TKS Kuhn FeedMixer User manual

TKS Operator’s manual

1

988876TKS Kuhn FeedMixer EN, 2016

Operator’s manual

TKS

Kuhn FeedMixer

From serialno.: 022 -

TKS Operator’s manual

2

We,

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

declare that the product:

TKS Kuhn - CENTRAMIX

has been built in conformity with the Machine Directive 2006/42/EC and meets the

relevant fundamental health and safety requirements.

Kverneland, 9 September 2016

Tønnes Helge Kverneland

General Manager

Enter the serial number

of the machine here :

T. Kverneland & Sønner AS, manufacturer of agricultural products, reserves the right

to change the design and/ or specifi cation of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

1 General safety instructions

1.1 CE - Declaration of conformity

TKS Operator’s manual

3

1.2 Guarantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/ or repairs. Claims must be reported within the

guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to TKS

or TKS’s distributor/ importer within the 10th of the month following the one in which the defect was

reported.

The defective parts shall be marked with the claim number and be kept for up to 6 months so that

TKS or TKS’s distributor/ importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any consequential

damage.

The guarantee is not valid if:

a) third party spare parts are used, or the product is repaired or altered without the

approval of TKS

b) the operating and servicing instructions have not been followed.

c) the machine has been used for other purposes than those for which it is designed.

The guarantee does not cover damage due to normal wear and tear.

Offi cial safety regulations specify requirements that apply to the users/ owners and manufacturers

of this machine, relating to the careful review of safety hazards that may arise when this type of

machine is used correctly. Therefore, TKS and our importer/ distributor are not responsible for the

functioning of components that are not shown in the spare parts catalogue for this product.

TKS reserves the right to change the design of the product without this implying any obligations in

relation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial

number; see page 9 on Machine identifi cation.

TKS Operator’s manual

4

Content

1 GENERAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 POSITIONING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 USING FEEDMIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 MAINTENANCE AND CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 LOADING CELL AMPLIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 CE - Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 FeedMixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Model description and area of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.2 Machine identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.3 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.4 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.1 General safety instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.2 Additional safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.3 Overview of safety risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

