6.2 Programming Mode Parameter List

Hysteresis Parameter for Compressor Output ( Default = 1 )

MODBUS ADDRESS:40004

from 1 to 20°C for NTC (-50°C, 100°C) or PTC (-50°C, 150°C)

from 1 to 36°F for NTC (-58°F, 212°F) or PTC (-58°F, 302°F)

from 0.1to 10.0°C for NTC (-50.0°C,100.0°C) or PTC (-50.0°C,150.0°C)

from 0.1 to 18.0°F for NTC (-58.0°F,212.0°F) or PTC(-58.0°F,302.0°F)

Defrost Time Parameter

It can be adjusted from 0 to 999 minutes.

If it is selected 0 automatic or manual defrost is not performed.

( Default =10 ) MODBUS ADDRESS:40011

Defrost Repeat Cycle Parameter

It can be adjusted from 1 to 99 hours.

( Default = 1 ) MODBUS ADDRESS:40012

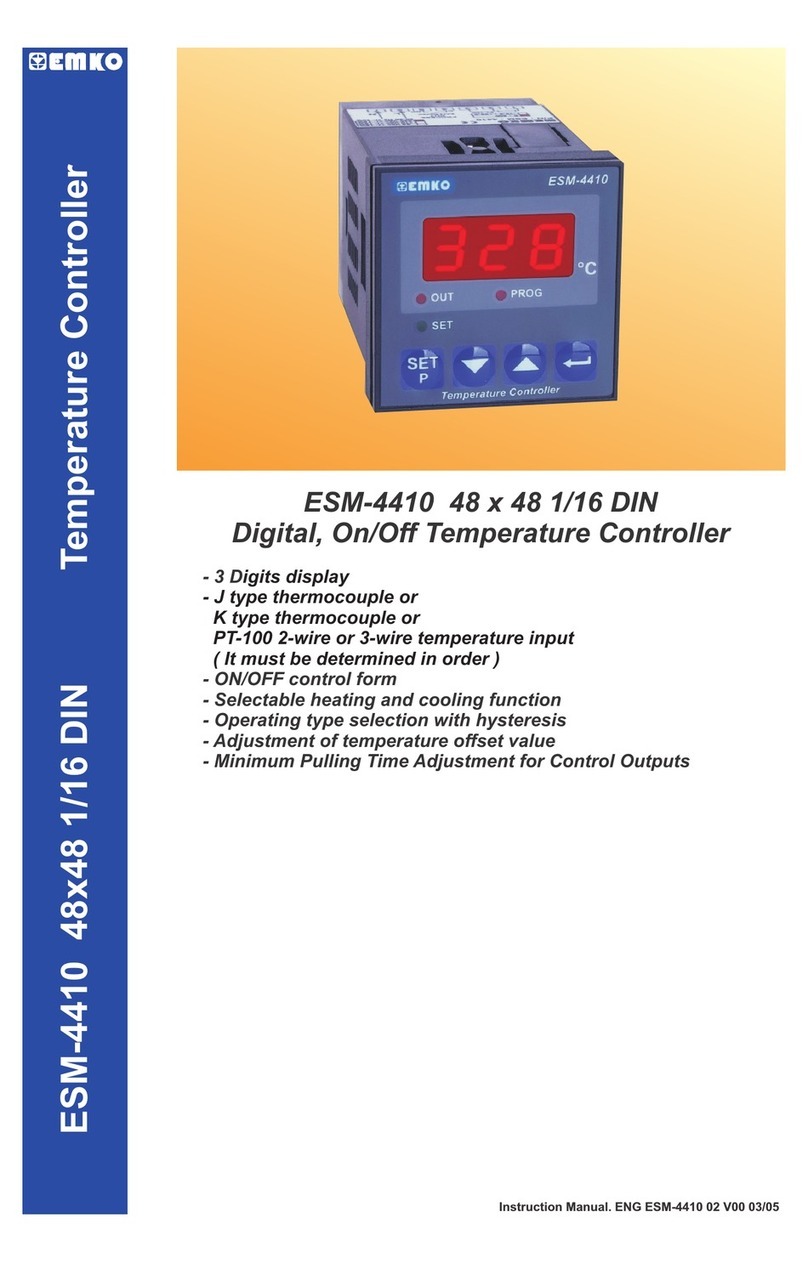

In ON/OFF control algorithm,

temperature value is tried to keep equal

to set value by opening or closing the last

control element. ON/OFF controlled

system, temperature value oscillates

continuously. Temperature value’s

oscillation period or amplitude around set

value changes according to controlled

system. For reducing oscillation period of

temperature value, a threshold zone is

formed below or around set value and

this zone is named hysteresis.

ON

OFF

Temperature

Control

Output

Set

HSt

Time

HSt

Time

Minimum Temperature Set Value Parameter(Default =Minimum Value of Device

Scale) MODBUS ADDRESS:40005

Temperature set value can not be lower than this value. This parameter value can be

adjusted from minimum value of device scale to maximum temperature set value

parameter

Maximum Temperature Set Value Parameter

(Default = Maximum Value of Device Scale) MODBUS ADDRESS:40006

Temperature set value can not be greater than this value.

This parameter value can be adjusted from minimum temperature set value parameter

to maximum value of the device scale.

Cabinet Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40007

From -20 to 20 °C for NTC(-50°C, 100°C) or PTC(-50°C, 150°C),

From -36 to 36 °F for NTC(-58°F, 212°F) or PTC(-58°F, 302°F),

From -10.0 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC(-50.0°C,150.0°C),

From -18.0 to 18.0°F for NTC(-58.0°F,212.0°F) or PTC(-58.0°F,302.0°F).

Defrost Type Selection Parameter ( Default =0 ) MODBUS ADDRESS:40010

Electric defrost.

Hot gas defrost.

Evaporator Sensor Selection Parameter ( Default =1 ) MODBUS ADDRESS:40008

Evaporator sensor is inactive.

Evaporator sensor is active.

Evaporator Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40009

If evaporator sensor selection parameter is 1, then this parameter is observed.

From -20 to 20°C for NTC(-50°C, 100°C) or PTC(-50°C, 150°C) ,

From -36 to 36°F for NTC(-58°F, 212°F) or PTC(-58°F, 302°F),

From -10.0 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC(-50.0°C,150.0°C),

From -18.0 to 18.0 °F for NTC(-58.0°F,212.0°F) or PTC(-58.0°F,302.0°F).

9

Decimal Seperator Enabling Parameter ( Default = 0 ) MODBUS ADDRESS:40003

Disable.

Enable.

Temperature Unit Selection Parameter ( Default = 0 ) MODBUS ADDRESS:40002

°C selected.

°F selected.

ENGLISH