Ecofreen MiSTER-T CYCLONE User manual

2 - Manual

CYCLONE

SAFETY INSTRUCTIONS

For Use By Qualified Personnel Only

When using your machine, basic precautions should always be followed, including the following.

Read all instructions. Use Mister-T Cylone only for its intended use.

Mister-T Cylcone has to be operated with DTF materials like DTF powder and DTF film.

Mister-T Cyclone comes up with 12 months warranty.

This warranty includes the whole construction of the machine, mechanical parts, electronics.

Consumable parts like filters and conveyor belt are excluded from the warranty.

The set-up and installation of the machine has to be done under supervision of an authorized person.

The installation has to be done by 2 or more persons following the instructions of this manaul.

Caution : The plug has to be pulled out of the power outlet while maintenance.

To prevent current overload, plug only one plug into one outlet.

The country that uses 110V must be electrically constructed by an electronic expert.(Refer to page 11.)

Never pull cord to disconnect the power, grasp plug and pull to disconnect from power outlet.

Protect the power cord by keeping it away from hot surfaces. Do not allow objects to sit on top of

the cord. This could cause damage to the cord and could become a fire hazard risk.

Caution : Do not operate machine with a damaged cord or if the equipment has been damaged.

Do not disassemble or attempt to repair the machine to prevent risks to injury.

Call or take it to a qualified service person for examination and repair.

Incorrect assembly or repair could increase the risk of fire, electric shock, or injury to persons

when the equipment is used.

Supervision is necessary for any machine being used by or near children. Do not leave equipment

unattended while connected.

Care should be taken to arrange the cord so that it cannot be pulled or tripped over.

To reduce the likelihood of circuit overload, do not operate other high voltage equipment on the

same circuit. (Power : 2800WATTS, 50/60 hz, 110V : about 26AMPS, 220V : about 13AMPS)

The machine should only be used by trained personal after reading and understanding of the manual.

Make sure to wear masks and safety goggles and work in a well-ventilated ara.

Important : Do not place the printer near the equipment as the printer is vulnerable to powder.

Ecofreen is not responsible for printer failures caused by placing the machine

next to the printer.

3

- Manual

CYCLONE

Table of Contents

Congratulations on your purchase of powder applicator

In order to work professionally with the machine and start production, please make sure you read

this manual carefully,

Reproduction of this manual requires written consent.

Errors and amendments of technical details excepted, all rights reserved.

We are not liable for any direct or indirect damages caused by the use of this product

Machine Parts Diagram

Specifications&Circuit Diagram

........................... 4

.................................. 5

Installation ............................................... 6

Operating Instructions

Control Panel

Filter

Nozzle&Conveyor Belt

Vacuum Cleaner

Weekly Maintenance

.....................................

.....................................

.....................................

.....................................

........................................

Operation ........................................

13

14

Trouble Shooting

.................................... 21

Maintenance

Warranty Information

(Important)

17

18

19

20

............................ 22

Table of Contents

4 - Manual

CYCLONE

Machine Parts Diagram

<FRONT>

<BACK>

Circuit Breaker

(inside)(Page.12)

Power Cord

Foot Switch

(Page.7)

Start

Button

(Page.16)

Heat Platen

(Page.15)

Ventilation

(Page.12)

Sensor

(Page.16)

Film Stand

(Page.8)

Emission filter

(Page.20)

Acrylic Lid

Control Panel

(Page.12)

* Please refer to the page.

