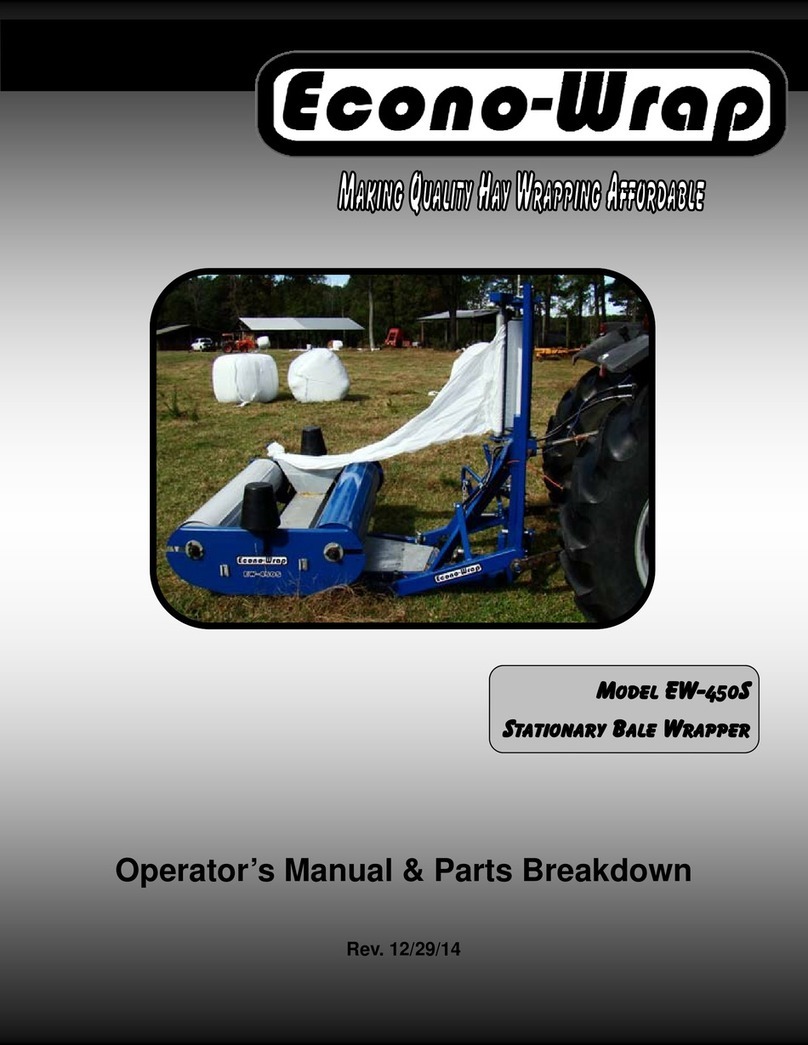

Econo-Wrap EW-450S User manual

Operator’s Manual & Parts Breakdown

Rev. 2/2019

Model EW‐450S (Version A)

Staonary Bale Wrapper

Technical & Operaonal Informaon

Length 100inches

Working Width 55inches

Weight of Machine 1,091lbs.

Dimensions of Bales Being Wrapped

Diameter 39inches‐63inches

Length Upto55inches

Weight of Bales Upto2100lbs.

Horsepower Requirement 40HPMinimum

Mounng Method 3PointHitch

Bale Wrapper Drive HydraulicMotor

Type of Oil in the Hydraulic System GearOil

Tractor Engine Revoluons 1500RPM

Roller Rotaons 2RPM

Bale Loading Device

Loadingdevicewithliingcapacitygreaterthantheweightof

thebalesbeingwrappedwiththeabilitytolibalehigherthan

4’.

