Ecolab POSITRONIC IV User manual

POSITRONIC IV

Installation and Operation Manual

20428/0303/0804 Copyright Ecolab Inc. 2004 9448-2502

This page intended

to be blank.

iii

TABLE OF CONTENTS

POSITRONIC IV

Installation and Operation Manual

1.0 PREFACE........................................................................................................ 1

2.0 INTRODUCTION.............................................................................................. 1

3.0 SPECIFICATIONS........................................................................................... 2

4.0 INSTALLATION PROCEDURES .................................................................... 5

4.1 Multiple Pump Pneumatic Controller ....................................................... 5

4.2 Single Pump Pneumatic Controller ......................................................... 5

4.3 Pump Shelf with Pump............................................................................ 6

4.4 Anti-Siphon Valve.................................................................................... 6

4.5 Ball Foot Valve ........................................................................................ 6

5.0 TYPICAL MULTIPLE PUMP INSTALLATION ................................................ 7

6.0 OPERATIONS ................................................................................................. 8

7.0 TROUBLESHOOTING..................................................................................... 9

8.0 PERIODIC MAINTENANCE .......................................................................... 10

9.0 PUMP SERVICING........................................................................................ 10

10.0 INSTALLATION OPTIONS............................................................................ 11

10.1 Adding a Solenoid and Regulator ......................................................... 11

10.2 S-2000 for Multiple Pump Controller ..................................................... 11

10.3 S-2000 for Single Pump Controller........................................................ 11

11.0 GRAPHS AND TABLES................................................................................ 12

12.0 REPLACEMENT PARTS............................................................................... 13

This page intended

to be blank.

1

The pump construction of the Positronic IV, primarily Teflon

and polypropylene, is capable of handling corrosive fluids. It

has the capability to 55 psig (3.8 bar) discharge pressure.

Minimum flow rate is 15 oz/min (445cc/min.) (when using a

meteringorifice,

refertoSection11, page 12

)anda maximum

of 1.2 gal/min (4540 cc/min). As product viscosity increases

from that of water and/or suction lift increases from zero feet

to a maximum of 3-1/2 ft (107 cm), maximum flow rate will be

less than 1.2 gal/min (4540 cc/min).

Operating sequence of the system begins when an electric

signal (i.e., timer or conductivity sensor) entering the pneu-

matic controller energizes a solenoid to open an air valve

allowingregulated airpressuretopower thepneumaticpump.

The solenoid requires 110/120 VAC, 50/60 Hz single phase

electricity. The compressed air entering the Pneumatic Con-

troller must be filtered to 5 microns. No air lubricator is to be

used.

Each pump consumes a maximum of 3 scfm (1.4dm3/s) at the

maximum air pressure of 70 psig (4.8 bars). Pump delivery is

controlled by the air pressure setting of a regulator.

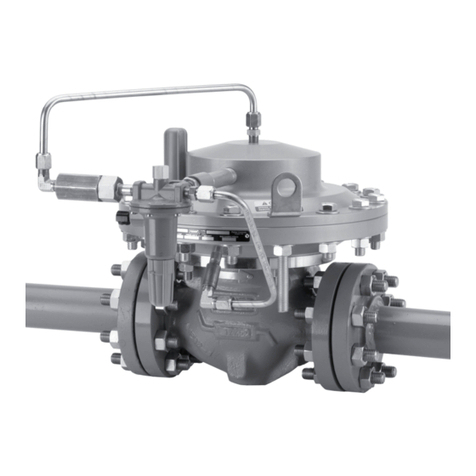

Components of the Positronic IV system consist of a pneu-

matic controller and an air operated double diaphragm pump.

Required accessories include a foot valve, anti-siphon valve

and a check valve.

1.0 PREFACE

It is imperative that all personnel concerned with the system

installation, operation and maintenance become familiar with

this manual. For a clean and functional installation, these

general instructions will provide the necessary guidance.

Understandingthis information will also helpyoumakeinstal-

lation modifications to meet the varying conditions and sur-

roundings.

