EcLine EC-PM-80320 User manual

Service Manual

EC-PM-80320

Thermal Printer

EC-PM-80320 Service Manual

- i -

Warnings, Cautions, and Notes

Pay attention to the following promises when using this manual:

Warning:

Warnings must be followed carefully to avoid bodily injury.

Caution:

Cautions must be observed to avoid damage to your equipment.

Note:

Notes contain important information and useful tips on the operation of your printer.

EC-PM-80320 Service Manual

- ii -

This Manual is to help qualified service engineers repair or adjust your EC-PM-80320.

Please read the manual carefully before repairing and adjusting your EC-PM-80320.

The warranty will not cover any trouble with or damage to the printer resulting from repair or modification

by unqualified persons.

Warning: Be sure to turn off the printer and disconnect the power cord from the AC outlet

before removing the upper housing. Failure to disconnect the power could result

in an electric shock.

Note: 1. It is strictly prohibit anybody or any group from copying or reprinting the content of

this manual in any means.

2. This manual is subject to change without notice.

3. We have tried our best to write this service manual. This manual was prepared with

the greatest care. If you should find any unclear points, mistakes, or omission,

please contact your local dealer.

EC-PM-80320 Service Manual

- iii -

Table of Contents

Chapter 1 Printer Introduction ..............................................................................................................1

1.1 Explanation and application ............................................................................................................1

1.2 Product type....................................................................................................................................1

1.3 Characteristic..................................................................................................................................1

1.4 Parts Identification ..........................................................................................................................2

Chapter 2 Control Panel Operation.......................................................................................................1

2.1 Control Panel ..................................................................................................................................1

2.1.1 Indicator LED............................................................................................................................1

2.1.2 KEY..........................................................................................................................................1

2.2 Self-Testing .....................................................................................................................................1

2.3 Hex Dump Printing..........................................................................................................................1

2.4 Restoring FactoryPrinter Settings ..................................................................................................2

2.5 Setting Slip Stitch............................................................................................................................2

Chapter 3 Specification..........................................................................................................................1

3.1 General Specification......................................................................................................................1

3.2 Interface Specification.....................................................................................................................2

3.2.1 Cash Drawer Interface .............................................................................................................2

3.2.2 Parallel Interface ......................................................................................................................3

3.2.3 USB Interface...........................................................................................................................4

3.2.4 Serial Interface.........................................................................................................................4

3.2.5 Ethernet Interface.....................................................................................................................5

3.2.6 Power Supply Inlet ...................................................................................................................5

Chapter 4 Printer Working Principle .....................................................................................................7

4.1 Working Principle of Thermal Print Head ........................................................................................7

4.1.1 Matching with thermal head and paper ....................................................................................7

4.1.2 The structure of thermal head ..................................................................................................8

4.1.3 Print position of data.................................................................................................................9

4.1.4 Electric Character of Thermal Print Head.................................................................................9

4.1.5 Timing Signal Figure ..............................................................................................................10

4.1.6 Thermal Head Resistance......................................................................................................10

4.1.7 Thermal Head Voltage............................................................................................................10

4.2 Sensor ..........................................................................................................................................10

4.2.1 Thermal sensor ......................................................................................................................11

4.2.2 Paper Sensor .........................................................................................................................12

4.2.3 Platen Position Sensor...........................................................................................................13

4.3 Working Principle of Control Unit ..................................................................................................13

4.3.1 Structure module....................................................................................................................13

4.3.2 Part’s Main Function...............................................................................................................14

4.3.3 Function of Interface...............................................................................................................14

EC-PM-80320 Service Manual

- iv -

4.3.4 Control System’s Principle Frame..........................................................................................16

