Econoline 36-1 DP Instructions for use

36-1 DP

PLEASE READ

BEFORE

USING THIS EQUIPMENT

DP 36-1

Assembly Instructions

PLEASE READ INSTRUCTIONS COMPLETELY

BEFORE STARTING

We thank you for purchasing the DP-36 pressure system. This system has

been specifically designed for the Dry Blast user who wishes to achieve

quality results on a number of surfaces for both low and high volume

requirements. Below you will find instructions on how to assemble your

unit upon receipt. If you have any questions on how to proceed with any

steps, contact Econoline Technical Service by phone at 1-800-253-9968

or fax at 1-616-846-6341.

NOTICE:

The DP36 is delivered skid-mounted to assure safe arrival. If any damage

is evident upon receipt, contact the carrier immediately to file your claim.

STEP 1 – Unpacking

Cut the packing straps by using heavy-duty scissors or wire cutter.

Remove the protective plastic wrap and cardboard. Open the front

door by unlatching and remove the light assembly, regulator and foot

pedal. Using a crescent wrench, remove the bolts to loosen the unit

from the skid. With assistance of others, slide unit gently off the skid

and place unit in desired work area.

STEP 2 – Light Fixture Installation

Unwrap the fluorescent light fixture and attach to the top of the

cabinet with hardware provided. Be sure to place the plastic

protective sheet between the light fixture and the cabinet to protect the

light source from abrasive damage during blasting.

STEP 3 – Window

Loosen wing nuts to remove window frame and peel protective covering

off from the window. Re-install and firmly tighten wing nuts to prevent

leakage around window.

STEP 4 – Dust Collector set-up

Unpack the dust collector and place within a few feet of the sandblast

cabinet. (Note: vacuum hose is packed in bottom barrel of dust collector.)

Attach one end of the plastic hose to the air inlet of the vacuum system and

attach the other end to the air outlet on the rear of the blasting cabinet.

Plug the dust collector line cord into outlet on the back of the lamp box.

See your dust collector manual for details and operation of your dust

collector.

STEP 5 – Regulator and gauge installation

Connect regulator and gauge assembly (nos.1 & 9) to the inlet ball valve

(no. 3). Be sure to place Teflon tape on the thread to assure a leak-free fit.

Using a pipe wrench, tighten the connection. When the regulator and

gauge has been installed, place the pipe tee (no. 2) and filter to the left of

the regulator and gauge.

