INCHES OF PITCH

Diameter and pitch must be

calculated as if Max-Prop Easy was

a normal xed propeller. Max-

Prop Easy then oers the great

advantage of pitch adjustability in

order to optimize the performance

of the propeller. If the engine does

not reach the desired RPM, reduce

the blade angle; on the contrary,

if the engine exceeds the desired

RPM, increase the blade angle.

The Max-Prop Easy allows an angle

variation of 2° increments, this

corresponds to a variation in the

engine RPM of about 13% at the

same boat speed. It’s possible

to change either the pitch to optimize the engine performance, or the rotation (for ex. if you

change the engine, or if there was a mistake when ordering the prop). If you have doubts about

the rotation: shaft rotation is determined from the stern of the boat looking forward. With the

engine in forward position clockwise rotation of the propeller means it is right hand “R”, and a

counterclockwise rotation is a left hand “L”.

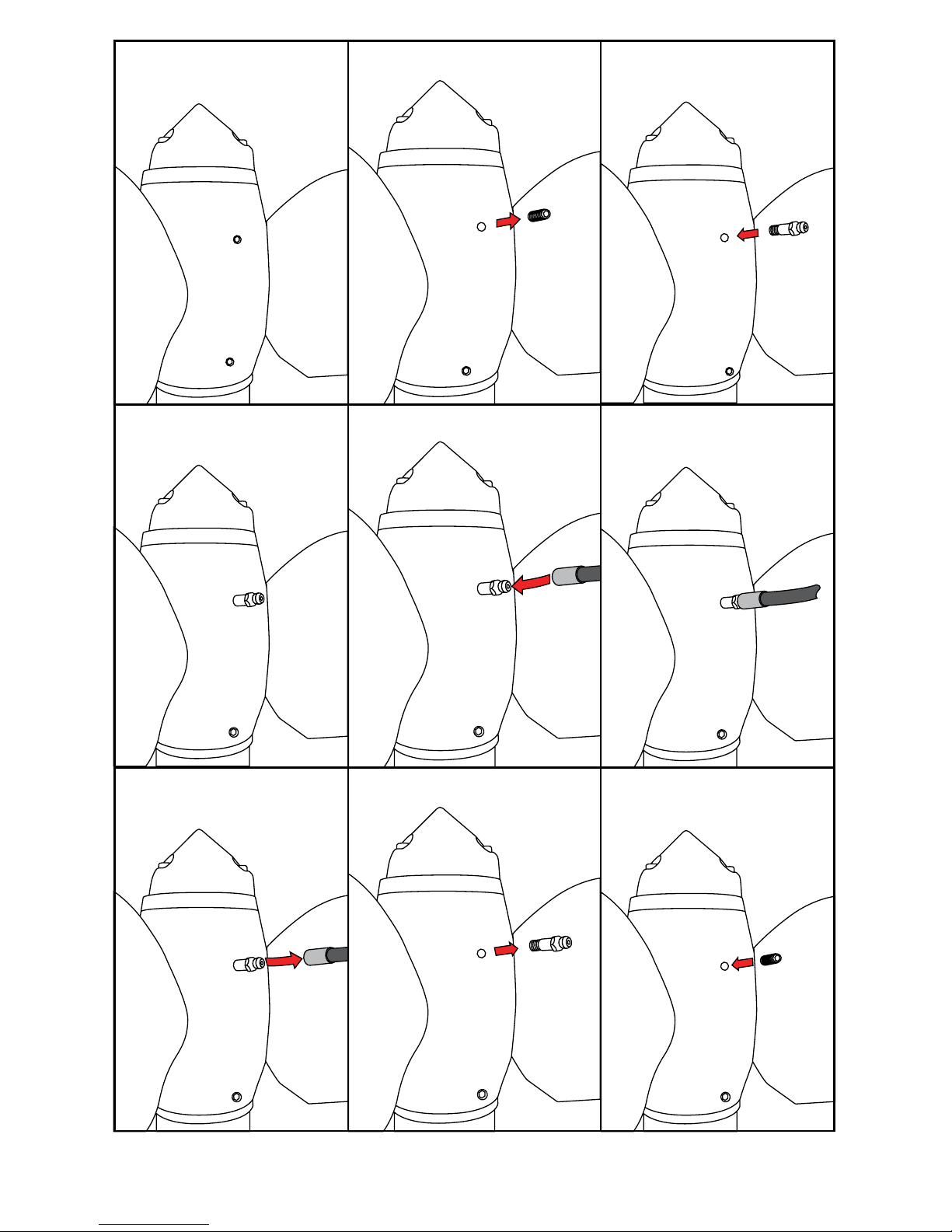

Pitch and rotation of the Max-Prop Easy can be changed as follows:

On the body of the propeller are two threaded bores, marked with letters “R” and “L”; within

these bores are placed two bolts.