Minimum Number of Bale Wraps 2(doublewithoverlapping)

Total Time for Double Wrapping (with a diameter of 4’) approx.90seconds

Total Number of Wraps (for bales with a diameter of 4’) 30”film‐18wraps(20”film‐26wraps)

Wrapping Counter Electronic

Type of Wrapping Film Specialpolyethylenefilm,0.025‐0.03mmthickwhichisstretcha‐

ble,self‐adhesive,withultra‐violetraystabilizer

Film Wrapping Rotaryknivesonafixedbracket,therotangframecungaer

loadingthenextbaleaerthefirstrotaonoftheframe

Unloading Wrapped Bales

Bylngthelowerframe(togetherwiththerotangframeand

thebale)backwardsaerunlockingit(bypullingtheline)and

aerparalliingofthewrapperonthe3‐PointHitchoftractor

Bale Wrapper Operaon 2people—1operangwrapperontractor,1loadingthebales

Introduction - General information

Persons operating the bale wrapper should absolutely consult the instruction manual and should have a

knowledge of OCCUPATIONAL SAFETY and HEALTH in the use of agricultural machinery;

The Bale wrapper is shipped with the operating instructions and warranty card in the complete state, any

unauthorized or willful changes in the design will cause the loss of it’s warranty;

The service and maintenance of the bale wrapper incompatible with this instruction manual releases the

manufacturer from liability for consequences resulting from its improper use and causes the warranty to be null

and void. The manufacturer reserves the right to make changes in the design of the machine not shown in this

manual and it’s description and intended use of machine and the basic technical data of this machine.

The bale wrapper, EW-450S, is a simple-to-use machine with a hydraulic drive. It’s intended use is for

the wrapping of individual bales of pre-dried hay from grasses and leguminous fodder plants with stretch film.

Plants intended for bales for silage should be mowed in the initial phase of earing. After a dozen or so hours of

pre-drying, the hay should be collected using the roll baler in a way that ensures maximum density with the

smallest amount of air in the middle of the bale. After the rolling of the bales, they should be wrapped as soon

as possible on the bale wrapper. The bales left unwrapped for long periods of time may be caused to resist the

putrefactive processes.

Bale wrapping with the film (foil), protects the mixture for ensilage before the long exposure to air, light

and moisture, creates favourable conditions for fermentation process. After wrapping, you must stack bales

in a maximum of two layers in a dry place on level ground. Particular attention should be paid to avoid

possible damage to the film. The damaged areas should be repaired in such a way as to ensure the continuity

of the layer. After approximately 6 to 8 weeks of storage at ideal temperatures, The haylage is then suitable for

the feeding of animals with the feed having reached it’s maximum nurishment level.

This bale wrapper is suitable for use with tractors of a 0.9 minimum class and

with power more than 30 KW equipped with a set of weights on the front axle.

Its design is adapted for it’s connection with the Three Point Hitch of the tractor.