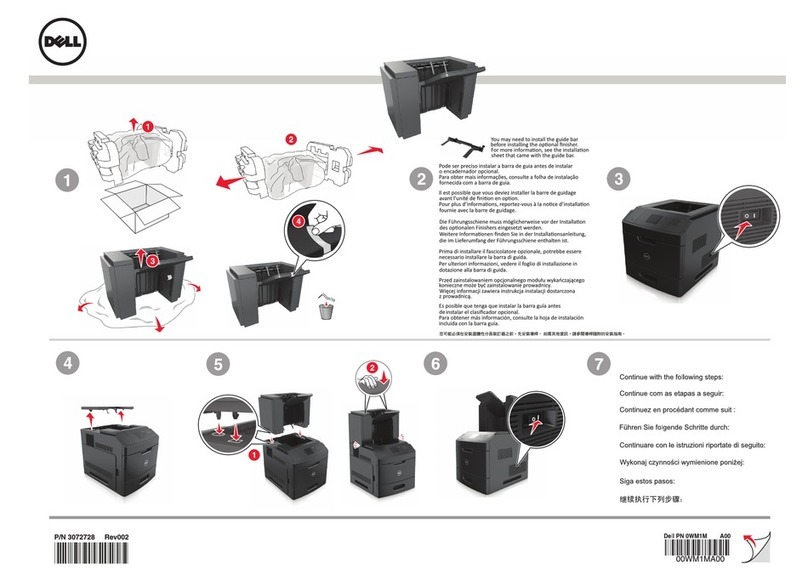

Chapter 5 Printer Installation and Removing.....................................................................................17

5.1 Removing the Enclosure...............................................................................................................17

5.1.1 Removing the Upper Cover....................................................................................................17

5.1.2 Removing the front cover.......................................................................................................18

5.1.3 Removing the Upper Housing ................................................................................................18

5.1.4 Removing the Bottom Housing...............................................................................................18

5.2 Disassemble MPM-80T Printer Assembly.....................................................................................19

5.2.1 Disassemble Bottom board cover...........................................................................................19

5.2.2 Disassemble MPM-80T Assembly..........................................................................................20

5.3 Disassemble Paper Feed Mechanism ..........................................................................................20

5.3.1 Removing the Platen Assembly..............................................................................................20

5.3.2 Loosen Rolling Ring...............................................................................................................21

5.3.3 Take Down the Platen ............................................................................................................21

5.4 Installation of Printer .....................................................................................................................22

Chapter 6 Troubleshooting..................................................................................................................23

6.1 Error Message on the Control Panel.............................................................................................23

6.2 Power Trouble...............................................................................................................................23

6.3 Print Badness ...............................................................................................................................23

6.4 Motor Abnormality.........................................................................................................................23

6.5 Cutter Abnormality........................................................................................................................23

6.6 Cash Drawer Interface Abnormality ..............................................................................................23

6.7 Cutter Jammed or Error ................................................................................................................23

Appendix A EC-PM-80320 Exploded View..........................................................................................25

A.1 Drawing for EC-PM-80320 ...........................................................................................................25

A.2 Parts List for EC-PM-80320..........................................................................................................26

Appendix B Mechanism Exploded View.............................................................................................28

B.1 Drawing for MPM-80T ..................................................................................................................28

B.2 Parts List for MPM-80T Drawing...................................................................................................29

Appendix C Main control PCB circuit diagram ..................................................................................31

EC-PM-80320 Service Manual

- 1 -

Chapter 1 Printer Introduction

1.1 Explanation and application

EC-PM-80320 printer is a kind of high-speed mini thermal printer with high quality, high reliability

and low noise. It does not need ribbon cartridge and can be operated easily. EC-PM-80320 printer

can be widely used in ECR, PC-POS and BANK POS for printing various kinds of receipts.

1.2 Product type

In order to fulfill different requirements and operating circumstance, manufacturer develops

EC-PM-80320 series products which are high-speed thermal mini-printers.

According to different data ports (interfaces), EC-PM-80320 series can be classified into different

models: EC-PM-80320, EC-PM-80320U, EC-PM-80320US, EC-PM-80320UE, EC-PM-80320UB

and EC-PM-80320UW.

EC-PM-80320 series printer is equipped with an auto cutter which has two options for the consumer

to select: partial cutter can only cut the paper with one point left while full cutter cuts the paper fully.

Interface:

EC-PM-80320 series products are configured with a cash drawer interface, you can choose one of

the following data interfaces when purchasing this product:

Model Interface

EC-PM-80320 Parallel interface

EC-PM-80320U USB interface

EC-PM-80320US USB interface + Serial interface

EC-PM-80320UE USB interface + Ethernet interface

EC-PM-80320UB USB interface + Bluetooth

EC-PM-80320UW USB interface + Wi-Fi

1.3 Characteristic

(a) Super high-speed printing

The maximal speed can reach to 220 mm/s.

