Ecolawn ECO250 User manual

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 1 | 17

THANK YOU for purchasing an Ecolawn Top Dresser. Your new machine has been carefully designed and

manufactured to provide years of reliable and productive service. This manual will provide you with safety

instructions and general maintenance tips that will help to keep your machine in top running order. Please

read this manual and assembly part/list carefully before assembling, operating, or servicing your

equipment.

Here is 5 Ecolawn Basic Rules of Operations:

1. Use quality screened material or compost;

2. Use appropriate load size and weight;

3. Load hopper gently, prevent loading compaction;

4. Think and plan application pass before attempting the field specially on slopes;

5. Run the spreader empty first as a test A good application is preparing ahead of time Make small

adjustments in the field and eliminate major repairs.

Please visit our website or call with any questions.

Website: www.ecolawnapplicator.com

Tel: 1-866-326-5296

A good application is preparing ahead of time!

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 2 | 17

TABLE OF CONTENTS

ENGINE AND WARRANTY 3

SAFETY INSTRUCTIONS 4

1. GENERAL

2. GUARDS

3. ENGINE

4. HOPPER

5. DECALS

OPERATING INSTRUCTIONS 5

1. PROPER TOPDRESSING

2. OPTIMAL OPERATION

3. MAIN USES

USING THE ECOLAWN FOR THE FIRST TIME 6

OPERATING THE ECOLAWN APPLICATOR 7

CHOOSING AN APPROPRIATE SUBSTANCE 10

1. QUALITY AND CHARACTERISTICS

2. FRIABILITY

3. MOISTURE CONTENT

TROUBLESHOOTING AND ADJUSTMENTS 11

GENERAL MAINTANCE 14

1. SHAFT BEARING

2. ENGINE OIL/FILTER

3. V-BELTS

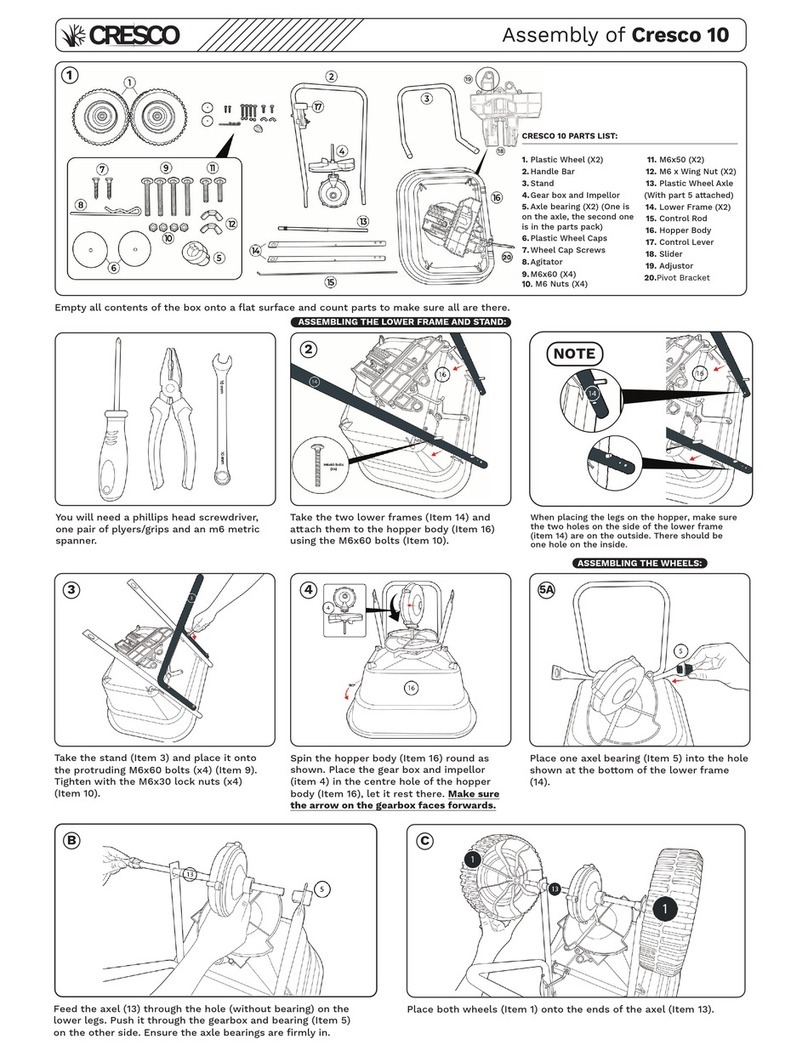

ASSEMBLY STEPS 15

AGITATORS 17

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 3 | 17

Engine

The Ecolawn Applicator's gear casing is filled with oil (SAE 30) before shipping, but the oil level must be

checked to ensure that it is filled to the proper level before operation. The engine does not have oil and

must be filled to proper level before starting. Use lead-free gasoline only. DO NOT USE OIL/GAS

MIXTURE. Please refer to the Engine Manual for additional information.

Ecolawn Applicator® One Year Limited Warranty

Terms: Ecolawn Applicators are guaranteed to be free of defects in materials or workmanship for one year

from the registered purchase date. To qualify, the applicator must be registered online at

www.ecolawnapplicator.com (under the product tab). This one-year warranty is extended only to the

original, registered purchaser of the Ecolawn Applicator.

Starting from the registered purchase date, Ecolawn will replace, free of charge, any part(s) on the machine

(excluding the engine*) that Ecolawn or an approved agent deems to be defective in material and/or

workmanship upon examination.

* Note: The engine is covered by its own guarantee; see engine manual for details.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 4 | 17