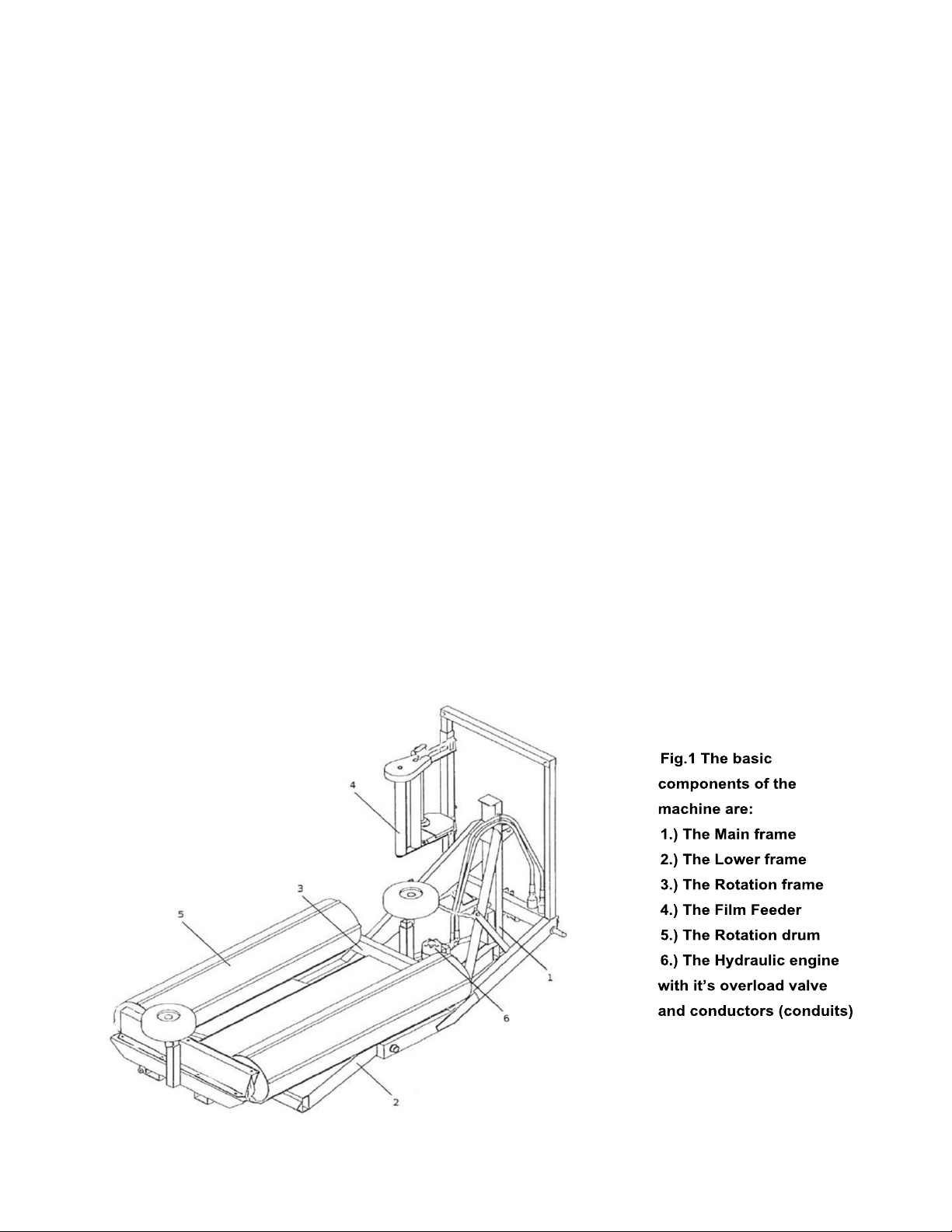

The Rotation frame shown as number 3 on the previous page placed on the lower frame shown as

number 2 is connected aligned with the main frame shown as number 1 and is suspended on the three-

point system of tractor. The lower frame together with the rotation frame is secured against deflection by a

movable locking pin. Unloading the bales from the bale wrapper is possible after unlocking the pin and after

the bale wrapper is raised using the Three Point Hitch of the tractor. It then unloads as the lower frame is

tilted and the frame is rotated thus unloading the bales

The movement of the rotation frame and the rotation drums shown as by the number 5 on the previous

page is carried out by the operation of the hydraulic motor, number 6 with overload valve wihich is operated

by the hydraulic pump of tractor. This overload valve provides for smooth starting and stopping of the

machine. It also protects the mechanical components of the drive from damage as a result of excessive

load. The valve is factory-tuned to the engine and sealed. It should not be adjusted unnecessarily..

The drive from the engine is transmitted via a 5/8” (10B) chain on the chain wheel of rotation frame.

This provides for a rotation of the bale along the vertical axis. Next, power is transmitted to the drums

welded via a conical toothed gear and two chain transmissions. This provides a rotation of the bale

with the appropriate ratio in the horizontal axis, this causes a partial overlapping film layers and

tightness of the layer. Roll of film is placed in the feeder (4). The film is stretched through the two tension

rolls connected with toothed gear, which ensures tight adhesion of subsequent layers of film.

The transmission ratio is chosen so as to ensure

the optimal stretching the film, however, if

necessary, stretching can be adjusted by

tightening the nut pressure of film. The maximum

extension/elongation of the film should not

exceed 70% of original length. That is, segment of

film with the length of 10 cm after stretching,

should not be longer than 17cm. should be applied a

polyester film, stretch film, self-adhesive with

stabilizer of ultraviolet rays with a thickness of 0.025-

0.03mm and the width of 500 or 750 mm.

Principles of safe operation of bale wrapper

Bale wrapper must be operated by adult with driving licence to the steering of agricultural tractors, having

knowledge of HEALTH and SAFETY at WORK in the use of agricultural equipment;

During installation, adjustment and repairs of bale wrapper, turn off the tractor engine and remove the keys

from the ignition, during these steps the bale wrapper should be lowered to the ground and tractor should be

stationary;

Before switching on the rotary drive, make sure that switching on the drive does not threaten anyone;

Staying of persons in work zone of bale wrapper and loader is prohibited;

Before starting work, check the condition of the machine and its completeness;

Work with machine damaged or without protective covers is prohibited;

Before starting work, check the condition of the hydraulic hoses/lines, work with broken or deformed lines/

hoses is prohibited;

Transport of bales on bale wrapper when traveling on public roads is prohibited;

Whenloadingbalesoneshouldpayspecialaenononpermissibleloadcapacityofloadingequipment.Exceedingtheloadcapacitymay

causedamagetomachineandaccident.

