ECHO MARINE ECHO Tec Watermakers Modular DC Series User manual

MODULAR DC SERIES

200-DML-1 / 240-DML-1 / 260-DML-1

OWNERS MANUAL

PAGES

2

Introduction

3

Specifications

4-5

Standard System Features, Options and Accessories

6

Flow Diagram

7-10

Installation Instructions

11

Installation Instructions Options

12-13

System Operation, Shut Down and Flush Procedure

14

Membrane Storage and Cleaning Procedure

15

Maintenance Timetable

16

Troubleshooting Guide

17

Membrane Element and End Plug Service Instructions

18-19

High Pressure Pump Service Instructions

20-21

Warranty

2

INTRODUCTION

ECHO MARINE LTD.

1st Avenue South, Chaguaramas, Trinidad W.I.

Telephone: 1-868-634-2027 Fax: 1-868-634-2026

E-mail: echotec@echo-marine.com

www.echotecwatermakers.com

Rev.2014.8

Congratulations on the purchase of your ECHOTec Watermaker. We trust that you will be

completely satisfied with our product. We thoroughly bench test every desalination

system before shipping and are confident that we have manufactured the finest

watermaker on the market.

Your watermaker will provide you with clean and safe drinking water for many years to

come if you follow the simple instructions in this owners’ guide. The purpose of this

manual is to allow you to become familiar with each component of your new ECHOTec

Watermaker.

By understanding the function, importance and normal operation of each part in the

system, the operator can readily diagnose problems when they first develop. Such

problems are easily corrected and require minor adjustments. If left unattended, a small

problem in one component may affect the rest of the system and can lead to an

expensive repair.

If you have any questions regarding the installation, operation or maintenance of your

watermaker please contact us. We are always happy to assist!

3

SPECIFICATIONS

RATED PERFORMANCE:

ECHOTec Model

Gallons per hour

Liters per hour

200 - DML - 1

8.5

32

240 - DML - 1

11

42

260 - DML - 1

13

50

Reverse Osmosis performance varies with the feed water temperature and salinity.

The rated performance is tested at 26C / 80F water temperature and 33g NaCl/ltr.

RO MEMBRANE TYPE:

Standard size high rejection TFC Polyamide, thin film composite, spiral wound, single pass reverse

osmosis element.

PRODUCT WATER QUALITY: minimum 500 ppm TDS

FEED WATER SALINITY RANGE: up to 50,000 ppm TDS ( NaCl )

PH RANGE: 4 –11

CHLORINE TOLERANCE: 1000 ppm hours

FEED WATER PRESSURE: 5”Hg to 60 psi

OPERATING PRESSURE: 900 psi

FEED WATER TEMPERATURE RANGE: min. 33F / 0.5C, max 113F / 45C

ELECTRICAL POWER REQUIREMENTS:

ECHOTec Model

amps @ 12.5 V DC

amps @ 25 V DC

amps @ 48 V DC

200 - DML - 1

19.8

9.5

n/a

240 - DML - 1

27

13.5

n/a

260 - DML - 1

38

18

9

4

STANDARD SYSTEM FEATURES

1) 1 PVC sea strainer

2 3/4” NPT x 5/8” barbed hose connection

2) Pre-Filter complete with 20 micron cartridge (5 and 20 micron with optional boost pump)

1 Stainless steel bracket with 8 screws

1 Service valve with 1 Nylon nipple and 3 barbed hose connectors (with boost pump) or

1 flush/storage valve with 1 Nylon nipple and 1 NPT female tee (without boost pump)

1 Filter wrench

3) 1 High-pressure pump unit with vibration dampers

4) 1 Pressure vessel with reverse osmosis membrane

5) 1 Stainless steel control panel completely assembled with

1 Pressure control valve

1 High pressure gauge

1 Product flow meter

1 Diverter (3-way) valve

1 Breaker (without boost pump) or

2 Breakers (with boost pump)

6) 1 Hardener / pH neutralizer kit with mineral element and 2pcs 3/8” compression fittings

1 Stainless steel bracket with 8 screws

7) 15 feet / 4.5 meter high pressure hose with 2 x stainless steel high pressure fittings attached

2 x stainless steel field attachable high pressure fittings

8) 20 feet / 6 meter 3/8” blue product water tubing

10 feet / 3 meter 5/8” braided intake hose

10 feet / 3 meter 1/2” braided reject hose or 10 mm tubing

9) 17 Stainless steel hose clamps (with boost pump) or

12 Stainless steel hose clamps (without boost pump)

5

OPTIONS AND ACCESSORIES

If the high-pressure pump is installed less than 1 foot below the waterline or an additional 5micron pre-

filter is added, the installation of an optional boost pump is recommended. The boost pump also extents

pre-filter element life, reduces maintenance and assists in priming the system after pre-filter changes.