(b) Installing paper easily

The platen roller part which can be opened make you install paper easily.

(c) High Resolution

Thermal print head with high density (8 dots/mm) can provide clear printing result.

(d) Long life-span

Be able to print paper with the length of 100km.

(e) Low noise

Thermal printing mode ensures low noise.

(f) Cleaning thermal print head easily

The platen roller part which can be removed make you clean the thermal print head easily.

(g) Preventing static

The frame ground connecting to the outside metal parts can reduce the faradic current

radiation to the minimum.

EC-PM-80320 Service Manual

- 2 -

1.4 Parts Identification

Figure 1-1 Main parts of the printer

Data Interface Cash Drawer Interface Power Supply Inlet

Figure 1-2 Back interfaces of the printer

Cover-open Button

Power Switch

Power Indicator

Error Indicator

Paper out Indicator

FEED Key

Manual Cutter

Front Cover

Upper Cover

Note: Please take the specific interface as standard.

EC-PM-80320 Service Manual

- 1 -

Chapter 2 Control Panel Operation

2.1 Control Panel

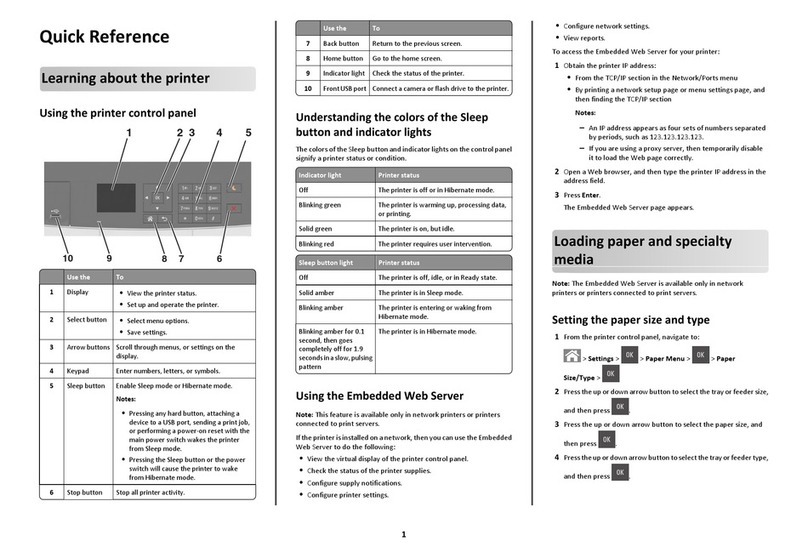

There are three LEDs and one key on the control panel shown as Figure 2-1.

2.1.1 Indicator LED

Indicator LED Description

POWER (Green) Denotes whether the printer’s power supply is connected or not. The indicator

LED is on when the power is connected.

ERROR (Red) Denotes printer’s status. The indicator LED is on when the malfunction

appears.

PAPER OUT (Red) Denotes printer’s paper status. The indicator LED is on when paper end or is

about to end.

2.1.2 KEY

2.2 Self-Testing

Self-testing lets you know if the printer is working properly. If the printer printouts the self-test

content normally, it denotes that there is nothing wrong with the printer except for the interface which

connecting to the computer. Otherwise, the printer should be repaired.

Hold down the FEED key and turn on the power switch while the printer cover is closed, the ERROR

LED blinks once with two beeps (if beeper is installed in the printer), loosen the key, then the printer

will print out self-test information such as the software version, update date and interface etc.

2.3 Hex Dump Printing

This function allows you to check whether the connection between the printer and the computer or

Key Function

【FEED】【FEED】controls paper feeding, you can enable or disable the key function with a

command. When enable, the paper will be fed continuously if you press and hold on it,

or stop if you loosen it.

Figure 2-1 Control panel

Note: Refer to “Error message on the control panel” for detailed information about LED

malfunctions in this service manual.

EC-PM-80320 Service Manual

- 2 -

terminal device works properly or not.

The method is that holding down FEED key while turning on the printer, the ERROR LED blinks

once with two beeps. Go on holding the key for about one second, and then loosen it after the

ERROR LED blinks once again with a beep. Turn off the printer when you want to exit this print

mode.