Top Hopper

Powder Ventilator

(inside)

Cyclone(inside)

5

- Manual

CYCLONE

Specifications

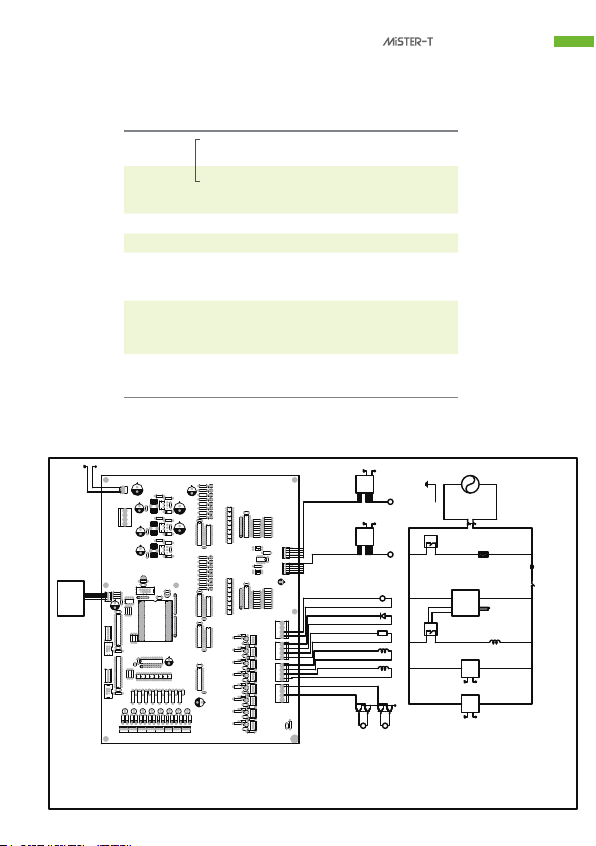

Circuit Diagram

Dimensions Applicator

2nd Conveyor

for Dryer

( Optional )

67 cm(W) x 126 cm(L) x 196 cm(H)

26.4 inch(W) x 49.6 inch(L) x 77.2 inch(H)

66 cm(W) x 120 cm(L) x 95 cm(H)

26 inch(W) x 47.2 inch(L) x 37.4 inch(H)

35.8 inch(W) x 55.1 inch(L) x82.7 inch(H)

About 200 kgs (about 441 lb)thgieW

Conveyor Belt

45 cm x 110 cm (17.7 inch x 43.3 inch)

Lap Time

(40 cm x 50cm )

(16” x 20”)

Standard : 14 sec

High Production : 8 sec

Power Supply 2800WATTS, 50 / 60 HZ

- 110V : about 26 AMPS

- 220V : about 13 AMPS

* It may be changed according to the power of vacuum cleaners.

Packing (Wooden Pallet) 91 cm(W) x 140 cm(L) x 210 cm(H)

1 2 64

3132 34

63

33

470J

470J

470J

10KJ

TIP122

OUT_1

+24V

RS485

OUT_2 OUT_3 OUT_4

CON18. Film detection sensor

CON17. Foot switch

CON16. Start switch

CON15. N.C.

CON14. N.C.

CON13. N.C.

Start butten lamp

GND

Enable

BREAK

Speed

GND

Speed

Forward,Backward

Enable

BREAK

Forward,Backward

Case (+)

(-)

S.S.R.-2

S.M.P.S.

DC24V

(+)

(-)

S.S.R.-1

Relay-1

Relay-2

24V

S.M.P.S.

DC12V

12V

12V

(+)

(-)

Relay-1

M

(+)

(-)

Relay-2

M

Powder outlet valve motor run

Vacuum valve motor run

Powder outlet valve motor open, close

Vacuum valve motor open,close

Powder outlet vibrate motor

S.S.R.-1

M

Lamp

AC110V,

AC220V

24V

B.L.D.C.

MOTOR

DRIVE

24V

M

B.L.D.C.

MOTOR

DRIVE

24V

M

CON20. Powder outlet valve sensor

CON19. Vacuum valve sensor

Vacuum

Cleaner

Outlet

Conveyor Motor

Impeller Motor

Control

Panel

Vacuum

Valve

Motor

Powder

Outlet

Valve

Motor

Temp.

Controller Temp.

Sensor

Heat Ray

Emergency

Switch

Power

Switch

Installation

Gently open the back door of the machine and find the zipper bag inside the machine

and please check if all the components are in the zipper bag.

<Open the circled door>

<Components in zipperbag>

①

②

③

④

⑤

⑥

⑥

①Brushes(2ea) : Brushes are included due to maintenance work.

