5

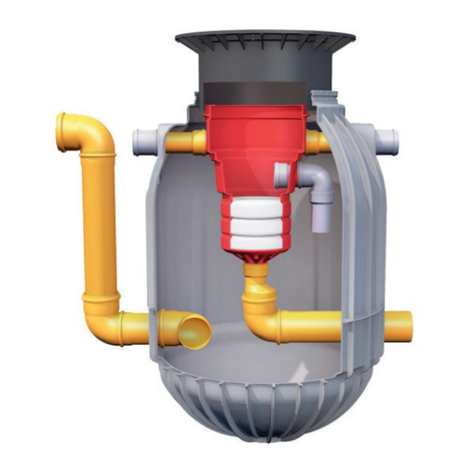

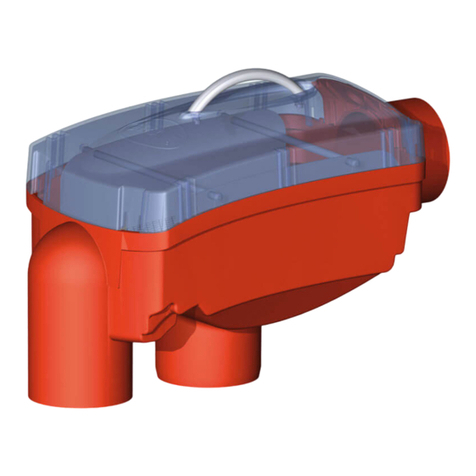

5.1 Preparation of the excavation

So that sufficient working room is available and the filter can be correctly installed, the sur-

face area of the excavation should exceed the filter dimensions on all sides by approximately

50 mm. The excavation hole must be level and smooth. The depth of the excavation must

be measured so that the final installation depth of the filter bottom is at a maximum 1050

mm. The base of the hole requires a layer of smooth sand approximately 10 mm deep.

Important: The setting down surface for the filter must be level to ensure an optimal perfor-

mance.

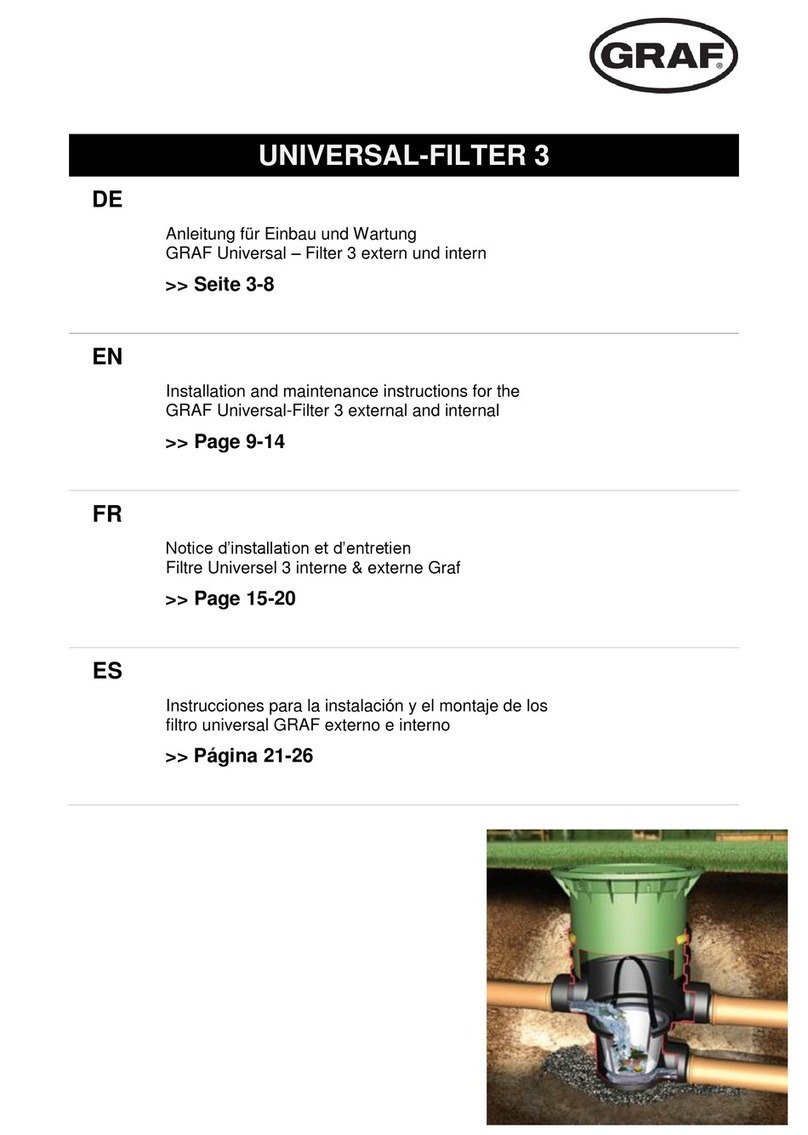

5.2 Placing in the excavation and laying the connections

The filter is installed in the prepared excavation and is then connected to the relevant pipes.