WARNING:Theseinstallationandservicinginstruc-

tions are for use by qualified personnel only. The

installationmustbeinaccordancewithlocalplumb-

ing and electrical codes.

2.0 INTRODUCTION

2

3.1 Dimensions

• Height: 13-1/2 in. (34.3 cm)

• Length: 11-1/8 in. (28.3 cm)

• Width: 5-5/8 in. (14.3 cm)

3.2 Services Required

Compressed air: MAX 120 psig. (8.3 bars)

MIN. 80 psig (5.5 bars)

AIR FLOW 9 scfm (4.2 dm3/s) MIN.

Electrical: 110/120 VAC, 50/60 Hz Control signal

WARNING: - The supply air line must not contain an air

lubricator.

3.0 SPECIFICATIONS

3.3 Equipment Supplied

The Multiple Pump Pneumatic Controller is supplied with a

1/4" ball valve and 5 micron filter for the supply air. It contains

a 5 station manifold, with three stations having pump control

solenoids, regulators and two blanks for additional solenoids

and regulators.

The Multiple Pump Pneumatic Controller has an octal socket

fora 24VACrelayand 10pointterminalblockfor the120VAC

control signal.

Four wall mounting anchors and screws are included.

Figure 1

3

3.1 Dimensions

• Height: 9 in. (22.9 cm)

• Length: 8-3/4 in. (22.2 cm)

3.2 Services Required

Compressed air: MAX 120 psig (8.3 bars)

MIN. 80 psig (5.5 bars)

AIR FLOW 3 scfm (1.4 dm3/s) MIN.

Electrical: 110/120 VAC, 50/60 Hz.

WARNING: - The supply air line must not contain an air

lubricator.

3.3 Equipment Supplied

This controller is supplied with a 1/4" ball valve and an air

regulatorwitha5micronfilterforthesupplyair,apumpcontrol

solenoid, and a 4x4x2 PVC junction box. Four 8-32 x 1/2"

mounting screws are included. A length of 1/4" O.D. plastic

tubing for the pump air line is supplied.

3.0 SPECIFICATIONS (con't.)

Figure 2

SINGLE PUMP PNEUMATIC CONTROLLER

4

3.1 Dimensions (Pump Shelf with Pump-Fi ure 3)

• Height: 8-1/4 in. (21 cm)

• Length: 7-3/4 in. (19.7 cm)

• Width: 9-1/2: (24.1 cm)

3.2 Services Required

Compressed air: MAX 70 psig (4.8 bars)

AIR FLOW 3 scfm (1.4 dm3/s)

Thecompressedairisreceivedfromthepneumaticcontroller.

3.3 Equipment Supplied

One pump is supplied with the pump shelf. Supplied for the

pump are the product inlet and outlet elbows and the air

connectionfitting.Includedwiththepumpshelfarethemount-

ing fasteners.

3.0 SPECIFICATIONS (con't.)

3.1 Dimensions (Pump Bracket - Fi ure 4)

• Height: 4-3/8 in. (11.1 cm)

• Length: 23-1/8 in. (58.7 cm)

• Width: 3/4 in. (1.9 cm)

3.2 Description

This bracket is capable of supporting (3) pump shelves.

PUMP SHELF WITH PUMP

Figure 3

Figure 4

5

4.1 Multiple Pump Pneumatic Controller

HINT: If this system is replacing a different system, label

anycontrolwirespriortodisconnectingthatwillberecon-

nected to the new system.

1. Locate a practical place for the Pneumatic Controller so

theair lines fromthe controller to the pump do notexceed

50ft(15meters).Also,considertherelativelocationofthe

compressed air source that will be connected to the

controller's air inlet.

(See item 4).

2. For air lines to pumps, 1/4" O.D. tubing is recommended

for lengths up to 25' and 3/8" O.D. tubing is used for

lengths from 25 to 50 ft.

Refer to Figure 5.

3. Mount the controller using the enclosed wall mount an-

chors and screws.

4. For the main air supply line, due to air supply require-

ments, it is recommended to use 3/8" sch. 40 pipe mini-

mum for a maximum length of 50 ft.

