ECH2O Tec. Watermakers 500-PRO-1 User manual

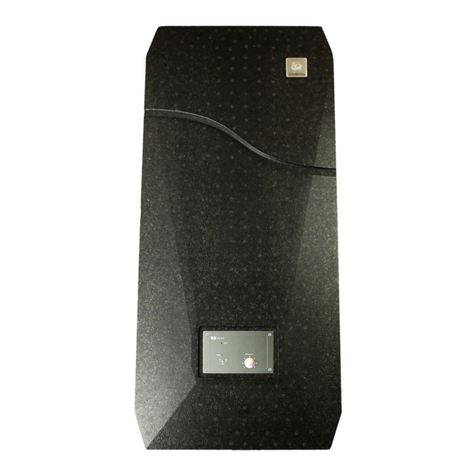

PRO SERIES

VERTICAL SYSTEM

230V / 50HZ

500-PRO-1 / 900-PRO- 2

1200-PRO- 3 / 1500-PRO- 4

OWNERS MANUAL

PAGE

2 INTRODUCTION

3 SPECIFICATIONS

4 STANDARD SYSTEM FEATURES

5 INSTALLATION INSTRUCTIONS

6-7 OPERATION INSTRUCTIONS

8 MEMBRANE CLEANING PROCEDURE

9 MAINTENANCE TIMETABLE

10 PRESSURE VESSEL ENDPLUG C ANGING PROCEDURE

11 ELECTRICAL DIAGRAM

12 TROUBLES OOTING GUIDE

13-14 IG PRESSURE PUMP REPAIR INSTRUCTIONS

15-16 LIMITED WARRANTY

TM

E

EE

E

C

CC

C

H

HH

H

2

22

2

O Tec.

O Tec.O Tec.

O Tec.

Watermakers

INTRODUCTION

Thank you for choosing an ECHO Tec. reverse osmosis desalination system. We trust that you will

be completely satisfied with our product.

The Beach House eries has been specially designed for small hotels, marinas and beach houses.

The high power efficiency and low maintenance cost makes high quality RO water in many cases

more economical than land supplied water, if available.

The purpose of this manual is to allow you to become familiar with each component of your new

ECHO Tec. desalination system.

By understanding the function, importance and normal operation of each part in the system, the

operator can readily diagnose problems when they first develop. uch problems are easily corrected

and require minor adjustments. If left unattended, a small problem in one component will affect the

rest of the system and can lead to an expensive repair.

If you have any doubts or questions, please contact us. We are happy to help “customize” the

seawater reverse osmosis desalinator for your special needs.

ECHO MARINE LTD.

1st Avenue South,

Chaguaramas

Trini a W.I.

TELEPHONE: 1-868-634-2027

FAX: 1-868-634-2026

E-MAIL: echo[email protected]

www.watermakers.net

SPECIFICATIONS

Rated Performance

:

ECHO Tec: 500 – PRO – 1 min. 20 gallons – 75ltr. / hour

900 – PRO – 2 min. 38 gallons – 140ltr. / hour

1200 – PRO – 3 min. 50 gallons – 210ltr. / hour

1500 – PRO – min. 60 gallons – 260ltr. / hour

Reverse Osmosis performan e varies with the feed water temperature and salinity. The rated

performan e is tested at 26°C / 80°F water temperature at a salinity of 35g/l. A de rease in produ t

water quantity of 10 to 15% in the first year is normal and expe ted.

RO Membrane Type:

Standard size high reje tion TFC Polyamide, thin film omposite, spiral wound, single pass reverse

osmosis element.

