eco3energy PAW-TD20C1E5-UK User manual

1

PLEASE LEAVE THIS MANUAL WITH THE UNIT AFTER INSTALLATION

145963-06 04-2019

Installation Manual

PAW-TD20/30C1E5-UK

PAW-TD20/30C1E5-UK-1

Thank-you for purchasing the PAW unvented hot water cylinder.

-

Guide.

-

Contents

Page no.

...........................2

.......... 4

3. Pipe connections ...............................4

............. 5

5. Draining and Flushing........................5

6. Electrical installation ..........................5

..........................9

.....................................10

... 11

10. Warranty ..........................................12

.......................................... 13

This cylinder is manufactured and approved in accordance with EN 12897 : 2006

2

1. General information

1.1 Health and Safety regulations

-

The PAW cylinder should be transported and stored in a vertical position.

1.2 Siting the PAW cylinder

-

1.3 Component Check list

•

• Tundish

•

•

•

1.4 Components factory tted

•

•

•

1.5 Documentation supplied

•

1.6 Supply requirements

pipe to the unit.

1.7 Expansion vessels

-

1.8 Compatible ttings and components

1.9 Non-compatible products.

unvented cylinders.

3

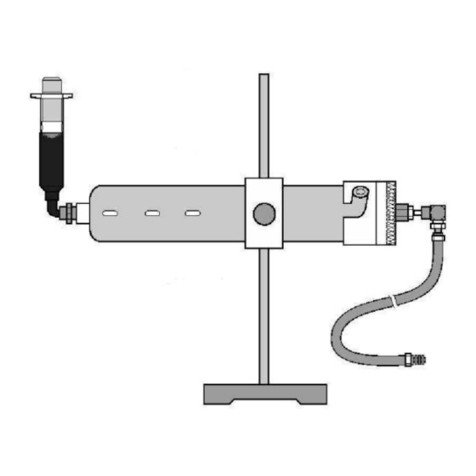

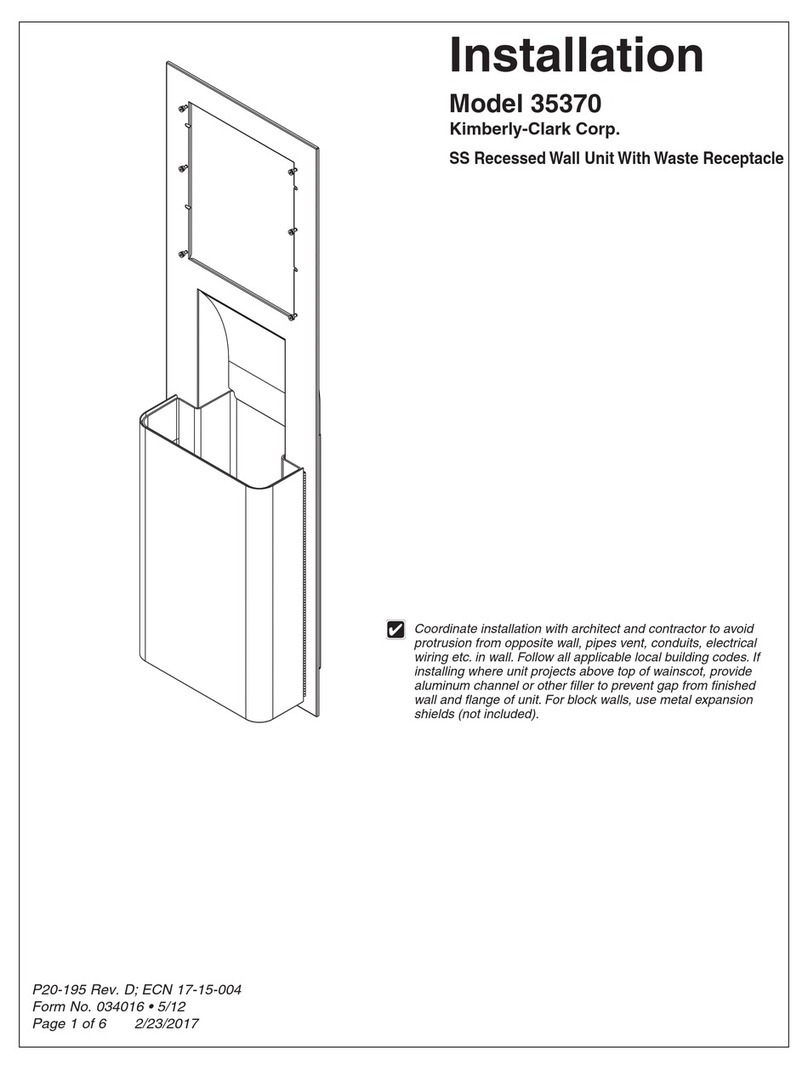

General Layout

Key

1

2

3

4

5-

92020

6 Tundish

7 71234

8

80314

9

80345

10 Cold Water Inlet

11

12

13 Discharge Pipe

14

15

16

1

6

5

4

3

2

7

16

8

15

13

9

1110

10

12

A-A

B ( 0,2 : 1 )

L-L ( 1:12 )

N ( 1 : 6 )

R ( 1 : 6 )

T ( 1 : 6 )

U ( 1 : 6 )

A

A

B

L

L

N

R

T

U

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Format

Designed by:

Approved by:

Scale

Title Date:

A\S OSO, N - 3300 Hokksund Tlf: 32 25 00 00 Fax: 32 25 00 90

Drawing no. Rev

Drawing type:

This drawing is copyright and

shall not be reproduced or

disclosed to a third party without

express permission by OSO

Hotwater A\S Norway C

Projection

15.10.2018

Panasonic PAW-TD20C1E5-UK 1:12

2D

16-0703 03

A3

PB

All dimensions are specified in millimeters (mm) unless otherwise stated.