5. Connect supply air line to the ball valve preceding the

5 micron filter. Leave the ball valve closed.

Refer to

Figure 5.

NOTE: Do not use an air lubricator.

6. Turn regulator control knobs full counter clockwise. This

will effectively shut off the air supply to the pump until

regulating to desired pressure.

7. Connect pump air lines to the fittings on the right side of

the controller by wrench tightening the fitting nuts, maxi-

mum of one turn beyond finger tight.

Refer to Figure 5.

8.

Connect 110/120 VAC, 50/60 Hz control wire to the right

side of the 10 point terminal block.

Refer to Figure 6.

NOTE - Remove white common wire harness when

more than one process controller is entering the

pneumatic control cabinet. Use individual neutrals/

commons in place of the harness.

9. Connectagroundwiretothepostlocatedtotherightofthe

terminal strip.

Refer to Figure 6.

4.2 Sin le Pump Pneumatic Controller

1. Mount the controller to the left side of the pump cabinet

using the four 8-32 x 1/2" screws that are supplied.

Refer

to Figure 8.

2. Bring a 110/120 VAC, 50/60 Hz signal into the bottom of

the junction box and wire nut to the solenoid leads.

Refer

to Figure 7.

3. Connect supply air line to the ball valve preceding the

5 micron filter/regulator. Leave the ball valve closed.

NOTE - Do not use an air lubricator.

4. Turn regulator control knob full counter-clockwise.

5. Install free end of the 1/4 O.D. tubing to the air inlet side

ofthe pump. Thetypeoffittingon the pumptoreceivethis

tubing requires approximately 1/2 inch insertion of the

tube to be automatically retained. Make a reference mark

1/2" from the tube and prior to the insertion.

Refer to

Figure 8

4.0 INSTALLATION PROCEDURES

Figure 5

Figure 6

Figure 7

6

Toremovethetubefromthistypeoffitting,firstpullorpush

the gray collar towards the fitting body, then pull out the

tube.

4.3 Pump Shelf with Pump

1. The shelf may be directly mounted on a wall using the

supplied wall mount anchors and screws. For multiple

pump mountings, the Multiple Pump Mounting Bracket

may be used.

Refer to Section 3, page 4

.

2. Mount the shelf so the pump inlet is a maximum of 3-1/2

ft. (107 cm) above the drums lowest possible liquid level

and 10 ft. (3 meters) maximum horizontal. Always locate

the pump above the product drum.

3. Take the free end of the "Pump Air Line" coming from the

pneumaticcabinetandinsertitapproximately1/2inchinto

the fitting on the side of the pump. It will be automatically

retained. Make a reference mark 1/2" from the tube and

prior to the insertion

Toremovethetubefromthistypeoffitting,firstpullorpush

the gray collar towards the fitting body, then pull out the

tube

4. If a 3/8" OD pump air line is required (

See Section 4.1 #2

on page 5

), it may be adapted to the pump fitting as

illustrated.

Refer to Figure 9.

5. For product lines, use 19/32" OD x 3/8 ID EVA reinforced

tubing for the discharge line. Install this line to the top

pump port.

6. Install1/2"ODx3/8"IDpolyethyleneorEVA(unreinforced)

tubing for the intake line. The unreinforced EVA tubing is

preferred because of its flexibility. Install this line to the

bottom pump port.

7. Install on the intake line a foot valve.

Refer to Section 4.5

below.

4.4 Anti-Siphon Valve

Install the anti-siphon valve according to the direction of the

specific installation case. Match anti-siphon valve to product

being dispensed. See replacement parts.

CASE 1 - (injecting into the suction side of the CIP pump and

when the chemical feed pump is above injection point).

1. Placean anti-siphon valve within 2 ft of the chemicalfeed

pump in its discharge line. Also install a second anti-

siphon valve ahead of the check valve at the injection

point. Condition of this case is based on the pump being

above the product tank.

Refer to Figure 10.

CASE 2 - (Injecting into the suction side of the CIP pump and

when the chemical feed pump is below injection point).