Boost pump with intake hose barb, outlet hose barb, 4 feet / 1.2 meter wire reinforced intake hose,

10 feet / 3 meter braided feed hose, 5 micron pre-filter housing, bracket, fittings and cartridge (all

assembled).

5 Micron Pre-filter Housing (1 filter housing, 1 pre-filter cartridge, 1 bracket, 1 3/4” NPT nipple)

An additional 5 micron pre-filter is only recommended in connection with the optional boost pump.

Note: The 5micron filter must be installed as a second filter in flow direction

Maintenance Kit

10 Pre-filters, 5 and/or 20 microns

1 Spare sea strainer screen

2 Active carbon filters (fresh water flush)

1ltr. High pressure pump oil

Extended Maintenance Kit

2 Motor brushes

1 Acid cleaning compound

1 Alkaline cleaning compound

2 Storage compounds (Biocide)

1 Complete spare seal and O ring kit (except high pressure pump)

Fresh water flush kit for installation with boost

pump (filter housing, charcoal cartridge,

stainless steel bracket, 8 screws, shut off valve,

2 x 1/2” hose barb connectors, 1/2” tee, 10ft

1/2” braided hose, 5 x 1/2” hose clamps)

Fresh water flush kit for installation without

boost pump (filter housing, charcoal cartridge,

stainless steel bracket, 8 screws, shut off valve,

2 x 5/8” hose barb connectors, 5/8” tee, 10ft

5/8” braided hose, 5 x 5/8” hose clamps)

Low pressure gauge

The low pressure gauge indicates when the pre-filters have to be

changed. Select pressure range according to freshwater pressure.

6

FLOW DIAGRAM

Shown with Optional Equipment

7

INSTALLATION INSTRUCTIONS

HIGH PRESSURE PUMP UNIT

Mount the high pressure pump/motor unit horizontally in a dry and ventilated location. Maximum ambient

temperature for continuous duty is 40˚C / 104˚F.

CAUTION: Motor gets hot during prolonged operation.

PRESSURE VESSEL (MEMBRANE HOUSING)

Mount the pressure vessel(s) with the provided brackets vertical (with the flow upwards) or horizontal

in a convenient location away from the heat of the engine as close as possible to the high pressure

pump.

The membrane is sealed within its housing by plugs at both ends. Inside the housing is a small amount

of preservative to keep the membrane moist and prevent bacterial growth. The shelf life of the

preservative, under best conditions, is one year.

When all other components and hoses/tubes are completely assembled, remove the caps on the high

pressure fittings and the sealed tube from the product water outlet on the membrane housing/s and

then finish making all final hose/tube connections. This will insure that the membrane is kept moist.

CONTROL PANEL

Mount the control panel preferable trough a bulkhead or on any panel in an easily accessible

location as close as practical to the membrane housing(s).

8

SEA STRAINER

Mount the sea strainer with the provided 3/4" NPT nylon nipple directly to

the intake of the 20 micron pre-filter housing. If an optional boost pump is

required (refer to “Available Options and Accessories”), mount the sea

strainer in a serviceable location in between the sea-cock of your choice

and the boost pump.

CAUTION: To avoid excessive mechanical stress, do not mount the sea

strainer directly to the sea-cock.

Connect the barbed fittings with the supplied coil reinforced intake hose and secure all hoses below water

level with two hose clamps. For boost pump installation refer to the installation instructions for optional

equipment (page 11).

FILTER HOUSINGS

Mount the pre-filter in a serviceable location and connect the bottom port of the cleaning / storage valve

with the 5/8” reinforced vinyl hose to the intake hose barb fitting of the high-pressure pump (lower fitting).

Secure the hose with hose supplied clamps.

CAUTION: Install all plumbing to eliminate any air pockets in the system.

CAUTION: If you have to re-seal NPT fittings, use a maximum of three wraps of Teflon tape on the

threads. Always keep the tape back from the end of the fittings (at least two threads). Do not allow any

tape to enter the system.

HIGH PRESSURE HOSE

The high pressure hose has factory mounted high pressure couplings on each end (also included are two

field attachable fittings). This hose comes in a 15 feet / 4.5 m length, so it may be cut to suit your needs.

Leave a little extra length of hose to avoid stress on the system components.

CAUTION: Never bend the high pressure hose tighter than a 6”/15 cm radius.

Assembly instructions for the stainless steel field attachable high-pressure couplings

1) Cut the hose in a clean 90angle preferably with a cutting disc or fine tooth hacksaw.

2) Un-assemble the coupling (remove threaded inner part from outer part).

9

3) Rotate the socket (outer part) anti clock wise on to the hose until hose bottoms. Back the hose out

½ turn to allow for expansion of the hose during assembly.

4) Apply dishwashing liquid mixed 1:1 with water on to the nipple (inner part) of the high-pressure

fitting and the inside of the hose.