SAFETY SIGNS

2,3. Before commencement of machine operation, please refer to the instruction manual.

4,5,7. Moving components, keep a minimum distance of 2m.

6. Chain transmission, please take special care .

9.Direction of rotation of the rotating frame

Permissible speed when driving on public roads

Warning plate in white and red stripes

2

WARNING!

ALWAYS READ

THE USER MANUAL

BEFORE STARTING

THE MACHINE!

5 KEEP DISTANCE

FROM WORKING MACHINE

minimum 2 meters

Functioning, operational use of bale wrapper

Transport and loading

Bale wrapper is suitable for transporting on Three Point Hitch of tractor. During transport on public roads,

please observe the following principles:

Hydraulic hoses should be connected to a hydraulic pump.

Hydraulic system of bale wrapper should be filled with oil, therefore longitudinal rotating frame set in the

transport position, will be secured against rotation;

Locking pin of the lower frame should be inserted in order to block it against deflection;

Warning plate in white and red stripes with the red warning light and triangular plate must be mounted in a

visible way;

To secure the suspension pins one should use only original and functional cotters. The use of substitute

protections such as bolts, wires etc. is prohibited;

Transporting bales on bale wrapper when travelling on public roads is prohibited.

Before loading of bale wrapper on transport of lorries, one should mount the machine on a wooden

pallet and take precautions against before displacement.

Assembly with tractor

Correct assembly of bale wrapper with the tractor should be made according to the following principles:

After removing the agricultural hitching from tractor, withdraw it to evenly placed bale wrapper;

Connect the machine with Three Point Hitch of tractor while adjust the length of the single upper

connecting link;

Protect the connections with pins and original cotters of tractor equipment;

Connect the quick release couplings of hydraulic hoses of tractor with hydraulic installation

sockets;

Sensor cable of of overwraps must be connected with counter, counter put in a prominent position in

the tractor cab;

Attempt/test of the operation

Before start wrapping, you should check the operation of the machine:

Raising on Three Point Hitch of tractor;

Smoothness and direction of rotation of rotating frame and drums (rotations of the frame - to the left /

counter clockwise);

Operation of the interlocking, tilting the lower frame and the state of the chain. A chain attached to the

brackets of main frame restricts/limits the size of the tilting while unloading the wrapped bale. After lowering

of bale wrapper and return of the lower frame to horizontal position, locking pin when extended secures

the frame before tilting;

At the start of the hydraulic system please take special care, one should check whether in the field of rotation

of rotational frame with drums there are no people or objects, starting the warning with sound signal;

During operation the wrapper, the pin must absolutely block lower frame before tilting;

Extension /elongation of film as a result of tension, must not be more than 70% i.e. the length of the

unstretched film of 10 cm should increase to not more as 17 cm and width for the film of 750 mm should

not be smaller than 600 mm and for film of 500, not smaller than 400 .

Attention!

Before starting the machine, please take particular care. Lower frame must be secured before

tilting with locking pin.

Installation of film

To install the film roll, one should tilt the bracket with rubber rollers.

After removing the clamping nut, install the roller so that was embedded on the lower clamping ring, then

secure from the top with clamping ring and the clamping nut. Clamp/press down the bracket with rubber

rollers, check whether they are properly pressed against film. In the event of non-parallelism on the contact

of film roller and rubber roller, one should adjust the position of the roll by overbending the fastening rod. In

accordance with the diagram, drag the film by rubber rollers so that it is possible to grasp the tip of the

film.

Fig.7DiagramofinstallingFilmRoll

Loading, wrapping and unloading bales

Loading bales on bale wrapper one should carry out using the available devices with lifting capacity more

than 1000 kg and with the possibility of lifting at the height of the minimum 1m. Loading and wrapping

bales should be carried out in an area of subsequent storage of bales. This will prevent damage to the

film, that may take place during the movement of bales. Before loading, rotating frame with drums

should be set along the tractor. Such setting provides the best access to the machine during loading and

operating/maintenance during the wrapping. Bale wrapper with the tractor should be on level ground and

pin, which locks the lower frame should be protruding. Before starting the wrapping, bale should be in

the center of the length of the rotating drums at equal distances from the side wheels. Next, you need

attach the tip of the film, which protrudes from the feeder to bale, preferably to string as far away from

feeder.

