Econo-Wrap EW-450S User manual

Operator’s Manual & Parts Breakdown

Rev. 12/29/14

Model EW-450S

Stationary Bale Wrapper

2

TABLEOFCONTENTS

GeneralInformaon………………………….……………..….2

IntendedUseoftheMachine………………………………3

GeneralSpecificaons&DescriponofMachine…4

Transport&Installaon……………………………….………5

OperaonofMachine………………………...……………….6

TestRun……………………………………………………………6

FilmInstallaon…………………………………..……………6

Switchingto20"Film………………………………………..7

LoadingBalesOntoWrapper&Wrapping………..7

UnloadingWrappedBales&FilmCung…….……8

DriveChainAdjustment……….……………………………9

Failures&TroubleShoong……...………………………10

Storage………..……………………………………………………….11

RemovalofUsedParts………………………………………….11

SafetyofUse&Warnings……………………………………..11

SafetySymbols………………………………………………….….12

Technical&OperaonalInformaon………………….13

Maintenance…………………..…………………………………….14

LubricaonInstrucons………….…………………………….14

PartsBreakdown….……………………………………………….15

WarrantyInformaon…………………...…………………….27

GENERALINFORMATION

UponpurchasingtheEW‐450SBALEWRAPPER,thebuyerre‐

ceivesa12‐monthwarrantyfromthedateofpurchase.Ifthe

machineisdamagedthroughnofaultofthebuyer,he/sheis

entledtosubmitacomplainttothemanufacturerorseller.If

theuserfailstocomplywiththeinstruconmanual,he/she

loseshis/herrightsresulngfromthewarranty.Moreinfor‐

maononcomplaintsiscontainedinthewarrantycard.Ifnec‐

essary,furtherinformaonwillbeprovidedbythemanufactur‐

er.

Whencontacngthemanufacturerorseller,pleaseprovide

thetype,serialnumber,yearofmanufactureofthebalewrap‐

per(thisinformaonshouldbecopiedfromtheserialnumber

plate,whichisaachedtothemainframe).

Inthisinstruconmanual,instruconscrucialforsafetyare

markedwiththefollowingwords:

NOTE!REMEMBER!IMPORTANT!

NOTE!

Aconscontrarytotheinstrucon

manual,failuretocomplywithsafety

regulaonsortheuseofbalewrapper

thatisnotconsistentwithitsintended

usecancauseaccidents.Theusershall

beliablefortheconsequencesofsuch

acts.

3

IntendedUseoftheMachine

Thebalewrapperisintendedforwrappingsinglebalesofsemi

‐dryhayfromgrassesandlegumescollectedbybalers

(moisturecontentofapprox.60%).

Aerbeingwrappedwithspecialself‐adhesivestretchfilm,

balesareintendedtobeusedforhaylage.

Thewrappercanbeusedforbalesupto4’6”long;withadi‐

ameterof3’‐5’andweighingupto2,100lbs.Specialfilm

30”(or20”)wideshouldbeusedforwrappingbales.

Film‐wrappedbalesofhaylageallowforconsiderablereduc‐

onofnutrientlossesascomparedwithtradionalsilaging

methods(piles,silos).

Theharvestedmaterialshouldbecollectedusingabaleraer

beingdriedforseveralhours(dependingontheweathercon‐

dions).Balesshouldberolledveryghtsothattheaircon‐

tentinsidethebaleisreducedtoaminimum.

Balesshouldbewrappedonthewrapperassoonaspossible,

two hours aŌer rolling at the latest.Wrappingbalestoolate

willresultinthematerialbecomingover‐dried,whichpro‐

motestheoccurrenceofdisadvantageousprocesses.

Wrappedbalesshouldbeleforfermentaoninadryplace

onasmoothsurfaceforatleast6‐8weeks.Thisprocessshould

takeplaceatabove‐zerotemperatures,oneshouldmakesure

thatthefilmonthebalesisnotdamaged.Ifdamageoccurs,

thisplaceshouldbesealedagain.

Balescanbeplacedhorizontallyorvercallynexttoeachother

withnomorethantwolayers.

Twomonthsaertheharvest,haylagecanbefedtoanimals.

Usingthewrapperforotherpurposesshallberegardedasim‐

properuse.Meengandcompliancewiththecondionsper‐

tainingtotheuseofthemachine,itsoperaon,repairsaccord‐

ingtothemanufacturer'srequirementsformaninseparable

partoftherequirementfortheconsistentusewiththeintend‐

eduse.

NOTE!

Exerciseparcularcauonatthebrack-

etwithsharprollerknivesforcung

thefilm.Lackofcauonmayresultin

handinjuries.

NOTE!

Thebalewrappermanufacturershall

notbeheldliableforlossesresulng

fromtheuseofawrongtypeoffilm.

NOTE!

Warningsckersmustalwaysbelegi-

ble.Iftheyarenolongerlegibleorbe-

comedamaged,newsckersshouldbe

boughtatpointsofsaleandreplaced.

NOTE!

