EcLine EC-3150 User manual

User’s

Manual

EC-3150

ipt

Printers

Proficient

in

Commercial

POS

Rece

:

General

Information

s-sisien

nidad

3

KA

Rui

tele

e

miii

a

3

2.2

Main

EE

3

Printer

Pants

ainia

3

.

Paper

Roll

installation

............ooooooccconcccnnnoconoccccconcconononncononononnnnnnnncnncnnannas

5

Kr

WE

8

5A

Specification

Table-

cosida

9

.

Setting

Up

the

Printer

20.0.0...

ccccsseeenseeeeeseeeeeeseeeeseeeneeseeeeeseeeeesseneaseenes

Gel

UMPACKIN

DEE

6.2

Power

Cable

Connection

6.3

Data

Cable

Connection

E

EIER

le

Power

On

Utilities

oia

a

naa

A

AE

EEN

ESES

EE

1.2

Gap

Sensor’

el

NEE

7.3

Hexadecimal

DUMPING

...ccooooccconcccnooccnonnconnncconnnononnncnn

cnica

on

cnnn

nora

n

rra

nn

r

ran

nr

naar

r

rana

crnnos

E

RE

Me

EE

7.3

Printer

initializatión

cotidiana

.

Indicators

and

Buttons.

8

indicators

cian

dar

he

een

an

eases,

32

BUÍONS

cta

a

s»

Maintenance

conmiccncncnnnnccnnnnnnnn

cnica

incre

RK

e

e

ia

14

Thermal

Barcode

Printers

1.

Introduction

Thanks

for

choosing

our

new

thermal

label

printer

EC-3150.

This

product

provides

reliable

performance

and

high

printing

quality

at

economic

price.

With

powerful

functions

and

easy

operation

design,

EC-3150

is

your

best

choice

of

thermal

label

printer.

A

CAUTION,

NOTE

A

CAUTION:

MUST

COMPLY,

OTHERWISE

HUMAN

GET

HARM

AND

DEVICES

DAMAGE.

A

NOTE:

IMPORTANT

INFOMATION

AND

TIPS

FOR

PRINTERS

OPERATION.

SAFETY

WARNING

PLEASE

READ

THE

BELOW

WARNINGS

AND

NOTES

CAREFULLY

BEFORE

USING

THE

PRINTER.

1.1

SAFETY

WARNING

A

CAUTION:

THE

PRINT

HEAD

IS

A

HEATED

PART,

PLEASE

DO

NOT

TOUCH

THE

PRINT

HEAD

AND

OTHER

PARTS

AROUND

IT

IN

AND

AFTER

THE

PRINTING

PROCESS.

A

CAUTION:

DO

NOT

TOUCH

THE

PRINT

HEAD

AND

PLUG-IN

PARTS

TO

AVOID

PRINT

HEAD

DAMAGE.

A

CAUTION:

DO

NOT

TOUCH

THE

PAPER

TEAR-OFF

KNIFE

TO

AVAOD

GETTING

HARM.

1.2.

Safety

Notice:

*

Don't

touch

the

printer

head

with

anything.

*

Don't

touch

the

cutter

blade.

*

Don't

bend

the

power

cord

excessively

or

place

any

heavy

objects

onto

it.

*

Don't

use

the

printer

when

it

is

out

of

order.

This

can

cause

a

fire

or

and

electrocution.

*

When

connecting

or

disconnecting

the

plug,

always

hold

the

plug

but

not

the

cord.

*

Keep

the

desiccant

out

of

children's

reach.

*

Use

only

approved

accessories

and

do

not

try

to

disassemble,

repair

or

remodel

it

by

yourself.

*

Install

the

printer

on

the

stable

surface.

Choose

firm,

level

surface

where

avoid

vibration.

*

Don't

let

water

or

other

foreign

objects

into

the

printer.

*

Don't

connect

a

telephone

line

into

the

peripheral

drive

connector.

*

We

recommend

that

you

unplug

the

printer

from

the

power

outlet

if

no

use

it

for

a

long

period

.

Thermal

Barcode

Printers

2

.

General

Information

2.1

Introduction

EC-3150

is

designed

for

real-time

and

batch

label

printing,

which

is

applicable

in

the

field

of

transportation,

logistics,

post,

retail

sale,

and

etc.