Tolerance based on ISO 2768-1 very coarse

266

866

1265 -3

10+

Return

34

" BSP female

Flow

34

" BSP female

CW inlet

34

" BSP female

155

0

595Ø

1,5kW 1x230V

365

90°

Power supply/

Thermistor cable

inlet

Va cuumIn s ul at ed

Pa nels ( V IP)

1.8m²

Ø22mm

Vacuum

Insulated

Panel

(VIP)

492Ø

1087

P&T valve 1/2"

HW outlet

34

" BSP female

Thermistor housing

Power supply/

Thermistor cable

duct

Immersion Heater w/

Thermostat & Safety

Cut-out

Housing for

Thermistor probe

Power supply and Thermistor cable inlet

679

640

Cylinder Thermostat

w/Safety Cut-Out

and Sensor pocket

HWC

34

" BSP female

A-A

B ( 0,2 : 1 )

L-L ( 1:12 )

N ( 1 : 6 )

R ( 1 : 6 )

T ( 1 : 6 )

U ( 1 : 6 )

A

A

B

L

L

N

R

T

U

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Format

Designed by:

Approved by:

Scale

Title Date:

A\S OSO, N - 3300 Hokksund Tlf: 32 25 00 00 Fax: 32 25 00 90

Drawing no. Rev

Drawing type:

This drawing is copyright and

shall not be reproduced or

disclosed to a third party without

express permission by OSO

Hotwater A\S Norway C

Projection

15.10.2018

Panasonic PAW-TD20C1E5-UK 1:12

2D

16-0703 03

A3

PB

All dimensions are specified in millimeters (mm) unless otherwise stated.

Tolerance based on ISO 2768-1 very coarse

266

866

1265 -3

10+

Return

34

" BSP female

Flow

34

" BSP female

CW inlet

34

" BSP female

155

0

595Ø

1,5kW 1x230V

365

90°

Power supply/

Thermistor cable

inlet

V acu um Ins ul at ed

P ane ls( VIP )

1.8m²

Ø22mm

Vacuum

Insulated

Panel

(VIP)

492Ø

1087

P&T valve 1/2"

HW outlet

34

" BSP female

Thermistor housing

Power supply/

Thermistor cable

duct

Immersion Heater w/

Thermostat & Safety

Cut-out

Housing for

Thermistor probe

Power supply and Thermistor cable inlet

679

640

Cylinder Thermostat

w/Safety Cut-Out

and Sensor pocket

HWC

34

" BSP female

A-A

B ( 0,2 : 1 )

L-L ( 1:12 )

N ( 1 : 6 )

R ( 1 : 6 )

T ( 1 : 6 )

U ( 1 : 6 )

A

A

B

L

L

N

R

T

U

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Format

Designed by:

Approved by:

Scale

Title Date:

A\S OSO, N - 3300 Hokksund Tlf: 32 25 00 00 Fax: 32 25 00 90

Drawing no. Rev

Drawing type:

This drawing is copyright and

shall not be reproduced or

disclosed to a third party without

express permission by OSO

Hotwater A\S Norway C

Projection

13.04.2018

Panasonic PAW-TD20C1E5-UK 1:12

2D

16-0703 02

A3

PB

All dimensions are specified in millimeters (mm) unless otherwise stated.

Tolerance based on ISO 2768-1 very coarse

266

866

1265 -3

1 0+

Return 34" BSP female

Flow 34" BSP female

CW inlet 34" BSP female

155

0

595

Ø

1,5kW 1x230V

365

90°

Power supply/

Thermistor cable

inlet

V a cu u m I n s ul at ed

P ane ls ( V IP)

1.8m²

Ø22mm

Vacuum

Insulated

Panel

(VIP)

492Ø

1087

P&T valve 1/2"

966

HWC

34" BSP female

HW outlet 34" BSP female

Thermistor housing

Power supply/

Thermistor cable

duct

Cylinder Thermostat

w/Safety Cut-Out

and Sensor pocket

Immersion Heater w/

Thermostat & Safety

Cut-out

Housing for

Thermistor probe

Power supply and Thermistor cable inlet

679

640

1

6

5

4

3

2

7

9

8

15

13

1110

10

12

PAW-TD..C1E5-UK PAW-TD..C1E5-UK-1

A-A

B ( 0,2 : 1 )

L-L ( 1:12 )

N ( 1 : 6 )

R ( 1 : 6 )

T ( 1 : 6 )

U ( 1 : 6 )

A

A

B

L

L

N

R

T

U

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Format

Designed by:

Approved by:

Scale

Title Date:

A\S OSO, N - 3300 Hokksund Tlf: 32 25 00 00 Fax: 32 25 00 90

Drawing no. Rev

Drawing type:

This drawing is copyright and

shall not be reproduced or

disclosed to a third party without

express permission by OSO

Hotwater A\S Norway C

Projection

15.10.2018

Panasonic PAW-TD20C1E5-UK 1:12

2D

16-0703 03

A3

PB

All dimensions are specified in millimeters (mm) unless otherwise stated.

Tolerance based on ISO 2768-1 very coarse

266

866

1265 -3

10+

Return

34

" BSP female

Flow

34

" BSP female

CW inlet

34

" BSP female

155

0

595Ø

1,5kW 1x230V

365

90°

Power supply/

Thermistor cable

inlet

Vacu u mIns ul at ed

Pane ls ( VIP )

1.8m²

Ø22mm

Vacuum

Insulated

Panel

(VIP)

492Ø

1087

P&T valve 1/2"

HW outlet

34

" BSP female

Thermistor housing

Power supply/

Thermistor cable

duct

Immersion Heater w/

Thermostat & Safety

Cut-out

Housing for

Thermistor probe

Power supply and Thermistor cable inlet

679

640

Cylinder Thermostat

w/Safety Cut-Out

and Sensor pocket

HWC

34

" BSP female

4

3. Pipe Connections

2. Preparation of installation area

2.1 Positioning the unit

water heater.

