ECO SISTEMS Water-pro Compact S-90 12V User manual

eco-sistems

ECO-SISTEMS WATERMAKERS S.L.

Owner’s Manual

WATER-PRO SERIES

COMPACT S-60/90 12/24V DC

Version: 150720

Referencia: 45200012

Eco-Sistems Watermakers, S.L.

Oficina: C/ Horta nº 22 – Almacén: C/ Gran Vía Puig i Cadafalch nº 233

(08203)- Sabadell – Barcelona (Spain)

Tel: 34.93.710.89.50 – Fax: 34.93.712.23.55

E-mail: info@eco-sistems.com

Web: www.eco-sistems.com

WATER-PRO COMPACT S-60 12/24V DC

COMPACT-ASSY

S-60 12/24 V DC

FEEDING-ASSY

S-60 12/24 V DC

LOW PRESSURE

FILTER SET

FILTER WRENCH

HOSE 1/2 BLUE

HOSE CLEAR BRAID

O

20

TUBE 8X6 BLUE

8 -HOSE CLAMP 12/22

2- HOSE CLAMP 16/27

CONNECTOR

O

8TUBE X

1/4 BSP PLASTIC

2-ADAPTER 1/2 BSP

X 1/2 BARB PVC

ADAPTER 3/4 BSP X

3/4 BARB PVC

POWER BOX

WATER-PRO COMPACT S-90 12/24V DC

COMPACT-ASSY

S-90 12/24 V DC

FEEDING-ASSY

S-90 12/24 V DC

LOW PRESSURE

FILTER SET

FILTER WRENCH

HOSE 1/2 BLUE

HOSE CLEAR BRAID O20

TUBE 8X6 BLUE

8 -HOSE CLAMP 12/22

2- HOSE CLAMP 16/27

CONNECTOR O8TUBE X

1/4 BSP PLASTIC

2-ADAPTER 1/2 BSP

X 1/2 BARB PVC

ADAPTER 3/4 BSP X

3/4 BARB PVC

POWER BOX

TABLE OF CONTENTS

CHAPTER I:

•Installation, operation and maintenance.

-System components.

-I.1. Installation.

-I.2. Hydraulic connections.

-I.3. Electronic control panel.

-Remote control panel.(optional)

-I.4. Electrical connection.

-Adjust and alarms.

-I.5. First start up.

-I.6. Start-up.

-I.7. Turning the unit off.

-I.8. Maintenance of the unit.

CHAPTER II:

•Storage and Cleaning.

-II.1. Storage precautions.

-II.2. Shutting down for short periods of time.

-II.3. Shutting down for long periods of time.

CHAPTER III:

•Parts listing and exploded view of the ST-15/CERAMIC

Eco-sistems pump.

-ST-15/CERAMIC Eco-Sistems pump elements

CHAPTER IV:

•

Filter and Membrane Replacement.

-IV.1. Changing the filters.

-IV.2. Membrane replacement.

CHAPTER V:

•Warranty and identification sheet.

•Dealers and After-Sale Service List.

CHAPTER I

INTALLATION, OPERATION

AND MAINTENANCE

WATER-PRO COMPACT S-60/90 12/24 V DC

1

23

4

9

8

5

10

11

12

13

15

16

17

22

19

21

+

-

12/24 V DC

O20

O20

O15

O15

O15

O8

18

14

7

6

23 ST

OP

LAVA

DO

FRESH FLUSH

eco - siste ms

STOP

PRODUCCION

PRODUCTION LAVADO

FRESH FLUSH

20

O20

Chapter I Page 1

Chapter I Page 2

SYSTEM COMPONENTS

1. - Seacock valve to uptake the sea water.

2. - Check Valve.

3. - Protection pre-filter (Washable mesh filter).

4. - Low pressure booster pump 12/24V DC motor.

5. - Low Pressure Gauge.

6. - 5 microns filter contraîner.

7. - Expansion Vessel.