Salt Rejection: min. 99.5%

Salinity Range: System 500 / 900 up to 50,000 ppm TDS ( NaCl )

1200 up to 40,000 ppm TDS ( NaCl )

1500 up to 36,000 ppm TDS ( NaCl )

PH Range: 4 – 11

Chlorine Tolerance: 1000 ppm hours

Operating Pressure: 725 to 800 psi ( ontinuous duty)

Feed Water Pressure: 0 to 60 psi

Feed Water Temperature Range:

min. 33°F / 0.5°C, max 113°F / 45°C

Electrical Power Requirements:

230V 50Hz single phase 11.2amps at 230V

220/380/440V 50Hz three phase 3.8amps at 380V

Safety Switch Off Functions:

1) High RO pressure: above 1000 PSI

2) Low high-pressure pump feed pressure: below 1.5 PSI

3) High produ t salinity (optional)

STANDARD SYSTEM FEATURES

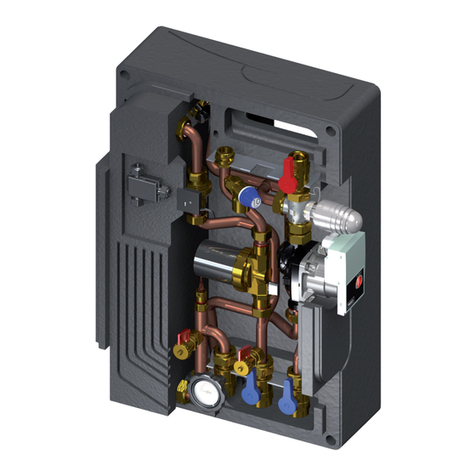

1) Fully assembled desalination system in aluminum vertical flame with shock mounted

316Ti high pressure pump, control panels, RO vessels and 5 and 2 micron cartridge

filtration system.

2) 1 Fresh water flush kit with hose and 316SS hose clamps

3) 1 Product water tube 1 ft / 3m

1 Reject hose ½” 1 ft / 3m with 2pcs 316SS hose clamps

1 Intake hose ¾” 1 ft / 3m with 2pcs 316SS hose clamps

4) 1 Handheld TDS Meter

5) 1 Biocide solution, 1 acid cleaning solution, 1 alkaline cleaning solution

6) 1 Owners Manual

INSTALLATION INSTRUCTIONS

Position the desalination system in a cool and dry location. Mount the system using all four mounting

holes.

The electrical installation should only be done by a professional electrician. Check the correct

volta e before installin the system.

The cable labeled with the system’s voltage and frequency is to be connected to the power supply. The

cable marked “F D PUMP” is to be connected to the feed pump or should be insulated / removed

where pressurized seawater is available.

SEAWATER FEED PUMP (Optional Equipment)

Mount the feed pump in a dry location below the waterline of the vessel. Connect the intake of the feed

pump with the vessel’s sea strainer. Connect the outlet of the feed pump with the intake of the

desalination system located at the pre-filter assembly. Secure all hoses with the supplied hose clamps.

PRODUCT WATER TUBING

Connect the product water outlet marked “SAMPL ” with a test station of your choice. Connect the

product water outlet marked “TANK” to your storage tank.

REJECT WATER TUBING/HOSE

Connect the outlet of the pressure control valve on the back of the flow control panel with the 1/2”

reinforced PVC hose to a thru hull fitting preferably above the waterline or drain of your choice.

FRESH WATER FLUSH KIT

Install the fresh water flush filter housing at a location near to the desalination system. Connect the flush

port of the three-way service valve at the pre-filter assembly of the desalination system with the outlet of

the flush filter housing marked “OUT”. Supply pressurized fresh water to the shut off valve of the fresh

water flush filter housing.

SYSTEM OPERATION INSTRUCTIONS

The reverse osmosis membrane contains a preservative solution to prevent microbiological

gro th. If ingested, may cause irritation of the gastro-intestinal tract, colic, diarrhea, or other

similar symptoms.

Therefore, discard all the product ater for at least thirty minutes of initial operation or after

storage before drinking or use in food preparations!

Do not operate the system using contaminated feed ater sources (oil, chlorine or other

chemicals).

Have you filled the high-pressure pump ith the proper amount of oil (SAE90 gearbox oil)?

1) Open the seacock and the seawater shut off valve on the pre-filter assembly.

2) Open the pressure control valve on the flow control panel all the way, counter-clock wise.

3) Set the flush service valve at the pre-filter assembly to the “CLOSED” position (center).

4) Set the diverter valve on the flow control panel to the sample “TEST” position.

5) For the initial start up and after filter changes, set the selector switch on the electrical

control panel to the “FEED” position (feed pump only) and purge the system until all

entrapped air has escaped.