The

printer

can

be

connected

with

other

equipment

with

various

interface

cards,

such

as

Parallel,

Serial,

USB

and

LAN.

It

supports

different

paper

media,

including

thermal

paper

roll,

thermal

label

paper

and

sticker

paper.

The

printer

provides

direct

thermal

printing

at

selectable

printing

speed

of

2.0,

3.0,

4.0

5.0

and

6.0

inches

per

second.

It

accepts

roll

feed,

die-cut

and

fan-fold

labels.

All

common

barcode

format

and

QRCODE

are

available.

Font

and

bar

codes

can

be

printed

in

4

directions

and

in

1

to

10

times

enlargement

size.

High

performance

and

efficiency

of

label

printing

save

your

time!

2.2

Main

Features

@

Support

thermal

paper

roll,

thermal

label

paper

and

sticker

paper.

O

High

speed

printing,

From2~6inch/s

O

Auto

paper

adjusting

function.

@

Auto

temperature

control

for

durable

printing.

@

Module

design

for

different

application.

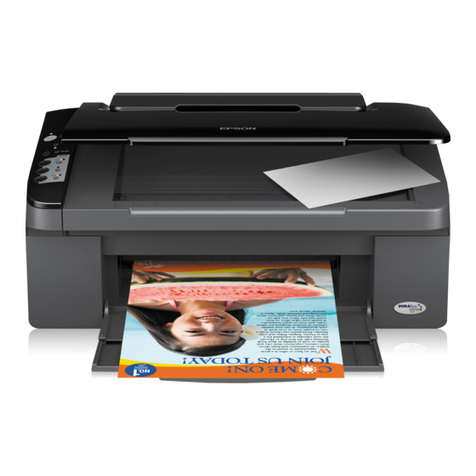

3.

Printer

Parts

(DÉI

1)

1-

Top

Cover

2-

Base

housing

3-

Top

Cover

Open

Button

4-

Backing

Paper

Opening

5-

Label

Opening

6-

Feed

Button

7-

Pause

Button

8-

Error

Indicator

9-

ONLINE/POWER

Indicator

Thermal

Barcode

Printers

Ce

A

11

|

|

15

14

13

12

(PS

2)

10-

Power

Switch

11-

Power

Jack

12-

Cashdrawer

Jack

13-

Parallel

Interface

14-

USB

Interface

15-

Serial

Interface

(DÉI

3)

(DÉI

4)

16-

Print

Head

17-

Paper

Roll

18-Label

Guide

19-

Paper

Presence

Sensor

20-

Peel-off

Roller

Lever

21-

Light

Transmission

Sensor

Light

Source

22-

Paper

Roll

Spindle

23-

Light

Transmission

Sensor

Receiver

24-

Peel-off

Spindle

25-

Peel-off

Roller

26-

Text

sensor

Thermal

Barcode

Printers

4.

Paper

Roll

Installation

(1)

Insert

the

paper

roll

spindle

into

a

paper

roll,

and

place

the

paper

roll

into

the

printer.

Fixing

tab

on

the

paper

roll

spindle

should

be

inside

the

internal

paper

roll

mount.

Adjust

the

paper

roll

spindle

position

with

the

paper

roll

mount.

©

Press

the

top

cover

open

button

and

the

top

cover

lift.

paper

roll

EE

6)

KE

(E

7)

(2)

Insert

the

paper

roll

spindle

into

the

paper

roll,

and

adjust

the

spindle

position

to

make

it

in

the

center

of

the

paper

roll.

Thermal

Barcode

Printers

©

Place

the

paper

roll

into

the

internal

paper

roll

mount.

Please

make

sure

the

paper

printing

side

face

up

as

shown

in

the

below

photo.

x

SC

VY

(DÉI

8)

(DÉI

9)

(2)

Loading

label

for

peel-off

mode

©

Thread

the

label

through

the

label

guides

and

move

the

label

guides

to

adjust

the

fitness

paper

width.

(P

10)

@)

Pull

down

the

peel-off

roller

lever

to

unlock

the

peel-off

roller.

Lever

stands,

the

peel-off

roller

is

locked.