8. - ST-15/CERAMIC High pressure pump with energy saving system.

9. - High Pressure Gauge.

10. - R.O. Membranes and vessels.

11. - (OPTIONAL) -Three ways valve for the produced water.

12. - Produced Water Flow meter.

13. - Anti Cl carbon filter.

14. - Produced water output to the tank.

15. - Brine discharge thru-hull.

16. - Switch.

17. - Direct produced water output. (CONTROL)

18. - Boat fresh water input

19. - FLUSHING Solenoid Valve.

20. - Power Box.

21. - DIGITAL Control Panel.

22. - (OPTIONAL) Three way valve for wintering.

23. - (OPTIONAL) Remote Control Panel.

Chapter I Page 3

I.1. Installation.

(See diagram Chapter I Pages 1 and 2)

To install the unit the following inlet and outlet connections are needed:

•Sea cock valve (1) with a minimum nominal pitch of 3/4” Gas for sea water

intake, which should be installed as low as possible at the bottom of the hull in

order to prevent possible cavitation problems due to air suction.

•½” Gas female thread through-hull fitting (15) to connect the internal blue tube

Ø15 that drains rejected the water into the sea.

•¼” Gas female thread inlet in the main tank for the intake of fresh water produced

•Ball valve installed in the water line pressure out of the boat with female

R ½ "Gas for water intake (18) Wash System.

•Options: Three way valve (22) for winter storage and valve (11) for a direct take

of the produced fresh water.

WARNING

It is very important to place the feeding assembly below the waterline and to check

that at least a minimum flow of 15 litres/ minute is supplied to the system to prevent

the pump from cavitation due to fall in pressure.

The rest of the components belonging to the unit can be installed at a higher level,

provided that they do not exceed a distance of 4 or 5 metres.

The membranes are normally delivered assembled inside their containers. In case

they haven’t been factory-installed, look in chapter IV for the assembling

instructions.

After all components have been placed and fixed, the unit will be ready for hydraulic and

electrical connection, which will be covered in the following sections.

Chapter I Page 4

I.2.Hydraulic connections.

The connection between the various components will be made with the tubes supplied

with the unit, as shown in the diagram in Chapter I Pages 1 and 2.

•The two suction connections between the sea cock valve (1) and the check valve

(2) will be made using the transparent Ø20 tube.

The remaining seawater circuit sections will be made with the blue tube Ø15. This is a

special tube developed to work with pressures up to 20 bar, and it is not

recommended to replace it with a different one (even with similar characteristics)

To make the connections proceed as indicated below:

•Elbow inlet (18) Vessel pressure circuit

•Pump outlet (4) and 5-micron filter inlet (6).

•Pre-filter outlet (6) and the inlet elbow (E) in the high-pressure pump (8).

•Outlet elbow (S) in the high-pressure pump (8) and the brine outlet (15).

The referred elbows marked as E and S are located in the back / lower part of the high

pressure pump (8)

Connect the elbow located in the lower part of the flow meter (12) to the to the main tank

adaptor using the blue Ø 8 polyamide tube (this adaptor is delivered with a plastic cap,

remove it before the installation).

As an optional,

a three way valve (11) can be installed in the line of produced water to

have a direct fresh water outlet. It can be very useful having a direct fresh water outlet,

without passing trough the main tank, (this valve must be one that never closes the water

flow).

As a general rule, the tube sections should be as short and as straight as possible to

avoid unnecessary pressure drops, and the connections should be completely

airtight so that air does not enter the circuit during the water absorption process.

STOP

PRODUCCION

PRODUCTION

LAVADO

FRESH FLUSH

eco- sistems

WATERMAKERS, S.L.

Chapter I Page 5

I.3. Electronic Control Panel

The electronic Control Panel (21), shown in the diagram

of Page 1 Chapter I consists of two push buttons that

allow for an increase or decrease in the Motor pump’s

feeding speed (4) and three buttons equipped with light

indicators that allow for a complete control of the

system.