6) In the “AUTO” position, press the “START” button until the pressure on the low

pressure gauge “OUT” has build up. If the high pressure pump motor stops, purge the

system again and start the system in the “AUTO” position as before.

7) Close the pressure control valve slowly clockwise and increase the operating pressure

until the specified fresh water output for your model is achieved not exceeding 800PSI.

Caution: Never allo any leaks in your hose or pipe connections. Reseal ith Teflon tape

or change O rings as required.

8) Check the quality of the product water with the TDS meter. If the water is pure (under

500ppm TDS), switch the diverter valve on the control panel to the storage tank position.

SYSTEM SHUT DOWN PROCEDURE

1) Switch the diverter valve to the “TEST” position.

2) Open the pressure control valve all the way counter clockwise.

3) Switch the selector switch off.

4) Fresh water flush the system (see next page).

5) Close the seawater shut off valve on the pre-filter assembly and the seacock.

FRESH WATER FLUSH PROCEDURE

Caution: The fresh ater pressure should not exceed the range of the lo pressure gauge/s.

The installation of a pressure reducer may be necessary.

You should fresh water flush your watermaker after every use or infuse a biocide solution for long

term storage. The fresh water flush prepares your watermaker for a shut down period of seven days

maximum. You can repeat the flush procedure every seven days, to extend the short term storage.

1) Open the pressure control-valve all the way counter-clockwise.

2) Close the shut off valve on the pre-filter assembly and make sure the shut off valve on the

flush filter is open.

3) Open the fresh water flush valve on the pre-filter assembly. Your fresh water pressure

pump should now turn on. Allow fresh water to flow until all salt water is flushed out of

the system (1-2 mins).

For the next flush procedure, test how long it takes until the brine at the reject outlet of

the watermaker becomes fresh (taste or use TDS meter).

4) Open the seawater shut off valve and back flush the pre-filter system with fresh water.

5) Close the fresh water flush valve, the seawater shut off valve and the seacock.

MEMBRANE STORAGE PROCEDURE

If you intend to store your watermaker for more than ten days, growth of microorganism will

degrade the RO membranes performance.

The RO membranes should be flushed with a biocide solution to preserve the membrane for long-

term storage of up to ten months.

1) Fresh water flush the system.

2) In a clean plastic container, mix 5 gallons 20 litres of un-chlorinated fresh water with

200 grams (2 3 container) of Echo Tec. Preservative # 3.

3) Switch the three-way valve to the service position. Switch the diverter valve to the

sample position. Switch the shut off valve to the off position.

4) Open the pressure control valve all the way anti-clockwise.

5) Infuse the storage solution with the service hose connected to the three-way valve while

running the high-pressure pump without applying pressure. Press and hold the “START”

button with the selector switch in the “OFF” position to run the high pressure pump only.

When the solution has been infused, release the start button and remove the pre-filter

cartridges for dry storage.

Under best conditions your watermaker is now prepared for a shut down period of ten months.

Discard the product water for at least thirty minutes of initial operation, after storage, before

drinking or before use in food preparations.

MEMBRANE CLEANING PROCEDURE

The membranes of the ECHO Tec. Watermaker must be chemically cleaned when the

product water output drops by 20% of the specified amount. The fre uency of this

occurring will vary greatly depending upon feed water. Fouling of the membranes will

naturally occur during normal

usage of the ECHO Tec. Watermaker. Increased amounts of fouling without proper

cleaning of the membrane will reduce the performance of your water maker. Cleaning of

the membranes will not enhance the uality (TDS reading) of the product water.

CAUTION: The use of chemicals or cleaning me hods o her han hose ou lined in

he cleaning ins ruc ions will void he ECHO Tec. warran y. Nonionic surfac an s

for membrane cleaning or o her chemicals no approved in wri ing by Echo Marine

L d. will void he elemen warran y.

CAUTION: Cleaning chemical #1 is an alkaline de ergen . See warning label on

side of he con ainer and observe all safe y precau ions on label.

CAUTION: Cleaning chemical #2 is an acid, a mineral scale remover. See warning

label on side of con ainer and observe all safe y precau ions on label.