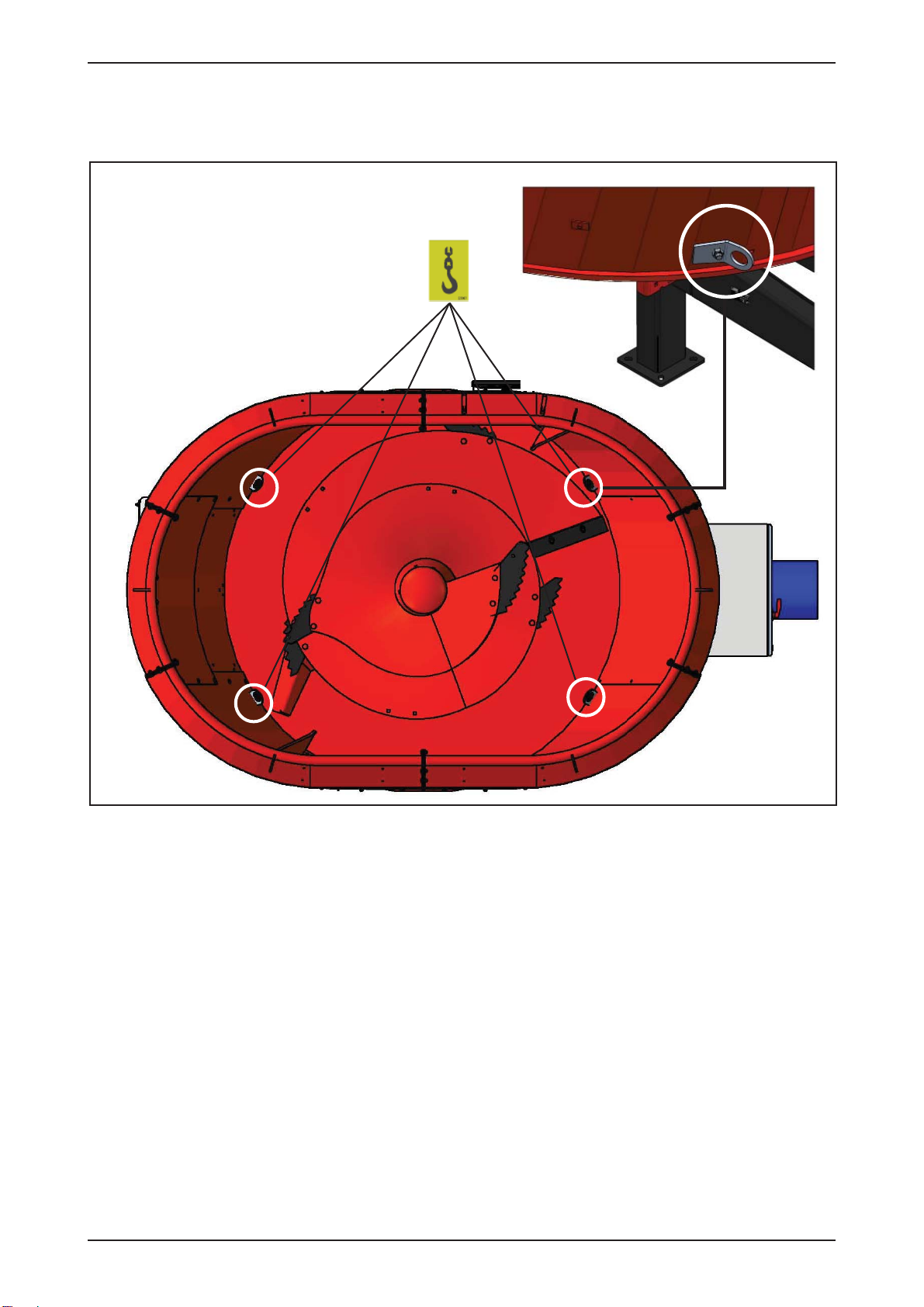

1.5.4 Lifting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5.5 New machine - caution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5.6 Lifting point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TKS Operator’s manual

5

2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1 Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2 Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Overfl ow extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4 Counter knives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5 Door location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Positioning and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Check gear oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 Remote control of the feedout process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Using FeedMixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Loading sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Feed quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4 Mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Warning sounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TKS Operator’s manual

6

6 Maintenance and care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 Recommended bolt torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.4 FeedMixer – operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Shear bolt protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.6 The auger knives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.7 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.8 Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.9 Filling with a pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.10 Lubrication table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.11 Oil change gear motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.12 Lubricating the power transmission shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

7 Loading cell amplifi er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8 Recycling - waste to resource - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

TKS Operator’s manual

7

1.3 Introduction

Congratulations on buying your new TKS product. You have chosen a functional, high quality

product. A network of helpful dealers will be able to advise you on its use, as well as provide

servicing and spare parts.

All TKS products are designed, tested and built in close cooperation with farmers and machine

workshops to ensure optimal effi ciency and reliability.

Please read this instruction manual carefully and familiarise yourself with the machine‘s manner

of operation before starting to use it. There are many conditions and variables that can aff ect the

machine’s functionality and manner of operation. It is therefore vital that you consider all known

conditions and adapt usage according to these. A good understanding of the machine‘s manner of

operation and performance, together with a high degree of knowledge with regard to feeding and

feed types/consistencies will ensure the best possible result. The machine is a highly advanced

feed robot that operates without the need for supervision and must be used in accordance with the

applicable instructions from the manufacturer and other regulations in force at any given time.

By being thorough and making the necessary adaptations to local conditions, you will ensure the

best possible results.