5) Hold the socket preferably in a vice and screw the nipple all the way into the hose. The straight

fitting is supplied with a hexagonal plug as an assembly tool.

Run one of the high-pressure hoses from the output of the HP pump (O ring sealed fitting) to the O ring

sealed fitting at the end of the membrane that is marked IN.

CAUTION: A minimum hose length of 3 feet / 1m is required for pulsation dampening. The hose can be

coiled where needed.

Run the second high-pressure hose from the outlet of the RO membrane housing to the pressure control

valve in the control panel. Do not over tighten the high pressure fittings. They are O-ring sealed and need

little torque to lock only.

CAUTION: When connecting the high pressure hose to the membrane housing (s), avoid over tightening.

The fitting is o-ring sealed and does not require much torque.

PRODUCT WATER TUBING

Using the blue product water tubing, connect the center fitting of the membrane housing with the bottom

fitting (inlet) of the flow meter in the control panel. Connect the tubing or hose from each output port of

the 3-way valve to your water tank and to the taste/test station of your choice.

CAUTION: Under no circumstances should the product water line be allowed to become blocked while

the system is running. Do not install shut-off valves anywhere in this line.

CAUTION: Do not allow chlorinated water from your storage tank to flow back into the R.O. membrane.

You may directly “T” your product water line into the tank vent (Refer to the Flow Diagram). This avoids

chlorinated water to back flow from your water tanks into the R.O. membrane and does not require a new

fitting in your tank. This solution requires a vent of sufficient diameter as the product water will have to

flow against the escaping air. If the product line must be installed below tank water line, an optional non-

return valve should be installed.

An existing hand pump style spigot, with a check valve only can be used as test station. If using this type of

spigot for two sources (tank and test), install low-pressure non-return valves in the tank- and product line

and “T” both into the existing hand pump spigot.

10

HARDENER / PH NEUTRALIZER KIT

THOUGH-HULL FITTING (not supplied)

ELECTRICAL INSTALLATION

The electrical installation should only be done by a professional electrician according to the local

regulations with regards to safety. Electrical installation materials are not supplied.

The ECHOTec post treatment element contains a mixture

of minerals that returns bicarbonate alkalinity, correcting

pH only enough to reach a neutral equilibrium. This

dramatically reduces corrosion on metal tanks, boilers,

washing machines and plumbing due to acidic product

water.

Install the hardener / pH neutralizer housing at a

serviceable location in line with the product water tubing

from the diverter valve on the control panel to the

freshwater storage tank. (Refer to flow diagram on page 6)

Note: Observe the flow direction indicated on the housing.

REJECT WATER TUBING / HOSE (BRINE)

Connect the outlet of the pressure control valve on the

control panel with a reject thru-hull of your choice

(preferably above the water line as an indication for proper

operation of the system).

The boat’s designated intake thru-hull should be located in

an area that will always be in the water when the boat is

used under normal running conditions,

A trough hull fitting with strainer scoop could be helpful.

Installed with the opening facing the bow, it typically

generates a small amount of pressure while moving

through the water. It is important not to place the thru-

hull fitting directly forward of a speedometer pickup. It is

also wise not to place the intake thru-hull slightly aft or

outboard of a holding tank, head or galley sink overboard

discharge.

11

INSTALLATION INSTRUCTION –OPTIONAL EQUIPMENT

BOOST PUMP

Install the submersible boost pump with the electric motor sideways (horizontal) below the water line, in

between the sea strainer and the pre-filter(s). The intake is at the center of the pump. The outlet should

ideally point upwards or sideways with the fitting to the top to prevent air pockets.

Avoid elbows/90˚fittings in your plumbing if possible. The complete pump head can be turned in case the

outlet direction is not suitable for your installation.

The ECHOTec “Orbital” Magnetic Drive Pumps eliminate the conventional shaft seals found in most pumps.

This means that there is no rotating seal to wear and allow the liquid being pumped to leak out.

We rely on the liquid being pumped to lubricate the impeller-magnet assembly spinning on the stationary

spindle. If the pump is run dry for longer than 10 minutes, the assembly may “freeze” onto the spindle.

All pumps can be serviced with the use of a screwdriver. The only moving part in the pump other than the

motor is the impeller-magnet assembly. This assembly rotates on a stationary spindle and up against a

thrust washer.

Note: The boost pump includes the 5 micron pre-filter option.

5 MICRON PRE-FILTER

Connect the filter housing with the supplied ¾” nylon nipple to the standard filter housing and

reconnect the reinforced vinyl hose. The 5micron cartridge has to be installed as the second filter in

flow direction.

5 MICRON PRE FILTER WITH LOW PRESSURE GAUGE

The optional 5micron pre filter housing with low pressure gauge has to be installed as a second filter in

flow direction.

FRESHWATER FLUSH SYSTEM

Install the active carbon filter housing at an easily accessible location close to your seawater intake line

and any pressurized water line. Connect the fitting on the shut off valve of the carbon filter housing to

your boats’ pressurized water line.