Safety Instructions

This manual describes the operation of the Ecolawn Applicator spreader only. Engine operation is not

included in this manual. Please consult the engine manual for relevant information.

1. General

•Never allow children to operate power equipment.

•Do not use the Ecolawn Applicator on any grade that is too steep for a riding mower.

•Do not modify the Ecolawn Applicator. Any alterations to the machine will void the warranty.

•Use the Ecolawn Applicator ONLY for its intended purpose.

•Keep hands and objects out of the hopper and away from the agitator/mixer while the motor is running.

•Use only original Ecolawn parts to repair the Ecolawn Applicator.

2. Guards

Do not run the engine or operate the machine when any of the guards have been removed. This may result

in severe injury and/or damage to the unit.

3. Engine

Remove the spark plug wire when the machine is not in use to prevent unauthorized operation.

4. Hopper

The hopper's maximum load is 440 lb (200 kg). Never exceed the maximum load capacity; this may

damage the spreader.

5. Decals

Replacement safety decals are available at no cost from Ecolawn.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 5 | 17

Operating Instructions

1.Proper Topdressing

When topdressing, follow the same pattern you would use when mowing. Start with the sections of lawn

that are farthest away from the supply source to avoid repeated traffic over the areas that have been top-

dressed.

Types of Spreading Materials:

•Screened compost

•Granular and pelletized products

•Sand

•Soil

•Crumb rubber

•Soil amendments

•Custom blends

2. Optimal Operation

Never exceed the maximum load capacity of the hopper (440 lb/200 kg). Some substrates (such as sand or

soil) are much denser than others, so it is not possible to judge load size visually. The same volume of

sand or soil can weigh significantly more than compost. Overloading the hopper may damage the spreader.

Comparative: Materials and Weights

Material Volume Weight:

Compost: (60% humidity) 10 cubic feet 300 lbs

Mix Blend: 50% compost, 50% sand 10 cubic feet 550 lbs

Sand: 10 cubic feet 800 lbs

3. Main Uses

The Eco 250 Broadcast Top Dresser is designed for compost topdressing, sand topdressing, lawn

restoration and renovation, soil amending, and over seeding. To learn more about topdressing, please visit

our website at www.ecolawnapplicator.com.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 6 | 17

Using the Ecolawn Applicator for the First Time

Before using the spreader for the first time, check the oil and gas levels on the engine, the reducer and the

fuel tank. While the spreader has been pre-adjusted for immediate use, some minor adjustments may be

necessary. We recommend the following startup procedure to ensure that the machine is properly adjusted

before use.

