the boiler control enables the boiler to produce heat until the storage sensor second from the top S2 registers a

sufficient temperature. When this happens, the Boiler Control disables the boiler again.

The additional installation of the Boiler Control ensures that the boiler will only be switched on when needed and, in this way, the

operating time of the XRGI® system will not be reduced. This is particularly important with parallel circuits and warm water provision

so that the boiler does not start up unnecessarily, although the heat production of the XRGI® system and the storage volume are

sufficient to deliver heat.

After the assembling of the Boiler Control, it does not require further adjustments.

The Boiler Control is controlled according to the top two Storage Control temperature sensors in the storage tank

and the predetermined flow temperature Tf.

SCOPE OF DELIVERY Modules Boiler Control unit, one green system plug, one Q-Network cable

CABLE DIMENSIONS Q-Network cable m10

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 130 x 35 x 80

Weight kg 0.165

Fig. 2.23 - Boiler Control

Fig. 2.24

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

16

T1

T2

T3

T4

The control centre (central control of the virtual power plant) communicates the required operating strategy for the XRGI® system.

The XRGI® controller guarantees the operating mode (on, off or modulating mode) on the XRGI® system. Here, the storage tank plays

a key role and enables the management of the storage tank to be separated from the heat and the power production. The EC POWER

control individually defines the optimum mode of operation for each property based on:

■level of the storage tank

■actual heat demand

If no operating strategy is communicated by the control centre, the XRGI® system operates heat-controlled.

The EC POWER solution works on the basis of the operating status of the decentralised installed system and thus guarantees:

■Simple and stable supply (without safety reserves for emergency heat demand)

■Completion of the operating strategy by individual and selective emptying of the storage tank

■No incorrect forecasts of the heat demand and the required expertise for this

■Simple set-up of a virtual power plant at minimal cost

■Fast achievement of an efficient virtual power plant even with smaller systems

SCOPE OF DELIVERY Modules VPP Gateway unit, one green system plug

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 130 x 35 x 80

Weight kg 0.165

The VPP Control is activated by means of potential-free contacts.This external control is independent of the manufacturer. For in-stan-

ce, it can be provided by the building’s own BMS, a small controller or a remote data transmission. The control voltage from the VPP

Control must be 24V and the cable cross-section must be 6 × 0.8 mm2. The control cable is connected to the VPP Control by the

supplied system plug (green).

The VPP Control is integrated into the Q-Network by the supplied CAT6 quality

RJ45 patch cable. A longer cable of the same quality can be provided on-site if the

supplied cable of 3 metres is not long enough. The VPP Control must be integrated

on the control side (i.e., the VPP Control can be connected either to the Power Unit

or to the iQ-Control Panel). Connection to the iQ-Control Panel is preferable.

OPERATING MODES

All the required functions needed for the operation of a virtual power plant can be provided with only

five operating modes.

SIGNAL 1: XRGI® system runs at„maximum“

The XRGI® system starts up when sensor T2 signals„cold“. It works until no further system cooling is pos-

sible (i.e., the engine constantly exceeds the outlet temperature of 95 °C).

SIGNAL 2: XRGI® system runs at„minimum“

The XRGI® system starts up when sensor T1 is„cold“. The controller tries to keep sensor T1 warm by swit-

ching between small load or modulating operation and maximum power. Thus, the XRGI® system largely

ensures the provision of heat without filling up the storage tank. The XRGI® system stops at the latest

when T1 signals„warm“.

SIGNAL 3: No production by the XRGI® system

The XRGI® system and one available electric heater, if fitted, remain switched off. The heat generation

must be ensured by an additional heat generator, controlled by a controller independent of the VPP.

SIGNAL 4: Electric heater runs at„minimum“

The electric heater starts up when sensor T1 is cold. The controller tries to keep the sensor T1 warm. Thus,

the electric heater largely ensures the provision of heat without filling up the storage tank.

SIGNAL 5: Electric heater runs at„maximum“

The electric heater starts up when sensor T2 signals „cold“. It works until the storage tank has been fully

charged.

2.2.1.5 V P P G AT E W AY

Abb. 2.25 - VPP Gateway

Fig. 2.27 - Electrical connection

Fig. 2.26

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

17

2.2.1.6 E L E C T R I C H E AT E R C O N T R O L

The Electric Heater Control must be integrated into the storage tank circuit together with a 30 kW-E heater with pump and three-way

mixing valve in order to charge the storage tank.

The Electric Heater Control relay responds when electrical heating is wanted. Thus, water can to be heated to 85 °C with power. The

Electric Heater Control relay is switched off as standard.