Connect the filter outlet to the supplied T-connector. Connect the two remaining ports of the T-

connector to the outlet of the storage/cleaning valve on the pre-filter housing and to the intake of the

high pressure pump (refer to the flow diagram).

12

SYSTEM OPERATION INSTRUCTIONS

CAUTION: The reverse osmosis membrane contains a preservative solution to prevent microbiological

growth. If ingested, it may cause irritation of the gastro-intestinal tract. Therefore, discard all the product

water for at least thirty minutes of initial operation or after system storage before drinking or before use in

food preparations!

CAUTION: Do not operate the system using contaminated feed water sources (oil, chlorine or other

chemicals).

CAUTION: Check proper oil level with dipstick or show glass (center of show glass).

CAUTION: Have you removed the shipping plug from the high pressure pump and replaced with the

enclosed breather oil cap? Failure to do so may damage the crankshaft oil seals of the pump.

1) Open the seawater intake valve (sea cock).

2) Open the pressure control valve, on the control panel, all the way counter-clockwise.

CAUTION: Never start the system with the high-pressure control valve closed.

3) Set the cleaning/storage valve to the pre-filter position (towards the filter).

4) Set the diverter valve to sample position (left).

5) Switch on the boost pump (optional).

6) Switch on the high pressure pump.

7) Flush the air out of the system. Crack open pre- filter housings if needed.

Check for brine discharge at the output location.

CAUTION: Never allow any leaks in your hose or tube connections.

CAUTION: Do not attempt to re-seal the stainless steel product water outlet fitting on the membrane

vessel end cap by further tightening as this could damage the thread of the plug. Remove the fitting, apply

new Teflon tape, insert the fitting and hand tighten plus ¼ turn.

8) Close the pressure control valve slowly clockwise to allow air bubbles to work themselves

out of the system.

9) Adjust the water pressure to achieve the specified product output with a maximum reading of

900 PSI on the pressure gauge in the control panel. If you operate the watermaker in brackish

or lake water, adjust the working pressure not to exceed the specified product water rate.

10) Taste the product water at your sample station. If the water is pure, switch the

diverter valve to fill your storage tank.

13

SYSTEM SHUT DOWN PROCEDURE

1) Switch the diverter valve to sample station.

2) Open the pressure control valve all the way counter-clockwise.

3) Switch off the electric motor and the boost pump (if installed).

4) Close the seawater intake valve.

FRESH WATER FLUSH PROCEDURE

The fresh water flush exchanges the seawater in the membrane element/s with fresh water und should be

performed after each use of the watermaker. Skipping the flush does not save water as the product on next

operation must be dumped longer to clear the membrane element. The simple flushing procedure avoids

biological growth due to the dying microorganisms contained in seawater and dissolves mineral build up

that may clog the membrane element/s. Repeated every 14 days, the fresh water flush also avoids the need

for chemical preservation, otherwise to be performed for long-term storage.

CAUTION: The boats fresh water pressure should not exceed the range of the low pressure gauge.

1) Open the pressure control valve all the way (two full rounds after the spring releases) counter

clockwise.

2) Close the sea water intake valve or switch the cleaning/storage valve to the closed position.

3) Open the fresh water flush valve.

Your boats’ fresh water supply pump should now turn on (larger fresh water pumps will cycle on and off).

Allow fresh water to flow until all salt water is flushed out of the RO System. For the next flush procedure,

test how long it takes until the brine at the outlet becomes fresh.

PRE-FILTER BACKWASH PROCEDURE

As part of a long term storage, you may remove the pre-filter cartridges from the housings or perform a

pre-filter backwash procedure. If there is no momentary shortage of fresh water, the back wash may also

be useful to reduce product water discharge time until the product is free of odor after each start up.

1) Open the seacock and switch the cleaning/storage valve to the sea water position.

2) Allow fresh water to flow until all salt water is flushed out of the pre-filter(s), boost pump and the

sea strainer (approximately 30 seconds, depending on the flow rate of your vessel’s fresh water

pump).

3) Close the seacock.

MEMBRANE STORAGE PROCEDURE

If you intend to store your watermaker for more than ten days, growth of micro-organism may degrade the

RO membrane(s) performance and the RO membrane(s) should be flushed with a biocide solution. This will

preserve the membrane for long-term storage of up to ten months.

If you have installed the optional fresh water flush system, it is recommended to back flush the pre-filter(s),

the boost pump and the sea strainer with fresh water (see above). Close the seawater intake valve (sea

cock) and remove the pre-filter cartridge(s).

14

1) In a clean plastic container, mix 2.5 gallons / 10 liters of un-chlorinated fresh water with 100 grams

(1/3 container) of ECHOTec membrane preservative # 3 (Metabisulfite)

2) Switch the three-way valve to the cleaning/storage position.