Duringtestrunsandbalewrapperoper-

aon,thepresenceofbystanders,and

especiallyofchildren,neartheworking

machineisforbidden.

NOTE!

Beforeliingthewrapperatthethree-

pointconnecon,thebackwindowof

thetractorcabmustbeclosed.

REMEMBER!

Itisforbiddentotransportthebale

wrapperwithaloadedbale.

NOTE!

Regulaonspertainingtoaccidentpre-

venonaswellasallbasicregulaons

regardingoccupaonalsafetyand

trafficregulaonsmustbecomplied

withonalloccasions.

NOTE!

Theengineofthetractorandthebale

wrappercanbestartedonlyaermak-

ingsurethatpoweringtherotang

framedoesnotposearisktoanybody.

REMEMBER!

Beforestarngtheoperaon,thebolt

lockingtherotangframeshouldbe

released.

NOTE!

Theoperaonwithremovedcoversis

forbidden.

4

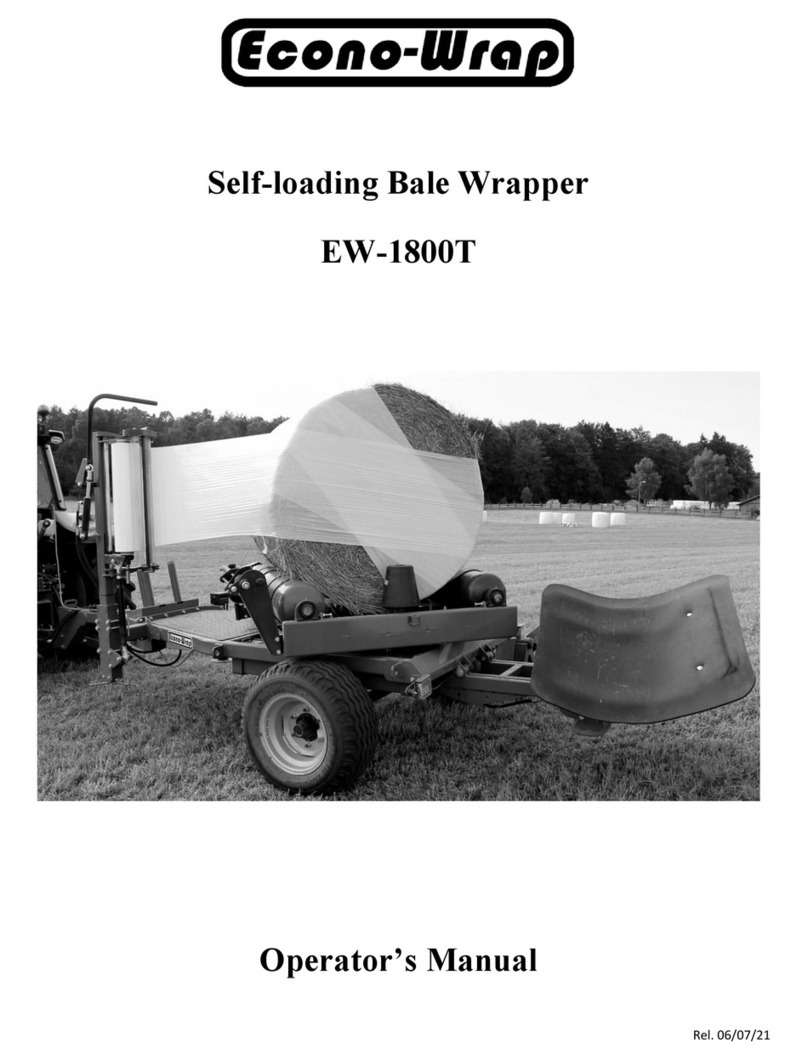

GeneralSpecificaons&DescriponofMachine

Themainframe(1)ofthewrapperisaachedtothethree‐

pointsuspensionsystemofthetractor.Thelowerframe(2)is

fixedtothemainframeusingtwobolts(8)securedwithresili‐

entretainingpins.Arotangframe(3)withrollers(9),upon

whichbalesareloaded,ismountedonthelowerframe.Abar‐

rier(12)andafilmdispenserareinstalledonthevercalbeam

(11)ontherightsideofthemainframe.Bothvercalbeams

(11)areconnectedatthetopwithaU‐profile(13).Thewrap‐

perispoweredfromthehydraulicinstallaonofthetractor

withahydraulicmotor(5)throughaspecialvalve(14),which

ensuresasmoothstart‐upandstoppingoftherotangframe.

Thepowerfromthehydraulicmotoristransmiedontothe

chainwheeloftherotangframewitha5/8”chain(15).Inthis

way,aerthedriveisturnedon,therotangframeofthe

wrapper(togetherwiththebalebeingwrapped)rotates

aroundthevercalaxis.Intherotangframe(3),thereisan

openbevelgearbox(10).