1. Placeananti-siphonvalveaheadofthecheckvalveatthe

injection point.

Refer to Figure 10.

4.5 Ball Foot Valve

1. The ball foot valve is used along with the drum probe.

4.0 INSTALLATION PROCEDURES (con't)

Figure 8

Figure 9

Figure 10

7

5.0 TYPICAL MULTIPLE PUMP INSTALLATION

8

6.1 Multiple Pump Pneumatic Controller

1. Check that all pump control regulator adjustment knobs

are in the full counter-clockwise position.

2. Check that the pump intake probes are in the appropriate

products.

3. Open the air inlet ball valve.

Refer to Figure 11.

4. While pressing the manual operator button on the sole-

noidvalvewitha"pen tip",rotatetheregulator adjustment

knob until the pump starts (approximately 18 psig or 1.2

bars)

5. Continue to increase the air pressure to establish the

pressure needed for the required flow rate.

Refer to the

graphsinSection11,page12

touseasaset-upguideline

to determine this approximate air pressure.

6. Fine tune the delivery by taking a solution sample and

titrate it.

7.

Referto paragraph "6.3 Pump"

below for additional pump

delivery information when less than 20 oz./min.

6.0 OPERATIONS

6.2 Sin le Pump Pneumatic Controller

1. Checkthattheregulatorcontrolknob isinthefullcounter-

clockwise position.

2. Check that the pump intake probe is in the product.

3. Open the air inlet ball valve.

4. While pressing the manual operator button on the sole-

noidvalvewitha"pen tip",rotatetheregulator adjustment

knob until the pumps starts (approximately 18 psig or 1.2

bars).

Refer to Figure 12.

5. Continue to increase the air pressure to establish the

pressure needed for the required flow rate.

Refer to

graphs in Section 11, page 1

2 to determine this approxi-

mate air pressure.

6. Fine tune the delivery by taking a solution sample and

titrate it.

7.

Referto paragraph "6.3 Pump"

below for additional pump

delivery information when less than 20 oz./min.

6.3 Pump

Flow rate is primarily regulated by controlling the pump air

pressure. An air pressure of at least 20 psig (1.4 bars) (for

water) is required to have the pump operate.

Alternatively the flow rate may be regulated by the discharge

pressure. It may become necessary to control the delivery by

usinga needle valveororificeinthedischarge line toincrease

the discharge pressure when the required pump operating air

pressure is at the minimum and the flow rate must be further

reduced. Referencing the performance curves in

Section 11,

page12

,youwillseeforagivenairpressure how the flow rate

decreases as the discharge pressure increases. An example

of when a needle valve or orifice will help to increase the

discharge pressure is for tank top feeding. The orifice should

beusedratherthentheneedlevalvewhenflowrateslessthan

20 oz./min. (590 cc/min.) are needed.

Refer to Section 11,

page 12 - Table 1

for Orifice options.

1. Place the orifice assembly in the discharge line.

2. Fine tune the delivery by taking a solution sample and

titrate it.

Figure 11

Figure 12

9

7.0 TROUBLESHOOTING

Problem Cause or Failure Mode

WARNING - Wear safety goggles, rubber gloves and other required protective clothing when removing the pump

from its circuit. Proceed with caution when disconnecting the discharge line because it may be pressurized. When

disconnecting a discharge line fitting, place a rag over the fitting to shield yourself from any possible spray.

Action

1. Pump will not run Air line blocked

Pump directional valve in neutral

position

No electrical power to the unit

Low air pressure

Check air line for passage of air.

Press white plastic reset button on the

pump below air supply port

Take corrective action (fuses, timer,

solenoid coil, etc,)

Check plant air supply.

2. Pump will not prime Liquid intake tube is blocked

No air to the pump

Intake line fittings not tight

Take corrective action

Take corrective action

Take corrective action

3. Pulsating Flow Some pulsating flow is normal

Clogged check valve, intake or dis-

charge

Air in the intake line

None Required

Disassemble

per Section 9, page 10

.

Clean check valves, then reassemble.

Clean product tank and intake line.