2.2 Protection from frost

-

3.1 Cold water supply

3.1.2-

terrupted supply.

3.1.3

3.1.4

3.1.5-

3.1.6

3.1.7

together in a Tee as shown on page 3.

3.1.8

3.1.9

3.1.10

3.2 Hot water supply

3.3 Balanced cold water supply (optional).

-

3.4 Secondary return (optional)

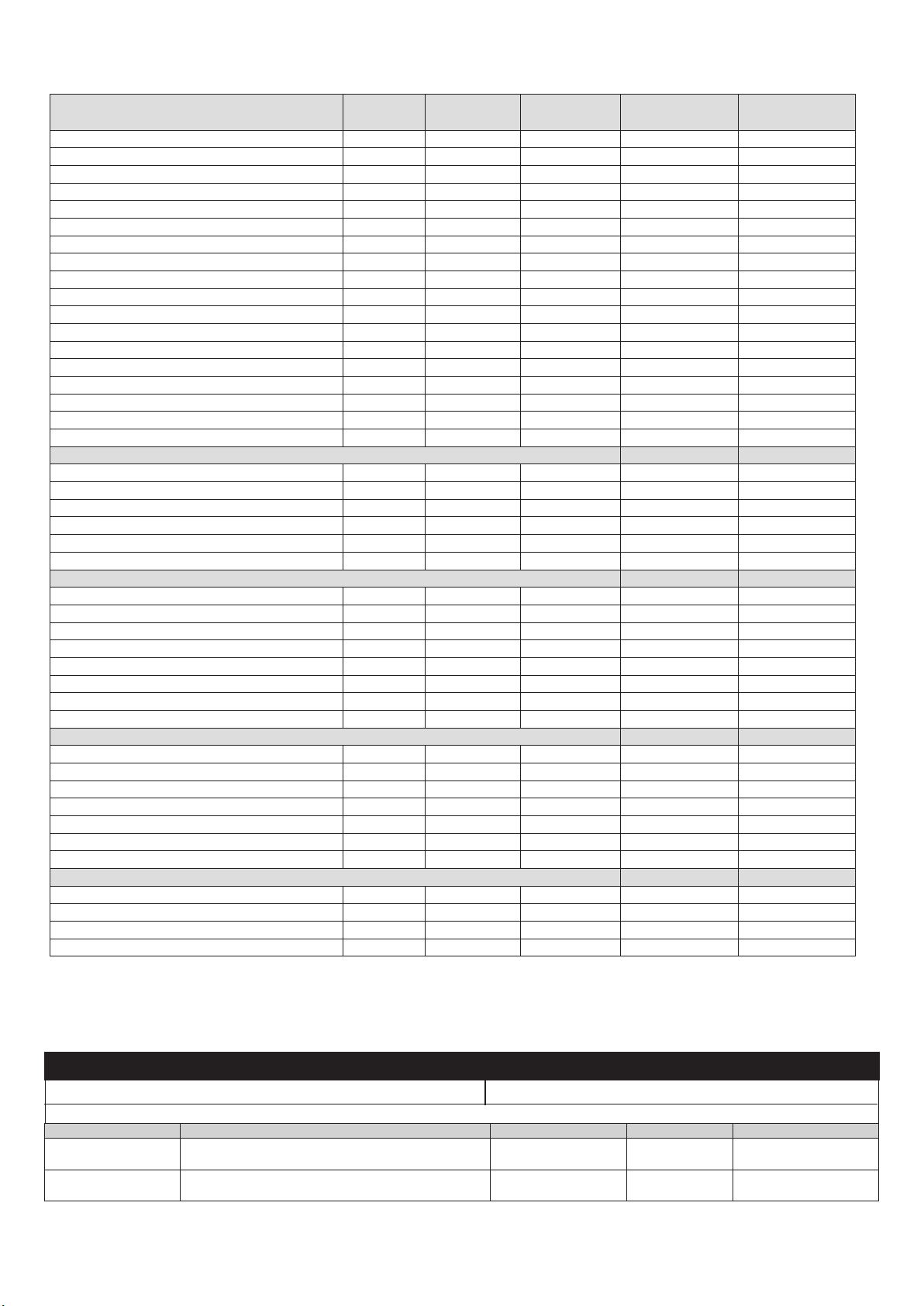

3.5 Discharge pipe

5

4. Commissioning and lling up

5. Draining & ushing out the system

4.1 Commissioning

4.1.1

4.1.2

4.1.3

pipe.