2.4 Restoring Factory Printer Settings

The function is to clear the settings stored in the printer and to restore the factory settings for

correlative parameters.

The method is that holding down FEED key while turning on the printer, the ERROR LED blinks once

with beeping twice at the same time. Do not loosen the key until the ERROR LED blinks once with

beeping once in about one second. Keep on pressing until ERROR LED blinks one more time with a

beep in about one second. At this time, turn off the printer and the function takes effect.

2.5 Setting Slip Stitch

If needed, Slip Stitch is used to upgrade printer firmware or it should be closed in normal working

condition. When to upgrade, pull out the Slip Stitch Cap after the printer is turned off, and then

holding down FEED key while turning on the printer again, the ERROR and PAPER OUT LEDs

blinking once at the same time, which denotes that the printer enters into the online-upgrade mode.

Loosen the key and then use the computer software equipped with the printer to upgrade. Turn off

the printer after finishing upgrading, plug Slip Stitch Cap and then the printer can be working

normally.

When plugging into

When pulling out

Slip Stitch Cap

Slip Stitch

Figure 2-2 Setting slip stitch

Note: Do not change the Slip Stitch without any permission of the factory, or the printer can

not work.

EC-PM-80320 Service Manual

- 1 -

Chapter 3 Specification

3.1 General Specification

Item Description

Printing method Direct thermal printing

Dot density 576 dots/line (203×203 DPI)

Effective printing width 72 mm

Max paper feed speed 220 mm/s

TF50KS-E (Japan paper co.ltd)

Thermal roll paper model AF50KS-E (JUJO THERMAL)

Width: 79.5 ± 0.5 mm

Weight: 53 ~ 80 g/m2

Maximum diameter: Φ80 mm

Paper thickness: 0.065 ~ 0.15 mm

Paper specification

Character set ASCII: 13 international character sets

Line spacing 1/6 inch, or programmable in 1/203 inch increments

Interface

This printer can be equipped with the following interfaces:

Parallel interface (Centronics)

USB interface (2.0 Full-Speed)

USB interface (2.0 Full-Speed) + Serial interface (RS-232C, DB9)

USB interface (2.0 Full-Speed) + Ethernet interface (10/100Base-T)

USB interface (2.0 Full-Speed) + Bluetooth (2.0/2.1+EDR)

USB interface (2.0 Full-Speed) + Wi-Fi (802.11b/g/n)

Cash drawer interface RJ-11, 24V(DC)/1A

Special function Automatic cutter, Online parameter settings, Online software upgrade

Input buffer 4 MB

ESC/POS Emulation

Character printing command: Support ANK characters, user-define characters

and enlarge Chinese characters 1~8 times

printing, adjust character line spacing

Dot image printing command: Support different densities dot images and

downloading image printing, save NV bitmap

without electricity (Can save LOGO for long)

Linear bar code: UPC-A, UPC-E, EAN-13, EAN-8,

CODE39, CODE128, ITF-25,

CODABAR

Control command

Bar code

Two-dimension code: PDF417, QR CODE

Input voltage: 100 ~ 240 V(AC)

Power Supply

(AC adapter) IN Frequency: 50Hz/60Hz

Note: 1. Only one of the data interfaces is supplied when leaving the

factory.

2. Please take the specific interface as standard.

Note: The inner diameter of paper shaft is Φ12 mm and the outer

diameter of paper shaft is Φ18 mm

EC-PM-80320 Service Manual

- 2 -

Output voltage: 24 V(DC)

OUT Current: 2.5 A

Temperature: 5 ~ 35℃

Operating environment Humidity: 25 ~ 80%RH (No condensation)

Temperature: -40 ~ 55℃

Environmental

conditions

Storage environment Humidity: ≤93%RH (40℃, No condensation)

Weight Approx. 2 Kg

Noise <38 dB (A) (ISO7779 standard)

Physical dimensions 145 mm (Width) × 200 mm (Depth) × 145 mm (Height)

Control panel One key and three LEDs

Paper type Thermal roll paper

Power consumption

①Operating: 40 W; ②Standby: Approximately 3.2 W

Code page 76 kinds

Certificate CE/FCC

3.2 Interface Specification

The printer is configured with one cash drawer interface and one data interface (Parallel interface,

USB interface, USB interface + serial interface, USB interface + Ethernet interface, USB interface +

Bluetooth or USB interface + Wi-Fi). Please connect the printing and the computer with correct

cables.