Check product reservoir for being

empty, check intake line for cracks and

loose fittings, check vertical studs

(Fig

14, page 10)

for tightness.

4. Low Flow Rate Discharge line blocked

Liquid intake tube is blocked

Debris caught in pump valves

Check the check valve or anti-siphon

valve

Take corrective action

Remove pump manifolds to clean

valves.

Refer to Section 9, page 10

5. Discharge Line Drains Anti-siphon valve leaks

Anti-siphon valve not properly installed

Replace valve

See Section 4, paragraph 4.4, page 6

6. Intake Line Drains Foot valve leaks Disassemble, clean, and reassemble

10

8.0 PERIODIC MAINTENANCE

1. Manually drain air filters monthly. These filters have an

automatic drain, but a monthly check should be done.

Annually replace filter element.

Refer to Figure 13.

2. Check day tank(s) for debris.

3. Check exterior of fittings, anti-siphon valves and check

valves for leaks.

4. Check product and air tubing for cracks or damage.

9.0 PUMP SERVICING

WARNING-Wearsafetygoggles,rubberglovesandother

required protective clothing when removing the pump

fromitscircuit.Proceedwithcautionwhendisconnecting

the discharge line because it may be pressurized. When

disconnectingadischargelinefitting,placearagoverthe

fitting to shield yourself from any possible spray.

9.1 Pump Check Valve Servicin

1. For safety reasons, disconnect air line a pump.

See

Section 4, paragraph 4.3, page 6

for method of line

disconnection.

2. Disconnect product discharge line at the CIP unit.

3. Reconnect air line at the pump.

4. Pump water to flush out the product within the pump.

5. Remove pump from shelf.

6. Using two-10mm wrenches, one for each nut at opposite

endsofaverticalstud,removethenuts andwashersfrom

the four vertical studs.

7. Separate the discharge (top) manifold from the pump.

Removetheo-rings,valveguides,valvesandvalveseats.

Examine the valves and valve seats for damage or em-

bedded debris.

Refer to Figure 14.

8. Turn the pump upside down and separate the intake

(bottom) manifold. Remove the o-rings, valve seats and

valves.Examinethevalveseatsandvalvesfordamageor

embedded debris.

HINT - If reusing the o-rings replace with the beveled side

towards the mating part (valve seat or guide).

Refer to

"DETAIL" in Figure 14.

HINT - Before reinstalling the vertical studs, note that the

studshaveashorterthreadlengthononeendasopposed

to the other. Place the nuts and washers on the short end

of the studs before installation.

9. Reassemble the intake side first. Begin by squarely plac-

ing the valve into the pump, lay the valve seat onto the

valve and position the o-ring. Next, install the manifold,

install the mounts and insert the four studs.

10. Holding the intake manifold firmly on the pump, turn the

pump right side up and place it on a work surface.

Figure 13

Figure 14

11

11. Begin assembling the discharge side by installing the

valve seat. Squarely locate the valve onto the seat. While

keeping the valve centered install the valve guide. Install

the o-ring, manifold and secure with washers and nuts.

12. Tighten nuts to 35 to 45 in-lbs.

10.0 INSTALLATION OPTIONS

10.1 Addin a Solenoid and Re ulator

1. Remove the ty-wraps that are supporting the solenoid

leads inside the control cabinet.

2. Remove the (10) screws on the exterior right side of the

control cabinet that are holding the air manifold mounting

panel to the cabinet. With the manifold attached to the

panel, pull the panel away from the cabinet.

3. To allow mounting a solenoid and regulator, remove the

port covers from the next available manifold station.

4. Mount the solenoid and regulator as shown in

Figure 15

.

Secure their mounting screws firmly.

5. Remount the manifold panel.

6. Attachthe solenoid leadstothenextavailableposition on

the terminal block.

7. Attach the ty-wrap mount in the cabinet.

8. Individuallybundle the solenoid leads andsecurethemto

a mount with a ty-wrap.

9. Install the pressure gauge by inserting the gauge tube

end, about 1/2 inch, into the mating part on the solenoid

valve.