5.1 Draining

5.2 System ushing

3.6 Primary Flow and Return and Motorised valve

3.6.1

3.6.2

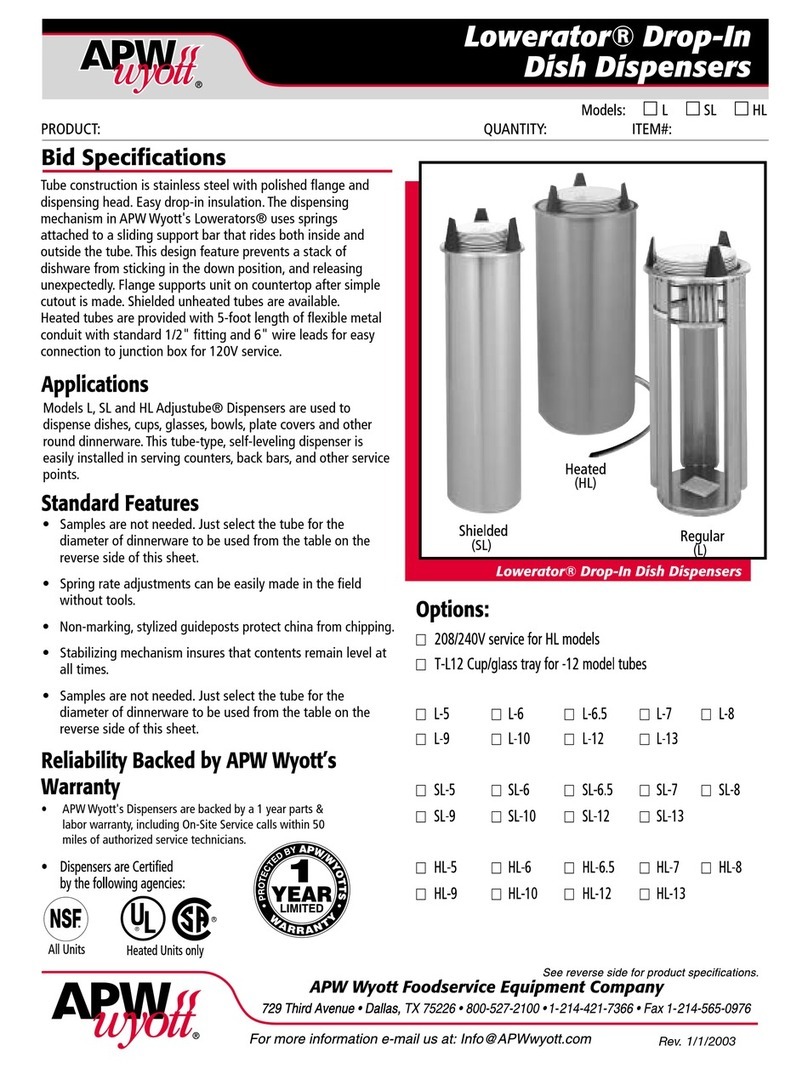

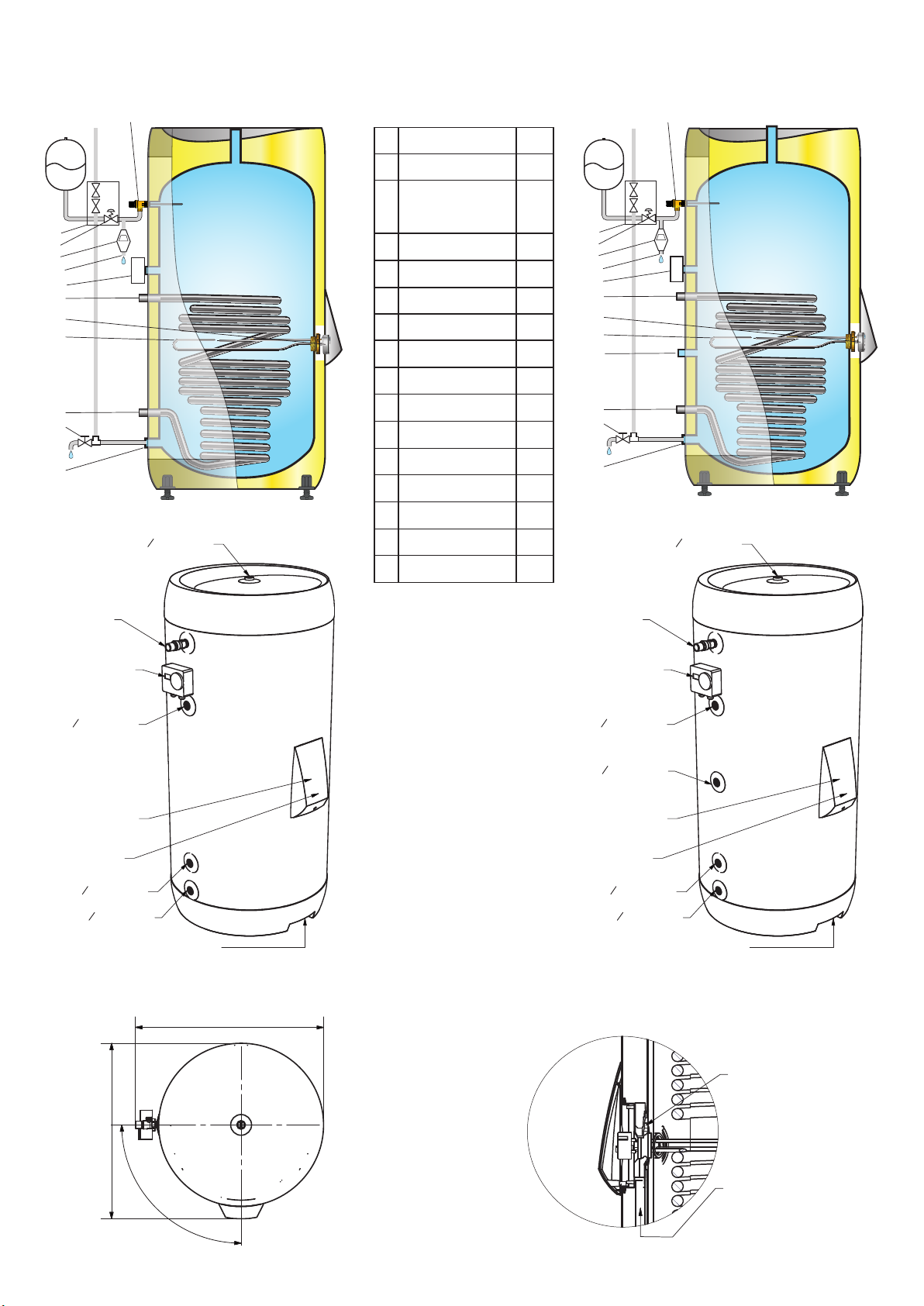

6. Electrical installation - all wiring must conform to current IEE regulations

6.1 Immersion heater Thermostat

-

OSO Hotwater AS can not be held

responsible if alternative wiring plans are used.