This functionality acts together with the VPP module.

SCOPE OF DELIVERY Modules Electric Heater Control unit, one control cable

CABLE DIMENSIONS Control cable m 3

Cable dimensions mm23 x 0.5

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 130 x 35 x 80

Weight kg 0.165

Fig. 2.28 - Electric Heater Control

Fig. 2.29

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

18

2.2.1.7 M O D B U S G AT E W AY

The Modbus Gateway has two main functions:

READING INFORMATION

Information is immediately available after connection to the network (without further equipment).

EXTERNAL CONTROL OF THE XRGI® SYSTEM

After the initialisation of the XRGI® control software, the operation of the XRGI® system can be controlled by an external control. After

the initialisation of the external control, the current software version of the XRGI® system is operated in heat-controlled mode without

external control (the other operating modes will be available in the future).

The description of the interfaces includes details on the main functions.

REQUIREMENTS FOR USE

The Modbus Gateway can only be used if the Central Control PCB with integrated modem is fitted in the iQ-Control Panel (the modem

is separate with the old Central Control PCB). XRGI® systems with older Central Control PCB’s can be upgraded. EC POWER provides

an upgrade kit.

The control must have the software version 1.11.5 or higher. A software update is needed if an older software version is fitted in an

XRGI® system.

CONNECTION TO EXTERNAL SYSTEMS

External systems can be connected to the RS485 bus via the Modbus RTU.

The data registers within the Modbus protocol are kept up to date by the EC POWER control software and/or read by the external

control.

The description of the interfaces includes details about programming the external connection.

SCOPE OF DELIVERY Module Modbus Gateway unit, one green system plug, one Q-Network cable

CABLE DIMENSIONS Q-Network cable m 5

DIMENSIONS

AND WEIGHT

Dimensions, W x H x D mm 130 x 35 x 80

Weight kg 0.165

Fig. 2.30 - Modbus Gateway

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

19

2.2.1.8 S T O R A G E T A N K

SCOPE OF

DELIVERY

Modules Storage Tank 500 l

including one

storage control

Storage Tank 800 l

including one

storage control

Storage Tank 1,000 l

including two

storage control

OUTPUT Heat capacity (at 40 °C temperature difference) kWh 22 35.2 44

Heat loss W 100 116 136

Qst kWh/24h 2.408 2.772 3.271

OPERATING

PARAMETERS

Max. operating pressure bar 6 6 6

Max. operating temperature ºC 95 95 95

CONNECTIONS Flow G2“ 2“ 3"

Return G 2“ 2“ 3“

Drain G 1“ 1“ 1“

Air vent G ½“ ½“ ½“

INSULATION Jacket (PU hard) mm 70 95 95

Lid (PU hard) mm 70 95 95

Base (PU hard) mm 50 50 50

DIMENSIONS

AND WEIGHT

Dimensions, Ø x H (with insulation) mm 810 x 1,850 990 x 1,910 990 x 2,240

Dimensions, Ø x H (without insulation and

deaerator)

mm 650 x 1,750 790 x 1,825 790 x 2,155

Tilted height Ltr 1,815 1,875 2,195

Nominal volume Ltr 500 800 1,000

Actual volume Ltr 525 796 957

Empty weight (with insulation and panel) kg 112 147.5 187.5

Immersion sleeve (inside diameter) mm 8 8 8

The storage volume of 500 litres per XRGI® system should not be undercut.

The EC POWER storage tank with external Storage Control ensures that heat produced in the XRGI® system is stored when the consumer

uses less heat than expected or no heat. This prevents the XRGI® system from cutting in and out, and the operation of the XRGI® system

becomes more efficient after start-up with longer production times. The installation of a storage tank is mandatory for the correct and

proper operation of the XRGI® system. The heating water in the storage tank is heated by the heat exchanger in the Q-Heat Distributor

and stored in the storage tank from above.

The connecting method of the storage tank determines its efficiency and the effective available storage capacity. The storage tank must

be integrated hydraulically with only two connections – independent of the selected hydraulic system. The installation of a storage

tank with four connections (as with hydraulic header) leads to the cold return water mixing with the warm flow water. This reduces the

storage capacity and as a result can cause malfunctions of the control, which leads to the XRGI® system cutting in and out and shortens

its technical product life.

Connect the storage tanks in series if several are used. Experience has shown that parallel circuits produce unsatisfactory results and

should not be used. Use a minimum of one Storage Control with four temperature sensors for a storage volume of 1 m³. Improved

operating results can be achieved when at least two Storage Controls with a total eight temperature sensors are installed.

The EC POWER storage tank with external Storage Control guarantees the proper operation of the system.

Fig. 2.31 - Storage Tank

Fig. 2.32 Fig. 2.33 Fig. 2.34

XRGI®

- INSTALLATION GUIDE VERSION 1.0 2018

20

810

1850

1460

70

340

520

700

880

1060

1240

1420

1600

60

H

3 nuts

M12x45

Tubes

Ø10x1

180

285

1555

1400 150 1570 150

1"

2"

Aerator ECP

2"

1/2"

810

1850

1460

70

340

520

700

880

1060

1240

1420

1600

60

H

3 nuts

M12x45

Tubes

Ø10x1

180

285

1555

1400 150 1570 150

1"

2"

Aerator ECP

2"

1/2"

1910

990

1480

70

410

580

750

920

1090

1260

1430

1600

60

G

3 nuts

M12x45

Tubes

Ø10x1

180

285

1575

1420 170 1550 170

1"

2"

Aerator ECP

2"

1/2"

1910

990

1480

70

410

580

750

920

1090

1260

1430

1600

60

G

3 nuts

M12x45

Tubes

Ø10x1

180

285

1575

1420 170 1550 170

1"

2"

Aerator ECP

2"

1/2"

2240

990

1810

380

600

820

1040

1260

1480

1700

1920

70

60

H

3 nuts

M12x45

Tubes

Ø10x1

180

285

1905

1750 170 1550 170

1"

3"

Aerator ECP

3"

1/2"

2240

990

1810

380

600

820

1040

1260

1480

1700

1920

70

60

H

3 nuts

M12x45

Tubes

Ø10x1

180

285

1905

1750 170 1550 170

1"

3"

Aerator ECP

3"

1/2"

E

E

DIMENSIONS AND CONNECTIONS

Fig. 2.36 – Storage tank 500 litres.

Fig. 2.37 – Storage tank 800 litres

Fig. 2.38 – Storage tank 1,000 litres

This manual suits for next models

3

Table of contents

Other EC POWER Heating System manuals

Popular Heating System manuals by other brands

SAMITECH

SAMITECH Heat Wrap Smart instruction manual

Vent-Axia

Vent-Axia Sentinel Kinetic CWHL SELV User, installation, commissioning & servicing instructions

Seisco

Seisco SH-05 owner's manual

Heatpol

Heatpol Home Plus Economy installation manual

Carrier

Carrier 48DD Product data

Mitsubishi Electric

Mitsubishi Electric PZ-61DR-E manual

Dometic

Dometic Kohler 7APU Operation and installation

Airxcel

Airxcel Aqua-Hot 200 Series installation manual

Chromalox

Chromalox HSK-PC installation instructions

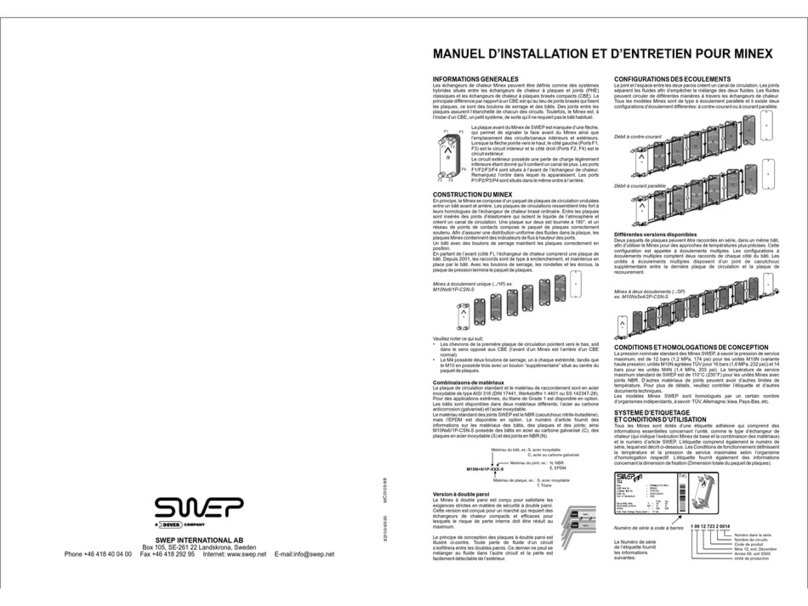

Swep

Swep Minex M10 installation manual

aldes

aldes VEX400 Installation and maintenance manual

Daikin

Daikin VRV IV+ Installer and user reference guide