eclisse E-MOTION User manual

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

EN

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

E-MOTION

Automatic control E-MOTION for a single automatic sliding door Pocket

sliding system ECLISSE UNICO, ECLISSE LUCE UNICO ECLISSE UNILATERALE,

ECLISSE EWOLUTO® SCORREVOLE

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

2

EN

INDEX

0. INTRODUCTION.................................................................................................................................................. 2

1. DETAILS ............................................................................................................................................................... 3

2. TECHNICAL AND SERVICE DATA ................................................................................................................. 6

3. DEMOLITION AND DISPOSAL ...................................................................................................................... 9

4. PART I. INSTALLATION MANUAL ............................................................................................................... 10

4.1 INTRODUCTION ....................................................................................................................................10

4.2 RISK ANALYSIS.......................................................................................................................................10

4.3 PRE-INSTALLATION OPERATIONS ..........................................................................................................11

4.4 INSTALLATION PHASES..........................................................................................................................11

5. PART II. USER AND MAINTENANCE MANUAL ..................................................................................... 31

5.1 DETAILS .................................................................................................................................................31

5.2 RISK ANALYSIS.......................................................................................................................................31

5.3 USE INSTRUCTIONS ...............................................................................................................................33

5.4 MAINTENANCE......................................................................................................................................35

5.5 PROBLEMS AND SOLUTIONS.................................................................................................................35

5.6 FINAL CHECK AND TUNING OF E-MOTION CONTROL ...........................................................................37

5.7 DECLARATION OF CONFORMITY OF INSTALLATION..............................................................................38

5.8 DECLARATION OF CONFORMITY...........................................................................................................39

0. INTRODUCTION

Dear client,

We would like to thank you for trusting ECLISSE, which you have shown in purchasing the innovative

automatic control E-MOTION, which can be installed in our pocket systems ECLISSE UNICO, ECLISSE LUCE

UNICO, ECLISSE UNILATERALE, ECLISSE EWOLUTO® SCORREVOLE.

ECLISSE always offers products designed and developed according to very high production models and

requirements, thus ensuring high quality performance and ease of use and installation.

This manual contains important information, needed for a correct and safe installation of the automatic

control. We would like you to read the operating and use instruction carefully before installing and using

E-MOTION automatic control.

Kind regards,

ECLISSE S.R.L.

Luigi De Faveri

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

3

EN

1. DETAILS

This manual applies to:

installation

use and maintenance

of the E-MOTION automatic control.

The installation part is restricted to qualified technical personnel only.

1. 1 GENERAL WARNINGS

Before installing, using or doing the maintenance of E-MOTION automatic control, you must read

and understand this manual thoroughly.

This manual is part of the automatic control and should be kept by the customer or user for future

reference by the customer or by the installer or maintainer.

This manual aims to provide all the necessary instructions to ensure proper installation and maintenance.

ECLISSE S.r.l. reserves the right to modify and improve the manual and the described product at any time

without notice.

The data presented in this document have been prepared and checked with great care, but ECLISSE

S.r.l. declines all responsibility for any inaccuracies due to errors or omissions in printing or transcription.

The E-MOTION automatic control installed in a single leaf subframe constitutes a machine as described in

the Machinery Directive 2006/42/EC.

The full analysis of the essential health and safety requirements, as set out in the Annex to the Machinery

Directive, must be considered valid only if:

The procedures described in the installation manual have been followed correctly.

The type of installation corresponds to that shown in the manual.

Any procedure or action taken in the operation, installation, operation, maintenance and use of the

machine not intended and described in this manual will not be covered by this analysis.

In this way ECLISSE S.r.l. is not responsible and the installer will assume full responsibility for the

fulfilment of the essential health and safety requirements.

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

4

EN

1. 2 WARNINGS FOR CORRECT INSTALLATION OF THE AUTOMATION:

Verify that the ductwork for the passage of the conductors is carried out correctly; if it is possible

to prepare the wiring.

Ensure that the automation, the floor, the door guide and the surface of the underbody are level and

squared with the counter-frame.

Install the new track with the motorisation. Ensure that there are no obstacles and that the track is

correctly inserted.

Install the motorisation, taking care not to pinch cables.

To fit the track, remove the metal protection, “remove the plastic protection only if this is indispensable”

(this should always be refitted to prevent the circuits being accessible).

It is preferable to conduct the final test of the travel without the door panel, check the actual travel of the

carriage (if possible, test with a cardboard or light plywood template that simulates the size of the door

panel – not included).