After making sure that the inclusion of the drive does not endanger the surroundings, can start wrapping

including hydraulic drive from the tractor cab. When wrapping, the tractor engine must maintain approximately

1500 rpm. Bale wrapping should occur after 24 (film 20” setting) or after 16 (film 30” settomg) rotations of

rotating frame (after about 1 minute of the wrapping). Fully wrapped the bale should have two layers of film, what

provides a fully leak-proof protection before the access of air and water. After wrapping, one should stop the

machine at the time when rotating frame with drums is in perpendicular position to the axle of the tractor and

the direction of travel. After unlocking the locking pin and lifting of bale wrapper on Three Point Hitch of tractor,

will occur the tilting of the lower frame and self-acting unloading the bale. Do not cut off the film prior to loading.

For the purpose of loading the next bale, one should lower of bale wrapper and lock the lower frame with the

locking pin. The drums must be set in the position as for first loading.

Recommendations for use

During operation of bale wrapper, special attention shall be paid to the technical condition and tension of

driving chains. After starting a new bale wrapper and after wrapping approx. the ten of bales, check tension

of driving chains, in particular of driving chain of rotating frame. To carry out the adjustment of the driving

chain of rotating frame, A)Remove Center Table Guard, B)Remove Gear Covers C) Rotate Bale Tray 90

degrees and D) Remove Front Frame Guard.

Once the chains are exposed, loosen the four nuts M12 (1) of the base of the hydraulic motor. Then, after

loosening the counter nut (2) screw in the bolt of chain tension (3) so that the deflection in the middle of the

longest segment of chain had about 20 mm.

After the adjustment and control/inspection of the technical condition, lubricate the

chain with oil for driving chains.

The overload valve adjustment

If during operation we determine no smoothness of operation, machine jerking, one should carry out the

adjustment of the overload valve. When adjusting hydraulic hoses must be connected to the installation of the

tractor.

Adjustment is carried out by means of the adjusting screw marked with the symbol 50 located on the left

side of the valve. After removing/unscrewing the plastic cover, loosen the counter nut. After unlocking the bolt by

unscrewing it, we increase the smoothness of machine operation. After each half turn of bolt, tighten up the

counter nut and check the effect of adjustment.

Attention!

Do not adjust the valve unnecessarily. When adjusng, please take special care during each starng/ run of the ma‐

chine.

Film width Adjustment

The 450S is intended to bale wrapping with two types of the film about widths 20” and 30” . To adapt the

machine to wrap another available type of film, one should:

Film Rollers

Adjust the height of the pressure of upper film by changing the height of the locking pin

Roller Rotatonal Chain

Change the position of the chains driving the rotating drums – respectively for the film 20” on z-34 gears /

toothed wheels and for film 30” on z-23 gears / toothed wheels . The length of the chains should be changed

using the appropriate half-chain link. The gears are located behind the shield on the back of the Bale Tray.

ChainPosionfor30”‐Sch.1

ChainPosionfor20”‐Sch.2

30”

20”

The Height of the

pressure posion for

the 2 wrap sizes

NOTE: WRAPPER COMES SET UP STANDARD IN THE 20” SETTING FOR FASTER WRAPPING.

30” FILM MAY BE USED IN THIS POSITION. ADJUST WRAP REVOLUTIONS ACCORDINGLY.