CAUTION: Do no mix differen cleaning chemicals oge her. Do no use differen

cleaning chemicals oge her a he same ime. Mix he cleaning chemicals separa ely

and use hem separa ely.

No e: All cleaning and preserving procedures can be done with either sea water or non-

chlorinated freshwater. However, the cleaning process is more effective using non-

chlorinated freshwater.

To clean the ECHO Tec. reverse osmosis membranes mix one container (330gram) of

cleaning chemical #1 with 5gal / 20ltr of water at 104° F / 40° C.

Re-circulate (disconnect the reject water hose and lead it in the cleaning container) the

solution wi hou pressure for up to 60 min. (observe the maximum operating

temperature of 112° F / 45° C). Do not allow the cleaning container to run dry or air to

enter the system.

It is important that the fresh water, remaining from the last flush is dumped before the

reject hose is led in the cleaning container to ensure the re-circulation of the undiluted

cleaning solution only.

Use cleaning chemical #1 first. If the performance does not improve, use the acid cleaner

#2 at the same ratio and instruction.

MAINTENANCE TIMETABLE

The following maintenance timetable is an estimate of the time intervals at which maintenance may

be required only. This schedule must be adjusted to the regularity of usage, the condition of the

intake water, the length of time the system is exposed to seawater and the total running time

following each system cleaning.

COMPONENT MAINTENANCE

REQUIRED

TIME INTERVAL

INTERMITTENT DUTY

Seawater intake

strainer

Inspect and clean intake. 000 hrs, or when clogged.

Pre filters Replace or clean elements and

clean housings.

When system intake pressure

drops below 5psi.

Charcoal flush filter Replace element. Every 6 months.

High pressure pump Change crankcase oil.

Change packings, seals

and O-rings.

Initial change after 50 hrs.

Every 200 operating hours or

6 months.

Every 2000 hrs or when

leaking.

R.O. membrane When production decreases

by 20%.

Replace

Clean with acid and/or

alkaline cleaning compound.

When cleaning does not

increase production.

Flow meter Clean inside the clear tube.

Disconnect product tubing and

infuse muriatic acid. Rinse

thoroughly!

Whenever dirty.

MEMBRANE CHANGING PROCEDURE

PRESSURE VESSEL END PLUG CHANGING PROCEDURE

1) Remove the product port (if installed) and the high pressure fitting.

2) Remove the two/three M6 bolts.

3) Remove the two/tree loc ing plates (loc s)

4) Remove the bac ing plate

5) Pull the end plug with the aid of a hand tight inserted product port in one fast pull.

Should the plugs O-ring (PL01)get stuc in the groove of the pressure vessel, it will be more

difficult to pull the plug. If the plug gets stuc , tap it in, apply silicone lubricant to the

vessel’s inner wall and remove it in one fast pull.

6) Inspect the end plug for hairline crac s or damages on the O-rings and O-ring

grooves.

7) Pull the membrane on the product pipe out of the pressure vessel or remove both

plugs and push the membrane out (in flow direction!)

8) Insert the new membrane observing the correct direction of the lipped seal ring on the

high pressure entry side of the membrane (lip against flow direction).

9) Clean the product port and end plug threads from remaining Teflon sealant.

10) Apply Teflon sealant to the threads of the product port.

11) Insert the end plug and reassemble all components visa versa starting with (5).

It is important not to over tighten the pro uct port/s to avoi the en plug to crack.

110/

220V

24V

TO

HIGH PRESSURE

PUMP

TO

LOW PRESSURE

PUMP

MOTOR

STARTER

R1

MOTOR

STARTER

R2

TRANS-

FORMER

START SWITCH S1

PUSH BUTTON NO

SELECTOR SWITCH S2

3-POSITION, MAINT.

4 CONTACTS, NO

T1

HIGH PRESS.

SWITCH S4

NC

LOW PRESS.

