2

Copyright© 2010 By Echo, Incorporated

All Rights Reserved.

Ta b l e o f Co n T e n T s

Introduction................................................................2

- The Operator's Manual .......................................2

Safety .........................................................................3

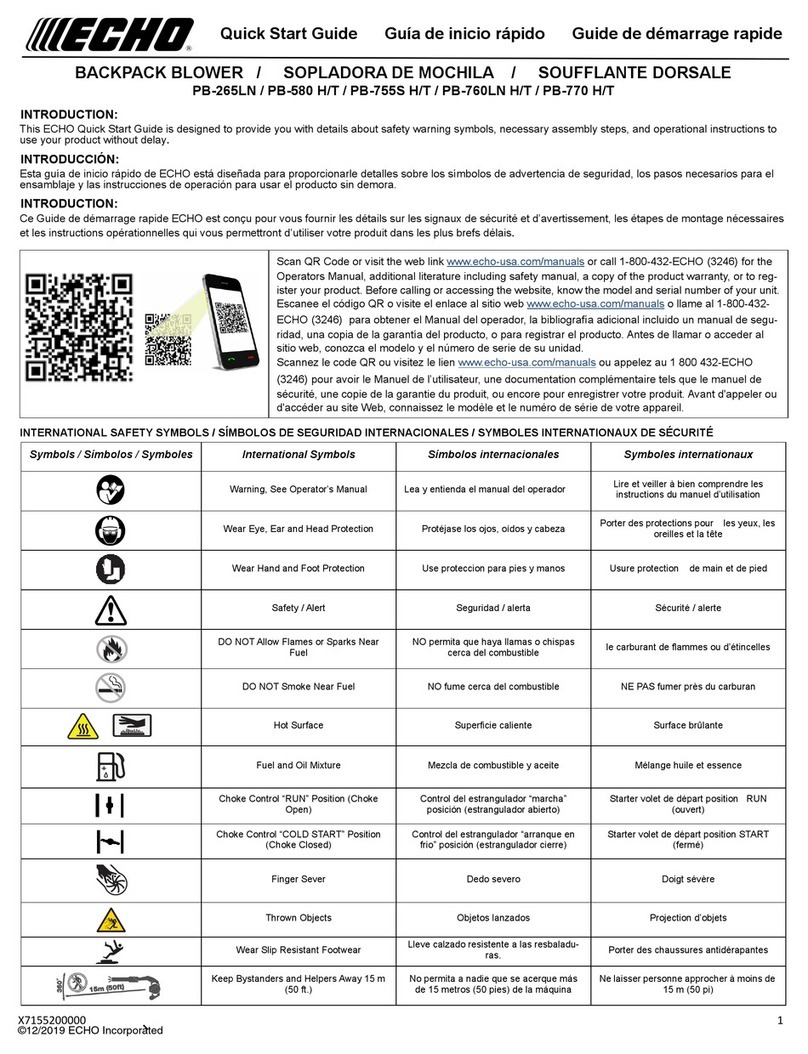

- Manual Safety Symbols and Important

Information .........................................................3

- International Symbols.........................................3

- Personal Condition and Safety Equipment ......... 3

- Equipment Check................................................6

Emission Control .......................................................6

Description.................................................................7

Contents .....................................................................8

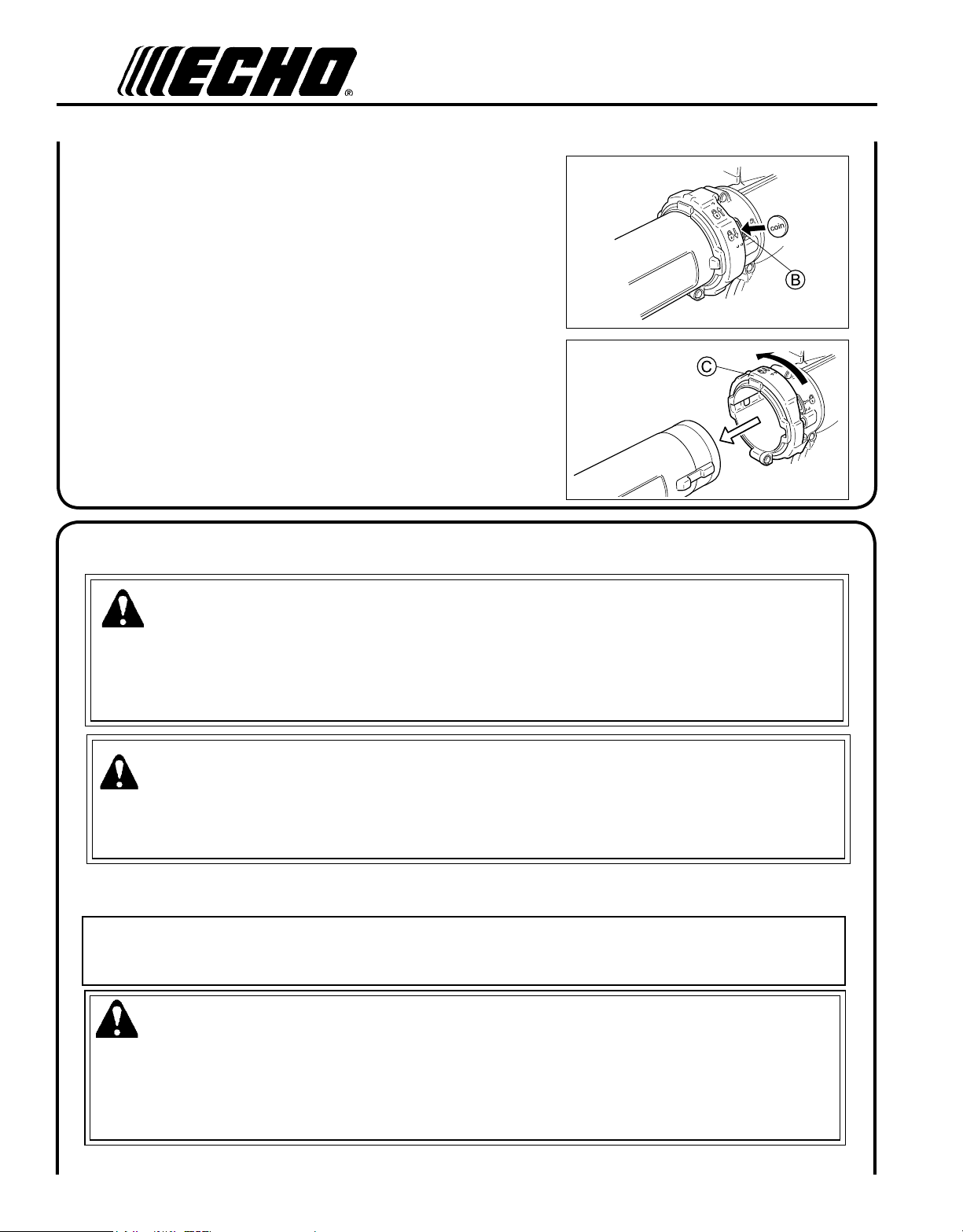

Assembly....................................................................9

- Blower Application.............................................9

Operation..................................................................10

- Fuel ...................................................................10

- Starting Cold Engine.........................................12

- Starting Warm Engine.......................................13

- Stopping Engine................................................13

- Operating Blower..............................................14

Maintenance.............................................................15

- Skill Levels .......................................................15

- Maintenance Intervals.......................................15

- Air Filter ...........................................................16

- Fuel Filter..........................................................16

- Spark Plug.........................................................17

- Cooling System.................................................17