Step 1. The spreader's belts are new, so they may not adhere perfectly to the pulleys; they may slip when

the machine is started for the first time until they are properly seated. Before loading the spreader with

substrate, start the engine and let it idle and run it around empty for about 10 minutes to allow the belts to

become seated properly on the pulleys.

Step 2. Fill the hopper to 1/3 capacity (see Page 7, Step 1), then fully run the spreader at this 1/3 level for

the first 3 or 4 loads.

Step 3. Fill the hopper to its maximum capacity (440 lb/200 kg) and begin using the spreader normally.

Step 4. After one hour of use, visually inspect the spreader. Vibrations combined with a heavy load may

cause the nuts and bolts to loosen. Tighten these if necessary.

Step 5. After 8 hours of use, inspect the nuts and bolts again and tighten if necessary.

If some pulleys do not run correctly after these trials, please refer to Ecolawn Application: Troubleshooting

and Adjustments (pages 11-13).

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 7 | 17

Operating the Ecolawn Applicator

Step 1. Filling the Hopper

To fill the hopper, first ensure that the Feed Trap (Figure 1) is properly closed by pulling up on the Feed

Trap Lever (Figure 2).

Fill the hopper with the substrate to be spread. Note: Never exceed the hopper's maximum load capacity

(440 lbs/200 kg); this can damage the machine.

Figure

1

Figure

2

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 8 | 17

Figure 1

Step 2. Starting the Engine

Before starting the engine, make sure the conveyor system is not engaged. Be sure that the Conveyor

Action Lever (Figure 3) is disengaged and the Feed Trap is properly closed, then start the engine. For

additional information about operating or troubleshooting the engine, consult the Engine Manual.

Figure 3

Step 3: Topdressing with a Substrate

After loading the machine, start the engine. In order to spread the substrate, you must open the Feed Trap

to desired height. (Figure 2). Pull the Conveyor Activation Lever toward you. Squeeze the Self-Propel

Handle (Figure 4) to move the spreader forward and spread the substrate. Note: The engine's speed

determines the ground speed and the width over which the substrate is spread. The height at which the

feed trap is open determines the thickness at which the substrate is spread.

Figure 4

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 9 | 17

Step 4. Stopping the Spreader

When the hopper is empty, disengage the Conveyor Lever to stop the conveyor belt. Close the feeding trap

with the Feeding Trap Lever. If filling the hopper again, propel the machine to the substrate source and

release the Self-Propel Handle to stop the spreader, turn the engine off, and then refill the hopper.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 10 | 17

Choosing An Appropriate Substance

1. Quality and Characteristics

It is very important to choose a high-quality topdressing substrate. For greatest cost efficiency,

Ecolawn recommends using a bulk substrate which is friable, has a moisture content lower than 65%, and

contains no inorganic matter (stone, plastic, glass, etc.) or non-composed organic matter (such as wood

pieces).

2. Friability

A friable material is one that crumbles easily into small fragments. A substrate that is not very friable

appears to be composed of numerous, compact pieces which do not readily break down. Screening a

substrate makes it much more friable. Additionally, a substrate containing 10% sand is more friable and will

flow more smoothly and efficiently through the applicator.

3. Moisture Content

To help the substrate flow freely from the hopper, you may lightly bounce the spreader by moving it up and

down while topdressing. This will loosen the substrate so that it can flow freely from the hopper.