•The first button, from left to right, is marked with the word

PRODUCCION/PRODUCTION and it is equipped with a green LED light. It

starts the system.

•The central button is marked with the word STOP and it is equipped with a red

LED light. It stops the system.

•The third button, from left to right, is marked with the word LAVADO/FRESH

FLUSH and it is equipped with a blue LED light. It starts the timed Fresh Water

Flush cycle.

For a proper operation, the system doesn´t allow the change from the Production

function to the Flush function without pressing the STOP button. The flushing time

is programmed for a period of 2 minutes where the booster (feeding) pump is

turning at the 60% of the normal production r.p.m.’s.

Remote Control Panel. (Optional)

The remote control panel (23) shown in the Diagram on

Page 1 Chapter I consists of three buttons with the

corresponding 3 light indicator. It allows for a total

control of the system from a remote location on the

boat. The connection cable length is 10 meters.

• Pushing the button marked with the word PRODUCTION and a green LED makes the

system start to produce fresh water.

• Pushing the button with the word STOP will stop the system.

• The button marked with the word WASH and a blue LED starts the automated fresh

water flush.

WATER-PRO COMPACT S-60/90 12/24V DC

MOTOR

12/24

V DC

-+

Chapter I Page 6

12/24 V DC

19

4

16

4

4 3 2 1

3

2

1

+ POWER

- POWER

+ PUMP

- PUMP

ALARMS

BACK SIDE

ELECTROVALVE

12 ó 24V DC ACCORDING

THE POWER SUPPLY

PRESSURE

SWICH N/C

(REGULATED 18 BAR)

CONNECTOR (red)

RJ-45 (ETHERNET)

S-60-C

25A. (24 V DC)

50A. (12 V DC)

S-90-C

40A. (24 V DC)

70A. (12 V DC)

BREAKER

21

23

REMOTE CONTROL PANEL CONTROL PANEL

REMOTO ETAPA

POTENCIA

GREEN

RED

BRN

WHITE

Chapter I Page 7

I.4. Electrical Connection.

The system comes equipped with an electrical motor for the low-pressure pump 12/24V

DC at 2000 rpm. It must be connected using the moisture shielded cable with a cross-

section appropriate for the distance between the batteries and the motor. The

recommended cables are the following ones:

Model / Power nominal motor 60 Litters/550watios 90 Litters/750watios

Batteries / Power Box Dist. 12 v DC 24 v DC 12 v DC 24 v DC

From 0 to 5 meters 25 mm

2

10 mm

2

35 mm

2

16 mm

2

From 6 to 12 meters 50 mm

2

16 mm

2

70 mm

2

25 mm

2

Circuit Breaker 50 A 25A 70 A 40A

These sections are appropriate to prevent voltage losses greater than 1.6% of the rated

voltage (0.2 V in 12 V DC).

A distance of more than 3 meters between the power box and the electric motor in the

low pressure pump must never be exceeded. For longer distances than the ones provided

in this table, please contact the manufacturer.

•Connect the two wires from the breaker with the corresponding power box

terminals marked as power supply (20) as indicated in scheme of (Chapter I Page

6).

•Connect the motor-pump terminals (4) with the ones marked as “Pump” in the

power box.

•Also a 4-wire 3 meter long cable is supplied with the motor, it comes connected to

the electro-valve and the pressure switch by one of its ends, this end of the cable

must be passed through the seals of the box and connected to their respective

terminals.

•Connect the control panel (21) and the head (20), using the supplied 6 meter cable

with red connectors RJ-45 (Ethernet) at both ends, taking care to connect one of

them to the plug marked as POWER STAGE. The remote control panel (23)

OPTIONAL must be connected to the plug marked as REMOTE using the 10

meter cable

•Make sure the pump’s direction of rotation is the correct one, marked by the water

inlet and the outlet, if it isn’t, reverse the polarity on the motor

connection.(Chapter I Page 6 )

As a general rule, the electric grid circuit should be properly protected, taking care

to oversize the connection cables to avoid voltage drops and unnecessary power

consumption.