Screws(3ea) : 3 screws are included for installing film stand.

Screws(2ea) : 2 screws are included for installing the film sensor.

Bands(3ea) : 3 bands are included for tightening the vacumm cleaner to the hose.

②

③

④

Keys(4ea) : 2 keys are included

Insulating tape(1ea) : 1 insulating tape is included for tightening the vacuum cleaner and the hose.

⑤

<Inside the door>

6 - Manual

CYCLONE

Installation

1. Machine Leveling

Please ensure the machine is properly placed and leveled. Otherwise, powder in the machine

will not applied consistently.

To level the machine, turn the machine feet clockwise to decrease height and counter clockwise

to increase the height.

<Wheel>

2. Install the foot switch.

Foot switch is in the side door.

Gently unscrew the side door and place the wire in the groove as the picture below.

* Make sure not to touch the other parts inside the door.

<Unscrew the circled side door>

<Inside the side door>

<Place the wire in the Groove>

Foot

Switch

Inside

7

- Manual

CYCLONE

Installation

3. Install the film stand.

Film stand is wraped with a tinfoil and is inside the bottom door.

Unpack the film stand and install as the shown picture.

<Open the circled door>

<Components> <Place the film stand>

<Film stand is packed with tinfoil>

After placing the both of the components, assemble the film stand with the screws in the zipper bag.

3 screws are required for assembly.

*Before placing the film stand, open the

acryl lid

8 - Manual

CYCLONE

Installation

4. Install the film sensor.

Film sensor is in the zipper bag.

Unpack the film sensor in the zipper bag and install as the shown picture.

<Film sensor is packed in the zipper bag> <Assemble the film sensor>

*2 screws are required for assembly.

Regarding film sensor, please refer to page.

<Assemble the film sensor>

9

- Manual

CYCLONE

Installation

5. Connect the vacuum cleaner

Connect the vacuum cleaner to the labeld hoses as shown in the picture.

After connecting the vacuum cleander, make sure to tighten the vacuum cleaner with

insulating tape and the bands.

<Bands and insulation tapes><Labeled hose>

<Tighten the vacuum cleaner>

*bands and insulation tapes are in the zipper bag

*Both vacuum cleaners are required at lease 1100 Watts to 1300 Watts.

10 - Manual

CYCLONE

Installation 11

- Manual

CYCLONE

5-1. Connect A tube to the inlet on the front of the Vacuum 1.

5-2. Connect B tube to the inlet on the fron of the Vacuum 2.

5-3. Connect C tube and the D tube to an acrylic box.

5-4. Connect E tube to the outlet of the vacuum cleaner which is located opposite of inlet vent.

**It is recommended to tape circled area from inside

to prevent the air leaking.

You can also find this details in the Appendix manual page 8&9.

5-5. Connect the hole to the outlet of the vacuum with a hose which is behind the vacuum cleaner.

The hole is located in the circled area behind the vacuum 1.

A Tube

B Tube

C Tube

D Tube E Tube

Installation

6. Ventilation(Option)

7. Connect the powder cord

Ventilation should be installed according to working enviorment.

The country that uses 110V must be electrically constructed by an electronic expert.

As 110V requires a lot of current, AC wire and Earth wire must be connected

upon user’s condition.

To reduce the likelihood of circuit overload, do not operate other high voltage equipment on the

same circuit. (Power : 2800WATTS, 50/60 hz, 110V : about 26AMPS, 220V : about 13AMPS)

*Required Ring blower spec*

diameter 4”, over 170CFM

<Circuit breaker>

Earth wire

AC wire

<Open the circled door>

12

- Manual

CYCLONE

13 - Manual

CYCLONE

Operation

Control Panel

1. Power On / Off

2. Emergency Button

3. Manual / Auto Button

Under the auto mode

- Conveyor speed, powder mix speed, lap time can be set.

- By pressing the start button and placing the film, the powder will be automatically

applied on the film

Under manual mode

- Each module can be excuted separately.

- By using manual mode, you can inspect all the functions on the machine.