Parts Breakdown

EW‐450S—VERSION A

ROTATING FRAME

POSITION PART NUMBER DESCRIPTION QTY

1AW‐T101WeldedFrame1

2AW‐T102RWeldedDrumRight 1

3AW‐T103DriveSha 1

4AW‐T104BevelGearLarge1

5AW‐T105BearingUnit206Set6

6AW‐T106GearGuardISet2

7AW‐T107GearGuardII1

8AW‐T108CoverforSlideBearings2

9AW‐T109MetalWheelSet2

10 Washer2

11SRE‐20M20SnapRing‐External2

12B63052RSBearing63052RS8

13SRE‐25M25SnapRing‐External4

14B60072RSBearing60072RS2

15AW‐T115Bearing10B2

16AW‐T116WheelAxleWelded2

17EP311‐0003Key8x7x401

18BM0812525BoltM8x1.25x258.81

19LNM08125NutM8x1.25Zn2

20NM1217535BoltM12x1.75x355.8Zn12

21FW13FlatWasherM13Fe‐Zn12

22LNM12175NutM12x1.75Zn12

23BM0812530BoltM8x1.25x305.81

24LNM08175LockingNutM8Zn1

25BM061016BoltM6x1.0x165.8Zn1

26AW‐T126Magnet‐SpeedSensor1

27NM0610NutM6x1.0Zn1

28STB4819TapScrew4.8x19Self‐Drilling15

AW‐T102LWeldedDrumLe 1

EW‐450S—VERSION A

ROTATING FRAME

EW‐450S—VERSION A

LOWER FRAME

EW‐450S—VERSION A

LOWER FRAME

POSITION PART NUMBER DESCRIPTION QTY

1AW‐T201LowerFrame1

2AW‐T202HydraulicEngine1

3AW‐T203SafetyValve1

4AW‐T204FrameCover(lid)1

5AW‐T205BaseofEngine1

6AW‐T206HydraulicHoses2

7AW‐T207HydraulicCoupler2

8

9AW‐T209CoverofGear1

10AW‐T210Chain10B1

11AW‐T211ChainWheelz‐121

12 Washero21Cu2

13AW‐T213BevelGearz‐171

14FW20M20FlatWasher 1

15LW20M20LockWasher 1

16LNM2025M20LockingNut 1

17LNM12175M12x1.75LockingNut 2

18AW‐T218ChainGuide2

19SSM0812520SocketScrewM8x1.25x205.84

20NM08125NutM8x1.254

21BM06101600BoltM6x1.0x165.8Zn2

22BM0812530BoltM8x1.25x308.8Zn1

23EP311‐0003Key8x7x302

24BM061016BoltM6x1.0x155.8Zn

25LW06M6LockWasher

26BM1217545BoltM12x1.75x455.8Zn2

27LNM12175LockingNutM12x1.751

28BM12175100BoltM12x1.75x1005.81

29LNM12175LockingNutM12x1.75Zn6

30FW12M12FlatWasherZn4

EW‐450S—VERSION A

MAIN FRAME

EW‐450S—VERSION A

MAIN FRAME

POSITION PART NUMBER DESCRIPTION QTY

1AW‐T301MainFrame1

2AW‐T302LateralCoupler/ConnecngLink1

3AW‐T303FeederArm2

4

5AW‐T305LockingLever1

6AW‐T306LockingPin1

7AW‐T307AgriculturalChain1

8

9AW‐T309SensorandCounterCable1

10AW‐T310Spring1

11AW‐T311FramePin1

12FW37M37FlatWasherZn

13

14BM1217570BoltM12x1.75x705.8Zn1

15FW12M12FlatWasherZn2

16LNM12175LockingNutM12x1.75Zn1

17BM12175350BoltM12x1.75x355.8Zn2

18FW12M12FlatWasherZn2

19LNM12175LockingNutM12x1.75Zn2

20BM1217545BoltM12x1.75x455.8Zn2

21FW12M12FlatWasherZn2

22LNM12175LockingNutM12x1.75Zn2

23BM1217570BoltM12x1.75x705.8Zn2

24BM1217530BoltM12x1.75x305.8Zn2

25FW12M12FlatWasherZn2

26BM1217525BoltM12x1.75x255.8Zn4

EW‐450S—VERSION A

FILM FEEDER

Other manuals for EW-450S

2

Table of contents

Other Econo-Wrap Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Farmi Forest Corporation

Farmi Forest Corporation VARIO 101 Operating, Maintenance and Spare Parts Manual

Chore-Time

Chore-Time H2 Installation and operator's manual

Brinsea

Brinsea ChickSafe Advance Installation and operating instructions

Munters

Munters RFS-6 Manual for use and maintenance

Amazone

Amazone ZG-TS 5500 WAB operating manual

MASSEY FERGUSON

MASSEY FERGUSON BETA 7360 Original Operator's Manual