The pitch of the propeller, both in forward and reverse position, can be easily varied by changing

the supplied bolts threaded into the body of the propeller with other bolts of a dierent length.

The pitch in forward rotation varies by changing the bolts placed in bore “R” if the propeller is

right-handed or changing the bolts placed in bore “L” if the propeller is left-handed. The list of

the pitch regulation bolts, that are supplied with every Easy propeller is indicated in g.4.

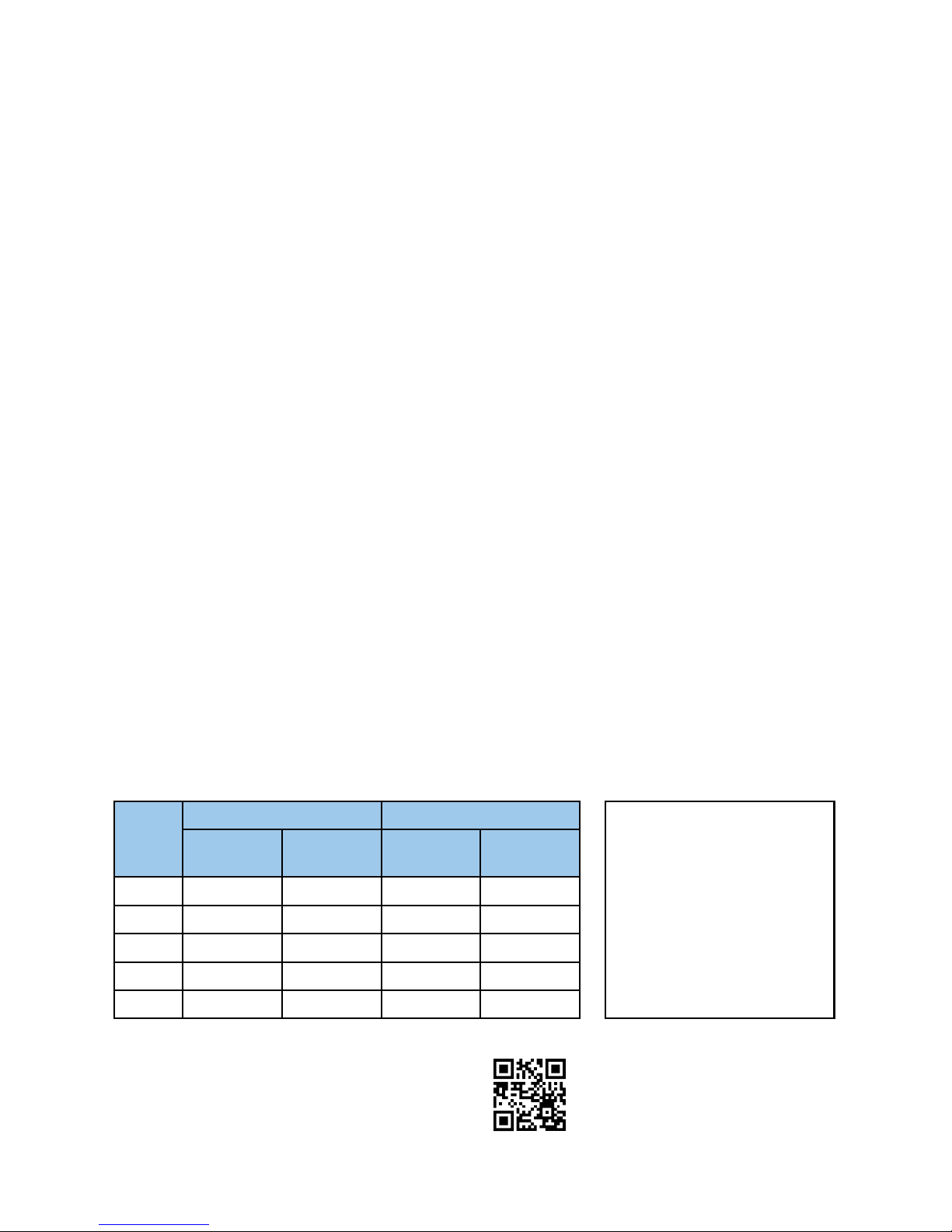

For example inserting the #20 bolt in the forward rotation and 2 in the reverse rotation will

provide a 20° angle for both front position and reverse rotation. Varying 1mm the length of the

bolts, blades inclination has a 2° variation

Blade

Angle

Right Rotation Left Rotation

Forward

Bore “R”

Reverse

Bore “L”

Forward

Bore “L”

Reverse

Bore “R”

16° 16 1 16 1

18° 18 18

20° 20 220 2

22° 22 22

24° 24 3 24 3

Fig.5 - Close up of the Left and

Right pitch adjustment bolts.

Fig.3b

Fig.4

5

TIP: Watch our YouTube video on how to adjust

the pitch, visit https://youtu.be/HJsnHCi2U6U

Or scan the QR code with a mobile device.