1

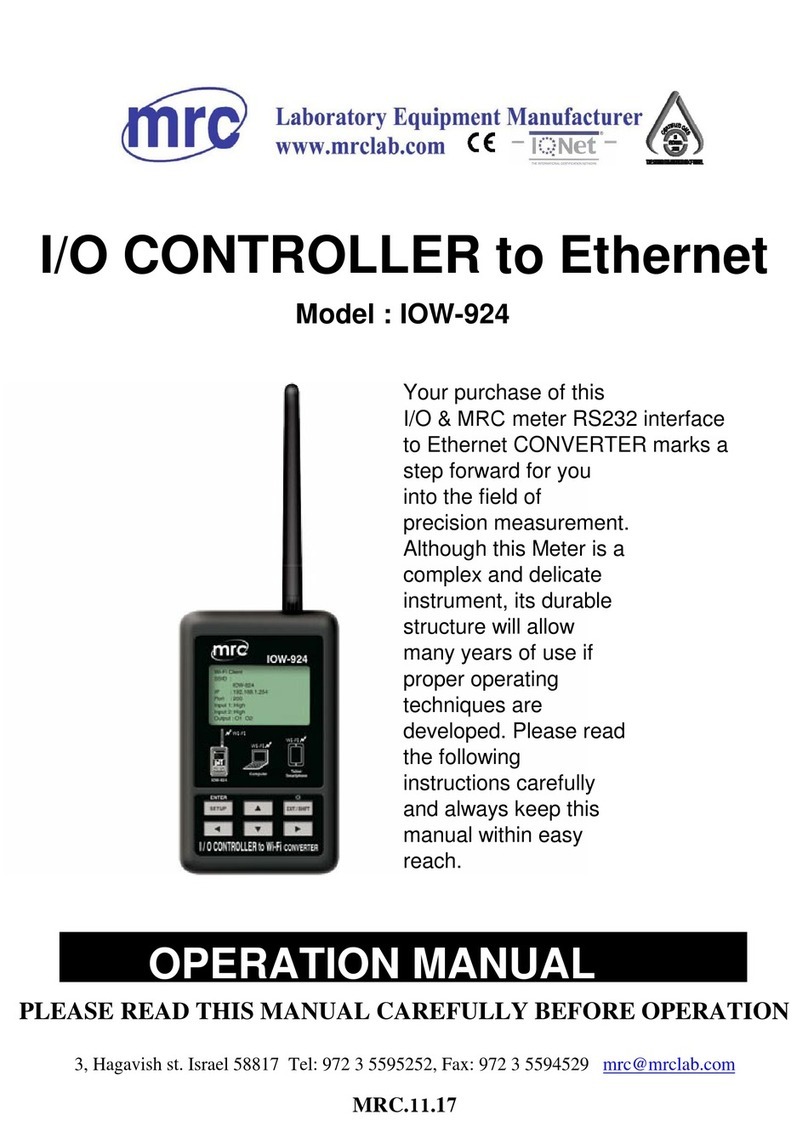

1. Safety Precautions

•Ensure that the label indicated the correct voltage before connecting the device to

power supply.

•Ensure good working environment free of explosive, hazardous and inflammable

substances. This product is intended for indoor use only.

•The instrument should be placed in a low humidity, well ventilated, less dust, water

free environment without the perpendicular incidence of sunshine and intense light

source. The environment should be free of corrosive gases or strong magnetic

interference, and far away from heating gas, fire and all other heat sources.

•Ensure that the instrument and its accessories are free of any potential defects.

•Ensure that the instrument is secured tightly and standard accessories supplied by

the manufacturers only should be used.

•Wear proper protective equipment while operating this instrument to prevent the

potential dangerous circumstances with the risk of splashing/ release of toxic or

inflammable gases.

•The power cable must be kept away from the surface of heating module rather than

shield the device.

•Please prevent water from splashing on the electrical elements of the product.

•The power supply is fully disconnected only if the power plug is pulled out.

•Before assembly, disassembly, cleaning or maintenance, the main power plug must

be pulled out.

•Ensure the vacuum pump‟s power is not more than the maximum power output by

the instrument.

Caution!

•Please carefully read the manual before operating the product, and

observe the specifications on safe operation.

•Ensure that only trained staff operates this product.

Ground protection for safety!

•Ensure that the power socket has been properly grounded before

operating the product