Chapter I Page 8

ELECTRONIC 12/24 V DC CONTROL PANEL ADJUSTS

(Recommended for experts only)

FLUSH WATER FLOW ADJUST

•Turn on the system while pressing the LAVADO/FRESH FLUSH button, the blue

LED on the control unit will turn on.

•After this, each key press of the ▲button will increase the pump’s speed in one

unit, and, every key press of the ▼button will decrease it in the same way.

•Once reached the wanted flush water flow press the Stop button, the red led will

get on, after releasing it the led will flash, this means the water flow has been

adjusted.

•Switch off the system and switch it on again to return to its normal functioning

HOUR METER READING

•Switch the system on while pressing the Stop button in the control panel.

•Both green and red LEDS will flash a few times.

•Each green flash is equivalent to 400 working hours and each red flash is

equivalent to 25 working hours. The total reading of working hours of the system

is given by the sum of all green and red flashes.

•The maximum count will be 8 green flashes and 3 red flashes, which makes a

3275 hour reading, from that moment the hour meter gets self-restarted, starting a

new reading cycle.

•The green led will flash 5 times when the system reaches 2.000 hours working,

which means the pump’s maintenance must be performed.

•Switch off the system and switch it on again to return it to it’s normal functioning.

12V DC FALL DOWN ALARM.

•The system will stop if the power sources voltage drops below 10 V DC, if this

happens the RED led will start blinking at a 3 times per second rate.

Chapter I Page

9

ALARMS AND PROTECTION OF THE 12/24 V DC POWER BOX

•There is a 3 Amp fuse, it can be found under the cover.

•If the aluminum radiator exceeds a temperature of 65 degrees the red led located

in the control panel will flash, then the power box will cut the power supplied to

the motor pump and the power box. To restore the original system conditions

proceed by turning off and on the unit.

•If the maximum pressure is exceeded the red led will remain on. To restore the

original system conditions proceed to turn off and on the unit.

•Both excessive temperature and pressure will cause a failure in the system, for

that reason the first thing to do will be finding the cause of the problem.

Chapter I Page 10

I.5. First Start Up.

•Check if all connections have been properly made and if the voltage at the

terminals is the appropriate one.

•Check if the Sea Cock Valve (1) is opened. In case the optional valve (11) is not

installed, its connection to the main tank will be removed.

•Make sure there is pressure in the boat’s fresh water circuit.

•Switch on the system by pressing the “PRODUCCION” button and check that

the pump’s direction of rotation is correct, gradually increase the pump’s motor

speed with the “▲”button making sure not to exceed the 60Kg/cm

2

,high

pressure (red zone) indicated on the high pressure pump gauge (9).

•Check that pressure in the control panel pressure gauge (5) lies between

approximately 12 and 14 kg/cm

2

, and does not exceed 15 kg/cm

2

under any

circumstances (red zone).

•The high pressure, indicated on the high pressure pump gauge (9), will gradually

rise until stabilizing at approximately 45-60 kg/cm

2

.

•In the first few minutes, some air bubbles will be observed in the panel control

flow meter (12). Those bubbles come from the interior of the membrane and other

system elements, causing some irregularities in the first high pressure work

cycles. They usually go away without purging the circuit.

•Approximately 5 minutes after the start-up, the “test tank” (17) should contain

about 5 liter of water produced in model 60 l/h (7.5 liter in model 90 l/h), which

determines that the production rate is correct, press STOP to stop the feed pump,

and after that, by pressing the FLUSH button the system will activate the electro-

valve (19) and the pump will work at slower speed for about 2 minutes, stopping

automatically once finished the flushing. By that time, a significant reduction in

both high and low pressure will be noticed, due to the fact that the fresh water will

has reached the membranes. This operation must be repeated twice at least, to

clean the new membranes and eliminate the membrane preservative that may have

accumulated inside them. During the flushing, the pressurized fresh water system

on the boat must be “ON”, providing approximately a 10 liters per minute flow.