Important: Before resetting the safety cut-out or

altering the thermostat setting isolate electrical

supply to the unit before removal of the lid.

Ensure the lid to the electrical box is replaced.

6

6.2 Motorised valve

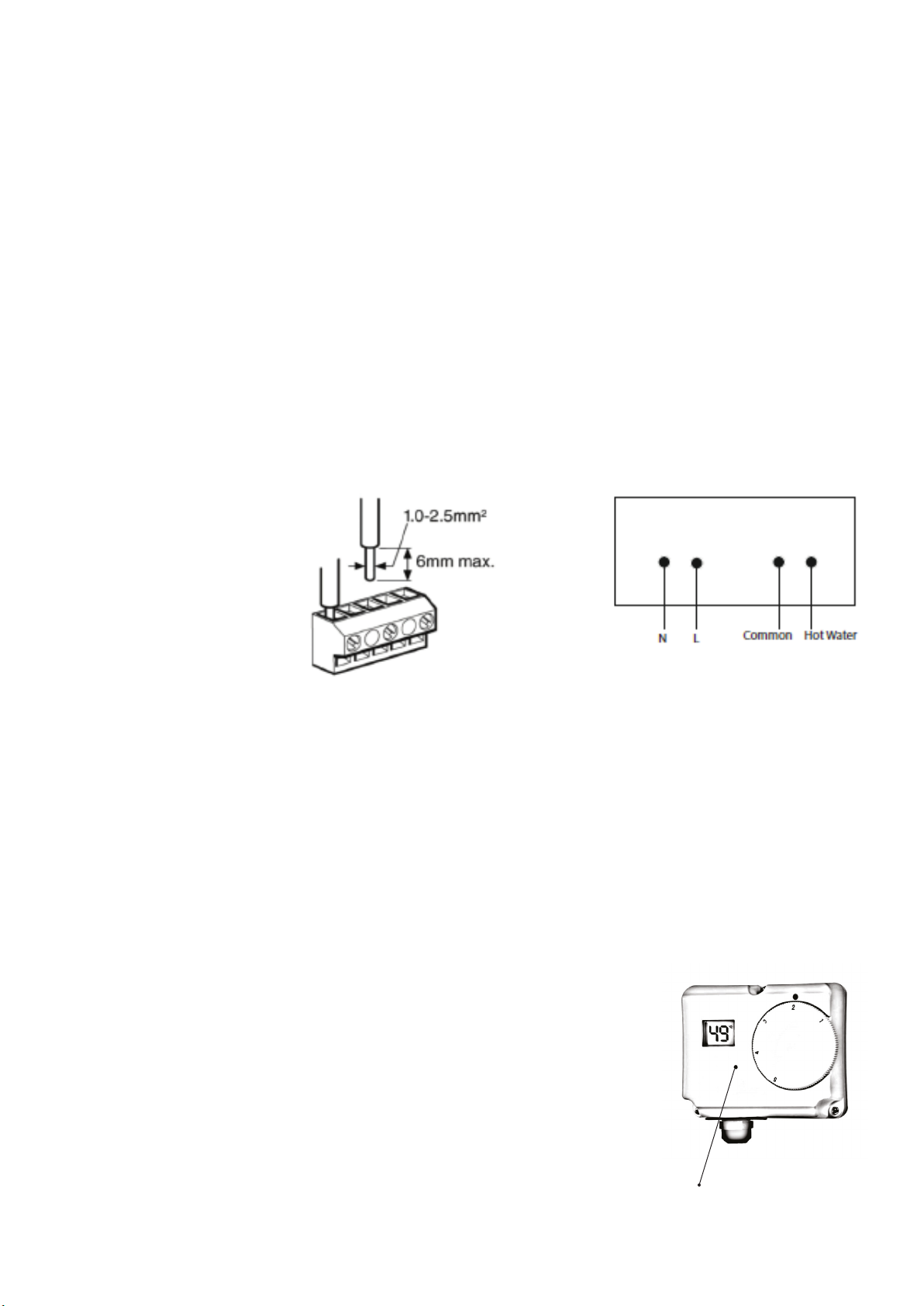

6.4 Digital Dual Cylinder Thermostat

-

-

-

-

-

pressed in.

Wiring Diagram

-

ing page 7 and 8.

supply.

6.4.1 Holiday Mode

-

OSO Hotwater AS can not be responsible if alternative wiring plans are used. Important: Before resetting the safety cut-out

or altering the thermostat setting isolate electrical supply to the unit before removal of the lid.

