2

TABLE OF CONTENTS

Introduction................................................................2

- The Operator's Manual .......................................2

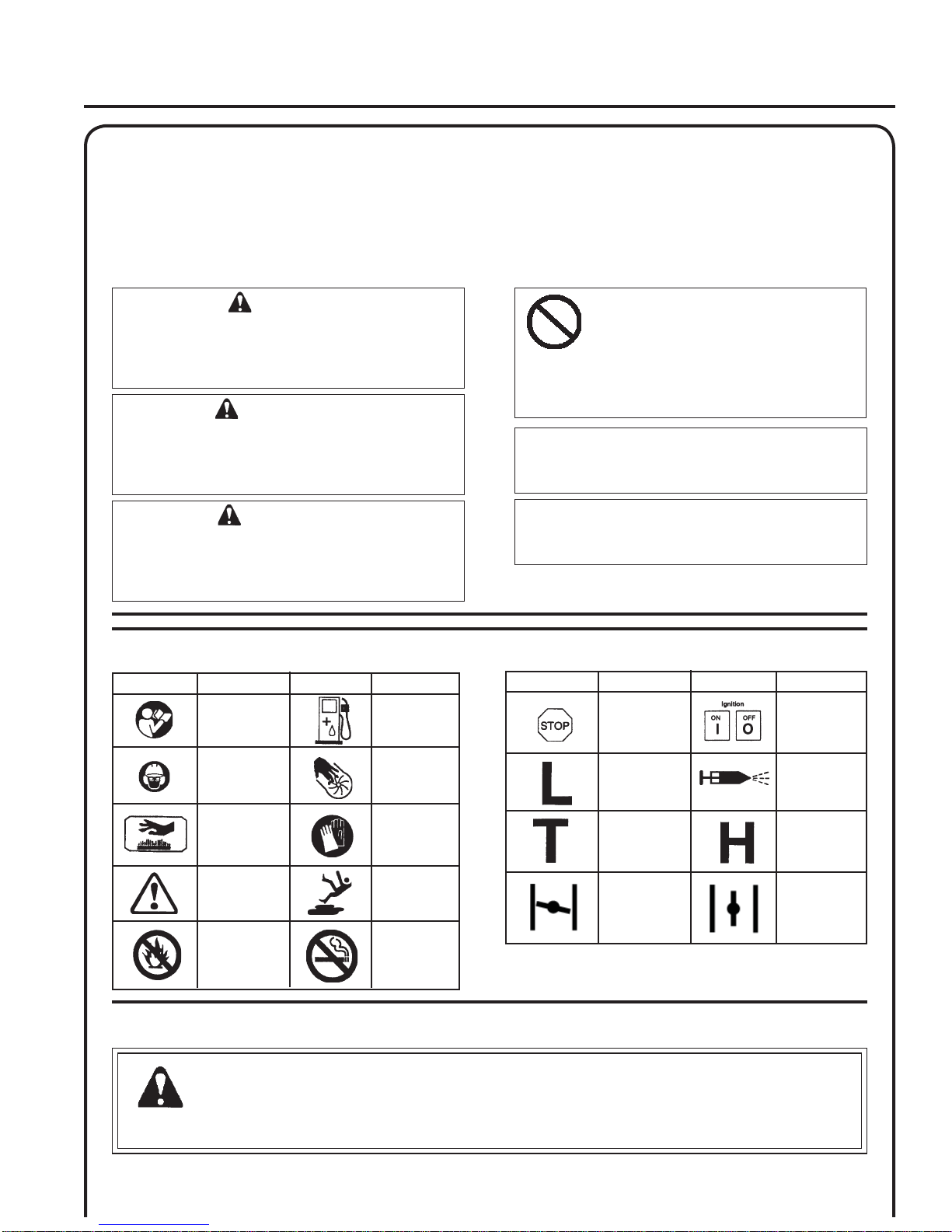

Safety .........................................................................3