Yours faithfully

T. Kverneland & Sønner AS

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

www.tks-as.no

Mail : [email protected]

Phone : + 47 51 77 05 00

Fax : + 47 51 48 72 28

TKS Operator’s manual

8

1.4 FeedMixer

1.4.1 Model description and area of use

FeedMixer is designed for cutting silage, round bales, square bales and most types of forage.

It cuts most types of round bales and silage. The cut depends on the consistency and type of feed.

FeedMixer is particularly useful for creating a good mix in a short time.

It is therefore suitable for mixing full feed, which often involves mixing feed types of very

diff erent consistency and character.

It is important that fi ner ingredients and smaller quantities are mixed quickly before the structure of

the feed is damaged. With its powerful motor and augerdesign, you will quickly obtain a loose and

homogeneous material that can be easily dispensed from all types of feed carts or

belts.

FeedMixer has vertical augers that produce a fi ne material in which the structure of the feed is

retained. It is particularly important with pre-dried material that the feed is not

compressed into wet lumps. This will reduce the feed intake to the animals.

To achieve the best possible result, more time and involvement is required than “traditional”

feedout methods. The quantities of individual feed types and the duration of the mixing process

must remain the same each time mixing is performed if composition and consistency are to remain

uniform – otherwise feed intake and production will be aff ected.

All functions are electrically operated. The counter knives are moved in position during mixing and

retracted during the discharging process.

Where FeedMixer has to discharging several times a day, the door is closed between each

operation.

FeedMixer can be equipped with a sensor that reset mixing time, when a new bale is loaded into

the machine while mixing process initiated

When weight system record loads under 200 kg in the mixer while discharging, the rotational

speed increases in order to clean the augers and threw off the rest of the feed.

FeedMixer can be supplied in sizes from 4 to 45 m3. Sizes of 8–15 m3 are supplied with one auger,

while sizes of 18–30 m3 are supplied with two augers. The electrical control system controls all

functions, and it has been confi gured for operating a conveyor belt. The mixing motor is controlled

by frequency inverter, enabling a soft start-up and stop.

The controller also includes measurement of power consumption, so you can keep an eye on what

it costs to use FeedMixer for a day, a week or a month, for instance. An electrical

stationary mixer is signifi cantly cheaper to run than tractor-powered models.

NB: The instructions given in this operator’s manual apply to standard operating conditions.

Individual circumstances may arise at the premises of the user that deviate from the

instructions provided here.

The need to make changes to the machines and equipment as a result of such

circumstances shall not constitute grounds for making a claim against the manufacturer or supplier.

Climate, temperature, grass types, time of cutting, cutting/pressing equipment and

conservation methods are some factors that may aff ect the functionality and performance of the

machine. It is important to adapt and adjust the machine to suit local conditions in order to achieve

the best possible result.

Chapter 1 describes the design of the machine and the functions of its individual components.

FeedMixer is occasionally pictured with optional equipment fi tted. Any optional equipment is

labelled as such in this instruction manual and can be supplied at an additional cost.

ICM_02

TKS Operator’s manual

9

1.4.2 Machine identification

The machine’s serial number and the address of the manufacturer are written on the machine.

See the illustration on this page.

Please use the information on the name plate when making any enquiries about spare parts or

servicing.

This product is CE marked. This mark, along with the associated written EU confi rmation, means

that the product fulfi ls current health and safety requirements, and complies with the following