3) Switch the diverter valve to the sample position.

4) Open the pressure control valve all the way counter clockwise (two full rounds after the spring

releases).

5) Use a large funnel or open container with barbed fitting to pour the solution into the

cleaning/storage hose or lead the hose into an elevated plastic container while running the high-

pressure pump. When the solution has been infused, switch off the watermaker.

Your watermaker is now prepared for a shutdown period of ten months.

CAUTION: After storage, discard the product water for at least thirty minutes of initial operation before

drinking or before use in food preparations.

MEMBRANE CLEANING PROCEDURE

ECHO Tec membrane element may be chemically cleaned when the product water output drops by 15% of

the specified amount. The frequency of this occurring will vary greatly depending upon feed water quality.

Fouling of the membrane will naturally occur during normal usage. Increased amounts of fouling without

proper cleaning of the membrane will reduce the performance of your water maker. A drop in production

of approximately 10% is normal and expected during the first year of operation.

Note: Do not clean when product salinity high. Clean only to restore output!

CAUTION: The use of chemicals or cleaning methods other than those outlined in the cleaning instructions

will void the ECHO Tec Warranty.

CAUTION: Cleaning chemical #1 is an alkaline detergent. See warning label on side of the container and

observe all safety precautions on label.

CAUTION: Cleaning chemical #2 is an acid, a mineral scale remover. See warning label onside of container

and observe all safety precautions on label.

CAUTION: Do not mix different cleaning chemicals together. Do not use different cleaning chemicals

together at the same time.

To clean the ECHO Tec. reverse osmosis membrane mix a solution of 1.5 to 2 % by weight with warm non-

chlorinated water (113° F / 45° C) in a clean plastic container. Use 10 ltr / 2.5 gal with 200 g or 2/3

container cleaning agent.

For safety reasons, we do not recommend you to install a 3 way re-circulating valve to facilitate the service

procedure. Disconnect the intake and reject water hose and lead them in the plastic container. Re-

circulate the solution intermittent without pressure for up to 60 min. There will be no flow at the fresh

water outlet.

CAUTION: Observe the maximum operating temperature of 113° F / 45° C. The high pressure pump might

over heat the solution on re-circulating.

It is important that most of the fresh water remaining from the last flush is dumped before the

reject hose is led in the cleaning bucket for re-circulation in order to avoid diluting the solution.

Use cleaning chemical #1 first. Only if the performance does not improve, use the

acid cleaner #2 at the same ratio and instruction

15

MAINTENANCE TIMETABLE

The following maintenance timetable is an estimate of the time intervals at which maintenance may be

required only. This schedule must be adjusted to the regularity of usage, the condition of the intake water,

the length of time the system is exposed to seawater and the total running time following each system

cleaning.

COMPONENT

MAINTENANCE REQUIRED

TIME INTERVAL (INTERMITTENT DUTY)

Sea Strainer

Inspect and clean

screen and housing…

every 200 hrs or when clogged. Observe low

pressure gauge if installed.

Pre filters(s)

Replace or clean element(s) and

clean housing(s)…

Boost pump: when pressure is lower than 0

PSI. No Boost pump: pressure lower than 5”Hg

Hardener / pH

neutralizer

Replace or refilled with the mineral

mix of another cartridge…

when 25% of the content has been dissolved to

guaranty sufficient contact surface

Carbon flush

filter

Replace element…

every 6 months

High pressure

pump

Change

crankcase oil…

7.5 oz./0.2 L SAE 90 Wt, non-detergent

Initial change after 50 hrs.

every 300 operating hours or 12 months

High pressure

pump

Change seals and O-rings…

every 5000 hrs or 3 years.

R.O. Membrane

Clean with acid and/or alkaline

cleaning compound…

Replace…

Note: Do not clean when TDS reads

high. Clean only to restore output!

when production decreases by 15%.

when cleaning does not

increase production.

Flow meter

*Infuse muriatic acid and rinse well…

when discolored/dirty

* Set the diverter valve to the sample position. Disconnect the product water tubing from the product port

at the membrane vessel and carefully infuse Muriatic acid, KR1 or Ospho with a syringe into the product

water tubing. Once the discoloring has cleared, re-connect the tubing, run the system and rinse the flow

meter with the product water. CAUTION: Adhere to the safety advises of the cleaning agents.

16

TROUBLESHOOTING GUIDE

MALFUNCTION

CAUSE

REMEDY

Inability to build up

pressure…

...with high pressure

gauge fluttering.

…with loud noise from

HP-pump.

(Low pressure gauge

reads below 10”Hg)

…during navigation

…with drop in RPM

Air enters intake plumbing.

Air in intake system

High pressure pump valve

stuck after long storage time.

Seacock closed

Seacock clogged (Barnacles?)

Strainer, filter/s fouled

Through hull fitting in wrong

location (suction trough

movement).