10.2 S-2000 for Multiple Pump Controller

1. Signal wires from the S-2000 should be connected to

terminals 2 and 7 of the octal socket. Remove from the

socketthepurplejumperwirebetween1and3.Installinto

the socket the 24 VAC relay (item 7 "Replacement Parts"

page 13). This will control "Pump 1".

Refer to Figure 16

.

10.3 S-2000 for Sin le Pump Controller

1. If a 24 VAC signal is used, make an additional hole in the

junction box (7/8 diameter is required for 1/2 electrical

conduit) for the 24 VAC signal. Use the special 24 VAC

relay assembly, (Item 12, "Replacement Parts" on page

13). Slide this assembly into the junction box. R

efer to

Figure 17.

9.0 PUMP SERVICING (con't.)

Figure 15

Figure 16

Figure 17

12

11.0 GRAPHS AND TABLES

The following orifice flow rate information is to be used as a guide.

ORIFICE AIR PRESS. PRODUCT FLOW RATE

-psig (bar) oz/min. (cc/m)

25 (1.7) 15 (440)

30 (2.1) 17.6 (520)

#56 DRILL 40 (2.8) 22.7 (670)

50 (3.4) 27.4 (810)

25 (1.7) 21 (620)

30 (2.1) 25 (740)

#55 DRILL 40 (2.8) 29.4 (870)

50 (3.4) 33.8 (1000)

TABLE 1

13

REPLACEMENT PARTS POSITRONIC IV

SECTION:

REF.

NO. PART NO. DESCRIPTION

1 8528-9221 COIL 120/110V MAC 35 SERIES

2 8526-5007 SLND VLV 1/8 FPT 120/110V 6.5 W

NC

3 8420-0351 REGULATOR AIR MAC 35A-00L

4 8538-0103 FILTER ELEMENT 5 MICRON

POLYP

5 8539-0284 PRSR GA 1-1/2 D. 1/8 MPT 100PSI

6 •9448-1272 SLND/REG KIT (INCLUDES REF

NOS. 2,3 AND 5)

7 8300-0174 RLY PLUG-IN 24V DPDT 10 AMP

8 8480-4673 PUMP MANIFOLD

9 8539-0086 PRSR GAUGE 2D 1/8 100# CB

10 8526-5015 SOLENOID VALVE 1/4 3 WAY - AIR

11 8528-9213 COIL 120/110V MAC 100 SERIES

12 9448-1280 RELAY ASM. PKD.

13 8300-0232 RELAY DPDT 10A 24VAC W/CVR

14 8420-0369 REG/FILTER AIR 1/4 NPT WATTS

15 8480-4657 YAMADA VALVE REPAIR KIT

(KIT INCLUDES PARTS FOR ONE

PUMP)

REF.

NO. PART NO. DESCRIPTION

16 •9448-1306 ORIFICE KIT #56

17 •9448-1298 ORIFICE KIT #55

18 •8552-3108 UNION - REDUCING

19 •8480-4665 YAMADA DIAPHRAGM KIT

20 8460-4834 YAMADA PUMP

21 9204-0112 ANTI-SIPHON VLV VITON

22 9204-1128 ANTI-SIPHON VLV KIT VITON

23 8578-5111 CONNECTOR 3/8 IDH X 3/8 MPT

POLYE

24 8578-5418 ELBOW 3/8 IDH X 3/8 MPT POLYP

25 8730-1131 HOSE CLAMP 5/16 TO 7/8 SS

26 8578-5392 ELBOW 3/8 HS X 1/4 MPT POLYP

27 9263-0573 BALL CHK VLV ASM 3/8 FPT

28 9448-2502 INSTALLATION AND OPERATION

MANUAL

•9204-1150 ANTI-SIPHON VLV KIT EPDM

•9204-1000 ANTI-SIPHON VLV KIT SILCONE

• PART NOT SHOWN

THE REPLACEMENT PARTS PAGE OF THIS MANUAL MAY NOT

CORRESPOND TO THE EQUIPMENT REPAIR PARTS MANUAL PAGES

Table of contents