4. Mode Button

- Under the auto mode, conveyor speed, powder mix speed and lap time can be set

by up and down button.

5. Cyclone Button(Under manual mode only)

- By pressing cyclone button, machine will go into a vacuum and the vacuum

cleaners will be operated.

6. Conveyor Button(Under manual mode only)

By pressing conveyor button, conveyor belt will be operated.

7. Impellar Button(Under manual mode only)

By pressing impellar button, impellar will be operated.

8. Vacuum Button(Under manual mode only)

By pressing vacuum button, the machine will go into vacuum.

9. Powder On / Off Button(Under manual mode only)

By pressing this button, nozzle will be opened or closed.

① ②

④

⑤

⑥ ⑦ ⑧

⑨

③

Operation

1) Turn on the circuit breaker which is inside the machine.

2) Turn on the power switch which is located on the control pannel.

Auto Mode

How to set modules.

Manual Mode

Recommendation

Conveyor speed Powder mix speed Lap time

1~10 levelRange 1~10 level

5 50sec5

1~99 sec

If the M/A button is off, the machine is in automatic mode.

When pressing the button, it will blink and the modules can be set.

-By pressing the mode button once, conveyor speed can be adjusted by Up and Down button.

-By pressing the mode button twice, powder mix speed can be adjusted by Up and Down buttons.

-By pressing the mode button three times, lap time can be adjusted by Up and Down buttons.

Each module can be excuted separately by pressing each button.

Each module can be inspected in the manual mode.

When pressing the button light will be on and will be operated.

Each modules can be set by pressing “Mode” button.

<Auto Mode>

<Manual Mode>

* Ensure the emergency button on the right side of the panel is not locked.

If the emergency button is locked, unlock by turning the button clockwise.

14

- Manual

CYCLONE

<Open the circled door> <Circuit breaker>

15 - Manual

CYCLONE

Operation (Continued)

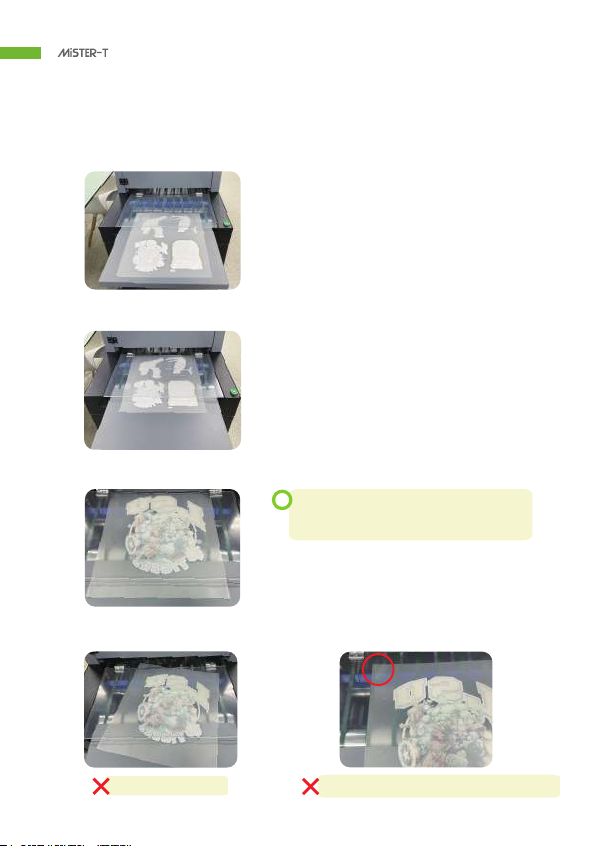

4) Gently place the film on the heat platen.

5) Gently slide the film almost to the end of the heat platen.

5) Place the film well so it doesn’t get jammed on the conveyor belt.

Heat Platen

Heat platen allows ink dry for a while for better quality at 50℃ or 122℉.

Additionally, it will get rid of humidity in the film.

*For some areas with high humidty, we recommend you to dry the the film.

*Press the button on the back side to lift the platen.