Assemble the door panel, strictly complying with the instructions.

Once the door panel has been adjusted, be sure to tighten the carriage-bracket screws.

IMPORTANT: the door panel must always be positioned at least 10 mm from the floor.

The automation should be installed in such a way so that it can be inspected: jambs, frames, fixtures etc.

must be removable;

- only some adjustments can be carried with the control installed

Attention:

- To carry out any repairs, the track must be removed.

Check that all accessories (door guide, jambs, frames, brushes, gaskets, brackets etc.) do not cause

friction.

Attention: in the maximum opening position, the door panel can stay at a gap of up to 50 mm with

respect to the jambs due to the motor magnet spacing.

Ensure that the door is not subject to lateral compressions/depressions (due to blowers, suction units,

etc.); this could activate the obstacle interception device and be read as an error.

Check the automation with the panel and accessories assembled. The end user is not able to perceive the

force that is actually applied to move the door.

If necessary, carry out adjustments, always paying attention to the position of the trimmers or dipswitches

and any consequent variations for proper operation of the device.

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

5

EN

1. 3 GENERAL RULES

The E-MOTION automatic control has been designed exclusively for pocket sliding systems

automation used by ECLISSE pocket sliding systems for single door.

It cannot be used for aims that are different from the ones described in this manual.

The E-MOTION automatic control has been designed and developed in compliance with all requirements

of EN “Power operated pedestrian doorsets -Safety in use-”.

E-MOTION has been designed to work correctly with a maximum weight of 80 kg per door.

ECLISSE S.r.l. declines any responsibility for any damage to people, animals or things.

Any alteration or substitution of parts or components of the guide, and the use of accessories or materials

that are not original, almost raises the risk so the producer denies any civil or penal liability.

It is forbidden to remove and/or change the directions and the signposting or accessories placed on the

automatic control system by the producer.

It is forbidden to stay in the sliding zone of the doors or operate near the moving mechanic parts.

1. 4 WARRANTIES

The warranty is void if the use of the E-MOTION automatic control does not comply with the

instructions and standards described in this manual and if components, accessories, spare parts

and control systems not supplied by ECLISSE are used.

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

6

EN

2. TECHNICAL AND SERVICE DATA

2. 1 TECHNICAL DATA E-MOTION - MECHANICS

2. 2 TECHNICAL DATA E-MOTION CONTROL - ELECTRICAL CHARACTERISTICS

DIMENSIONS

Width 52 mm

Height 58 mm

ELECTRICAL CHARACTERISTICS

Input Voltage: 230 V AC – 50/60 Hz

Current: 1 A

Fuse protection: 2,5 A

Power cable 3x1,0 mm2Length: 2 m

Power / Consumption Medium: 80 W

Peak: 120 W

Stand-By: 15 W

Electric motor Model: Linear PMSM Motor - Permanent magnet synchronous linear motor with Iron core.

Nº Poles: 4 Pitch Pole 25 mm

Nº Phases: 3

Voltage: 24 V DC – 5_A

Magnet: Neodymium 35H

Force <80 N

Control Type: Microprocessor type DSP for vectorial control of movement.

Course self-regulating.

Door weight self-regulating.

Accessories Voltage: 24 V DC

Current: 1 A

Functioning temperature Minimum: 5° C - Maximum: 60° C

DOOR WEIGHT

Minimum 0 kg

Maximum 80 kg

OTHER DATA

Noise

< 50 db

Use

Continuous

N° Cycles

> 1.000.000

ADJUSTMENT

Re-opening sensitivity

Opening speed

Door opened time

0 - 20 sec.

PARAMETER E-MOTION CONTROL

Passage Size

(mm)

Control length

(mm)

Track Lenght

(mm)

Opening

Speed

Closing

Speed

Guide Weight

(kg)

700 1420 735

Variable adjustment

0,20 - 0,70 m/sec.