6.4.1 Adjusting the 1 Hour Boost

7

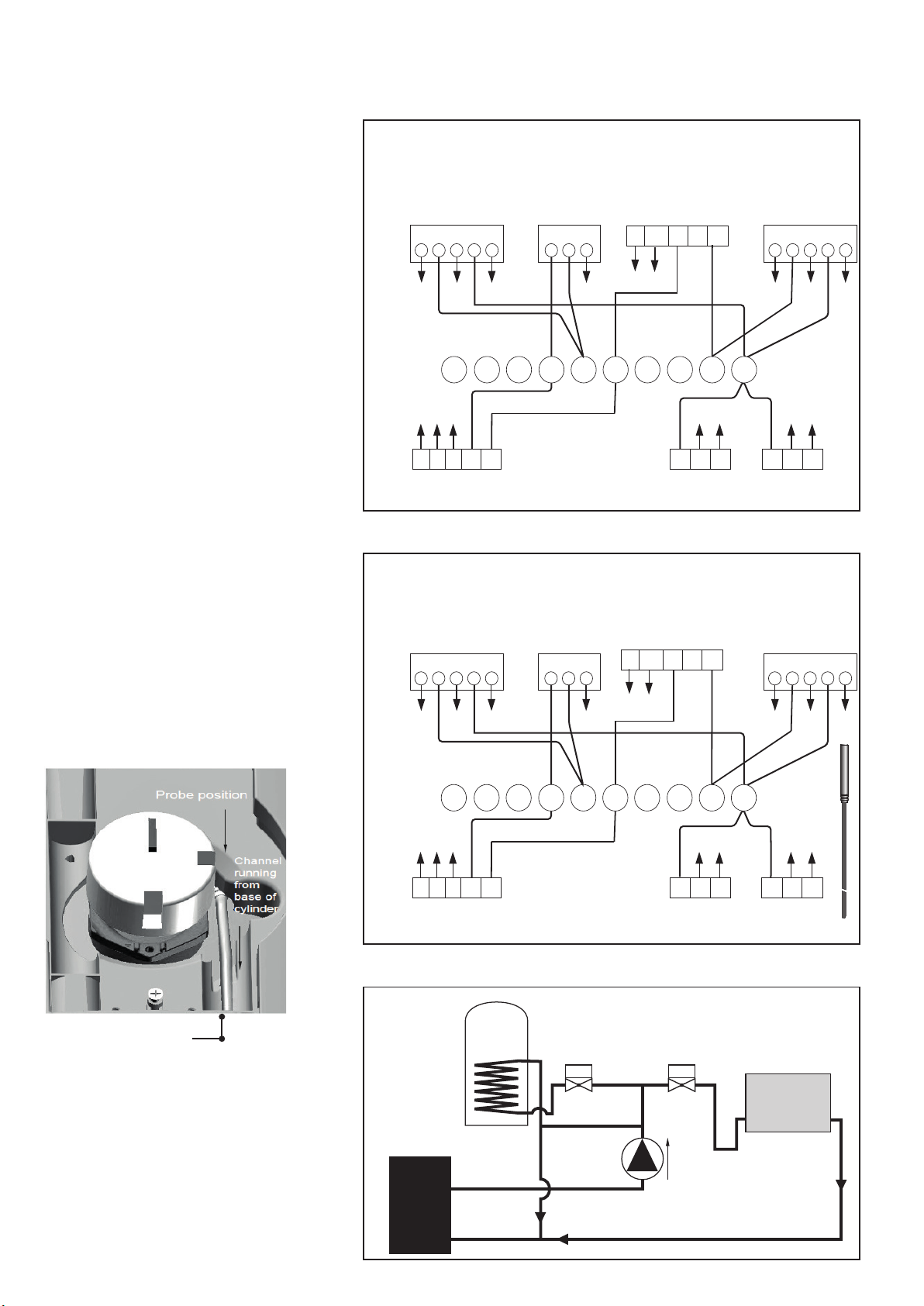

S-plan Wiring

PAW cylinders

Thermistor controlled Heat

Pumps/Boilers

attach to the cylinder.

to secure the sensor on the

PAW cylinder. The

the additional cylinder

Channel running

Pump

flow

2-port valve

(supplied)

Zone valve

(not supplied)

Automatic

bypass

Radiators/

UFH

HP/Boiler

Piping

Diagram

Zone Valve (DHW)

(supplied)

12

231

T6360B

357

3

G/Y

LNE 4

G Br Bl O

L NE L NE

Pump

1 2 323 23

22 31

V4043H

Cylinder

Thermostat

(supplied) Wired as

high limit stat

Isolated Mains

Supply From

Fused Spur

Zone Valve (Htg)

(not supplied)

Room

thermostat

L NE

69

2 31

V4043H

G B r B1 O

G/Y

4 8 10

Wiring for Thermistor Controlled Heat Pump

1 2

Thermistor

Thermistor wire

Connected to

Heat Pump control

system

12

231

T6360B

357

3

G/Y

LNE 4

G Br Bl O

L NE L NE

Heat Pump Pump

1 2 323 23

22 31

V4043H

Cylinder

Thermostat

(supplied)

Isolated Mains

Supply From

Fused Spur

Zone Valve (Htg)

(not supplied)

Room

thermostat

L N E

69

2 31

V4043H

G Br B1 O

G/Y

4 8 10

Wiring for Standard Heat pump

1 2

Zone Valve (DHW)

(supplied)