A substrate with a moisture content greater than 65% will tend to stick to the inside walls of the hopper and

other parts of the spreader. When working with a substrate with a high moisture content, coat the insides of

the hopper, as well as the spreading disk, with a graphite-based lubricant. Consult the SLIP Plate Lubricant

website at www.slipplate.com for more information.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 11 | 17

Troubleshooting And Adjustments

Important: Be sure the engine is turned off before performing any adjustments or maintenance on the

spreader.

The most frequently encountered problems involve the conveyor, but these can be easily resolved with a

few simple solutions. Check the following symptoms for your particular problem, and make the

corresponding adjustments as needed.

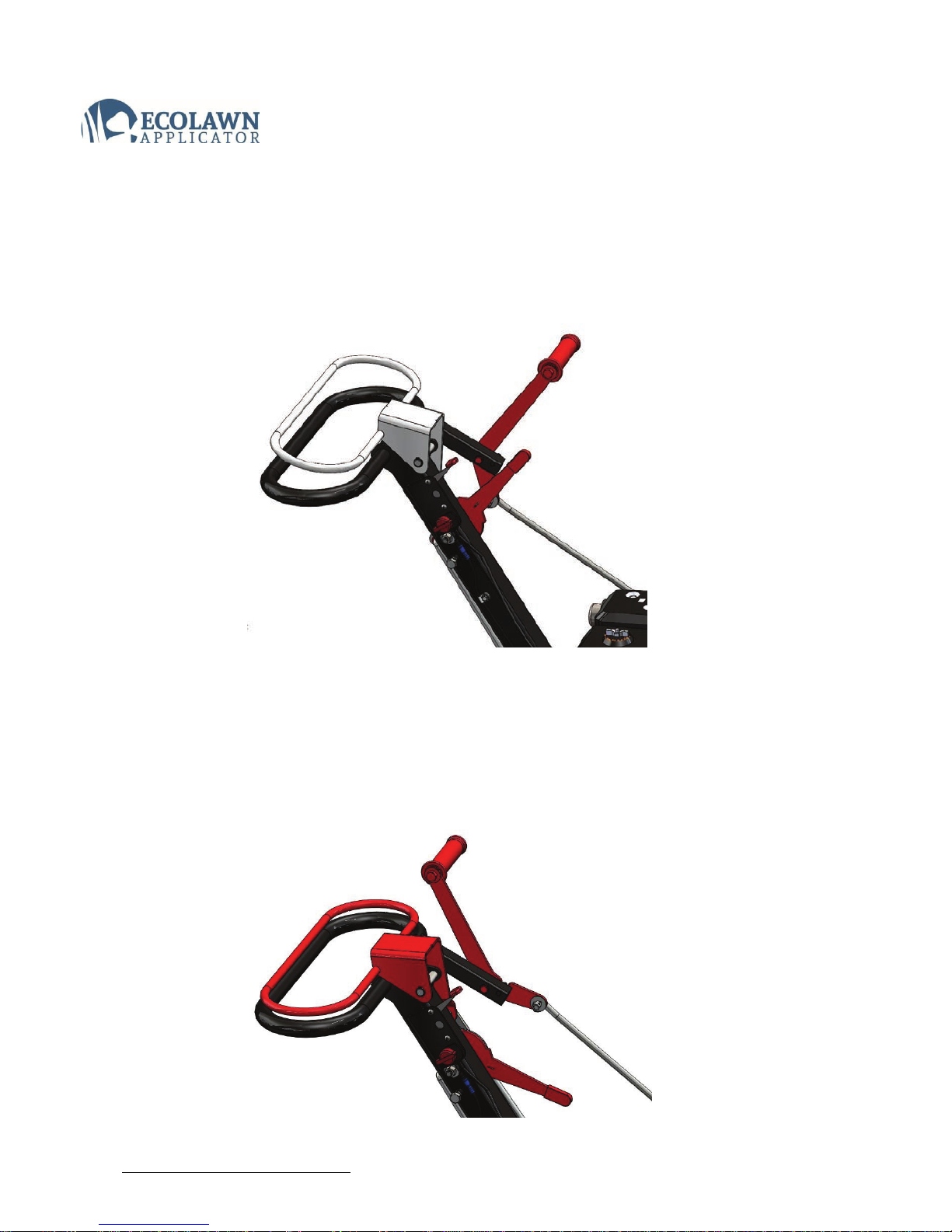

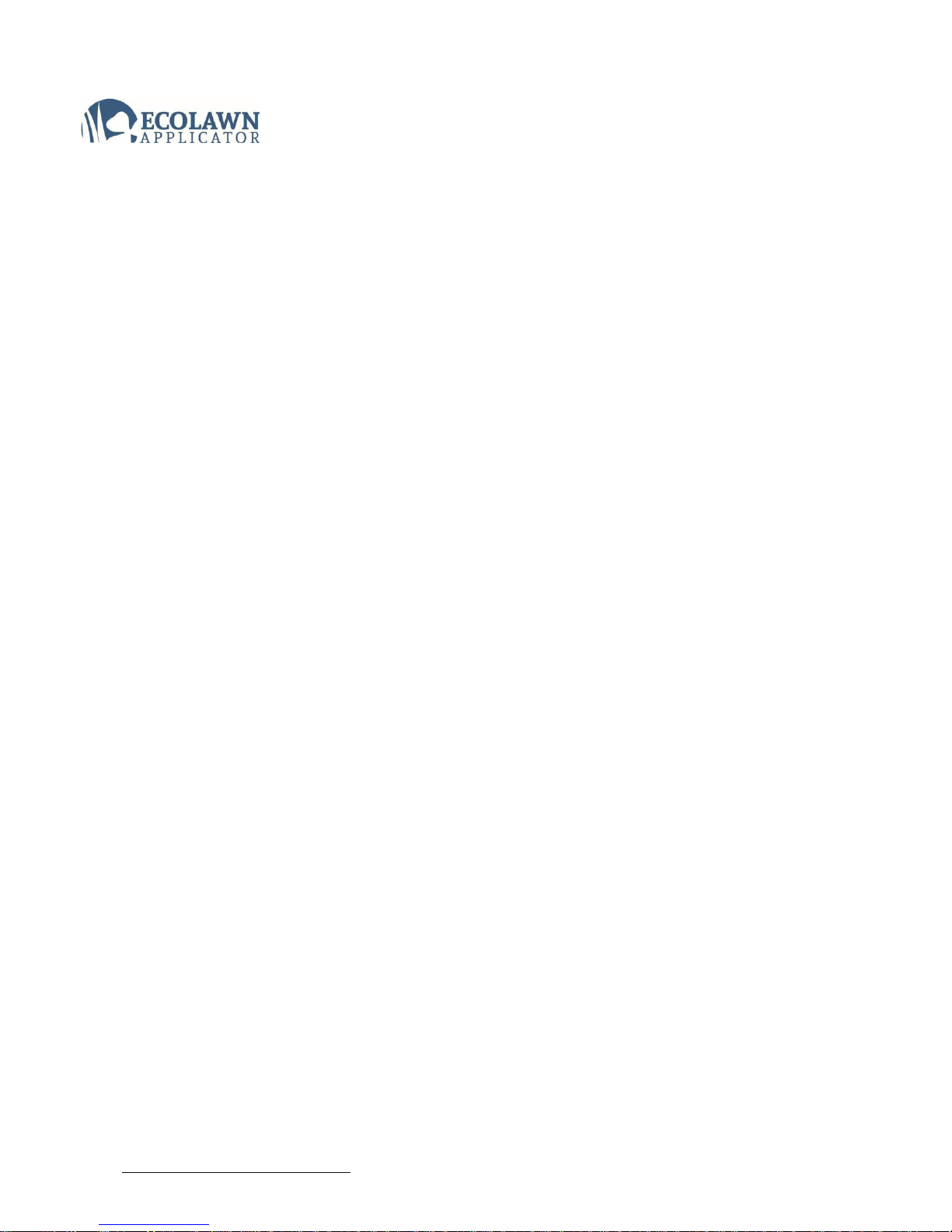

Symptom: The V-belts are slipping. The spreader's hopper is full. The conveyor has been activated

by activating the conveyor lever, but the conveyor belt does not turn because the V-belts are

slipping.