directives: Machine Directive 2006/42/EC

TKS Operator’s manual

10

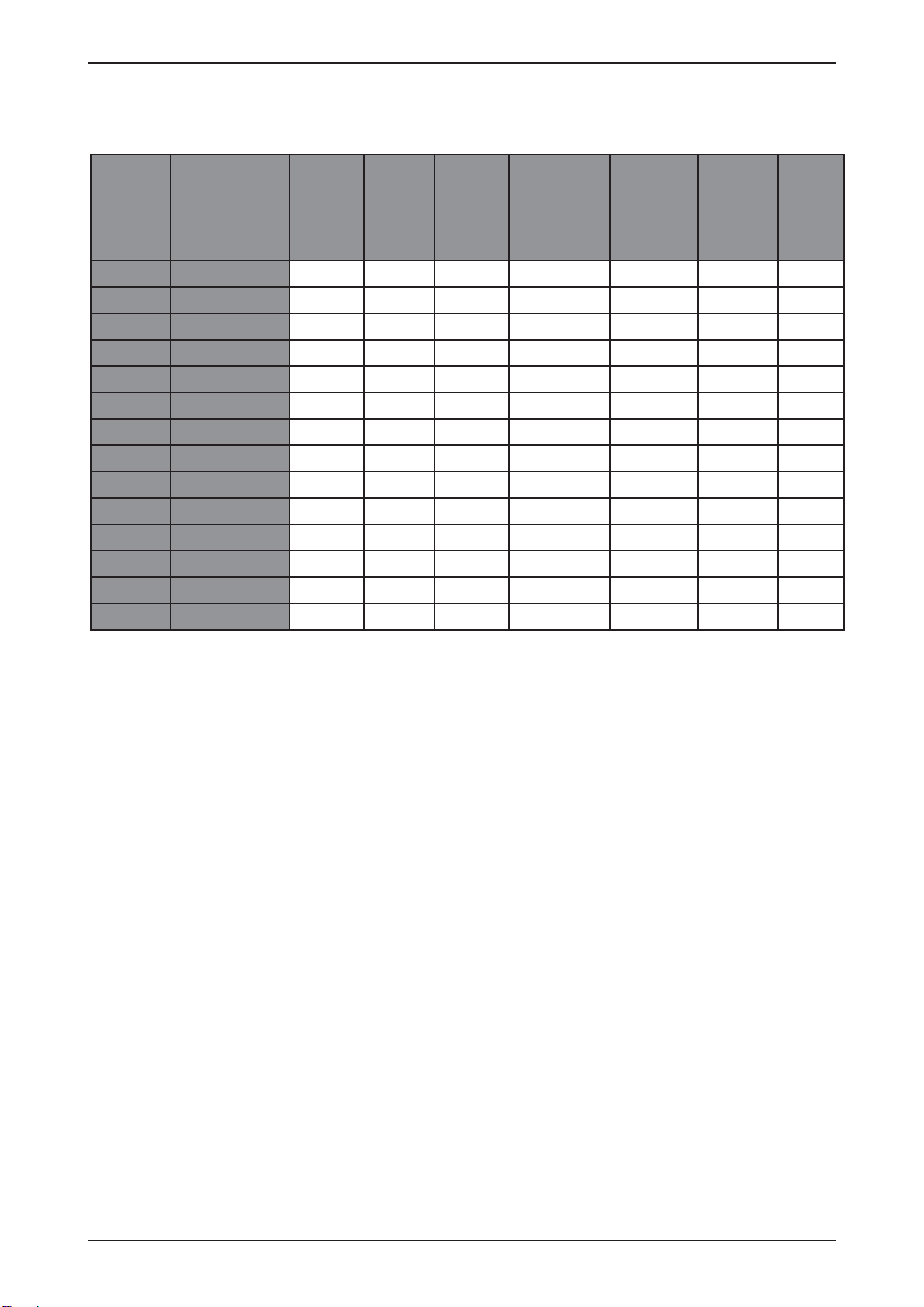

1.4.3 Technical data

Size in

m3

Auger

Type 80 VC

w/end door

Lenght

A

Height

B

Height

C

Lenght

with

control

panel

D

Height

with

legs

E

Load

Kg

Motor

kW

91S 3325 1691 2472 4157 2466 3455 22

11 1S 3350 1973 2487 4177 2748 3550 30

13 1S 3504 2242 2472 4177 3013 3660 30

15 1S 3583 2373 2471 4187 3143 3720 37

18 2S 5707 1690 2481 6573 2368 6060 37

22 2S 5760 1973 2481 6573 2651 6190 37

25 2S 5913 2243 2481 6573 2921 6340 37

27 2S 5987 2373 2481 6630 3051 6450 45

30 2S 6168 2562 2487 6731 3240 6385 45

28 3S 7995 1975 2810 8395 2575 9000 45

33 3S 8110 2245 2740 8510 2845 9500 45

39 3S 8260 2375 2862 8660 2975 10000 55

45 3S 8335 2525 2876 8735 3125 10500 55

27 2S 5987 2373 2481 6630 3051 6440 45

ICM_03

ICM_04

TKS Operator’s manual

11

Measure - FeedMixer

5

74

2

3

8

1

6

9

TKS Operator’s manual

12

1.4.4 Technical description

1 Mixing hopper

2 Extension kit

3 Auger

4 Weighting cell

5 Gear unit

6 El. cabinet

7 Gear motor

8 Feedout chute

9 Counter knives with activator

A

B

ICM_10

ICM_15

TKS Operator’s manual

13

Equipment:

A Loading cell

B Counter knife with activator

Equipement entièrement assemblé

TKS Operator’s manual

14

1.5

Safety Please pay particular attention to this symbol. It

designates a safety risk, and describes

precautions that must be taken to avoid

accidents.

Before operating, adjusting or repairing the

machine, the user, technician or owner should

familiarise himself with the safety instructions

contained in this installation manual.

Safety at work is your responsibility!

Please read and understand these general

safety instructions.

1.5.1

General safety instructions In order to be able to load the bale into the

hopper, the machine must be open.This means

that people may come into contact with moving

parts if they are standing in the immediate

vicinity of the machine while it is in use.

Warning! Once the auger is running, never

lean over the top edge of FeedMixer or enter

the hopper when the machine is operating.

If the machine is placed in a sunken fl oor, the

distance from the fl oor to the top of FeedMixer

must not be less than 1.5 m.