N

L

CNC NO

N

L

CNC NO

ST6400

Programmer

HW

ON

HTG

ON

ST6400

Programmer

HW

ON

HTG

ON Heat pump differential controler

8

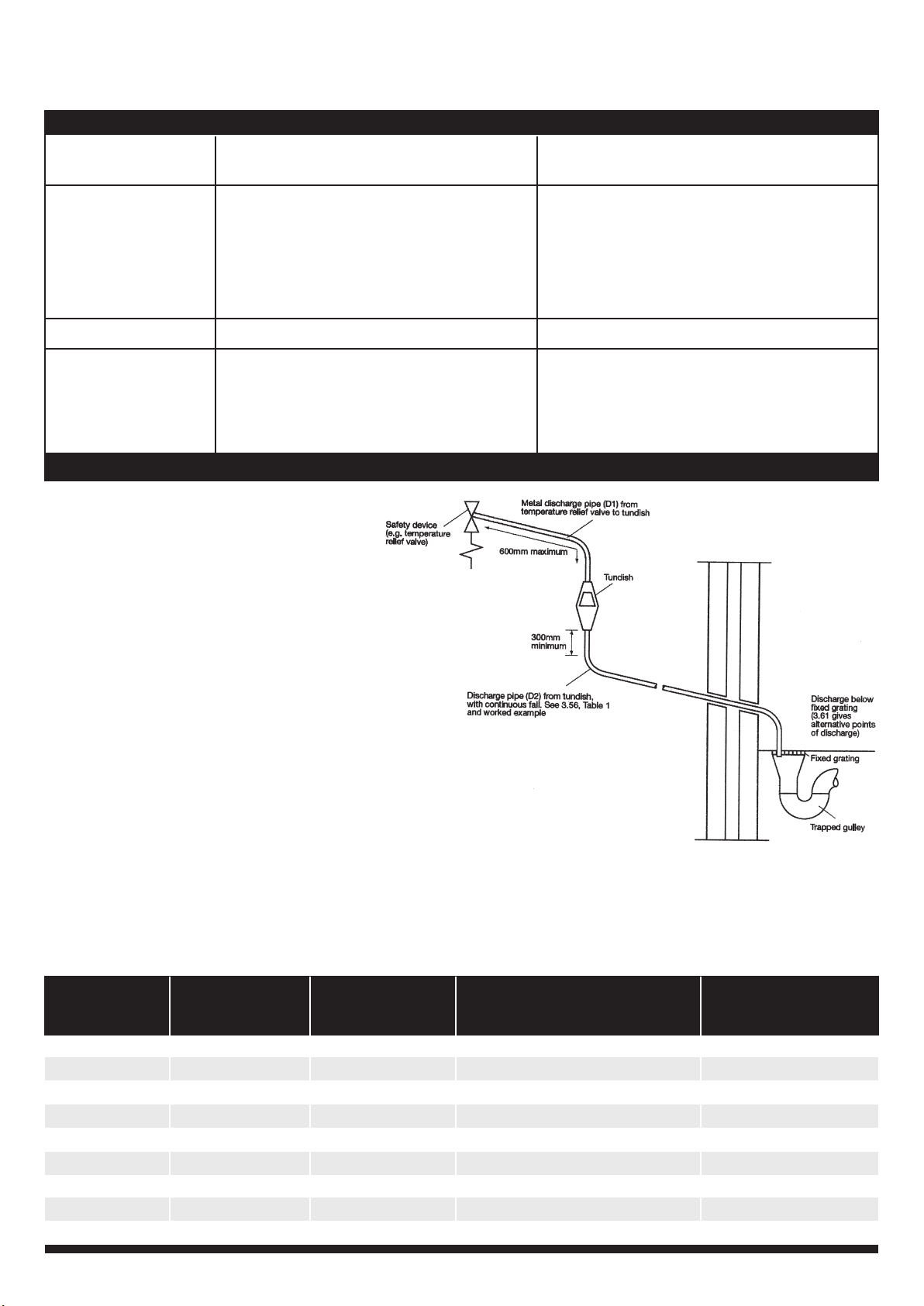

Y-plan Wiring

Thermistor controlled Heat

Pumps/Boilers

attach to the cylinder.

to secure the sensor on the

PAW cylinder. The

Channel running

12

E

231

T6360B

3

3 14

G O B1 Br

G/Y

NL E NL E NL

ST6400

Heat pump Pump

1 2 332 32

2 2 3

1

V4043H

Room

thermostat

Zone Valve (DHW)

(supplied)

Isolated Mains

Supply From

Fused Spur

Mid Position Valve

(not supplied)

L N E

6

G/Y

B1 W Gr O

3 2

V4073A1039

104 5 987

Cylinder Thermostat (supplied)

N

L

C NC NO

Thermistor

12

E

231

T6360B

3

3 14

G O B1 Br

G/Y

NL E NL ENL

ST6400 Heat pump differential controler Pump

1 2 332 32

2

23

1

V4043H

Room

thermostat

Zone Valve (DHW)

(supplied)

Isolated Mains

Supply From

Fused Spur

Mid Position Valve

(not supplied)

L N E

6

G/Y

B1 W Gr O

3 2

V4073A1039

104 5 987

Cylinder Thermostat (supplied )

wired as high limit Stat

N

L

C NC NO

Thermistor wire

Connected to

Heat pump control

system

Pump

flow

2-port valve

(supplied)

Mid pos. valve

(not supplied)

Radiators/

UFH

HP/Boiler

Automatic

bypass

Piping

Diagram

HW

ON

HW

OFF

HTG

ON

HW

ON

HW

OFF

HTG

ON

Programmer

Programmer

Wiring for Standard Heat pump

Wiring for Thermistor Controlled Heat Pump

9

7. Safety and servicing

7.1 Safety Cut-out

1. Wiring is incorrect.

2.

3.

4.

5.

6.

7. 2 Intermittent or slow discharge from tundish

1.

2.

3.

4.

seconds.

5.

6.

7.

8.

9.

7.3 Continuous very hot water discharge from tundish

7.4 Expansion vessel maintenance

-

value.

7.5 Guarantee

7.6 Servicing Procedure:

7.6.1 Expansion relief valve

7.6.2 Pressure reducing valve

7.6.3 Expansion relief cartridge

Do not overtighten.

7.6.4 Temperature and Pressure relief valve

7.6.5 Internal inspection

10

8. Fault Finding Guide

Alternative Discharge

dedicated to the unvented cylinder. The pipe

-

Important - note:

FAULT POSSIBLE CAUSE SOLUTION

No water ow from hot taps.

Water from hot taps is cold.

Intermittent water discharge.

Continous water discharge.

Minimum size of Maximum resistance allowed,

Minimum size of discharge pipe D2* expressed as a lenght of straight Resistance created by

Valve outlet size discharge pipe D1* from tundish pipe (i.e. no elbows or bends) each elbow or bend

11

Technical data

M.T. ITEM No. MODEL/IDENTIFIER Rating ErP Heat loss - W Storage vol.