Solution: The V-belts (denoted in red) are not tight enough. First remove the guards from the stretcher and

check the tension of the belts, which may be slipping on the pulleys that power the

conveyor belt. If the tension is incorrect, adjust it by lengthening the stretch rod of the conveyor activation

clutch, a few turns at a time, as follows:

1.Loosen the (yellow) jam nuts to adjust

the tension of the stretcher rod.

2.Turn the (green) stretcher collar

counter

clockwise to increase tension, or

clockwise to reduce it.

3.

Tighten the (yellow) jam nuts to lock the

tension at the proper level.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 12 | 17

Symptom: The spreader's hopper is full. The conveyor has been activated by pulling the conveyor

activation lever back, but the conveyor belt is not turning even though the stretch rod has been

adjusted properly and the conveyor drive roller is turning.

Solution: Adjust the tension of the conveyor belt rollers on each side, 1/2 a turn at a time, to increase the

tension on the conveyor belt, as follows: do this on both sides of the unit equally.

1.Loosen the three (yellow) nuts.

2.Tighten the horizontal (red) bolt to push the conveyor

belt roller forward about 1/2 turn

3.Tighten the three (yellow) nuts to hold the conveyor

belt in place.

4.

Repeat the same procedure on the other side, making

sure the adjustments to both sides

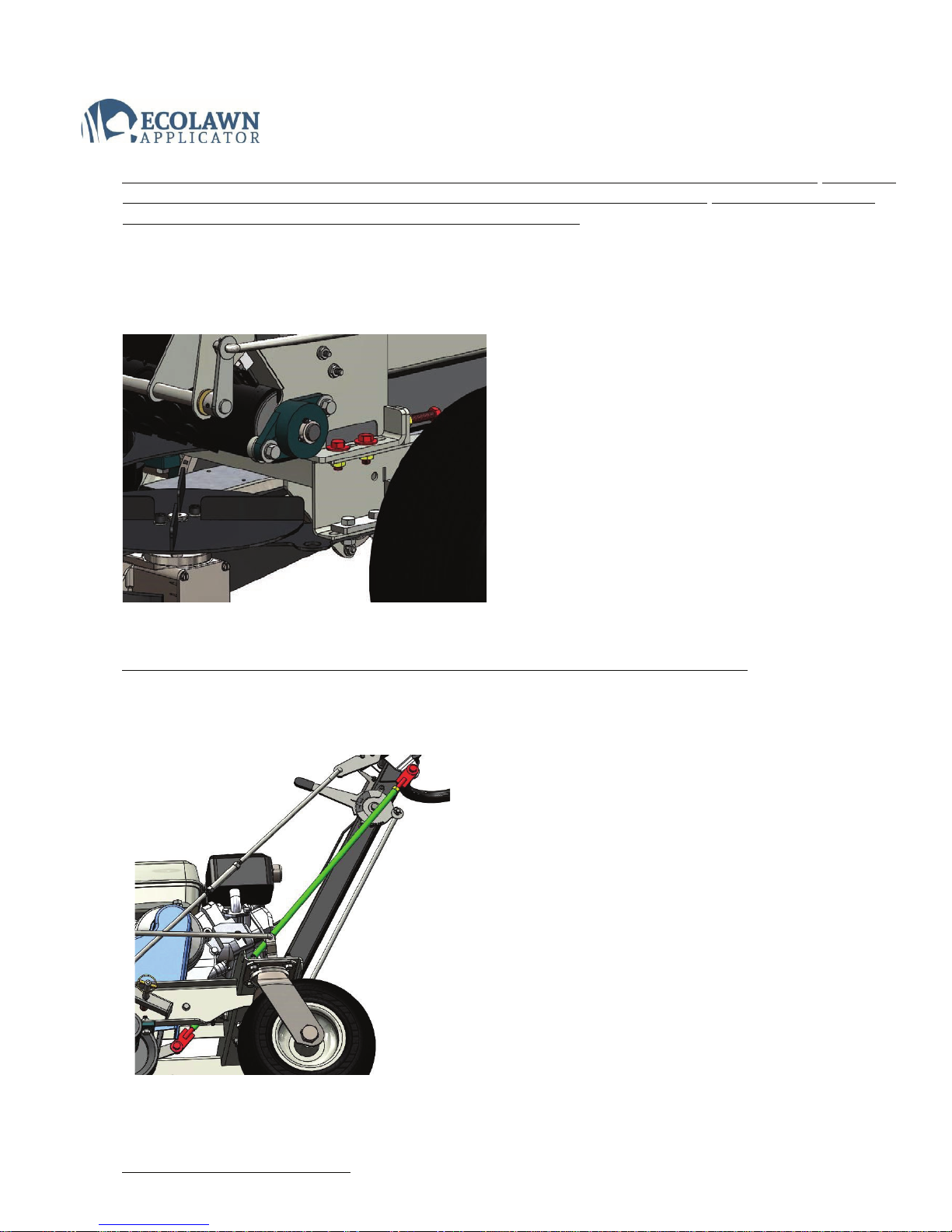

Symptom: The spreader does not move forward, or does so only with difficulty.

Solution: An adjustment to the tension of the activation arm of the Self-Propel Handle may be necessary:

1.Loosen the (yellow) jam nut to release the tension.

2.Turn the (green) adjustment collar clockwise to

increase pressure, or counter clockwise to reduce

pressure.

3.Tighten the (yellow) jam nut to maintain the desired

pressure.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 13 | 17

Symptom: The spreader moves forward and the conveyor works, but the spreading disk does

not spin.

Solution: To free the disk, turn the machine off, and then turn the spreading disk backward

manually to remove any debris. Visually inspect the pulleys and clean them as needed. If the

pulley used to turn the spreading disk is filled with substrate, it may cause the belt to come off.

Clean the pulley and the disk, then re-mount the belt on the pulley.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 14 | 17

General Maintenance

1. Shaft Bearings

Grease the two crankshaft ball bearings after every 50 hours of operation.

2. Engine Oil/Filter

Change the oil and filter after every 50 hours of operation. See the engine manufacturer's instructions.

3. V-belts

The proper belt tension is tight enough that the belts will not slip during operation. Occasionally, belt

tension must be readjusted. Do not over-adjust the tension, as this may damage other parts.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 15 | 17