SWITCH S5

NO

TANK FULL

SWITCH S6

NC

EXTERNAL

MAIN

IN

ELECTRICAL DIAGRAM, CONTROL BOX, ECHOTEC. PRO - BHL SERIES, VERSION 2008/03

R1 R2

LEFT CONTACTS

RIGHT CONTACTS

HIGH PRESSURE PUMP SYSTEM

TROUBLESHOOTING GUIDE

MALFUNCTION CAUSE REMEDY

The pressure Worn packing seals Replace seals

drops broken valve spring Replace spring

Fouled inlet strainer Clean strainer

Fouled pre-filter(s) Replace filter cartridge(s)

Cavitation Check suction lines for

restrictions

Water in crankcase High humidity Reduce oil change interval

Worn seals Replace seals

oisy operating Worn bearings Replace bearings, refill crankcase

with recommended lubricant

Cavitation Check inlet lines for restrictions

Check strainer and filter(s)

Inability to Discharge valve chamber Allow more time to prime

build up pressure has air trapped within it and ensure that there are no

air suction leaks.

Open valve chambers and allow

air to escape

Rough/Pulsating Worn seals Replace seals

operation with Check system for stoppage or

air suction leaks

pressure drop Cavitation Check inlet lines for restrictions

Excessive Worn plunger(s) Replace plunger(s)

leakage between Worn seals Replace seals

the high pressure

pump manifold Cracked plunger(s) Replace plunger(s)

and rear crankcase

section

High crankcase Wrong grade of oil Use specified type of oil.

temperature Improper amount of oil in crankcase Adjust oil level to proper

amount

HIGH PRESSURE PUMP REPAIR INSTRUCTION

SERIES EP-12-34 / EP-14-34 / EP-17-34

Disassembly se uence of the front end of the ECH

2

O Tec. high-pressure pump.

Refer to the pump diagram.

1) Remove the three discharge valve plugs and the three inlet valve plugs (32), with a 22 mm socket

wrench. Inspect the O-ring (33) or wear and replace i damaged.

2) With needle nose pliers, remove the inlet and discharge valve assemblies (32X). Insert a small

screwdriver between the valve seat (27) and the valve spring retainer (30) to separate the valve

assembly. Remove the O-ring (31). Inspect all parts or wear and replace i necessary.

3) Next, use a 5 mm Allen wrench to remove the 8 socket head cap screws (34). Care ully slide the

valve casing (26) out over the plungers. Remove the weep return ring (25), pressure ring (24) and

V-sleeve with support ring (23), rom the valve casing (26). Remove the V-sleeve (23) rom the seal

case (20). Inspect all parts, including O-ring (21) or wear and replace i necessary.

4) Check sur aces o plunger (16). A damaged sur ace will cause accelerated wear on the seals.

Deposits o any kind must be care ully removed rom the plunger sur ace.

A damaged plunger must be replaced!

5) I the ceramic plunger (16B) is damaged, remove the plunger bolt (16C). Discard the old plunger

(16B) and copper gasket (16D) and clean the old Locktite rom the plunger bolt (16C) and plunger

base (16A). Replace the plunger with the new one and Locktite the plunger bolt and torque to 120

inch-pounds.

NOTE: If there are deposits of any kind (i.e., lime deposits) in the valve casing, be certain that the

weep holes in the weep return ring and valve casing have not been plugged.

6) I the crankcase oil seals (19) are to be replaced, they can be removed by prying loose. Take care

not to make contact with the plunger. I the oil seals are not to be replaced, proceed to the back end

disassembly sequence and care ully pry the seals loose a ter the plungers have been removed rom

the crankcase.

Disassembly se uence of the back end of the ECHO Tec. high-pressure pump.

1) Be ore beginning, drain the oil rom the crankcase, through the oil drain (3A).

2) Remove the crankcase cover (3) and O-ring (4) rom the crankcase (1). To remove the cranksha t

(13), remove the bearing cover (7) and sight glass (8). Using a rubber mallet, remove the cranksha t

axially through the connecting rods by tapping on the end o the sha t. Do not bend or damage the

connecting rods during cranksha t removal.

3) Next remove the remaining bearing and radial sha t seal (11). Inspect both bearings and seal or

wear and replace i necessary.

4) Remove the connecting rod (15), then the plunger (16) and wrist pin (17), i necessary. Check the

plunger bore in the crankcase or wear. Inspect parts and replace as necessary.