Motor brushes worn

Tighten all hose clamps.

Allow more time to prime. If no boost pump is

installed, perform freshwater flush to assist

priming.

Open one by one all six hexagonal valve covers.

Inspect valves for movement.

Open seacock

Clean seacock

Clean strainer, change/clean filter/s.

Use strainer scoop (page 11).

Replace brushes

Pressure drops

frequently with change

of noise…

…during navigation

Air enters intake plumbing.

Air enters sea water intake

during navigation.

Tighten all hose clamps. Reseal NPT fittings.

Move through hull fitting to lower location.

Excessive leakage

between the high

pressure pump head

and crankcase…

…with water in crankcase

Worn high pressure seals

Cracked ceramic plunger

Cracked ceramic plunger

and/or worn HP/oil seals

Replace high pressure seals

Inspect for hairline crack. Replace plunger

and HP seals (page 18 / 3).

Inspect for hairline crack. Replace plunger (if

needed), high pressure seals and oil seals.

Product salinity reads

above 500ppmTDS.

Membrane element has

reached its service life time.

Replace membrane element. See instructions

on page 17.

Product output below

specification.

Low voltage or bad electrical

contact

Membrane element clogged

or reached its service life

time.

Check voltage directly at motor cables.

Clean membrane element (page 14).

Replace membrane element (page 17).

Leak on pressure vessel

end cap from salt water

…from fresh water

O-ring worn

Product port Teflon seal worn

Remove and inspect plug (page 17). Change O-

ring/s as needed.

Remove port, re-seal, install hand tight + ¼ turn

17

MEMBRANE ELEMENT AND END PLUG SERVICE INSTRUCTIONS

1) Remove the high pressure hoses and product tubing from the pressure vessel

2) If needed remove the complete vessel

3) Remove the three M6 bolts with a 5mm allen key on both sides of the vessel.

4) Remove the three locking plates (locks) on both sides.

5) Holding the product port, pull the product port end plug in one fast pull out of the vessel.

Note: Should the plugs O-ring (PL01) get stuck in the locks groove of the pressure vessel, it will be more

difficult to pull the plug. Tap the plug in and pull more vigorously.

If the product port is mounted on the high pressure OUT side:

6) Using a needle nose pliers, pull the membrane element on the product tube in flow direction.

6b) Push out the remaining end plug from the opposite side with a pipe, boat hook, etc.

If the product port is mounted on the high pressure IN side:

6) Using a short pipe or wooden support, push out the membrane element together with the

remaining end plug.

Inspect the end plugs for hairline cracks or damages on the O-rings and O-ring grooves.

7) Insert the new membrane element, observing the correct position and direction of the lipped

seal ring: High pressure entry side of the membrane, lip against flow direction.

8) If needed, clean the product port and end plug threads from remaining Teflon sealant and

re-apply 3 wraps only.

11) Insert the end plugs and reassemble all components visa versa.

CAUTION: Do not over tightening the product port/s. Hand tide plus ¼ turn. Thread may damage!