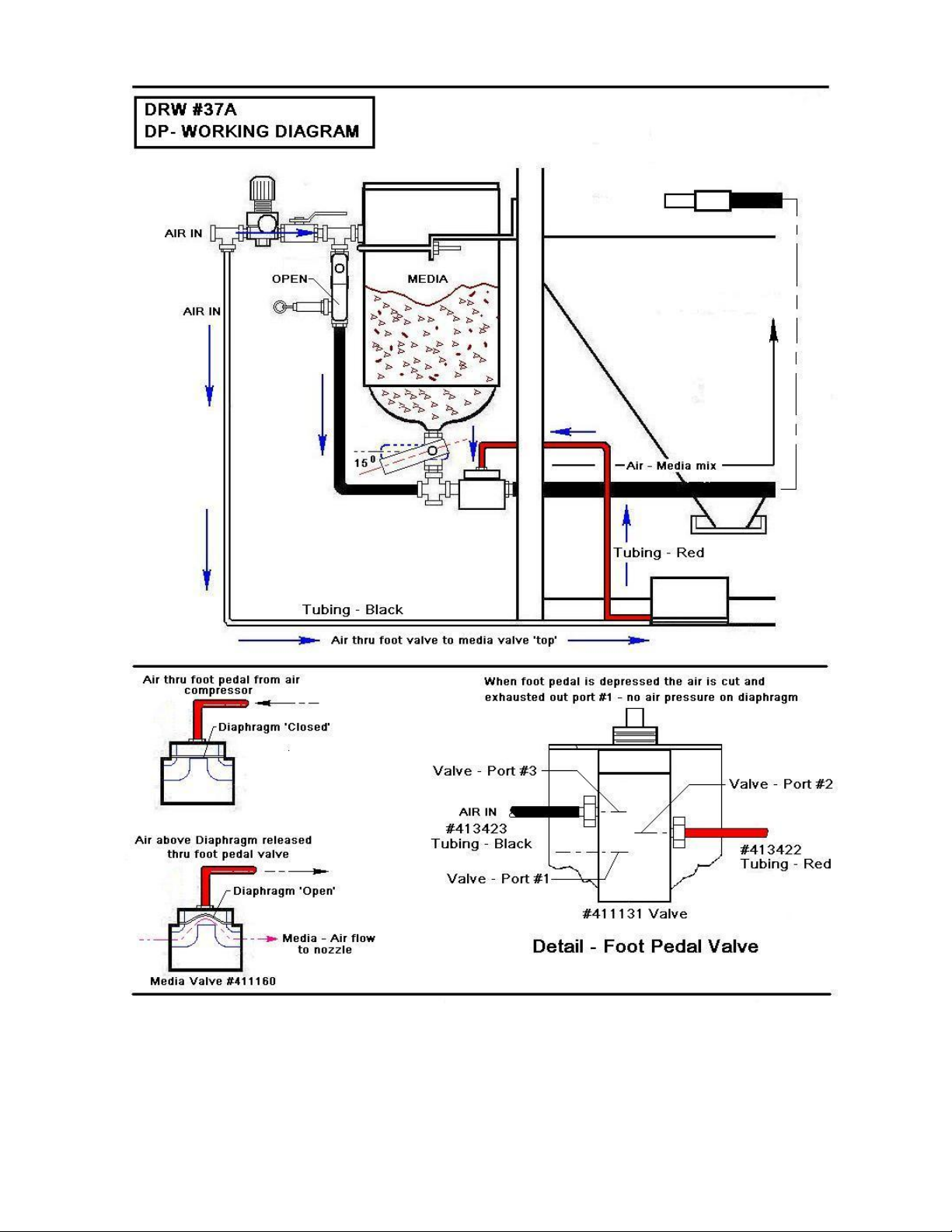

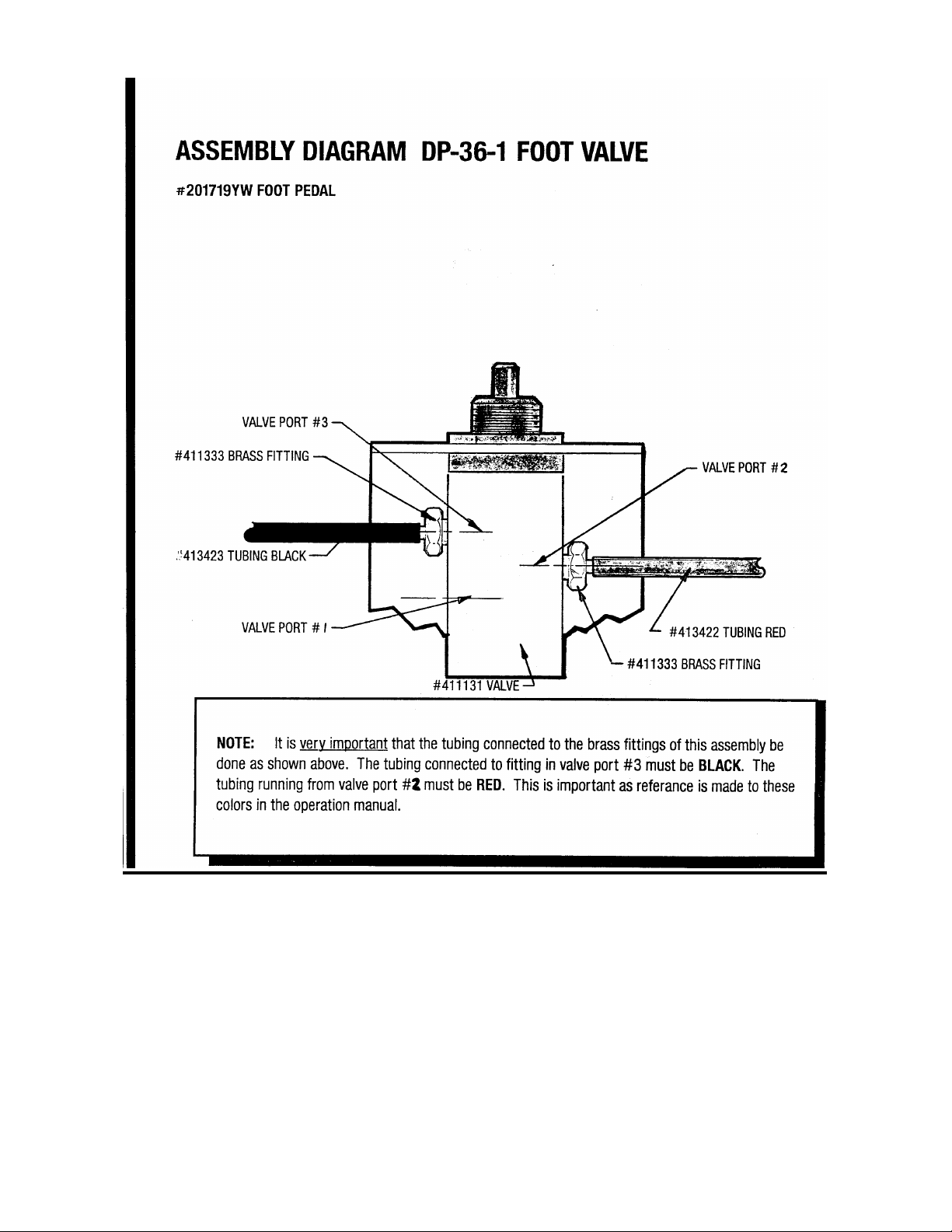

STEP 6 – Foot operated blast gun installation

Connect the black hose from the foot pedal valve to the brass hose barb in

the ¼ inch air filter (no. 12). Connect the red hose to the brass hose barb

on the media valve (no. 11).

*DO NOT USE QUICK DISCONNECTS*

STEP 7 – Attaching air line to sandblast system

NOTE: WE STRONGLY SUGGEST YOU HAVE A WATER / AIR

SEPARATOR PLACED BEFORE THE REGULATOR TO ASSURE

NO MOISTURE ENTERS THE SYSTEM. MOISTURE MAY LEAD

TO CLOGGING OF ABRASIVE MEDIA.

Close your air inlet ball valve (no. 3) and attach the airline from your

compressor to the pipe (1/2 inch NPT pipe thread) from your regulator and

gauge (or water / air separator if you have installed one). The “open”

position of the air inlet ball valve is when the lever is positioned over the

length of the valve. The “closed” position is when the lever is

perpendicular to the ball valve. When attaching the air supply to the DP-

36 the following assembly instructions are important for your system to

function properly.

*Air to the plumbing of your unit should be supplied by hose or pipe

with a minimum of 3/8” I.D. and we strongly suggest ½” I.D.

*Do not attach your air supply to the unit with quick connects, as

this greatly reduces the volume of air to the system and will

adversely affect the units performance.

*For your foot pedal and media valve to operate properly and to

maximize the life of the media valve and diaphragm – air line

pressure supplied to the regulator of the system must be maintained

at a constant 100 – 125 psi. (Note: this pressure is required to close

diaphragm in valve).

STEP 8 – Loading abrasive into pressure-pot

Pour the abrasive media into the pressure pot. Brush excess media into

the vessel to avoid it being sprayed into the air when filling the system

with air. The pressure pot holds up to 100 pounds of media for long

uninterrupted blasting. When reusing any abrasive media, be sure to

use a filter to remove any extraneous materials which could clog the

abrasive metering valve or the sandblast nozzle.

STEP 9 – Filling pressure-pot with air