Chapter I Page 11

I.6. Start-up

•Before starting up the system make sure the sea cock valve (1) is completely

open

.

•Ensure there is pressure in the boat’s fresh water circuit.

•Start the motor and check that the pressure in the low pressure gauge (5) lies

between approximately 10 and 12 kg/cm

2

, and does not exceed 15 kg/cm

2

under

any circumstances (red zone).

•High pressure will gradually rise until stabilizing at approximately 45-60 kg/cm

2

.

There may be some differences depending on the temperature and salinity of the

water.

I.7.Turning the unit off.

Before turning off the unit the system must be cleaned to prevent a compaction of the

membranes due to the biological fouling in it, proceed as follows:

•Press STOP to stop the low pressure motor pump.

•Press LAVADO/ FLUSH and the system will run the flushing system.

•At this point the unit will take fresh water from the pressurized fresh water system

in the boat. The low pressure pump must be ON, providing approximately a 10

liters per minute flow.

•For a proper cleaning of the membranes, the feed pump will work for 2 minutes

timed period, and it will be done approximately at 60% of its normal performance.

Chapter I Page 12

•The high pressure will fall to around 20-30 kg/cm2. This significant decrease in

high pressure means that the seawater contained in the membranes has been

cleaned out and replaced by fresh water. Changing the salinity and pH of the water

in the membrane prevents the biological fouling from latching on to the

membrane for a maximum period of 90 days. For longer periods see Chapter II,

Storage and Cleaning.

•As a safety measure keep the seacock valve closed (1) when the system is

switched off.

I.8. Maintenance of the unit.

•Regularly check the status of the Sea Strainer (3) and clean the mesh when

needed.

•Replace the 5 micron filter with a new cartridge at the beginning of each season or

every three months of continuous service.

•Change the charcoal cartridge at least once a year.

•When the pressure indicated in the high-pressure gauge (9) exceeds 65 kg/cm

2

(with a water temperature between 18ºC and 25ºC), the membrane should be

replaced by a new one.

•Periodically check the pressure in the accumulator (7), it should be a 8 Kg/cm

2

pressure without producing low pressure oscillations.

(An annual inspection by the Technical Support Service is recommended).

CHAPTER II

STORAGE AND CLEANING.

VERY IMPORTANT

REMEMBER THAT FOR A LONGER LIFE

OF YOUR MEMBRANE, YOU MUST

CLEAN THE SYSTEM WITH FRESH

WATER AFTER EVERY USE.

Chapter II Page 1

II.1 Storage precautions

PREVENTION OF CHEMICAL ATTACKS ON THE SYSTEM

Do not use for storage purposes, or expose the unit to, hydrogen peroxide, chloramine,

chloramine-T, N-chloroisocyanide, chlorine dioxide, hypochlorite, chlorine, iodine,

bromine, bromide, phenolic disinfectants or any other chemical element. The use of

unauthorized chemical elements, or the abuse of authorized ones, will invalidate any

warranty.

TEMPERATURE: Never expose the membrane during its storage to temperatures

higher than 50ºC or lower than 0ºC. Never store the membrane vessel under direct

sunlight. Freezing temperatures will result in mechanical damage to the system due to

the expansion of air on freezing. This will cause irreversible damage to the membrane.

DRYING OUT: Never allow the membrane to dry out. If the membrane dries out, up to

30% of production flow will be lost. It would cause irreversible damages to the

membrane. The membrane must always be kept damp.

BIOLOGICAL DIRT: Protect the membrane from biological dirt. Up to 40% of

production flow will be lost if the membrane gets dirty with biological slime. Some

production, but not all, can be recovered by following a thorough cleaning.

CHEMICAL DIRT: Protect the membrane from chemical attacks or dirt. Be careful

when using the system in ports that may be polluted with chemical products, oil or fuel.