Autoregulation complies with

EN 16363 “Low Energy” (**)

8,0

750 1570 835 8,5

800 1620 835 9,0

850 1770 935 9,5

900 1820 935 10,0

950 1970 1035 10,5

1000 2020 1035 11,0

1050 2170 1135 11,5

1100 2220 1135 12,0

1150 2370 1235 12,5

1200 2420 1235 13,0

1250 2570 1335 13,5

1300 2620 1335 14,0

DOOR WEIGHT (kg) 10 20 30 40 50 60 70 80

(**) Closing Speed (m/sec.) 0,57 0,40 0,33 0,28 0,25 0,23 0,21 0,20

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

7

EN

1ON/OFF Button

2 Power supply input 220V-50 Hz

3Accessories circuit connection

4RF receiver connection

5Domotics connection (reserved)

6External radar and lock connection

7Internal radar and buttons

connection

8Green led (internal radar signal

active)

9Orange led

(button signal active)

10 Green led

(external radar signal active)

11 Red led (lock signal active)

12 Accessories circuit connection

13 PC connection (reserved)

14 Microprocessor

15 Motor/ receiver connection

16 Motor/ receiver connection

17 Protection fuse 2 A

18 Operation

19 Regulation of opening speed

20 Regulation of closing sensitivity force

21 Regulation of door opened time

22 Dip switches (door Weight)

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

8

EN

POWER SUPPLY INPUT

EARTH

NEUTER

PHASE

EXTERNAL RADAR

OPTEX OA-203

INTERNAL RADAR

OPTEX OA-203

Green-Yellow

Red

White

White

Yellow

Grey

Grey

Brown

Blue

White

Yellow

Grey

Grey

Lock

Internal

button

External

button

Blue

Brown

EXTERNAL RADAR AND LOCK CONNECTION

INTERNAL RADAR AND BUTTONS CONNECTION

ELECTRICAL CHARACTERISTICS

POWER SUPPLY

Voltage 230 V AC

Power 120 W

Current 0,75 A

Frequency 50/60 Hz

NORMATIVA

2006/42/CE

2004/108/CE

2006/95/CE

EN 60335

6

7

2

LINEAR MOTOR

Type: “PMSM” Permanent magnet synchronous motor

Iron core. 3 Phases - 4 Poles - 24 V

Magnets: Neodymium 35 H Pitch Pole 25 mm

Consumption: Peak 120 W Force: 80 N

Medium 80 W IP: IP 22

Stand-By 15 W Class: I

ACCESSORIES

Power: 24 W Power supply 24 V DC

Consumption 1 A

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

9

EN

3. DEMOLITION AND DISPOSAL

PACKAGING DISPOSAL

Package components can be assimilated to municipal waste and they can be disposed of without any

difficulty, simply doing the waste separation for recycling.

Before proceeding we advise you to verify the specific directives, in the installation place.

AVOID RELEASE TO THE ENVIROMENT!

PRODUCT DISPOSAL

Our products are made of different material. Most of them (aluminium, plastic, iron, electric cables) can

be assimilated to municipal waste. They can be recycled by the waste separation and disposal in the

authorized centres.

Other components (printed circuit board, radio control’s batteries etc.) could contain pollutants.

These one should be removed and given to companies entitled to recovery and disposal of waste.

Before proceeding we advise you to verify the specific directives, in the disposal place.

AVOID RELEASE TO THE ENVIROMENT!

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

10

EN

4. PART I. INSTALLATION MANUAL

4. 1 INTRODUCTION

This part of the manual is dedicated to qualified installers only.

Before installing the E-MOTION automatic control, you must read and fully understand this part of the

manual.

The installation of the E-MOTION automatic control must be performed by competent technical staff in

possession of technical tools required by the law in the place of installation.

4. 2 RISK ANALYSIS

Below is the table with details of the different phases of installation, risks and safety measures to be

taken:

N° Phase Risks Protection measures

0Track disassembly Cut - Crushing Gloves

1EMOTION automatic control description Cut - Crushing Gloves

2Cover disassembly Cut - Crushing Gloves

3Control installation in the pocket system Cut - Crushing Gloves

4Electronic components Cut - Crushing Gloves

5Accessories testing and connection Cut - Crushing Gloves

6Functioning test Cut - Crushing Gloves

7Cover assembly Cut - Crushing Gloves

8.a Wooden door installation Cut - Crushing Gloves - Safety shoes

8.b Glass doors installation Cut - Crushing Gloves - Safety shoes

9Commissioning ON Cut - Crushing Gloves

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

11

EN

4. 3 PRE-INSTALLATION OPERATIONS

Read the manual before installation: it is important for your safety to respect the instructions in this

document. Incorrect installation can cause serious injury.

Make sure the installation area is closed to unauthorized persons.

During installation and maintenance, use accident prevention equipment.

Make sure that the package includes all the necessary components for the guide assembly and that they

are in good condition. Prepare all the required tools for assembly.

During assembly and connection make sure to operate without tension.