*Before rasing the platen, open the acryl lid first.

If the film is far too behind from the conveyor, the film may not move forward.

The film is crooked. Film not placed in the middle of the conveyor belt.

Place the film in the middle of the conveyor belt.

*Make sure to give enough room between the film and

conveyor belt.

Operation (Continued)

Precautions

- Make sure both vacuum cleaners are powered. Otherwise, the machine will not operate properly.

- If there is too much powder inside the vacuum cleaners. The machine may not work properly. (Refer to Maintenance part.)

- Make sure not to insert crumpled film. The crumpled film may stuck on the conveyor belt.

- Do not exceed 2/3 of the powder in the hopper.

- Make sure to wear masks of safety goggles. Powder might irritate the eyes, throat and lungs which may cause

allergic reactions.

- Make sure to work in a well-ventilated area.

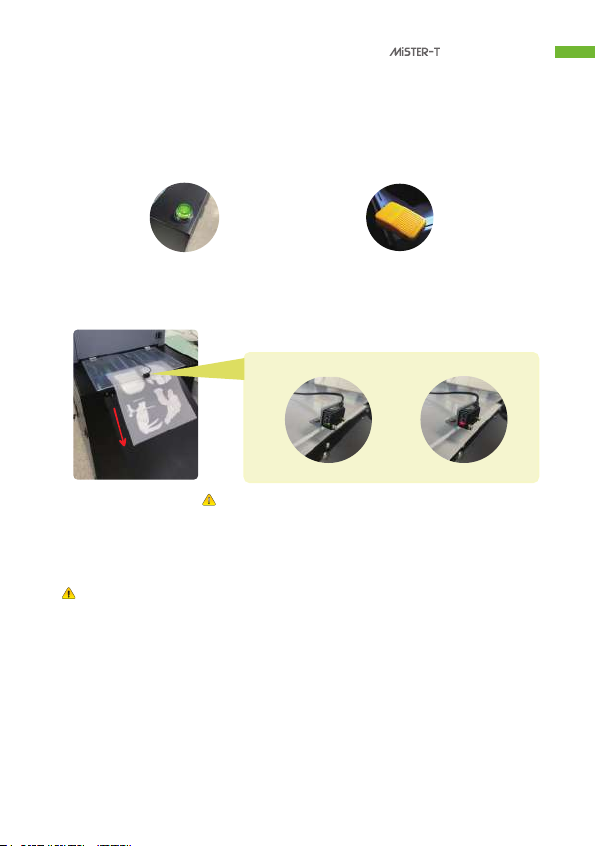

6) Press the start button or step on the foot switch to run the machine.

*Before pressing the start button, make sure to close the acryl lid.

7) The film will go through the powder box and will stop by the sensor at the end.

* The sensor at the back detects the film after applying the powder.

<Start Button> <Foot Switch>

<Film isn’t detected by the sensor> <Film is detected by the sensor>

Green Light On Red Light On

Caution : When the film reaches the sensor, all actions will be automatically terminated

in a few seconds.

Make sure not to touch the sensor with hands or other objects.

Otherwise, the sensor will detect the other objets and machine will be stopped

during operation.