Lever

down,

the

peel-off

roller

is

unlocked.

Thermal

Barcode

Printers

O-

(3)

Split

the

label

paper

and

backing

paper

manually

and

keep

the

label

paper

in

the

label

opening.

Thread

the

backing

paper

in

front

of

the

peel-off

spindle

and

into

the

peel-off

part.

WER

@

Pull

up

the

peel-off

lever

and

the

peel-off

roller

presses

on

the

backing

paper.

Close

the

top

cover.

Lever

down,

the

peel-off

roller

is

unlocked.

Lever

stands,

the

peel-off

roller

is

locked,

and

the

backing

paper

is in

the

peel-off

part.

Q

Thermal

Barcode

Printers

A

Note

If

the

peel-off

function

fails,

please

check:

1.The

printing

media

is

installed

correctly.

2.The

backing

paper

must

be

in

front

of

the

peel-off

spindle.

3.The

peel-off

roller

needs

to

press

on

the

backing

paper.

4.The

peel-off

roller

lever

must

be

stand.

Please

refer

the

pictures

below:

Label

Opening

———,

(PS

16)

Peel-off

Peel-off

Spindle

Spindle

Peel-off

Peel-off

Roller

Roller

Backing

Backing

Paper Paper

(PS

17)

3)

Loading

label

for

normal

print

mode

If

do

not

need

sticker

peel

off

automatically,

load

paper

roll

as

below:

Thermal

Barcode

Printers

5.

Specification

5.1

Specification

Table

Parameter

Printing

method

Direct

Thermal

Resolution

203DPI

Print

width

16-82mm

Print

speed

2~6inch,

Default

5

inch/s

Print

Memory

DRAM:

2M

FLASH:

2M

Wéieen

sensor

Thermal

Sensitive

Resistance

Print

head

Mi

itch

position

sensor

icroswite

Paper

detection

Photoelectricity

sensor

sensor

Interface

Serial+USB+Ethernet

Bar

code

CODE128,

EAN128,

ITF,

CODE39, CODE93,

EAN13,

EAN13+2,

EAN13+5,

EAN8,

EAN8+2,

EAN8+5,

CODABAR,

POSTNET,

UPC-A,

UPCA+2, UPCA+5,

UPC-E,

UPCE+2,

UPC-E+5,

CPOST,

MSI,

MSIC,

PLESSEY,

ITF14,

EAN14

QRCODE

Bar

code

Font

FONT

0

to

FONT

8

Graphics

Internal

font

Simplified

Chinese,

Traditional

Chinese

and

Korean

Enlargement

&

1

to

10

times

enlargement

in

both

directions

rotation

0”

,90”

,

270°

,

360°

rotation

:

Mono

PCX

and

BMP

files

can

be

Graphics

downloaded

into

FLASH

and

DRAM

Media

type

Continuous,

sticker,

fan-fold,

etc

Media

width

16mm

~

82mm

Media

Media

diameter

Max.

85mm

Paper

off

mode

Tear

off

and

Peel

off

Work

5

~

45°C,

20

-

80%RH

Environment

condition

Storage

-40

~

55°C,

<93%RH

(40°C

)

Physical

Diameter

230(D)

x

156(W)

x

147(H)mm

dimension

Weight

1.62kg

The

printer

supports

both

continuous

and

non-continuous

paper.

O

Continuous

type:

Paper

roll

@

Non-continuous

type:

1)

Label

roll;

2)

Sticker

paper.

Thermal

Barcode

Printers

6

.

Setting

Up

the

Printer

6.1

Unpacking

Please

unpack

the

printer

package,

and

inspect

the

parts

according

to

the

packing

list.

If

any

parts

are

missing

or

damaged,

please

contact

the

customer

service

of

your

purchased

reseller

or

distributor.

6.2

Power

Cable

Connection

(

19)

1)

Make

sure

the

printer

power

switch

is

OFF;

2)

The

printer

power

jack

is

a

3-pin

socket

and

for

24V

DC

power

input.

Please

plug

the

DC

cord

connector

into

the

printer's

power

jack

properly.

24V

DC

Á

CAUTION:

E

When

connecting

or

disconnecting

the

plug,

always

hold

the

plug

but

not

the

cord.