- Manual Safety Symbols and Important

Information.........................................................3

- International Symbols.........................................3

- Personal Condition and Safety Equipment.........3

- Equipment...........................................................6

Emission Control .......................................................6

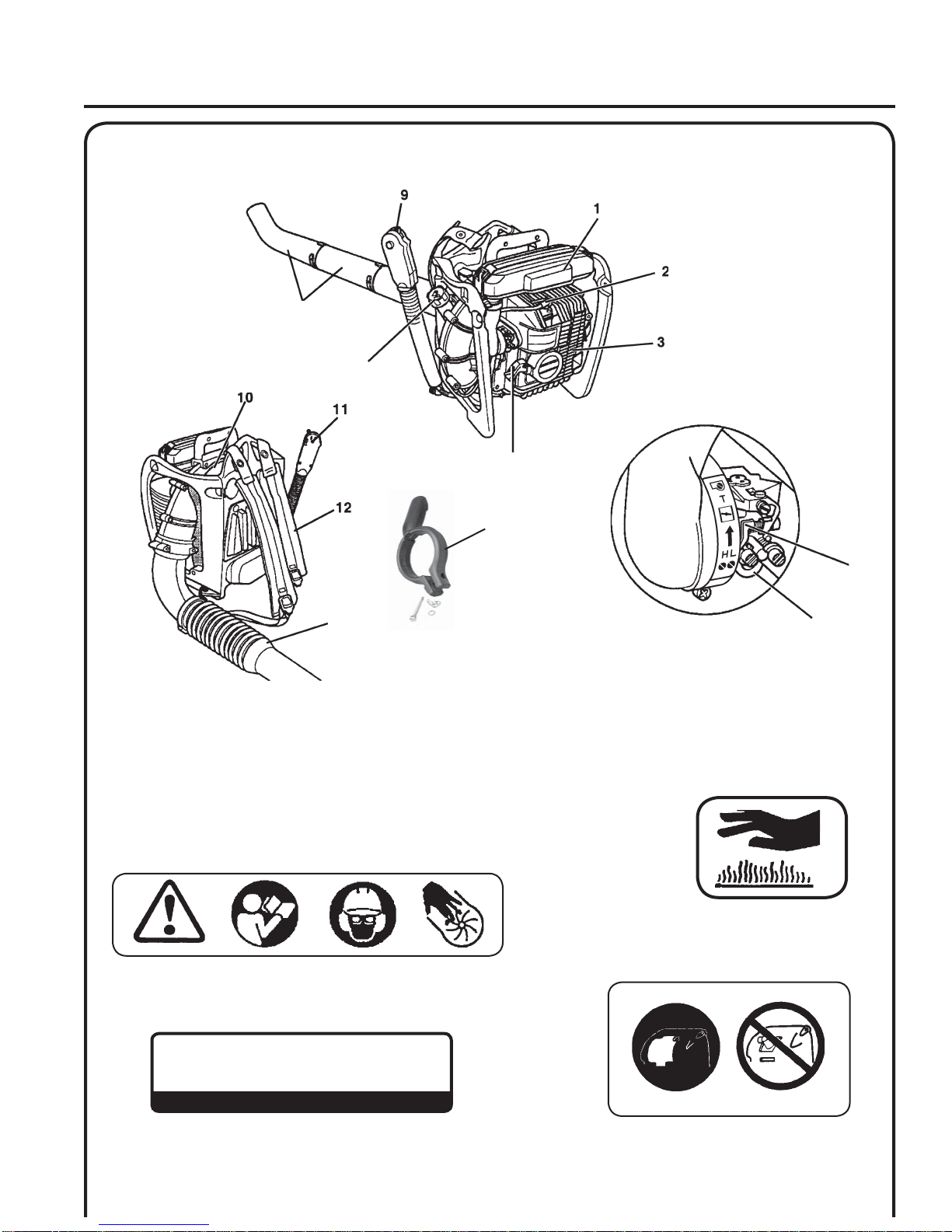

Description.................................................................7

Contents .....................................................................8

Assembly....................................................................9

- Install Blower Pipes / Stick Handle....................9

Operation..................................................................10

- Fuel...................................................................10

- Starting Cold Engine.........................................12

- Starting Warm Engine.......................................13

- Stopping Engine................................................13

- Operating Blower..............................................14

Maintenance.............................................................15

- Skill Levels.......................................................15

- Maintenance Intervals.......................................15

- Air filter ............................................................16

- Fuel Filter..........................................................17

- Spark Plug.........................................................17

- Cooling System.................................................18

- Exhaust System.................................................18

- Carburetor Adjustment......................................21

- High Altitude Operation................................21

Troubleshooting.......................................................23

Storage .....................................................................24

Specifications...........................................................25

Warranty Statements................................................26

Servicing Information..............................................28

- Parts ..................................................................28

- Service ..............................................................28

- Customer Assistance.........................................28

- Warranty Card...................................................28

- Additional or Replacement Manuals................28

- Manual Ordering Instructions...........................28

Specifications, descriptions and illustrative material in this

literature are as accurate as known at the time of publica-

tion, but are subject to change without notice. Illustrations

may include optional equipment and accessories, and may

not include all standard equipment.

Copyright© 2013 By Echo, Incorporated

All Rights Reserved.

INTRODUCTION

Welcome to the ECHO family. is ECHO product was designed and manufactured to provide long life and on-the-

job-dependability. Read and understand this manual. You will nd it easy to use and full of helpful operations tips and

SAFETY messages.

THE OPERATOR'SMANUAL

Keep it in a safe place for future reference. Contains specications and

information for safety, operation, maintenance, storage, and assembly

specic to this product.