It is a conditional requirement of using the

machine that no one must be in the immediate

vicinity of the machine during use.

In addition, in terms of machine type,

FeedMixer is of conventional agricultural design

and, from a safety perspective, the solutions

choosen are considered to be on a par with or

superior to existing products on the market.

Use of the machine

The machine must only be used for the purpose

for which it is designed.

Operating

The machine operator must remain at the end

of the machine where the control box and the

associated operating panel are mounted.

Supervision

The owner/operator must ensure that the area

is suffi ciently signposted and that there is no

unauthorised access.

TKS Operator’s manual

15

The machine’s method of operation

The operator must familiarise himself with the

machine’s method of operation and function so

that the machine can be used in a safe and

appropriate manner.

Keep a safe distance

Humans and animals must be kept away from

the machine when it is in operation.

Keep your distance from working, rotating

and moving parts.

Think safety at work

Never climb on the machine while it is operat-

ing.

When performing maintenance, the power

supply must be disconnected

Warning – audio and illuminated

indicator

The control system (software) has been

updated for safe start-up. A built-in buzzer

sounds for 30 seconds before start-up of the

machine. This audio signal is accompanied by a

light signal that fl ashes during the entire period

of operation.

Protective guards

Check that all guards are in place and installed

correctly. Do not start the machine until this has

been done. Damaged guards must be repaired

or replaced immediately.

Spare parts

For safety reasons we recommend that you

only use original spare parts. The use of

third-party spares invalidates the product

guarantee.

Maintenance

Ensure that the machine is properly maintained

and is kept in good condition. Never attempt to

change the mechanical workings of the ma-

chine.

The area in which the machine is

operating

Must be physically sealed off or locked to

prevent danger to humans or animals.

Control panel

The power supply must be cut off before

opening the panel.