3.2.1 Cash Drawer Interface

The cash drawer interface of the printer uses the RJ-11 connector, which is shown below.

Table 3-1: Cash drawer connector Pin assignments

Pin number Signal Direction

1 Frame GND ---

2 Cash Drawer drive signal OUT

3 Cash Drawer Open/closed signal IN

4 24VDC OUT

5 Cash Drawer drive signal OUT

Figure 3-1 Cash drawer interface

Note: Only when the product is unconnected with outer power supply,

it can achieve zero energy consumption state.

Note: All the technical instructions in this service manual are the laboratorial measurements

which are achieved under national standard store and work environment (room

temperature), the measuring paper accords with the specification in this service

manual.

6 1

EC-PM-80320 Service Manual

- 3 -

6 Cash Drawer Open/closed signal ground ---

Drive current≤24V/1A

3.2.2 Parallel Interface

EC-PM-80320 printer’s parallel interface is compatible with CENIRONICS protocol, supporting

BUSY/ACK handshaking protocol.

The connector is a 36-PIN connector, whose pins are indicated as below.

Table 3-2: Connector Pin Assignments

Pin number Signal Direction Description

1 /STB IN Trigger in low level, read the data in rising edge

2

3

4

5

6

7

8

9

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA8

IN

IN

IN

IN

IN

IN

IN

IN

These signals are respective represent the parallel

data from the first bit to the eight. “1” means high

level, while “0” means low level.

10 /ACK OUT

Acknowledge signal, Low level means that printer is

ready for receiving data.

11 BUSY OUT High level means printer is too busy to receive data

12 PE OUT High level means that paper is out.

13 SEL OUT High level with the pull-up resistor.

32 /ERR OUT Low level means the printer is in error state

14

,

15

,

17

,

18

,

34

,

36

NC --- NC

16

,

19

~

30

,

33 GND --- GND, “0” level in logic

Table 3-1 Cash drawer connector Pin assignments

Figure 3-2 Parallel interface

Note: Please use the cash drawer that meets the specification mentioned above.

Manufacturer will not honor warranty when using unauthorized cash drawer.

Note: ①“IN” means input to the printe

r

, “OUT” means output from printe

r

.

②The signal logical level is TTL level.

EC-PM-80320 Service Manual

- 4 -

Relative signal is shown as Figure 3-3.

3.2.3 USB Interface

USB interface is 2.0 Full-Speed version.

Contact Number Signal Name Typical Wiring Assignment

1 VBUS Red

2 D- White

3 D+ Green

4 GND Black

3.2.4 Serial Interface

EC-PM-80320 printer’s serial interface is compatible with RS-232C protocol, supporting RTS/CTS

and XON/XOFF handshaking protocol. Its connector is a DB-9 type connector and each pin’s

definitions are shown as figure 3-5.

Table 3-3 Pin assignments of the serial interface

Pin Number Signal From Description

2 RXD Host Receive data from Host

3 TXD Printer Sent control code X-ON/X-OFF and data to the Host

8 CTS Printer

“MARK” state means printer is too busy to receive

data; “SPACE” means printer is ready for receiving

data.

5 GND — Signal GND

BUSY

/ACK

DATA

/STB

0.5μS

0.5μS

0.5μS

0.5μS

0.5μS

Figure 3-4 USB interface

Figure 3-3 Timing signal in parallel interface

Figure 3-5 Sequence numbers of Serial connector

2 1

3 4

5 1

9 6

EC-PM-80320 Service Manual

- 5 -

4 DTR Printer Signal terminal is ready

The default settings in serial connecting way are 9600bps, 8 data bits, parity check disabled and 1

stop bit.

EC-PM-80320 printer’s serial interface can be connected with the standard RS-232C connector.

When connecting with a PC, the connecting picture is shown as Figure 3-6. While connecting with

an IBM PC or a compatible PC, you can connect the cable as shown in Figure 3-7.

3.2.5 Ethernet Interface

Ethernet interface of 10/100 Base-T can be connected to 10/100M.