Attention: It is important that all the pipes to be installed have a gradient of at least 1% in

the flow direction without sagging or bending downward. To effectively reduce the rate of flow

of the incoming water, about 2 metres of 100mm horizontal pipe should be installed before

the filter. This has the effect of improving filtration and so increasing the amount of water

able to pass through the filter into the tank.

Important: The diameter of the supply pipe (100mm) is the same diameter of the pipe to the

tank and to the storm water run-off.

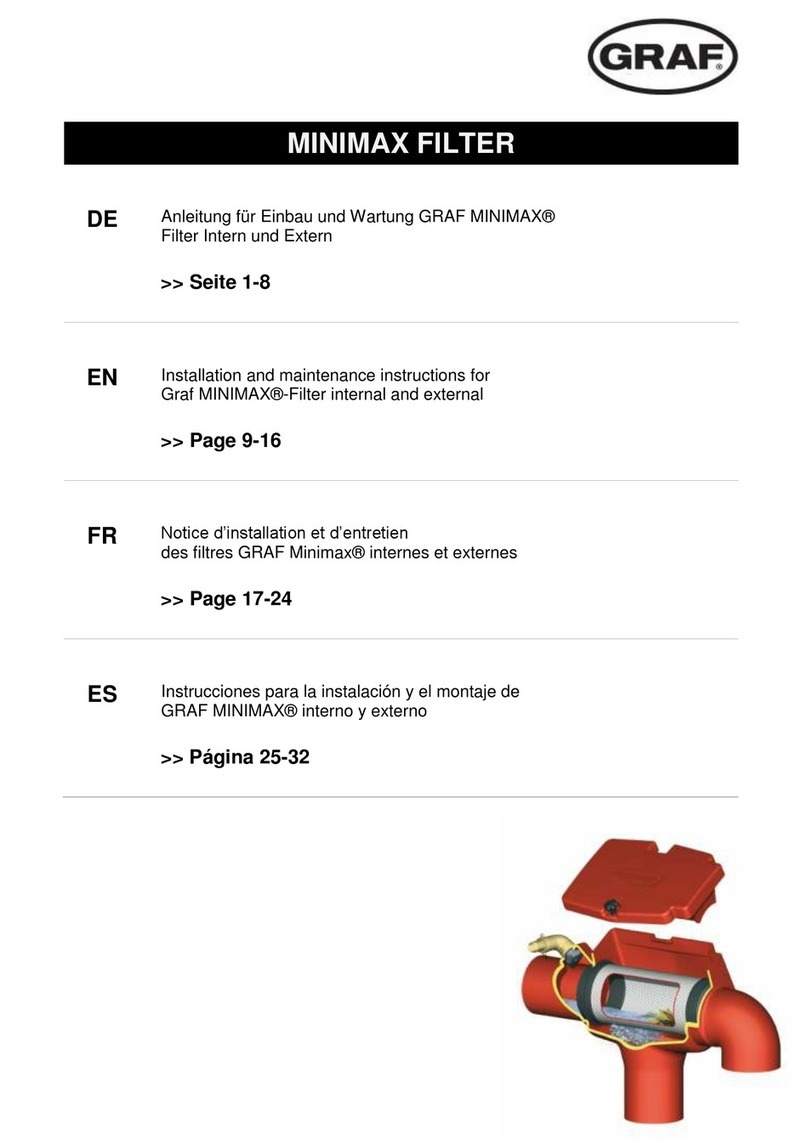

5.3 Telescope installation

The telescope is pressed into the filter housing from above. For excavation depths < 930 mm

the telescopic attachment and in some circumstances, the filter housing must be shortened.

It is important to ensure that the inlet pipe is not obstructed in any way by the telescope when

installed.

Before pushing in the telescope the profiled sealing ring is placed in the housings recess.

The telescope and the sealing ring must be thoroughly coated with the lubricating soap in-

cluded in the delivery (use no lubrication that is mineral oil based).

Attention: If the lubricating soap becomes dry and the telescope becomes difficult to move

then there is the danger that the sealing ring will be forced out of its recess. Before filling, the

sealing ring must be checked once again that it is seated correctly in position. The telescope

must be sufficiently embedded and supported that no forces are transferred to the housing.

5.4 Back Filling

Important: Before and during the filling, the horizontal position of the filter must be checked.

Smooth sand is required as backfill and must be tampered down lightly with a compacting

machine or hand held tamper in 30cm layers. Care must be taken during the embedding to

ensure the filter is not damaged. To ensure that no forces are applied to the filter housing,

the telescope must be well embedded and compacted.

5.5 Commissioning

Before commissioning the system the filter surface is to be thoroughly cleaned with a brush

and a solvent based cleaning fluid. Alternatively the filter sieve may be cleaned in a dish-

washer (40° max - 60°). Any dirt that gets into the filter housing during the assembly must be

thoroughly removed.

5.6 Servicing

The complete system is to be inspected at least every 3 months for leakage, cleanliness and

stability. The filter surface should be cleaned approximately every 3 months or according to

local conditions.

5. Excavation, Commissioning & Servicing