Grip the pressure pot handle located in the top of the pressure vessel

and lift firmly to secure ball seal in the opening while simultaneously

opening the air inlet ball valve (no. 3) slowly. A swishing sound will

indicate that the vessel is being filled with air. After a few seconds,

the handle will stay in place on its own. If this is not the case, open

the ball valve further to allow the vessel to fully compress.

When the system is fully compressed, the ball valve should be in the

fully opened position. Check your regulator and gauge to assure the

PSI is still at the desired setting. If not, adjust the regulator by turning

the control located on top. Next, make sure that ball valve (no. 5) is in

the “open” position.

STEP 10 – Controlling the abrasive media flow

The pressure-pot is fitted with an abrasive metering valve (no. 5) located

on the bottom of the vessel. To adjust the valve, align the valve lever

perpendicular to the valve body (closed position). Now turn the lever

down approximately 30 degrees. This should be a good position to begin

adjusting the media flow. Slide your arms into the gloves in the arm ports

of the cabinet, grip the blast hose firmly, and depress the foot pedal to

begin blasting (it is normal when starting to blast that one or two spurts of

abrasives come out of the nozzle before uniform blasting begins). Best

blasting is achieved when the abrasive can barely be seen as a mist in the

air/media stream from the nozzle. Too much abrasive in the flow will

reduce the ability of the system to blast effectively and will cause surging.

Too little abrasive flow will slow your blasting and yield poor results.

Opening the abrasive metering valve will put more media into the mix

while closing it will deliver more air and less abrasive. Once the metering

valve is properly set, it will require only occasional maintenance.

STEP 11 – Blasting

Best results are achieved by sandblasting between 20 and 80 psi and

holding the nozzle at a 90 degree angle to the surface at about 4 to 8 inches

away. Maintain a continuous, even movement of the nozzle to prevent the

media from cutting too deep into your work surface.