3.2.6 Power Supply Inlet

The EC-PM-80320 printer connects with a 24V±10% and 2.5A AC adapter. The power supply inlet is

Figure 3-6 Connecting with 9-Pin PC

Figure 3-7 Connecting with 25-Pin PC

Figure 3-8 Ethernet interface

Printer 9-Pin connector Host 9-Pin connector

DTR

CTS

GND

TXD

RXD

DSR

DCD

CTS

RTS

GND

RXD

TXD

4

8

5

3

2

6

1

8

7

5

2

3

Printer 9PIN connector Host 25PIN connector

DTR

CTS

GND

TXD

RXD

DSR

DCD

CTS

RTS

GND

RXD

TXD

4

8

5

3

2

6

8

5

4

7

3

2

Note: ①“From” means the source where signal comes out.

②Signal level is EIA level.

EC-PM-80320 Service Manual

- 6 -

shown as Figure 3-9.

Figure 3-9 Power supply inlet

EC-PM-80320 Service Manual

- 7 -

Chapter 4 Printer Working Principle

4.1 Working Principle of Thermal Print Head

EC-PM-80320 has one thermal print head which is made up of 640 fever dot-size components. The

print result is formed through thermal print head dot-matrix heating the thermal paper which is to be

black and matching the paper feed. The printable width of thermal print head is 576 dots. 32-dot null

data are input both in the left-side and right-side when printable data are transmitted.

4.1.1 Matching with thermal head and paper

The transverse section figure of thermal head matching with paper is shown as Figure 4-2.

4mm

0.125 mm

(paper feed pitch)

80 mm (paper width)

+

0

-

1

4mm 72 mm (print width)

Figure 4-1 Printable width and printable area

Figure 4-2 Thermal head matching with thermal paper

32 dots

0

.12

5

mm

3

2

dots

640 dots (80mm)

Max print width

576 dots (72mm)

Pinch roller

Thermal head

Thermal res

Paper sensor distance res about 8mm

Paper sensor

Thermal paper

EC-PM-80320 Service Manual

- 8 -

4.1.2 The structure of thermal head

Figure 4-3 shows electric theory of EC-PM-80320 thermal head.

Table 4-1 explains the relationship between DST module and the start-up fever component.

Thermal head contains several fever components a head-driver which is used to control and drive

the fever components. Along with the CLK signal, Serial data is transmitted from DATAIN to

shift-register synchronously, and to be saved in the latch-register with the LATCH signal cycle

time. Later on, print start-up signal (DST1, 2) will heat the corresponding fever component

according to the data latched in the latch-register. EC-PM-80320 thermal head prints 128 dots per

section according to the print content.

Because print separately can cut down the peak value of electricity caused by reducing the

average of print speed, which is useful to high-frequency print. When the print section is lower

than 128 dots, excrescent voice evokes or disruption can be produced and the print quality will

also be dropped. So please check the dots in advance.

When the dots of high-frequency are lower than 176, the phenomenon of paper glued occurs for

the reason of the surrounding temperature, drive voltage and paper used, which is also need to

check the dots in advance.

DST NO Numbers of fever component Dots/DST

DST1 1 to 384 384

DST2 385 to 640 256

Figure 4-3 Electric structure features of thermal head

Table 4-1 DST module and fever component

EC-PM-80320 Service Manual

- 9 -

4.1.3 Print position of data

The 384 dots from 1 to 384 are transmitted through DATA IN1, and the 256 dots from385 to 640 are

transmitted through DATA IN2.The print position of all data dots are shown as follows:

4.1.4 Electric Character of Thermal Print Head

(Ta=2 5±10℃)

Rating

Items Symbol Condition

Least Standard Most Unit

Resistance RH 630.5 650 669.5 Ω

Drive Voltage Vp 21.6 24.0 26.4 V

Drive Electricity Ip Most drive dots are

352dots at one time. -- 13.0 14.8 A

logical Voltage Vdd 4.75 5.00

.