TKS Operator’s manual

16

1.5.2

Additional safety

instructions

The machine is marked with a warning

signs. If these signs are damaged, they must

be replaced. The order number is shown on the

illustrations in this section.

Side 17 for their location on the machine.

Warning sign UH220532 (Fig. 1)

Be careful! Ensure that you read and

understand the instruction manual before using

the machine, and before making any

adjustments or performing any maintenance.

Warning sign UH220536 (Fig. 2)

Risk of crushing hand.

Keep away from the counter knives.

Warning sign 988346 (Fig. 3)

The main power switch must be secured by a

padlock.

Work should only be performed by

authorised personnel.

Warning sign UH220534 (Fig. 4)

Disconnect all electrical connections before

carrying out welding work or maintenance.

Fig. 3

Fig. 2

Fig. 1

Fig. 4

UH220532

UH220534

988346

988346

UH220536

TKS Operator’s manual

17

1.5.3 Overview of safety risks

TKS Operator’s manual

18

1.5.4

Lifting the machine The lifting straps are attached to the points

screwed into the bottom of FeedMixer.

See Fig. 5

Use an extra strap to help keep the machine in

position.

Caution!

Never stand underneath a suspended load.

Any persons carrying out lifting operations must

of course have the appropriate qualifi cations/

skills.

Be careful!

Keep your distance when moving the machine.

Ensure that there are no persons underneath or

near the machine during lifting.

1.5.5

New machine - caution Read the operator’s manual

Be particularly careful when starting a new

machine for the fi rst time. Installation faults,

incorrect operation, etc. may lead to expensive

repairs and loss of earnings. The TKS product

guarantee does not cover damage resulting

from failure to follow the recommendations

contained in the instruction manual.

Please pay particular attention to this symbol.

It is used to highlight important information, to

help prevent incorrect installation and

operation.

Pay particular attention to the following

when commissioning a new machine:

• Check that the machine is correctly installed

and that it is not damaged. Check to make

sure that electrical cables are long enough,

and positioned in such a way that they can

track the movements of the machine without

being damaged.

UH220307

ICM_09

ICM_22

A

TKS Operator’s manual

19

1.5.6 Lifting point

Fig. 5

Lifting point

Detach the four lifting points (A) after the machine is hoisted into place, and fi t them to the outside

of FeedMixer for subsequent use as and when needed. See Fig. 5

5

3

2

4

1

TKS Operator’s manual

20

2 Function

2.1 Auger

There is a shear bolt connection between

the lay shaft and the planet gear.

If the machine becomes overloaded the

shear bolt will shear, thus stopping power

transmission to the auger.

During the mixing process, the auger transports

the feed upwards to the middle of the mixing

hopper.

The feed then falls off the mixing auger and a

mixing cycle is created.

2.2 Knives The auger (2), which is equipped with knives

(1), fi nely chops up the feed constituents that

have been loaded into the mixing hopper.

A discharging arm (3) together with the blades

of the auger ensure a more stable and even

discharging process.

See Fig. 7

The knives on the auger can be set to an

aggressive position (4) or a normal

position (5). The adjustable knives allow the

mixing system to be adjusted to suit

individual operating conditions at the company

and the structure of the feed constituents.

Aggressive = short mixing time, higher power

consumption.

Normal = longer mixing time, lower power

consumption.

(E.g. if the fuses are smaller)

Fig. 6

Fig. 7

Table of contents

Other TKS Farm Equipment manuals

Popular Farm Equipment manuals by other brands

MacDon

MacDon 2000-B Operator's manual

Osborne

Osborne Big Wheel RN1 Series Assembly & operating instructions

Gaspardo

Gaspardo ELEFANTE Use and maintenance

Unverferth

Unverferth BLU-JET AT4615 manual

DuraTech Industries

DuraTech Industries HAYBUSTER CMF-1150 Operating Instructions and Parts Reference

Amazone

Amazone CatrosXL 4003-2 Original operating manual