Fig.7Diagramoftheself-loadingbalewrapper

1‐mainframe;2‐lowerframe;3‐rotangframe;4‐filmdispenser;5‐

hydraulicsystem;6‐resistancewheels;7‐wrappingcounter;8‐pin;9‐

roller;10‐bevelgearbox;11‐vercalbeam;12‐barrier;13‐con‐

necngU‐profile;14‐specialvalve;15‐mainchain;16‐rubberrollers;

17‐rolloffilm;18‐retainingpin;19‐line;20‐securingchain;21‐film

cuer;22‐countersensor

Thesubsequentlayersoffilmarewrappedaroundthe

baleasaresultoftheaforemenonedmoons.The

filmdispenser(4)consistsofaframeandasupport

bracketwithrubberrollers(16)coupledwitheach

otherbymeansofaspurgear.A

rollofwrappingfilm(17)isinstalledontheboltinthe

dispenserframeinaccordancewiththediagram

(seeFig.11).Theappropriatelyselectedposionbe‐

tweentherubberrollersandcloseadhesionofthefilm

(17)totherollers(16)ensuresstretchingandgoodand

accurateadhesiontothesubsequentfilmlayers.The

degreeoffilmlengtheningcanbeadjustedbyturning

thefilmrollpressurenut(see

Fig.11,item3).Thelowerframe(2)withtherotang

frame(3)issecuredagainstlngbythelockingpin

(18),whichissituatedonthemainframe(1).Whenthe

lockingpin(18)ismovedforwardbytheleversystem

aerpullingtheline(19)fromthetractorcabresultsin

unlockingthelowerframe(2),togetherwiththero‐

tangframe(3).Aerliingthewrap

Acuer(21)withrollerknivesforfilmcungisfixedto

therotangframe(3)bytherollerdrives(9).Thefilm,

whichwaspulledoutoftheinsertedbale,willbeintro‐

ducedbetweenthecuerflatbars(21)ontotheroller

knivesandcutoff.Rubberresistancewheels

(6)areplacedontransversebarsoftherotang

frame(3),whichprotectthebaleagainstslidingof

theroller,whileitisbeingwrapped.Whiletrans‐

porngthewrapperonpublicroads,the

transportcovermustbeplaced,insteadofoneofthe

retainingwheelsandthetriangularsignandthewarn‐

ingsignshouldbeplacedonthebracketsthatare

placedonit.Thebalewrapperisequippedwith

anelectronicwrappingcounter(7).Thecountersensor

(22)isinstalledonthesupportbracketopeningonthe

rightsideofthemainframe(1),whilethewrapping

countershouldbeplacedinavisibleplaceinthetractor

cabandthecableshouldbeconnectedtothesensor

(22).

1214 15 8

5

11 17 12

13

19

18

4

921

16

16 12

17

3

22

10

8

76

2

22 20

5

Transport&Installaon

Fortransport,thebalewrapperisinstalledonawoodenpallet

andsecuredagainstmovingduringtransport.Thebalewrap‐

perisintendedforstaonaryworkonafarm.Ifthebalewrap‐

peristransportedonpublicroadscoupledtothethree‐point

suspensionsystemofthetractor,thehydraulicsystemofthe

wrappermustbefilledwithgearoilandclosedtoensurethe

lockingoftherotangframeinthetransportposion,seeFig.

8.

Fig.8Wrapperintransportposion.

Beforedrivingontheroad,itisnecessaryto:

inserttheretainingpinintothevercalbeamofthemain

frametoprotectthelowerframeagainstlngback‐

wards,

puttherotangframeofthewrapperinthetransport

posion,

putthetransportcoveratthebackofthewrapper;install

awarningsignwithredandwhitestripeswitharedwarn‐

inglightandatriangularsigninthebracketsonthecover,

disconnectthehydraulichosesofthehydraulicsystemof

thetractor.

Installaon

Beforeaachingthebalewrappertothetractor,the

followingaconsmustbetaken:

removetheagriculturalhitchfromthetractor,

backthetractortoalignitwiththebalewrapper,

bothendsofthepush‐pullrodswiththeball‐and‐

socketjointsofthetractorshouldbemovedontotwolower

boltsandsecurethemwithcoerpins.

adjustthelengthoftheupperconnectorofthetractor

andconnectitsendwiththehitchbracketonthemain

frameofthebalewrapperusingtheconnectorboltand

protectitwithacoerpin,

inserttheplugsofthequickdisconnectcouplingsofthe

hydraulichosesintothevalvesocketsofthetractorhy‐

draulicsystem(Fig.9),

aachtheendofthebackframelockinglineataconven‐

ientplaceinthetractorcab,

unlocktherotangframe,

placethebale‐wrappingcounteratavisibleplaceinthe

tractorcab.Connecttheelectriccabletothecounter.

Fig.9Installaonofhydraulichosestothetractor.

IMPORTANT!

Allinstallaonworkmustbeperformed

withtheengineoffandthekeymustbe

takenoutoftheignionlock.

REMEMBER!

Useonlytheoriginalandtestedcoer

pinstosecurethebolts.Itisforbidden

touseotherprotecons,suchas

screws,rodsetc.

Other manuals for EW-450S

2

Table of contents

Other Econo-Wrap Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions