1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

INSTRUCTIONS FOR:

SHOT BLASTING CABINET

Model: SB951/C

1.2 GENERAL SAFETY

pWARNING! Ensure Health & Safety, government and local authority regulations relating to the the use of shot blasting are adhered to when

using this equipment. Familiarise yourself with the applications, limitations and potential hazards peculiar to the cabinet.

pWARNING! Disconnect the cabinet from the mains power and the air supply before attempting to change accessories or carry out any

servicing or maintenance.

3Maintain the cabinet in good condition Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous

and will invalidate the warranty.

3Locate cabinet in a suitable work area and keep area clean, tidy and free from unrelated materials. Ensure there is adequate lighting.

3Use only dry abrasives such as glass bead. We recommend Sealey item B5KG. Never use fluids or mix fluids with another media in the unit.

pWARNING! Always wear approved eye or face and ear protection when operating the cabinet.

3Keep the unit lid closed and secured when in use.

pWARNING! Ensure correct air pressure is maintained and not exceeded.

3Always keep the blast nozzle directed at the workpiece. Never use outside the unit and always use with the lid closed.

3Regularly check that the exhaust vent at the back of the cabinet is clear and not blocked and that there is space between it and any wall.

3Maintain correct balance and footing. Ensure the floor is clean and free from blasting media spillage. Wear non-slip shoes.

3Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery and contain and/or tie back long hair.

3Keep children and non-essential persons away from the work area.

7DO NOT use the cabinet for a task it is not designed to perform.

7DO NOT operate the cabinet if any parts are damaged or missing as this may cause failure and/or personal injury.

7DO NOT operate the cabinet with the lid open.

7DO NOT stand on the cabinet.

7DO NOT get the cabinet wet or use in damp or wet locations or areas where there is condensation.

7DO NOT operate the cabinet when you are tired or under the influence of alcohol, drugs or intoxicating medication.

7DO NOT leave the cabinet operating unattended.

3When not in use disconnect from the electrical mains and the air supply.

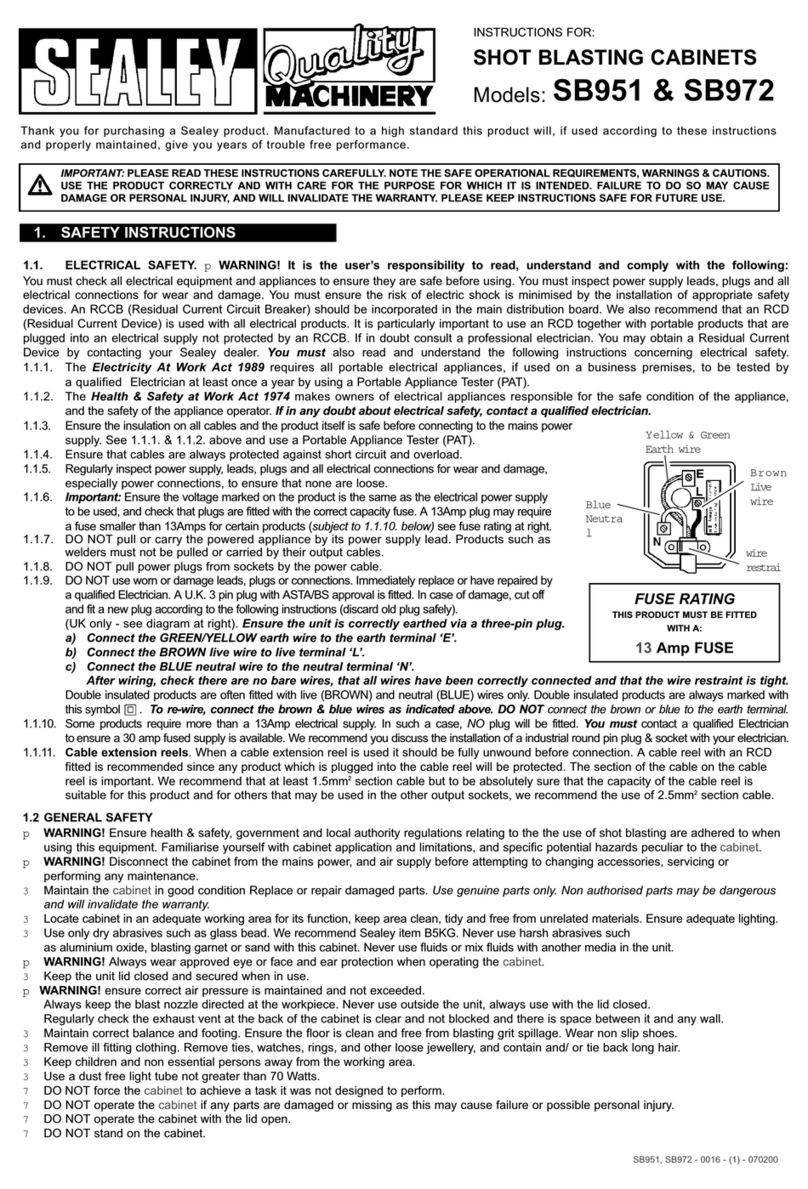

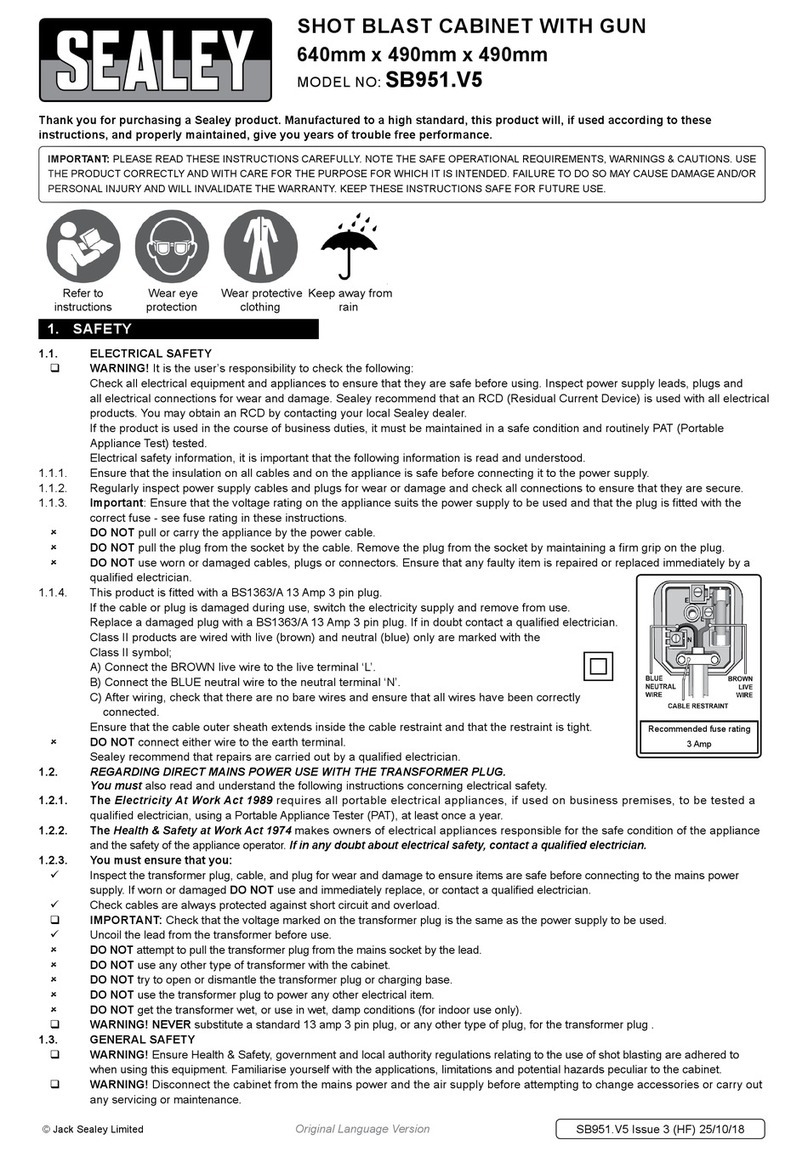

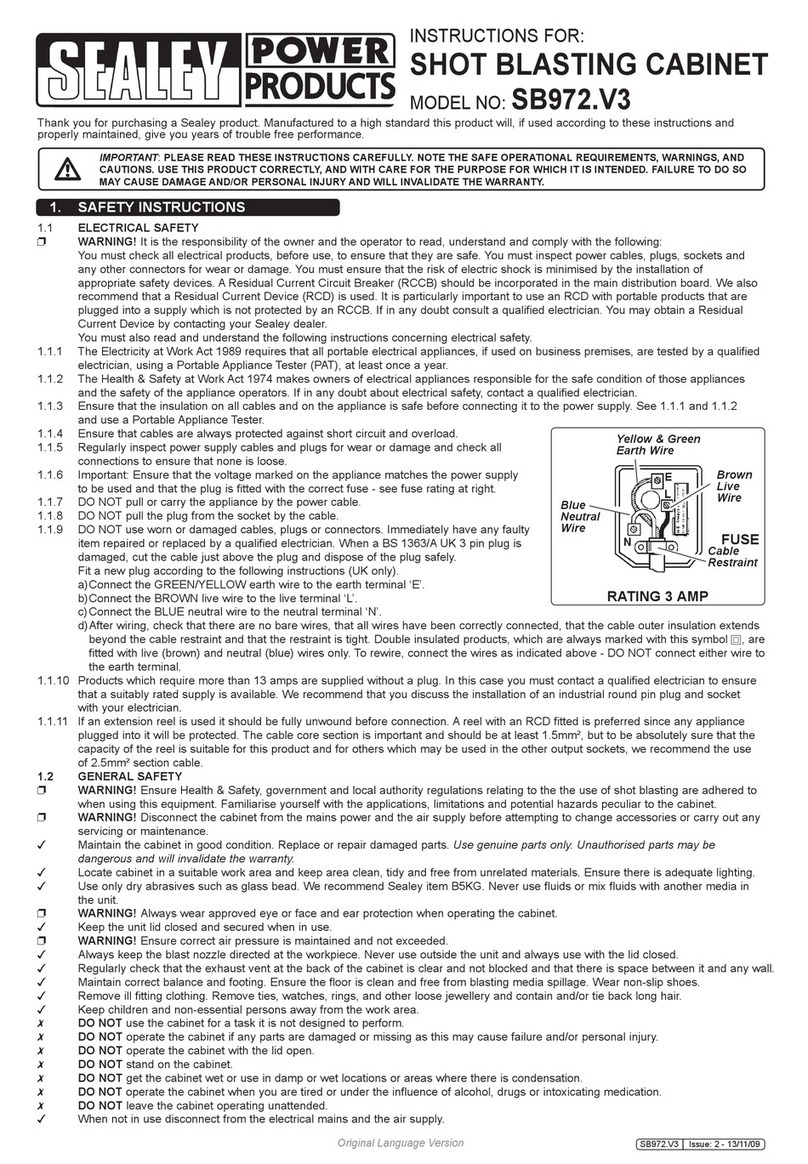

1.1. ELECTRICAL SAFETY

REGARDING DIRECT MAINS POWER USE WITH THE TRANSFORMER PLUG.

p WARNING! It is the users responsibility to read, understand and comply with the following electrical instructions:

You must ensure the risk of electric shock is minimised by the installation of appropriate safety devices. An RCCB (Residual Current Circuit

Breaker) should be incorporated in the main distribution board. We also recommend that an RCD (Residual Current Device) is used with all

electrical products, particularly portable equipment which is plugged into an electrical supply not protected by an RCCB.

You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by

a qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the appliance

and the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. You must ensure that you:

3Inspect the transformer plug, cable, and plug for wear and damage to ensure items are safe before connecting to the mains power supply. If

worn or damaged DO NOT use and immediately replace, or contact a qualified electrician.

3Check cables are always protected against short circuit and overload.

3Important: Check that the voltage marked on the transformer plug is the same as the power supply to be used.

3Uncoil the lead from the transformer before use.

7DO NOT attempt to pull the transformer plug from the mains socket by the lead.

7DO NOT use any other type of transformer with the cabinet.

7DO NOT try to open or dis-assemble the transformer plug or charging base.

7DO NOT use the transformer plug to power any other electrical item.

7DO NOT get the transformer wet, or use in wet, damp conditions (for indoor use only).

pWARNING! NEVER substitute a standard 13 amp 3 pin plug, or any other type of plug, for the transformer plug .

2. DESCRIPTION & SPECIFICATION

Model: SB951/C

Max. Air Pressure . . . . . . . . . . . . . . . . .100psi

Operating Air Pressure . . . . . . . . . . . . . .80psi

Max Air Flow @ 80psi . . . . . . . . . . . . . . .5cfm

Air Inlet Size . . . . . . . . . . . . . . . . . . . .1/4BSP

Length/Width/Height . . . . .630 x 530 x 480mm

Door Size . . . . . . . . . . . . . . . . . .535 x 440mm

The SB951/C shot blasting cabinet is constructed of steel with a replaceable viewing screen and internal illumination. Supplied with a shot blasting

gun the unit is suitable for glass beads, silicon carbide, aluminium oxide and silica sand. Excellent for use in a wide variety of workshop and

bodyshop cleaning applications. The cabinet requires a standard, clean, dry, workshop air supply.

SB951/C - 0016 - (1) - 050201