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 16 | 17

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 17 | 17

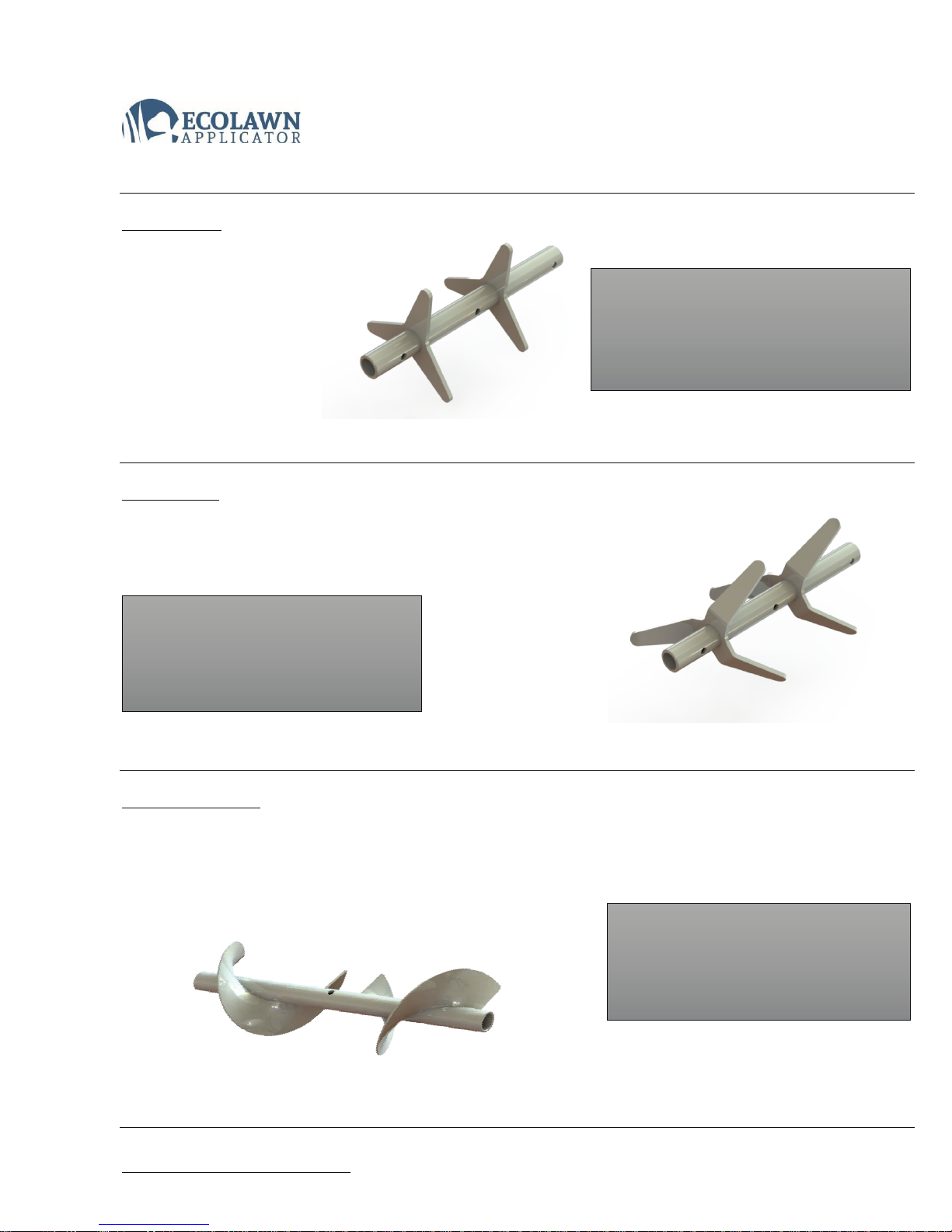

Short agitator - sand, heavy materials, for less resistance on agitator, Biochar products.

Trap door opening - full range.

Rotation – forward.

Long agitator - compost, dry materials, wet materials, for greater agitator power

Trap door opening - 3/4 to wide open.

Rotation - forward or reverse depending on specific product.

Corkscrew agitator - dry sand, screened crumbly compost, dry pulverized dirt,

powder materials, Biochar products and mealy products.

Trap door opening - 1/2 to wide open.

Rotation - forward or reverse depending on specific

product.

Pam spray for inside hopper.

LONG

AGITATOR

SHORT

AGITATOR

CORKSCREW

AGITATOR

REW AUGER

[CITEYOURSOURCEHERE.]

Table of contents

Other Ecolawn Spreader manuals

Popular Spreader manuals by other brands

Trynex International

Trynex International SnowEx SL-80 Owner's/operator's manual

CountyLine

CountyLine MS10 Operation and assembly manual

SnowEx

SnowEx V-Pro SP-2000 owner's manual

Wallenstein

Wallenstein MX Series Operator's manual

Agri-Fab

Agri-Fab 45-02103-101 owner's manual

Gardena

Gardena Comfort 425 Assembly instructions