16

- Manual

CYCLONE

17 - Manual

CYCLONE

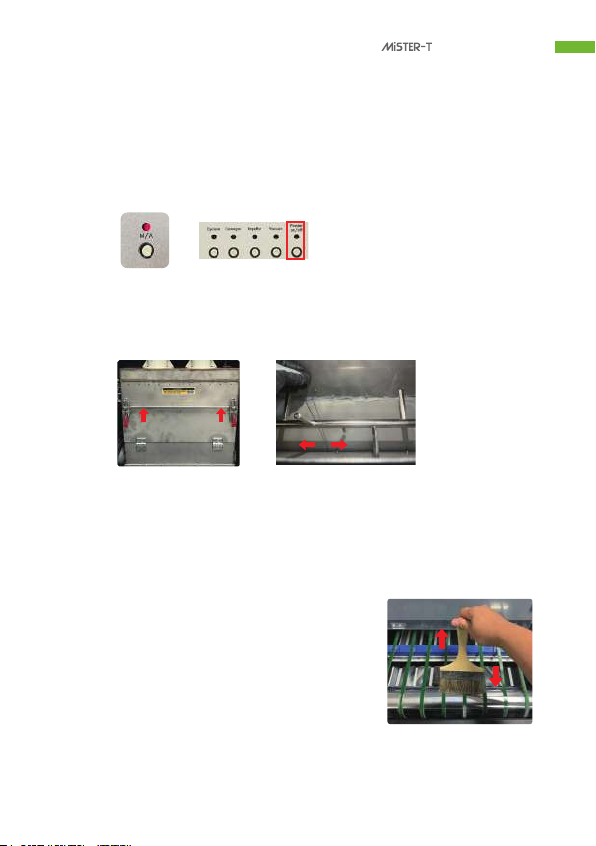

Daily Maintenance ①

Filter

Step 1 : Turn off the power switch and unplug all the vacuum cleaners.

Step 2 : Open the lid of powder box.

Step 3 : Go in to manual mode and press vacuum button.

Step 4 : Carefully remove the filter.

Step 5 : Remove the dust from the filter with a brush.

* Dust on the filter can contaminate the powder.

Brush off the filter everyday at the end of work.

*Precautions

* Make sure to wear gloves while cleaning the filter.

Wire inside the filter can damage your hands.

* Make sure to wear masks and safety goggles.

Powder can cause allergic reactions.

<Manual Mode>

Daily Maintenance ②

Daily Maintenance ③

*Precautions

* Make sure to wear masks and safety goggles.

Powder can cause allergic reactions.

Nozzle

Conveyor belt

Step 1 : Go in to manual mode like the shown picture below.

Press Powder On / Off button to empty the powder box.

Otherwise, it would be difficult to see inside the top hopper.

Step 2 : Unplug the power cord and the vacuum cleaners.

Step 3 : Open the lid of the top hopper

Step 4 : Powder lump can cause nozzle clogging and uneven application onto the film.

Move a thin wire back and forth between nozzle to make sure the nozzle is not clogged.

<Manual Mode>

18

- Manual

CYCLONE

Brush off the powder if there is too much powder

on the conveyorbelt.

Run the conveyor belt slowly while brushing off the conveyor.

Too much powder on the conveyor

will not hold the film and won’t carry the film to the end.

Nozzle Area

<Inside the top hopper>

19 - Manual

CYCLONE

Daily Maintenance ④

*Precautions

* Make sure to unplug the machine and the vacuum cleaners.

* Make sure to wear masks and safety goggles.

Powder can cause allergic reactions.

* The vacuum cleaner must be 1100W to 1300W.

Vacuum cleaner

Step 1 : Turn off the power switch and unplug all the vacuum cleaners.

Step 2 : Open up the vacuum cleaner and check the amount of powder inside.

Step 3 : Get rid of the powder in the vacuum cleaner.

Step 4 : Clean up the filter inside the vacuum cleaner with a brush.

*Reference

The vacuum cleaner has to be purchased separately and requires two units

(1100W to 1300W each)

Weekly Maintenance ①

Emission filter

Bottom Hopper

Step 1 : Turn off the power switch and unplug all the vacuum cleaners.

Step 2 : Unscrew the emission filter which is located in the front part of the machine.

Step 3 : Clean up the emission filter with a brush.

Step 1 : Go in to the manual mode like the shown picture

Step 2 : Take off the powder ventilator from the bottom hopper.

Step 3 : Prepare a plastic bag and place under the hole of the hopper,

or put the vacuum cleaner between the conveyor belt to vacuum up the powder.

Step 4 : Press powder on/off to release the powder from the top hopper.

* We recommend you not to reuse the left powder to maintain the quality of the powder.

*Precautions

* Make sure to wear masks and safety goggles.

Powder can cause allergic reactions.

Weekly Maintenance ②

<Manual Mode>

or

20

- Manual

CYCLONE

Table of contents