First Steps

Step 1:

Unpack the shipping box and use the supplied checklist to make sure all items are

present. If any items are missing, please contact us immediately.

Step 2:

Ensure the area where you are setting up the equipment has access to compressed

air. Air pressure should be between 0 and 100 psi (0 and 6.9 bar). If connecting to a

pneumatic dispenser, ensure that the dispenser itself is connected to a mains air

supply of at least 75 psi (5.0 bar).

Step 3:

Activate your one (1) year no fault warranty by filling in and returning the postage

paid warranty card.

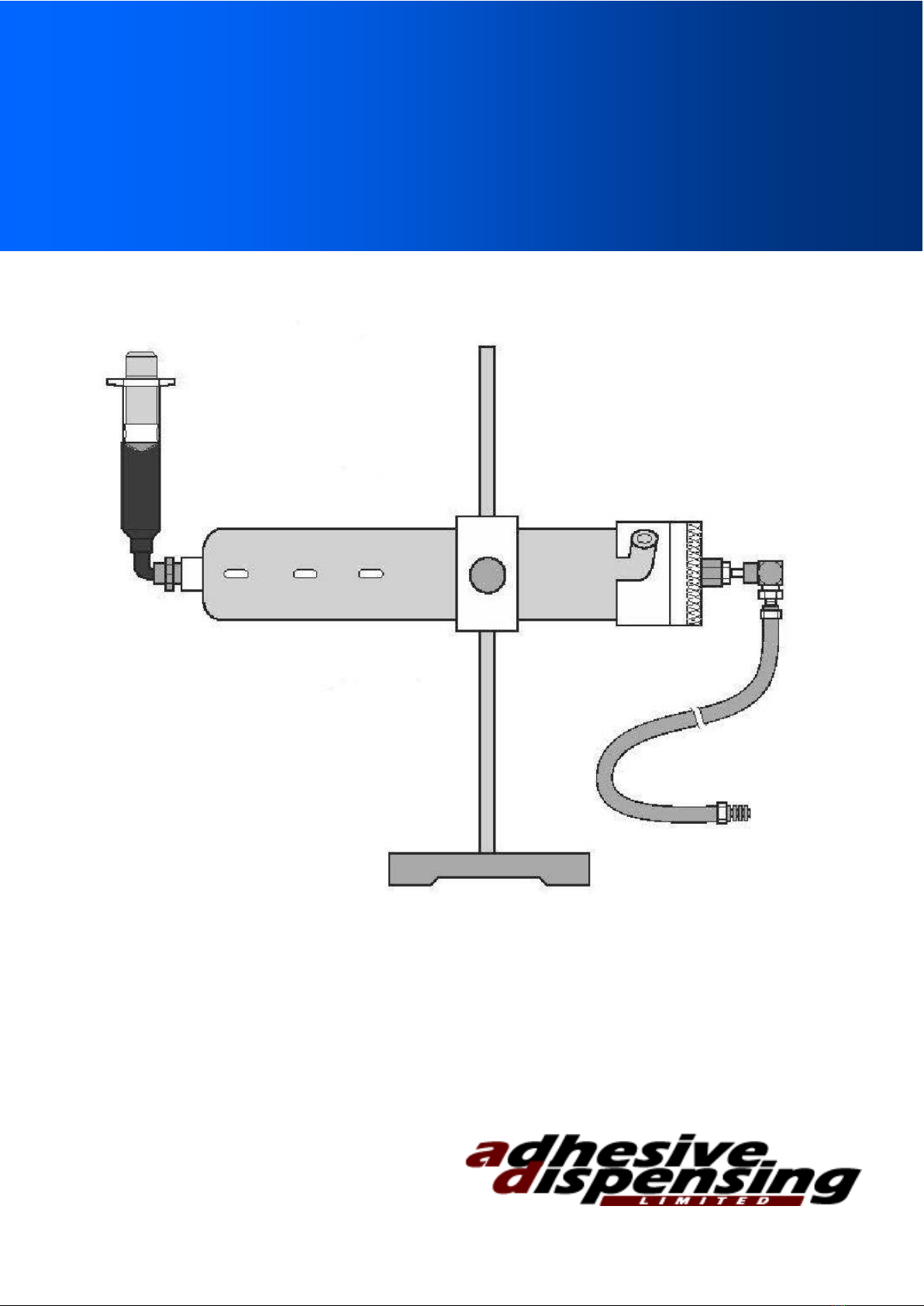

Assemble Stand: (Stand position can vary from drawing)

Unpack the shipping box and use the supplied checklist to make sure all items are

present. If any items are missing, please contact us immediately.

Place the stand on a flat surface/ work bench.

Thread the pole (1) into the base (2) by using the

supplied nut. Turn clockwise and tighten.

Slide the rod clamp (3) onto the pole (1) to your

suitable height and tighten the locking nut (4).

Attach cartridge mounting bracket with rod (16) to

the rod clamp (3) and tighten. Position the arm to

hold the reservoir horizontally as pictured.

Review the setup and adjust to the suitable height

for your application.

The base stand and upright rod part number is

918-033-000 and is built specifically to handle the

weight of a filled cartridge. Please ensure all screws

are tight before inserting the filled cartridge.

Setup

5