18

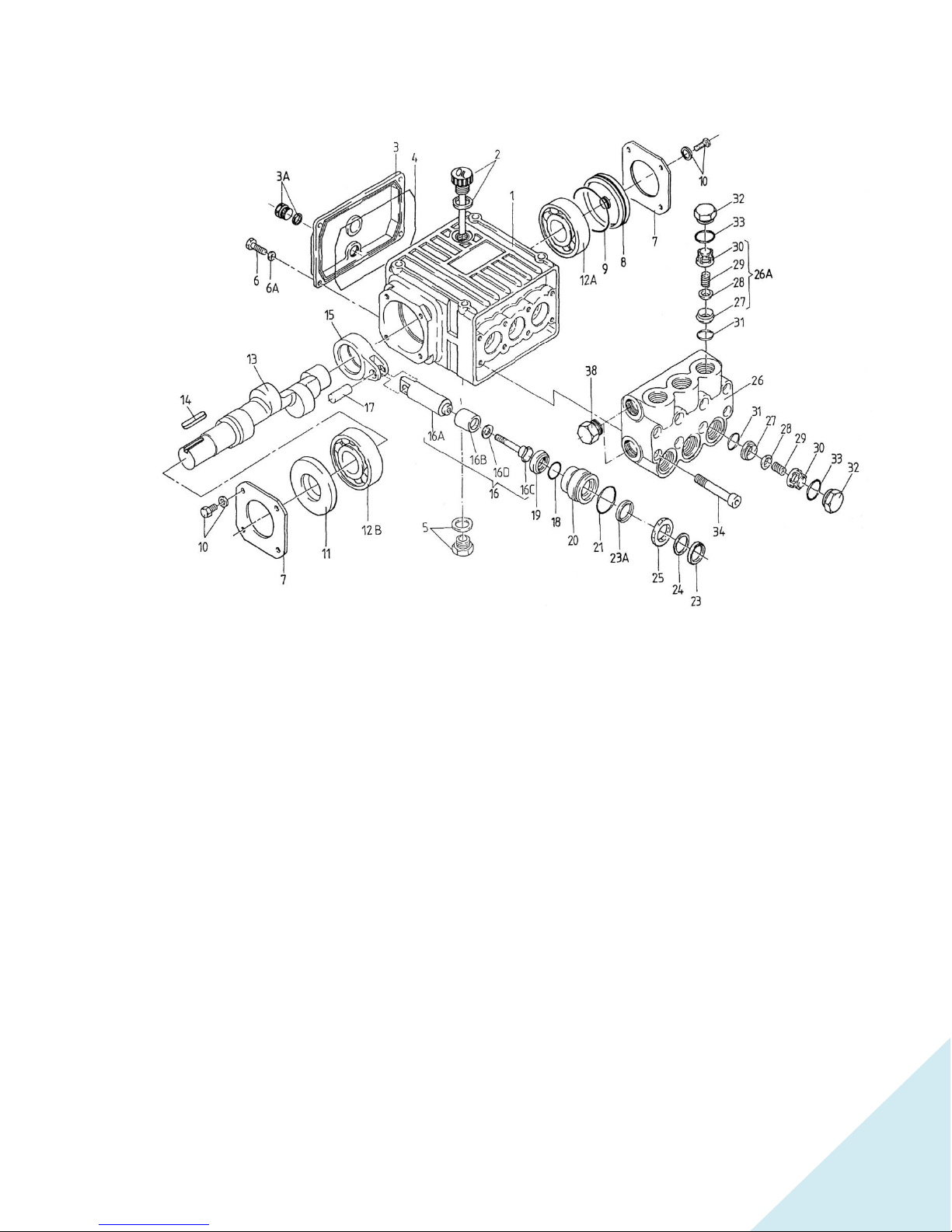

HIGH PRESSURE PUMP PARTS AND SERVICE INSTRUCTIONS

DISASSEMBLY SEQUENCE OF THE PUMP HEAD

Refer to the pump diagram.

1) Remove the three discharge valve plugs and the three inlet valve plugs (32), with a 22 mm socket

wrench. Inspect the O-ring (33) for wear and replace if damaged.

2) With needle nose pliers, remove the inlet and discharge valve assemblies (32X). Insert a small

screwdriver between the valve seat (27) and the valve spring retainer (30) to separate the valve

assembly. Remove the O-ring (31). Inspect all parts for wear and replace if necessary.

3) Next, use a 5 mm Allen wrench to remove the 8 socket head cap screws (34). Carefully slide the

valve casing (26) out over the plungers. Remove the weep return ring (25), pressure ring (24) and

V-sleeve with support ring (23), from the valve casing (26). Remove the V-sleeve (23) from the seal

case (20). Inspect all parts, including O-ring (21) for wear and replace if necessary.

4) Check surfaces of plunger (16). A damaged surface will cause accelerated wear on the seals.

Deposits of any kind must be carefully removed from the plunger surface. A damaged plunger

must be replaced!

5) If the ceramic plunger (16B) is damaged, remove the plunger bolt (16C). Discard the old plunger

(16B) and copper gasket (16D) and clean the old Locktite from the plunger bolt (16C) and plunger

base (16A). Replace the plunger with the new one and Locktite the plunger bolt and torque to 120

inch-pounds.

Note: If there are deposits of any kind (i.e., lime deposits) in the valve casing, be certain that the

weep holes in the weep return ring and valve casing have not been plugged.

19

6) If the crankcase oil seals (19) are to be replaced, they can be removed by prying loose. Take care

not to make contact with the plunger. If the oil seals are not to be replaced, proceed to the back

end disassembly sequence and carefully pry the seals loose after the plungers have been removed

from the crankcase.

DISASSEMBLY SEQUENCE OF THE CRANKCASE

1) Before beginning, drain the oil from the crankcase, through the oil drain (3A).

2) Remove the crankcase cover (3) and O-ring (4) from the crankcase (1). To remove the crankshaft

(13), remove the bearing cover (7) and sight glass (8). Using a rubber mallet, remove the crankshaft

axially through the connecting rods by tapping on the end of the shaft. Do not bend or damage the

connecting rods during crankshaft removal.

3) Next remove the remaining bearing and radial shaft seal (11). Inspect both bearings and seal for

wear and replace if necessary.

4) Remove the connecting rod (15), then the plunger (16) and wrist pin (17), if necessary. Check the

plunger bore in the crankcase for wear. Inspect parts and replace as necessary.

5) Should you find it necessary to service the plunger assembly (16), you can do so by removing the

tension screw (16D). Inspect all parts and replace as necessary.