80341850

A 43 192

80341950

A 49 284

Description Unit PAW-

TD20C1E5-UK PAW-

TD30C1E5-UK PAW-

TD20C1E5-UK-1 PAW-

TD30C1E5-UK-1

192 284 192 284

595 595 595 595

1270 1750 1270 1750

50 61 50 61

241 341 241 341

-

incoloy 825 incoloy 825 incoloy 825 incoloy 825

-

50 50 50 50

-

21 21 21 21

1.01 1.15 1.03 1.18

Watts

42 48 43 49

315 465 315 465

l/h

900 900 900 900

18.5 26.08 18.5 26.08

35 32 35 32

120 120 120 120

255 464 255 464

ErP class

-

A A A A

1 / 10 1 / 10 1 / 10 1 / 10

1 / 10 1 / 10 1 / 10 1 / 10

0.3 / 3 0.3 / 3 0.3 / 3 0.3 / 3

0.25 / 2.5 0.25 / 2.5 0.25 / 2.5 0.25 / 2.5

°C

70 70 70 70

°C 99

99

99

99

Secondary return

Inch

Inch

Inch

Cold water

Inch

Inch

Inch

Inch

8 8 8 8

Electrical characteristics

Electrical installation

-

IEEE regs IEEE regs IEEE regs IEEE regs

-

Phase

single single single single

°C

8-70 18-70 8-70 18-70

°C

60 60 60 60

0.8 / 8 0.8 / 8 0.8 / 8 0.8 / 8

°C

87 87 87 87

°C

80 80 80 80

12

1. Scope

-

shall apply.

2. Coverage

-

3. Conditions

•

•

•

•

•

•

•

•

•

• -

•

•

4. Limitations

•

•

•

•

•

•

Warranty

13

The code of practice for the installation,

commissioning & servicing of mains pressure hot water storage

Installation,Commissioning

and Service Record Log Book

CUSTOMER DETAILS

NAME

ADDRESS

TEL No.

IMPORTANT

The above does not aect your statutory rights.

INSTALLER & COMMISSIONING ENGINEER DETAILS

INSTALLER DETAILS

COMPANY NAME DATE

ADDRESS

INSTALLER NAME TEL No.

REGISTERED OPERATIVE ID CARD No.

(IF APPLICABLE)

REGISTRATION DETAILS

COMMISSIONING ENGINEER (IF DIFFERENT)

NAME DATE

ADDRESS

TEL No.

REGISTERED OPERATIVE ID CARD No.

(IF APPLICABLE)

REGISTRATION DETAILS

IT IS THE RESPONSIBILITY OF THE INSTALLER TO COMPLETE THIS LOGBOOK AND PASS IT

ON TO THE CUSTOMER. FAILURE TO DO SO MAY INVALIDATE THE CYLINDER GUARANTEE

14

APPLIANCE & TIME CONTROL DETAILS

MANUFACTURER MODEL

CAPACITY

TYPE

TIME CONTROL

UNVENTED

PROGRAMMER

litres SERIAL No.

TIME SWITCH

or

COMMISSIONING PROCEDURE INFORMATION

BOILER PRIMARY SETTINGS (INDIRECT HEATING ONLY) ALL BOILERS

IS THE PRIMARY A SEALED OR OPEN VENTED SYSTEM? SEALED OPEN

WHAT IS THE INDIRECT HEAT SOURCE FLOW TEMPERATURE? C

ALL MAINS PRESSURISED SYSTEMS

YES

WHAT IS INCOMING STATIC COLD WATER PRESSURE AT THE INLET TO THE

PRESSURE REDUCING VALVE?

HAS STRAINER (IF FITTED) BEEN CLEANED OF INSTALLATION DEBRIS?

HAS A WATER SCALE REDUCER BEEN FITTED?

WHAT TYPE OF SCALE REDUCER HAS BEEN FITTED?

NO

YES NO

UNVENTED SYSTEMS

YES

ARE COMBINED TEMPERATURE AND PRESSURE RELIEF VALVE

AND EXPANSION VALVE FITTED AND DISCHARGE TESTED?

IS PRIMARY ENERGY SOURCE CUT OUT FITTED

(NORMALLY 2 PORT VALVE)?

WHAT IS THE PRESSURE REDUCING VALVE SETTING (IF FITTED)?

WHERE IS OPERATING PRESSURE REDUCING VALVE SITUATED?

NO

YES NO

bar

HAS THE EXPANSION VESSEL OR INTERNAL AIR SPACE BEEN CHECKED? YES NO

WHAT IS THE HOT WATER TEMPERATURE AT THE NEAREST OUTLET? C

bar

ALL PRODUCTS

YES

DOES THE HOT WATER SYSTEM COMPLY WITH

THE APPROPRIATE BUILDING REGULATIONS?

HAS THE SYSTEM BEEN INSTALLED AND COMMISSIONED

IN ACCORDANCE WITH THE MANUFACTURER’S INSTRUCTIONS?

HAVE YOU DEMONSTRATED THE OPERATION OF THE

SYSTEM CONTROLS TO THE CUSTOMER? YES

YES

HAVE YOU LEFT ALL THE MANUFACTURER’S

LITERATURE WITH THE CUSTOMER? YES

COMPETENT PERSON’S

SIGNATURE

CUSTOMER’S

SIGNATURE

(To conrm demonstrations of equipment and

receipt of appliance instructions)

PLEASE FOLLOW THE INSTALLATION AND COMMISSIONING INSTRUCTIONS

IN THE INSTALLATION MANUAL SUPPLIED WITH THE EQUIPMENT

15

SERVICE INTERVAL RECORD

SERVICE PROVIDER

ENGINEER NAME

SERVICE 1

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 3

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 5

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 7

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 9

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 2

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 4

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 6

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 8

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

ENGINEER NAME

SERVICE 10

COMPANY NAME

TEL No.

COMMENTS

SIGNATURE

DATE:

HWSLB First Edition 01.03.02

16

This manual suits for next models

3

Table of contents