E

Avoid

pulling

the

power

cord,

otherwise

any

damages

may

cause

a

fire

or

electrocution.

Avoid

placing

the

power

cord

around

other

over

heated

equipment

to

prevent

power

cord

melting,

which

may

cause

a

fire

or

electrocution.

E

We

recommend

that

you

unplug

the

printer

from

the

power

outlet

if

no

use

it

for

a

long

period

6.3

Data

Cable

Connection

1)

Make

sure

the

printer

power

switch

is

OFF.

2)

Plug

the

data

cable

connector

into

the

printer's

interface

properly.

3)

Plug

the

other

end

of

the

data

cable

with

the

host

computer.

A

caution:

E

Please

do

not

plug

the

data

cable

when

the

printer

power

is

ON.

6.4

Media

Installation

To

install

the

sticker

paper

and

label

roll,

please

refer'4.

Paper

Roll

Installation".

7

~

Power

On

Utilities

There

are

five

power-on

utilities

to

set

up

and

test

printer

hardware.

These

utilities

are

activated

by

pressing

FEED

button

and

PAUSE

button.

7.1,

Self-Test

To

start

the

printer

self-test,

please

follow

the

below

steps,

1.

Turn

off

the

printer

power.

2.

Make

sure

the

paper

roll

is

installed

correctly

and

the

printer

top

cover

is

closed.

3.

Press

the

FEED

button

and

turning

on

the

printer

power

simultaneously.

When

the

self-test

paper

(chart

21)

comes

out,

release

the

FEED

button.

Thermal

Barcode

Printers

Self-test

Page

Sample:

SELFTEST.........cescseeceseeseeeseeneeeeeeeesees

Self-test

Mode

| | | |

HINN

|

|

|

|

|

|

|

|

|

(PS

20)

VERSION:

V1Ocissisisssceassecsseeisscsievssssecesraieceaza

Firmware

version

INTERFACE:

PARALLEL

Interface

type

SPEED:

5..

Print

speed

DENSITY:

7..

Print

darkness

SIZE:

76mm,

60

mm....

Paper

width

GAP:

Omm,

0mm

Gap

distance

CODE

PAGE:

43T

eege

eninin

Code

page

MILAGE

(m)

:

44.

7999999

REFERENCE:

0mm,

0mm

Sg

Reference

offset

DIRECTIONS:

O

‘Oh

sisscsissdicceasiveanin

veces!

Print

direction

SHIFT:

Printed

mileage

(meter)

Label

print

offset

Paper

tear-off

offset

Printer

functions

TEESE

SISSIES

SSSI

ISSO

IOI

III

III

A

SET

PEEL:

OFF.

SET

TEAR:

ON...

SET

HEAD:

ON

...Peel-off

mode

....

Tear-off

mode

...Cover

opening

sensor

SET

PRINTKEY:

OFF...

...Press

&

print

function

SET

REPRINT:

ON

...Auto

reprint

function

SET

KEYT

EFEED)

(ON).

iriiri

Feed

button

function

SET

KEY2

(PAUSE)

:

ON

TAIWANESE

BIG5:

TST24.BF2

button

function

Pause

button

function

Traditional

Chinese

CHINESE

GB2312:

TSs24

BE3

Simplified

Chinese

KOREAN

KSC5601:

ki

Korean

DRAM

FILE:

0

FILE

(S)

FLASH

FILE:

0

FILE

(S)

SECTOR

SIZE:

4

KB

Numbers

of

download

files

PHYSICAL

DRAM:

2048

KBYTES

‘ :

Physical

&

available

AVAILABLE

DRAM:

1024

KBYTES

FREE

memory

space

PHYSICAL

FLASH

2048

KBYTES

AVAILABLE

FLASH

1024

KBYTES

FREE

7.2

Gap

Sensor

Calibration

Gap

sensor

sensitivity

should

be

calibrated

at

the

following

conditions

1.

A

brand

new

printer

2.

Label

stock

changed

3.

Printer

initialization

Thermal

Barcode

Printers

This

function

is

to

reset

the

label

gap

sensor

sensitivity

when

the

printer

power

is

turned

on.