5.25 V

Logical Electricity Idd FCLK=8MHz,

fDI=1/2fCLK -- -- 64 mA

High VIH CLK, DAT, LATCH, DST 0.8*Vdd -- Vdd V

Input Voltage low VIL CLK, DAT, LATCH, DST 0 -- 02*Vdd V

High IIH DAT VIH=5V -- -- 0.5 uA

DAT Input

Electricity low IIL DAT VIL=0V -- -- -0.5 uA

High IIH DST -- -- 120 uA

DST Input

Electricity low IIL DST -- -- -2.0 uA

High IIH CLK -- -- 2.0 uA

CLK Input

Electricity low IIL CLK -- -- -2.0 uA

High IIH LAT -- -- 2.0 uA

LATCH Input

Electricity low IIL LAT -- -- -2.0 uA

High VDOH Opening estate,

Vdd=4.5V 4.45 -- -- V

DAT Output

Voltage low VDOL -- -- 0.05 uA

Figure 4-4 Print position of all data dots

Paper

DATA IN2 Data Input Arrange 385 386 …...639 640

Prin

t

Su

rf

ace

Paper in Direction

Th

e

o

r

de

r

o

f

p

rin

t

data

Data in

DATA IN1 D

ata

In

put

Arr

a

n

ge

12……

383

38

4

MP-

80

T Prin

te

r M

ec

h

a

ni

s

m

12

3

4

56

……………………………

638

639

6

4

0

EC-PM-80320 Service Manual

- 10 -

CLK Frequency f CLK -- -- 8 MHz

CLK Pulse Width tw CLK Refer to Timing signal

figure 35 -- -- ns

DAT Start-up Time setup DI Refer to Timing signal

figure 30 -- -- ns

DAT Holding Time thold DI Refer to Timing signal

figure 10 -- -- ns

DAT Output Delay td DO Refer to Timing signal

figure -- -- 120 ns

LATCH Pulse Width tw LAT Refer to Timing signal

figure 100 -- -- ns

LATCH Action Time tsetup

LAT

Refer to Timing signal

figure 200 -- -- ns

LATC Holding Time thold LAT Refer to Timing signal

figure 50 -- -- ns

DST Start-up Time tsetup

DST

Refer to Timing signal

figure 300 -- -- ns

Output Delay Time tDo Refer to Timing signal

figure -- -- 5 ns

4.1.5 Timing Signal Figure

4.1.6 Thermal Head Resistance

The resistance of EC-PM-80320 thermal head is about 630.5 to 669.5Ω.

4.1.7 Thermal Head Voltage

There is a drive IC inside the printer, whose drive voltage is from 21.6 to 26.4V and logical voltage

is from 4.75 to 5.25V.

4.2 Sensor

Table4-2 Electric character of Thermal head

Figure 4-5 Timing Signal Figure

EC-PM-80320 Service Manual

- 11 -

4.2.1 Thermal sensor

The thermal sensor whose function is to protect the print head and the user through checking the

print head’s temperature is set on the print head.

4.2.1.1 Checking the excrescent temperature of print head

EC-PM-80320 printer checks the excrescent temperature through soft and hardware. The print

head will stop heating the fever component when the temperature is higher than 80℃(thermal

resistance is lower than 3.80 KΩ). The print head will reheat the fever component when the

component’s checked temperature is lower than 60℃(thermal resistance is higher than 7.45

KΩ).The thermal head’s life will be infected seriously when the fever component is heated and its

temperature is continuously up to 80℃.

4.2.1.2 Thermal Resistance

The value of thermal resistance is determined by formula (1) at the temperature Tx (℃).

Formula (1):

Rx=R

25*EXP {B*(1/(273+Tx)-1/298)}

Rx: The value of thermal resistance at the temperature Tx(℃.

R25: 30KΩ±5% (25℃)

B: 3950±2%

Tx: Working temperature of print head.(℃)

EXP(A):Take natural logarithm e(2.71828)

Temperature.(℃)Value(KΩ)

0 100.99

5 77.85

10 60.57

15 47.53

Figure 4-6 Relationship between value of thermal resistance and temperature

Table of contents

Other EcLine Printer manuals

EcLine

EcLine EC-3150 User manual

EcLine

EcLine EC-PM-80320D User manual

EcLine

EcLine EC-3150 Owner's manual

EcLine

EcLine EC-PM-80250 User manual

EcLine

EcLine EC-3150D User manual

EcLine

EcLine EC-5890X User manual

EcLine

EcLine EC-PM-530B Series User manual

EcLine

EcLine EC-PM-530D Series User manual

EcLine

EcLine EC-80340 User manual

EcLine

EcLine EC-3150D-USB User manual