5) Should you ind it necessary to service the plunger assembly (16), you can do so by removing the

tension screw (16D). Inspect all parts and replace as necessary.

NOTE: In order to drive the pump from the side opposite the present shaft extension, simply

remove the valve casing from the crankcase and rotate the pump 180 degrees to the desired

position. Be certain to rotate the seal case as well, so that the weep holes are down at the six o’clock

position. Change the oil fill and the oil drain plugs. Refer to the repair instructions as necessary

for the proper assembly se uence.

Reassembly se uence of the ECHO Tec. high-pressure pump.

1) Reassemble plunger (16) and the connecting rod (15) with wrist pin (17). Place assemblies in

crankcase (1). Install cranksha t through connecting rods, again being care ul not to bend or

otherwise damage the connecting rods.

2) Replace le t and right side bearings (12A and 12B), i they were removed rom the cranksha t. Be

certain the bearings are pressed all the way onto the sha t and completely into the crankcase.

Replace radial sha t seal (11) bearing cover with sight glass (7 and 8) and crankcase cover with O-

ring (3 and 4).

3) I oil seals (19) were removed, replace with seal lip towards crankcase. Lubricate seal be ore

replacing.

4) Replace seal case (20) with O-ring (21) over plungers. Generously lubricate O-ring and oil seal

be ore reassembly. Replace V-sleeve (23) over plunger.

5) Generously lubricate V-sleeve (23). Assemble spacer and V-sleeve (23) into valve casing (26).

Assemble weep return ring and pressure ring (25 and 24) over plungers. Slide the valve casing over

plungers and seat irmly. Replace the eight-socket head cap screws (34) and tighten to 105 inch-

pounds in a crossing pattern.

6) Replace the six O-rings (31) and the six-valve assemblies (32X).

Replace the six valve plugs with O-rings (32 and 33) and tighten securely with a 22mm socket

wrench to 33 oot-pounds.

7) Fill crankcase with 7.5 ounces / 0.22 ltr o non-toxic, non-detergent SAE 90 gearbox oil.

ECHO TEC. WATERMAKER LIMITED WARRANTY

Echo Marine Ltd. warrants to the original purchaser for a period of twelve (12) months from the date of

shipment that the ECHO ec. watermaker will perform according to specifications. Echo Marine’s

liability under this warranty shall be limited to repair or replacement of the ECHO ec. watermaker at

Echo Marine’s option. Under no circumstances shall Echo Marine Ltd. be liable for consequential

damages arising out of or in any way connected with the failure of the system to perform as set forth

herein. his limited warranty is in lieu of all other expressed or implied warranties, including those of

merchantability and fitness for a particular purpose.

In the event of a defect, malfunction, or failure during the warranty period, Echo Marine Ltd. will repair

or replace, at its option, the product or component therein which, upon examination by Echo Marine,

shall appear to be defective, or not up to factory specifications.

o obtain warranty service, the defective product or part must be returned to Echo Marine’s Service

Center. he purchaser must pay any transportation or labor expenses incurred in removing and returning

the product to the service center.

he limited warranty does not extend to any system component which has been subjected to misuse,

neglect, accident, improper customer installation, or used in violation of instructions furnished by Echo

Marine Ltd. he warranty does not extend to components on which the serial number has been removed,

defaced or changed.

Echo Marine Ltd. reserves the right to make changes or improvements in its product during subsequent

production without incurring the obligation to install such changes or improvements on previously

manufactured equipment.

he implied warranties, which the law imposes on the sale of this product, are expressly LIMI ED, in

duration to the time period above. Echo Marine shall not be liable for damages, consequential or

otherwise, resulting from the use and operation of this product or from the breach of this LIMI ED

WARRAN Y.

his limited warranty service does not apply to normal recurring user maintenance as described below.