User

needs

to

start

the

calibration

of

the

gap

sensor

sensitivity

after

loading

a different

type

of

label

roll

or

the

printer

is

initialized.

Please

follow

the

steps

below

to

calibrate

the

gap

sensor:

1.

Turn

off

the

printer

power.

2.

Make

sure

the

label

roll

is

installed

correctly

and

the

printer

top

cover

is

closed.

3.

Press

and

hold

on

the

PAUSE

button,

then

turn

on

the

printer

power.

The

printer

will

automatically

calibrate

the

gap

sensor

sensitivity

and

save

the

gap

length

into

DRAM.

After

then

release

the

PAUSE

button.

7.3

Dump

mode

Please

follow

the

steps

below:

1.

Turn

off

the

printer

power.

2.

Make

sure

the

label

roll

is

installed

correctly

and

the

printer

top

cover

is

closed.

3.

Press

and

hold

on

the

PAUSE

button

and

FEED

button,

then

turn

on

the

printer

power.

When

the

POWER

indicator

(blue

light)

and

ERROR

indicator

(red

light)

light

simultaneously,

release

both

buttons.

The

printer

is

changed

to

Dump

Mode

and

print

as

below

chart.

RRA

IKK

e

IR

RK

AIK

IK

IKK IRR

III

*

NOW

IN

DUMP

MODE

*

KKK

ke ke

ek

RK

e k

k

AA

RARA RARA

RARA

SELFTE

QA

53

45

4C

46

54

45

ST

53 54

0D 0A

(BRA

21)

A

Note:

Printer

will

not

print

if

data

is

not

more

than

one

piece

of

label,

and

need

to

press

FEED

button

to

force

the

printer

to

print

it

out.

7.4

Skip

AUTO.BAS

User

can

download

an

auto

execution

file

(AUTO.BAS)

to

flash

memory.

Printer

will

run

the

AUTO.BAS

program

immediately

when

turning

on

printer

power.

The

AUTO.BAS

program

can

be

interrupted

by

the

power-on

utility.

Please

follow

the

steps

below

to

skip

the

AUTO.BAS:

1.

Turn

off

the

printer

power.

2.

Press

and

hold

on

the

PAUSE

button

and

FEED

button,

then

turn

on

the

printer

power.

When

the

POWER

indicator

(blue

light)

dims

and

ERROR

indicator

(red

light)

lights,

release

both

buttons.

The

printer

skips

running

the

AUTO.BAS

program.

And

then

the

POWER

indicator

lights.

Thermal

Barcode

Printers

7.5

Printer

Initialization

Printer

initialization

is

used

to

clear

DRAM

and

restore

printer

settings

to

defaults.

Please

do

the

gap

sensor

sensitivity

calibration

after

the

printer

initialization.

Please

follow

the

steps

below

to

initialize

the

printer:

1.

Turn

off

the

printer

power.

2.

Press

and

hold

on

the

PAUSE

button

and

FEED

button,

then

turn

on

the

printer

power.

When

the

POWER

indicator

(blue

light)

lights

and

ERROR

indicator

(red

light)

dims,

release

both

buttons.

The

printer

DRAM

is

cleared

and

printer

settings

are

restored

to

defaults.

8.

Indicators

and

Buttons

The

printer

has

two

indicators

(POWER

indicator

in

blue

light

and

ERROR

indicator

in

red

light)

and

two

buttons

(PAUSE

and

FEED).

8.1

Indicators:

Item

|

Indicators

Status

Descriptions

1

POWER

indicator

is

ON

ERROR

indicator

is

OFF

Printer

is

powered

on

and

in

normal

print

mode.

2

POWER

indicator

flashes

slowly

(640ms)

ERROR

indicator

is

OFF

Printer

is

paused.

3

POWER

indicator

flashes

fast

(160ms)

ERROR

indicator

is

OFF

Printed

label

is

peel-off

but

not

taken

off.

4

POWER

indicator

is

OFF

ERROR

indicator

flashes

fast

(160ms)

Printer

cover

is

opened.

5

POWER

indicator

is

OFF

ERROR

indicator

flashes

slowly

(640ms)

Paper

shortage

or

gap

sensor

calibrated

error.