4. 4 INSTALLATION PHASES

Usually these are the installation phases:

0. TRACK DISASSEMBLY ......................................................................................................................12

1. E-MOTION AUTOMATIC CONTROL DESCRIPTION ..................................................................14

2. COVER DISASSEMBLY......................................................................................................................16

3. CONTROL INSTALLATION IN THE POCKET SYSTEM................................................................17

4. ELECTRONIC COMPONENTS ........................................................................................................19

5. ACCESSORIES TEST AND CONNECTION....................................................................................20

6. FUNCTIONING TEST.........................................................................................................................22

7. COVER ASSEMBLY ............................................................................................................................23

8.a WOODEN DOOR INSTALLATION .................................................................................................24

8.b GLASS DOOR INSTALLATION ........................................................................................................27

9. COMMISSIONING ON .....................................................................................................................30

Here follow the visual instructions of each and every phase.

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

12

EN

0. TRACK DISASSEMBLY

1

2

3

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

13

EN

0. TRACK DISASSEMBLY

4

5

If needed

OK

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

14

EN

1. E-MOTION AUTOMATIC CONTROL DESCRIPTION

1Principal profile

2Hung-door track

3Stop – closing

4Stop – opening

5Linear motor 225x18x26 4P

6Control electronic

7Power electronic

8Accessories electronic

9Permanent magnets’ array

10 Lower cover

11a

Wooden door adjustable suspension

11b Glass door adjustable suspension

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

15

EN

ELECTRICAL SPECIFICATIONS - see pag. 8

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

16

EN

2. COVER DISASSEMBLY

Do not disassemble

1

3

2

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

17

EN

1

2

3

1a 1b

2a

3a

2b

3b

3. CONTROL INSTALLATION IN THE POCKET SYSTEM

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

18

EN

3. CONTROL INSTALLATION IN THE POCKET SYSTEM

4

5

Power supply

Power supply

Buttons

Buttons

OFF

230 V AC

EARTH

NEUTER

PHASE

Green-Yellow

Blue

Brown

Brown

Blue

230 V AC

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

19

EN

4. ELECTRONIC COMPONENTS

1a 31b 42

Operating

modes

Rugulation of sensitivity force

Obstacles detection

Door

weight

Door open time

adjustment

Operating

modes

1a

Switch

1

Switch

2

Operating

modes To confirm the change

OFF OFF Customer Mode Automatic

ON ON Cyclic Automatic

OFF OFF Without Remote Control Automatic

OFF ON With Remote Control Automatic

Opening

speed

adjustment

1b

Switch

1

Switch

2

Opening speed

adjustment To confirm the change in sensitivity

OFF OFF Average speed ON/OFF selector switch

ON OFF High Speed ON/OFF selector switch

OFF ON Low Speed or "Low Energy" ON/OFF selector switch

ON ON ON/OFF selector switch

Rugulation of

sensitivity force

Obstacles

detection

2

Switch

1

Switch

2

Rugulation of sensitivity force

Obstacles detection To confirm the change in sensitivity

OFF OFF High ON/OFF selector switch

ON OFF Medium high ON/OFF selector switch

OFF ON Medium low ON/OFF selector switch

ON ON Low ON/OFF selector switch

Door open time

adjustment

3

Switch

1

Switch

2Door open time adjustment To confirm the change in sensitivity

OFF OFF 2,5 Seconds ON/OFF selector switch

ON OFF 5 Seconds ON/OFF selector switch

OFF ON 10 Seconds ON/OFF selector switch

ON ON 20 Seconds ON/OFF selector switch

Inserting the door

weight

4

Switch

1

Switch

2Inserting the door weight To confirm weight

OFF OFF 0-20 kg ON/OFF selector switch

ON OFF 20-40 kg ON/OFF selector switch

OFF ON 40-60 kg ON/OFF selector switch

ON ON 60-80 kg ON/OFF selector switch

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

E-MOTION AUTOMATIC CONTROL

EC_MAN_IST_022

Rev. 5

20

EN

5. ACCESSORIES TEST AND CONNECTION

1

OFF

230 V AC

White

Yellow

Grey

Grey

Internal Radar

Other manuals for E-MOTION

1

Table of contents

Popular Controllers manuals by other brands

ZPA Pecky, a.s.