Pre-filter Cartridges Pump Valve Assemblies

Pump Seals Gauge Instrument Calibration

Pump Packings Pump Crankcase Oil

he ECHO ec. Membrane Element is guaranteed to be cleanable for a minimum of one year from date

of shipment, or commissioning of the system by Echo Marine Ltd, provided that cleaning instructions are

adhered to and foulant is acid soluble metal hydroxides and calcium carbonates or alkaline soluble

organic, inorganic substances and microbiological slimes. he ECHO ec. Membrane Element is not

guaranteed against iron fouling (rust), chemical attack, extreme temperatures (over 113º F/under 33ºF),

drying out, or extreme pressures (over 1000 psig).

CAU ION: Use of parts not supplied directly by Echo Marine (generic parts), including but not limited

to maintenance parts, pre-filter elements, cleaning and storage chemicals, pump oil, spare parts,

replacement parts, system components and or system accessories, shall void all warranties expressed or

implied.

ECHO MARINE LTD.

1st Avenue South,

Chaguara as

Trinidad W.I.

TELEPHONE: 1-868-634-2027

FAX: 1-868-634-2026

E-MAIL: echotec@echo- arine.co

www.water akers.net

This manual suits for next models

6

Table of contents

Other ECH2O Tec. Water System manuals

Popular Water System manuals by other brands

Pure-Pro

Pure-Pro RO103 user manual

AMK

AMK OWR 20 Planning, installation and commissioning

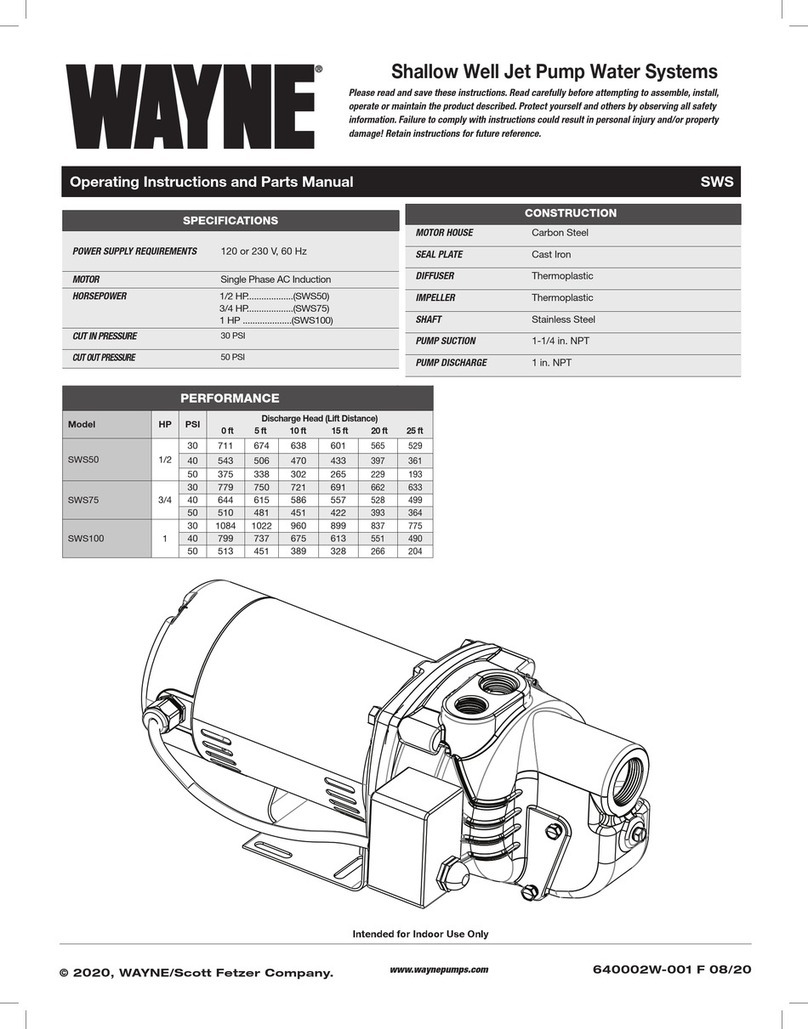

Wayne

Wayne SWS Series Operating instructions and parts manual

Watts

Watts OneFlow OF817-8H Installation, operation and maintenance manual

EINHELL

EINHELL GC-WW 8042 ECO Original operating instructions

Technische Alternative

Technische Alternative FRISTAR3-WP operating manual