- Exhaust System.................................................18

- Carburetor Adjustment......................................20

- High Altitude Operation ................................20

Troubleshooting .......................................................21

Storage .....................................................................22

Specications ...........................................................23

Warranty Statements ................................................ 24

Servicing Information ..............................................28

- Parts/Serial Number..........................................28

- Service ..............................................................28

- ECHO Consumer Product Support...................28

- Warranty Card...................................................28

- Additional or Replacement Manuals ................28

Specications, descriptions and illustrative material in this

literature are as accurate as known at the time of publica-

tion, but are subject to change without notice. Illustrations

may include optional equipment and accessories, and may

not include all standard equipment.

In T r o d u C T I o n

Welcome to the ECHO family. This ECHO product was designed and manufactured to provide long life and on-the-

job dependability. Read and understand this manual. You will nd it easy to use and full of helpful operating tips and

SAFETY messages.

T h e o p e r a T o r 'sm a n u a l

Read and understand this manual before operation. Keep it in a safe

place for future reference. It contains specications and information

for operation, starting, stopping, maintenance, storage and assembly

specic to this product.

1

Power Blower

Operator's Manual

MODEL PB-251

X75300

09/06

X753118

WARNING

Read rules forsa fe operatio n and instruc tions carefully. ECHO provi des this Opera tor's

Manual,which must be read and understood for proper and safeoperation.

PB251ef_091206.pmd