6

POWER

indicator

flashes

fast

(160ms)

ERROR

indicator

flashes

fast

(160ms)

Printer

overheated

protection

is

activated.

After

1

minute,

the

printer

will

check

again

the

temperature

of

print

head.

If

the

temperature

gets

right,

printer

resumes

working.

8.2

Buttons

Item|

Functions

Descriptions

1

Feed

Press

the

FEED

button

when

POWER

indicator

is

on

and

ERROR

indicator

is

off.

It

feeds

the

label

to

the

beginning

of

the

next

label

2

Pause

suspended.

Press

the

feed

button

during

printing

and

the

printing

job

is

3

Self-test

1.

Turn

off

the

printer

power.

2.

Make

sure

the

paper

roll

is

installed

correctly

and

the

printer

top

cover

is

closed.

3.

Press

the

FEED

button

and

turning

on the

printer

power

simultaneously.

When

the

self-test

paper

comes

out,

release

the

FEED

button.

Thermal

Barcode

Printers

4

Gap

sensor

calibration

|

1.

Turn

off

the

printer

power.

2.

Make

sure

the

label

roll

is

installed

correctly

and

the

printer

top

cover

is

closed.

3.

Press

and

hold

on the

PAUSE

button,

then

turn

on the

printer

power.

The

printer

will

automatically

calibrate

the

gap

sensor

sensitivity

and

save

the

gap

length

into

DRAM.

After

then

release

the

PAUSE

button.

5

Dump

mode

1.

Turn

off

the

printer

power.

2.

Make

sure

the

label

roll

is

installed

correctly

and

the

printer

top

cover

is

closed.

3.

Press

and

hold

on the

PAUSE

button

and

FEED

button,

then

turn

on the

printer

power.

When

the

POWER

indicator

(blue

light)

and

ERROR

indicator

(red

light)

light

simultaneously,

release

both

buttons.

The

printer

is

changed

to

Dump

Mode.

9.

Maintenance

9.1

Printer

Cleaning

To

ensure

the

printing

quality,

please

proceed

this

maintenance

section

to

keep

your

printer

in

good

conditions

and

extend

its

life.

Please

use

one

of

following

material

to

clean

the

printer:

Cotton

swab

Lint-free

cloth

Vacuum

/

Blower

brush

100%

ethanol

The

cleaning

process

is

described

as

following

Printer

Part

Method

Print

Head

1.

Turn

off

the

printer

power

before

cleaning

the

print

head.

2.

Allow

the

print

head

to

cool

for

at

least

one

minute.

3.

Use

a

cotton

swab

and

100%

ethanol

to

clean

the

print

head

surface.

Platen

Roller

1.

Turn

off

the

printer

power.

2.

Rotate

the

platen

roller

and

use

a

cotton

swab

or

lint-free

cloth

to

wipe

it

thoroughly

with

100%

ethanol.

Exterior

Wipe

it

with

water-dampened

cloth.

Interior

Use

a

vacuum

or

blower

brush

to

clean

the

dust.

Note:

E

Always

turn

off

the

printer

power

before

cleaning

the

printer.

E

Do

not

touch

print

head

by

hand.

Tweezers

is

not

allowed

to

use

for

cleaning,

otherwise

the

print

head,

platen

roller

or

sensor

may

be

damaged.

E

Please

use

100%

ethanol.

DO

NOT

use

medical

alcohol,

gasoline

or

acetone,

which

may

damage

the

print

head

and

platen

roller.

E

Do

the

sensor

calibration

after

cleaning

the

sensors.

E

Only

turn

on

the

printer

and

resume

printing

job

after

the

ethanol

volatilized.

Thermal

Barcode

Printers

Table of contents

Other EcLine Printer manuals

EcLine

EcLine EC-80 Series Owner's manual

EcLine

EcLine EC-PM-80320 User manual

EcLine

EcLine EC-80340 User manual

EcLine

EcLine EC-5890X User manual

EcLine

EcLine EC-3150D-USB User manual

EcLine

EcLine EC-3150 Owner's manual

EcLine

EcLine EC-PM-58110 User manual

EcLine

EcLine EC-PM-80250 User manual

EcLine

EcLine GP-5850 Series User manual

EcLine

EcLine EC-PM-80320D User manual