Chemical attacks are not covered by the warranty.

STORAGE: The inside of the membrane, which is dark and damp, is an excellent place

for microorganisms to reproduce. When the membrane is used, tested or operated

intermittently, it is exposed to microorganisms. Up to 50% of production flow can be lost

if the membrane is not stored correctly.

This manual suits for next models

3

Table of contents

Other ECO SISTEMS Marine Equipment manuals

Popular Marine Equipment manuals by other brands

Shenzhen Waytronic Electronics

Shenzhen Waytronic Electronics MicroSound V16.00 quick start guide

E2S

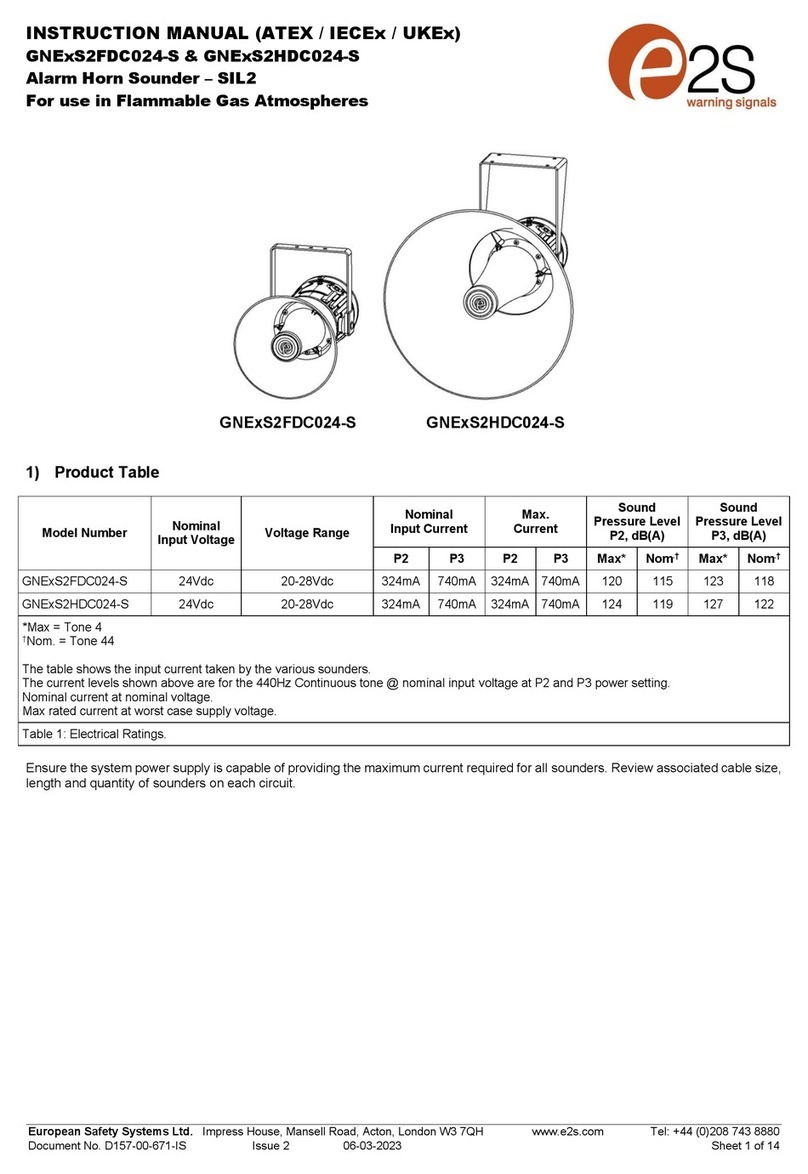

E2S GNExS2FDC024-S instruction manual

B&G

B&G RAM T0 user manual

Valeport

Valeport MIDAS Surveyor Operation manual

Airmar

Airmar SmartFlex SmartBoat ASM-C-T1-1 user manual

Dual

Dual AM505BT Installation & owner's manual