Note: In order to drive the pump from the side opposite the present shaft extension, simply

remove the valve casing from the crankcase and rotate the pump 180 degrees to the desired

position. Be certain to rotate the seal case as well, so that the weep holes are down at the six

o’clock position. Change the oil fill and the oil drain plugs. Refer to the repair instructions

as necessary for the proper assembly sequence.

REASSEMBLY SEQUENCE

1) Reassemble plunger (16) and the connecting rod (15) with wrist pin (17). Place assemblies in

crankcase (1). Install crankshaft through connecting rods, again being careful not to bend or

otherwise damage the connecting rods.

2) Replace left and right side bearings (12A and 12B), if they were removed from the crankshaft. Be

certain the bearings are pressed all the way onto the shaft and completely into the crankcase.

Replace radial shaft seal (11) bearing cover with sight glass (7 and 8) and crankcase cover with O-

ring (3 and 4).

3) If oil seals (19) were removed, replace with seal lip towards crankcase. Lubricate seal with silicone

grease before replacing.

4) Replace seal case (20) with O-ring (21) over plungers. Generously lubricate O-ring and oil seal

With silicone grease before reassembly. Replace V-sleeve (23) over plunger.

5) Generously lubricate V-sleeve (23). Assemble spacer and V-sleeve (23) into valve casing (26).

Assemble weep return ring and pressure ring (25 and 24) over plungers. Slide the valve casing over

plungers and seat firmly. Replace the eight-socket head cap screws (34) and tighten to 105 inch

pounds in a crossing pattern.

6) Replace the six O-rings (31) and the six-valve assemblies (32X). Replace the six valve plugs with

O-rings (32 and 33) and tighten securely with a 22mm socket wrench to 33 foot-pounds.

7) Fill crankcase with 7.5 ounces / 0.22 ltr non-toxic, non-detergent SAE 90 gearbox oil.

20

Sea Strainer Element

Pump Valve Assemblies

Pre-filter Cartridges

Gauge/Instrument Calibration

Auxiliary Tubing

Pump Crankcase Oil

Pump Seals and Packings

V or Timing Belt

Pump Bushings and Bearings

ECHOTEC WATERMAKERS LIMITED WARRANTY

Echo Marine Ltd. warrants for a period of 3 years (1 year for commercial applications)

from the date of shipment that the ECHOTec watermaker is free of defects in material and

workmanship and performs according to specifications. The triplex plunger high-pressure

pump head and the high pressure vessel/s (except end plugs, O-rings and fittings) are

warranted for life (10 years for commercial applications) to the original purchaser.

Echo Marine’s liability under this warranty shall be limited to repair or replacement of the

ECHOTec watermaker at Echo Marine’s option. Under no circumstances shall Echo Marine

Ltd. be liable for consequential damages arising out of or in any way connected with the

failure of the system to perform as set forth herein. This limited warranty is in lieu of all

other expressed or implied warranties, including those of merchantability and fitness for a

particular purpose.

In the event of a defect, malfunction, or failure during the warranty period, Echo Marine

Ltd. will repair or replace, at its option, the product or component therein which, upon

examination by Echo Marine, shall appear to be defective, or not up to factory

specifications.

To obtain warranty service, the defective product or part must be returned to Echo

Marine’s Service Center. The purchaser must pay any transportation or labor expenses

incurred in removing and returning the product. A return authorization must be obtained

before any part or component is shipped.

The limited warranty does not extend to any system component that has been subjected

to misuse, neglect, accident, improper installation, or used in violation of instructions

furnished by Echo Marine Ltd. The warranty does not extend to components on which the

serial number has been removed, defaced or changed.

Echo Marine Ltd. reserves the right to make changes or improvements in its product

during subsequent production without incurring the obligation to install such changes or

improvements on previously manufactured equipment.

The implied warranties, which the law imposes on the sale of this product, are expressly

LIMITED, in duration to the time period above. Echo Marine shall not be liable for

damages, consequential or otherwise, resulting from the use and operation of this

product or from the breach of this limited warranty.

This limited warranty service does not apply to normal recurring user maintenance as

described below.

This manual suits for next models

3

Table of contents

Popular Water Filtration System manuals by other brands

Culligan

Culligan Aqua-Cleer H-82 WT Use and care guide

Solmetex

Solmetex Hg5 Installation and maintenance instructions

Bibo

Bibo Bibo user manual

Sundstrom

Sundstrom SR 99-1 User instruction

GE

GE PNRQ20RBL Owner's Manual & Installation Instructions

TCi

TCi HarmonicGuard Series Installation, operation and maintenance manual

BLUGARDA

BLUGARDA BluFilter 1011 user manual

SHELCO FILTERS

SHELCO FILTERS RHB Installation, operation & maintenance manual

Zip Heater

Zip Heater HydroTap G4 user guide

Davey

Davey STERIFLO SF1000S mkII Installation and operating instructions

Filtech

Filtech DP 200 Use and maintenance manual

Oase

Oase BioSmart30000 operating instructions