2

Copyright© 2007 By Echo, Incorporated

All Rights Reserved.

INTRODUCTION

Welcome to the ECHO family. This ECHO product was designed and manufactured to provide long life and on-the-

job-dependability. Read and understand this manual and the SAFETY MANUAL you found in the same package. You

will find both easy to use and full of helpful operations tips and SAFETY messages.

THE OPERATOR'SMANUAL

Read and understand this manual before operation. Keep it in a safe

place for future reference. It contains specifications and information for

operation, starting, stopping, maintenance, storage, and assembly

specific to this product.

THE SAFETY MANUAL

Read and understand this manual before operation. Keep it in a safe

place for future reference. It explains possible hazards involved with the

use of Grass Trimmers and Brush cutters and what measures you

should take to make their use safer.

DANGER!

SRM/GT/PAS/SB/PE SAFETY MANUAL

Misuse may result in serious or fatal injuries. You must read, under-

stand, and follow these safety instructions, and the instructions in the

Operator’s Manual, before operating a Model GT Grass Trimmer, SRM

Trimmer-Brushcutter, PAS Pro-Attachment Series Powerhead, SB Split-

Boom Trimmer-Brushcutter, or PE Power Edger.

If you operate a model SB Split-Boom or PAS Pro Attachment Series

multi-attachment unit, you must also read, understand, and follow the

instructions in your PAS Attachment Operator’s Manual.

DANGER!

To locate your nearest Echo dealer, visit our website at www.echo-usa.com, or call 1-800-

432-ECHO (3246). Ask how to obtain a FREE Safety Video. Echo’s supplemental Trimmer

Safety Video provides helpful safety and operating information.

Metal blades are very sharp and can cause severe injuries, even if engine

is off and blades are not moving. Avoid contact with blades. Wear gloves

to protect hands.

X752000040

06/07

X7522270600

TABLE OF CONTENTS

Introduction ...............................................................2

- The Operator's Manual .......................................2

- The Safety Manual .............................................2

Safety .........................................................................3

- Manual Safety Symbols and Important

Information .........................................................3

- InternationalSymbols .........................................3

- Personal Conditions and Safety Equipment .......4

- Equipment ...........................................................6

EmissionControl........................................................7

Description ................................................................7

Contents ....................................................................9

Assembly ...................................................................9

- PlasticShieldInstallation.................................. 10

- Nylon Head Installation.................................... 10

- NylonLineInstallation ..................................... 10

- Front(Loop) Handle ......................................... 11

Operation ................................................................. 11

- Fuel ................................................................... 11

- StartingColdEngine ......................................... 13

- StartingWarmEngine....................................... 14

- Stopping Engine ............................................... 14

Maintenance ............................................................ 15

- SkillLevel.......................................................... 15

- Maintenance Intervals ...................................... 15

- AirFilter ............................................................ 16

- FuelFilter .......................................................... 16

- Sparkplug ......................................................... 17

- CoolingSystem................................................. 17

- ExhaustSystem................................................. 18

- Carburetor Adjustment ..................................... 19

- Lubrication........................................................ 20

Troubleshooting ...................................................... 21

Storage..................................................................... 22

Specifications........................................................... 23

ServicingInformation............................................... 24

- Parts/SerialNumber .......................................... 24

- Service .............................................................. 24

- ECHOConsumerProductSupport.................... 24

- Warranty Card .................................................. 24

- Additional or Replacement Manuals ................ 24

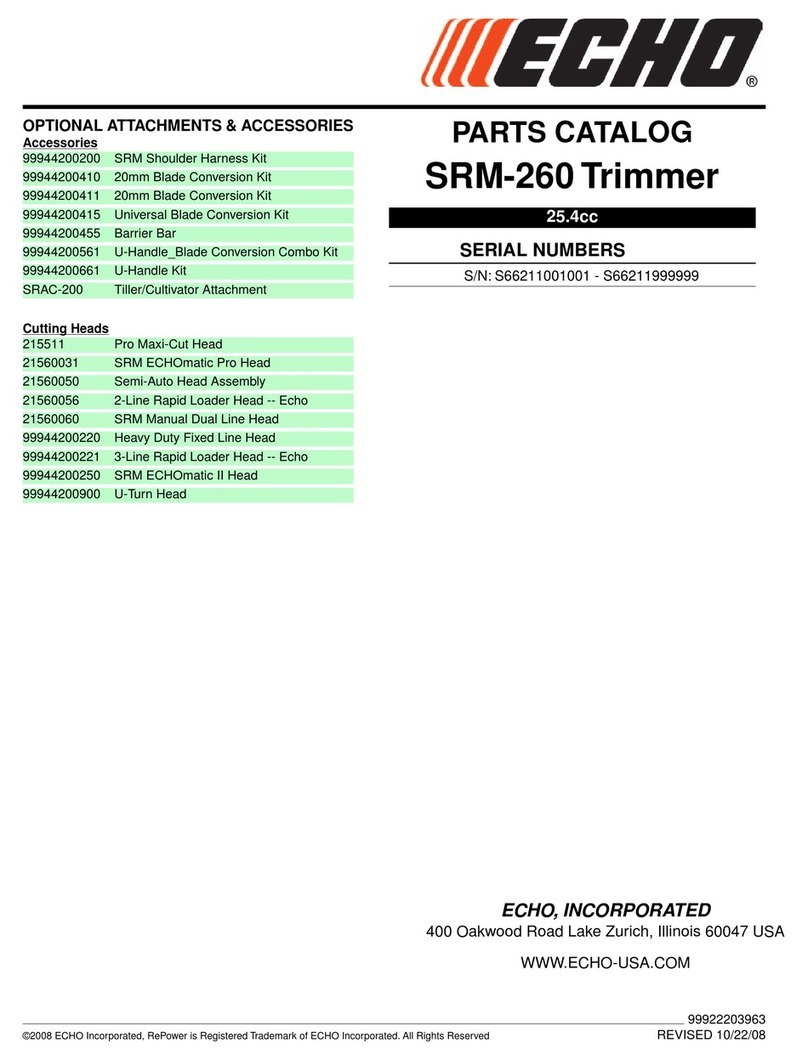

Specifications, descriptions and illustrative material in this

literature are as accurate as known at the time of publication,

but are subject to change without notice. Illustrations may

include optional equipment and accessories, and may not

include all standard equipment.