ZPA Pecky, a.s. Modact MOKP Ex Series Assembly and operation

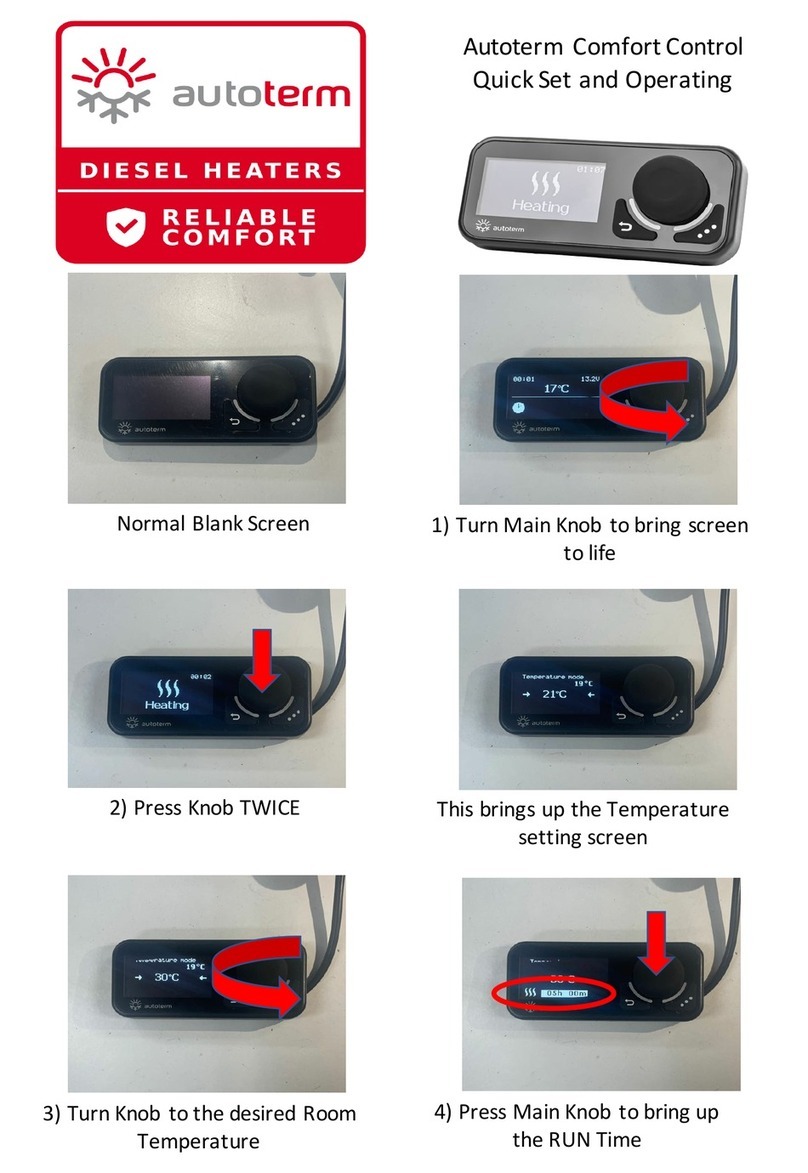

AUTOTERM

AUTOTERM Comfort Control PU-CC quick start guide

Carrier

Carrier TruVu UC561 Installation and startup guide

Alicat Scientific

Alicat Scientific BC Series operating manual

POLA

POLA HP36 Handbook

Toptech

Toptech MultiLoad II DIV-2 installation guide

Power Electronics

Power Electronics SE-4E15 user manual

SATA

SATA air carbon regulator operating instructions

Hoffman Controls

Hoffman Controls 816-10DH Installation & operating instructions

Danfoss

Danfoss MCA 123 POWERLINK operating instructions

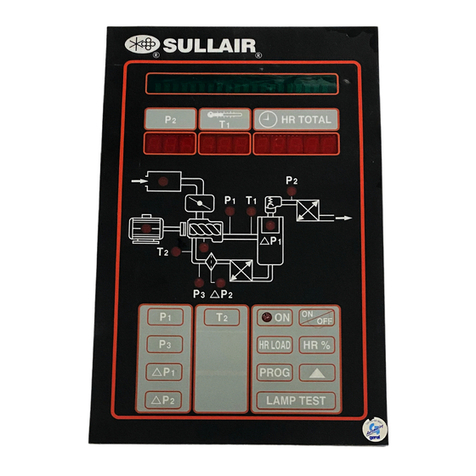

Sullair

Sullair SUPERVISOR CONTROLLER Operator's manual

Bettis

Bettis TEC2 quick start guide