NOTE: IF USING GLASS BEAD KEEP PRESSURE BELOW 40

PSI. GLASS BEAD SHATTERS INTO DUST ON CONTACT WITH

ITS TARGET AT PRESSURES OF 40 PSI AND ABOVE.

To stop blasting, release the foot pedal and the air media valve will shut

itself off automatically. To begin again, just press down on the foot pedal.

To shut down the system, simply close the air inlet ball valve (no. 3)

and press down on the foot pedal. The pressure relief valve (no. 12)

can be activated by pulling on the ring, however, depressing the foot

pedal is easier and can be accelerated by pulling on the pressure relief

valve simultaneously.

MAINTENANCE

To assure a long efficient life of the system, it is recommended to:

A. Replace nozzle when compressor can’t keep up, or media usage is

excessive.

B. Rebuild media valve when it starts to leak or doesn’t shut off.

C. Check abrasive metering valve when you can’t get correct abrasive

flow. If worn badly, replace.

D. Check hose barbs after 20 hours of use. If worn badly, replace.

E. Replace abrasive hose when it begins to soften or leaks media or air.

Water and/or oil in the air line will cause problems with the efficiency of

your blasting. Before blasting, always drain water and/or oil from air line.

We suggest that a quality water filter be installed in the air line between the

compressor and the blast cabinet.

Good visibility speeds up work. Clean dust from window often and

replace the plastic window underlayment and window when needed. The

lamp shield will also become frosted and require replacement. Visibility is

also affected by the condition of the dust collection system. The filter

should be cleaned often and the dust emptied from the canister regularly

(more than a gallon of debris is too much.)

If after extended use of the machine the gasket around the door or window

becomes damaged or worn, it can be replaced (see diagram).

This equipment is engineered to the finest point of simplicity. With

reasonable care it should give you many years of excellent service.

Blasting by its very nature is a high maintenance process. The

same forces acting to separate materials from targeted pieces

wear on the system itself.

Keep service parts in stock to avoid down time.

HELPFUL HINTS

1. Air compressor choice: Secure an air compressor that has

the capacity to produce a high volume (cfm) and high-pressure

(psi) of moisture –free air.

You must maintain a constant air pressure, not high one minute and

low the next, it must be constant.

2. Air supply line: Keep the air lines as short as possible.

DO NOT reduce the air line down to a quick disconnect when

attaching it to your blast equipment. In order to maintain the

high CFM and PSI you need at the blast nozzle; we suggest

using a minimum ½” I.D. air line from your compressor to the

blast machine.

3. Blast Nozzles: the blast nozzle size and design will

determine the cfm of air required. The larger the nozzle, the

greater the cfm needed.

4. As you begin blasting, record all data, compressor delivery

pressure, nozzle size (I.D.), regulator pressure, and abrasive

type and mesh size. When you are totally satisfied with your

results, be sure to record all data for future use and reference.

PARTS LIST FOR LARGE LIGHT BOX

COMPLETE ASSEMBLY #202835-LED

DESCRIPTION PART NUMBER

1. Light Box cover only 410466

2. Power Cord 411242

3. Light Switch (on/off) 411249

4. LED tube 7W / T8 / 5000K (2 required) 411240

5. Socket 411245

6. Lamp Shield – large (not shown) 411422

WARNING: This fixture has been modified and no longer operates fluorescent lamps. Ballast has

been removed and there is line voltage being supplied to sockets. DO NOT INSTALL FLUORESCENT

LAMPS.

411240 LED TUBE

#4

411245 Socket

#5

#3

411249

#

1

4104667

1

#7

411422

not shown

#2

411242

PARTS LIST FOR BLAST CABINET

DESCRIPTION Part #

411601

410545

18. Window frame

19. Window plexi-glass 12” x 24”

20. Window underlayment

1 piece 24” x 120”

10 pieces 12” x 24”

21. Window gasket material

(Specify number of feet required)

22. Latch assembly front door

23. Glove clamp (1 pair)

24. Gloves 24” x 6” seamless rubber (pair)

left hand only

right hand only

25. Armhole gasket

26. Front door gasket

27. Work table (expanded metal)

28. Side door handle assembly (set)

Consists of: Handle

Latch

29. Side door

30. Side door gasket

31. Lamp box gasket material

32. Lamp shield

33. Lamp box assembly complete

NOT SHOWN: Trap door spring

Trap door gasket

309344-66

411405

311535

313286

411403

411712

414511-2

412402

412402-L

412402R

411402

411403

201345

411701

411702

201326-66

411403

411403

411422

202835-LED

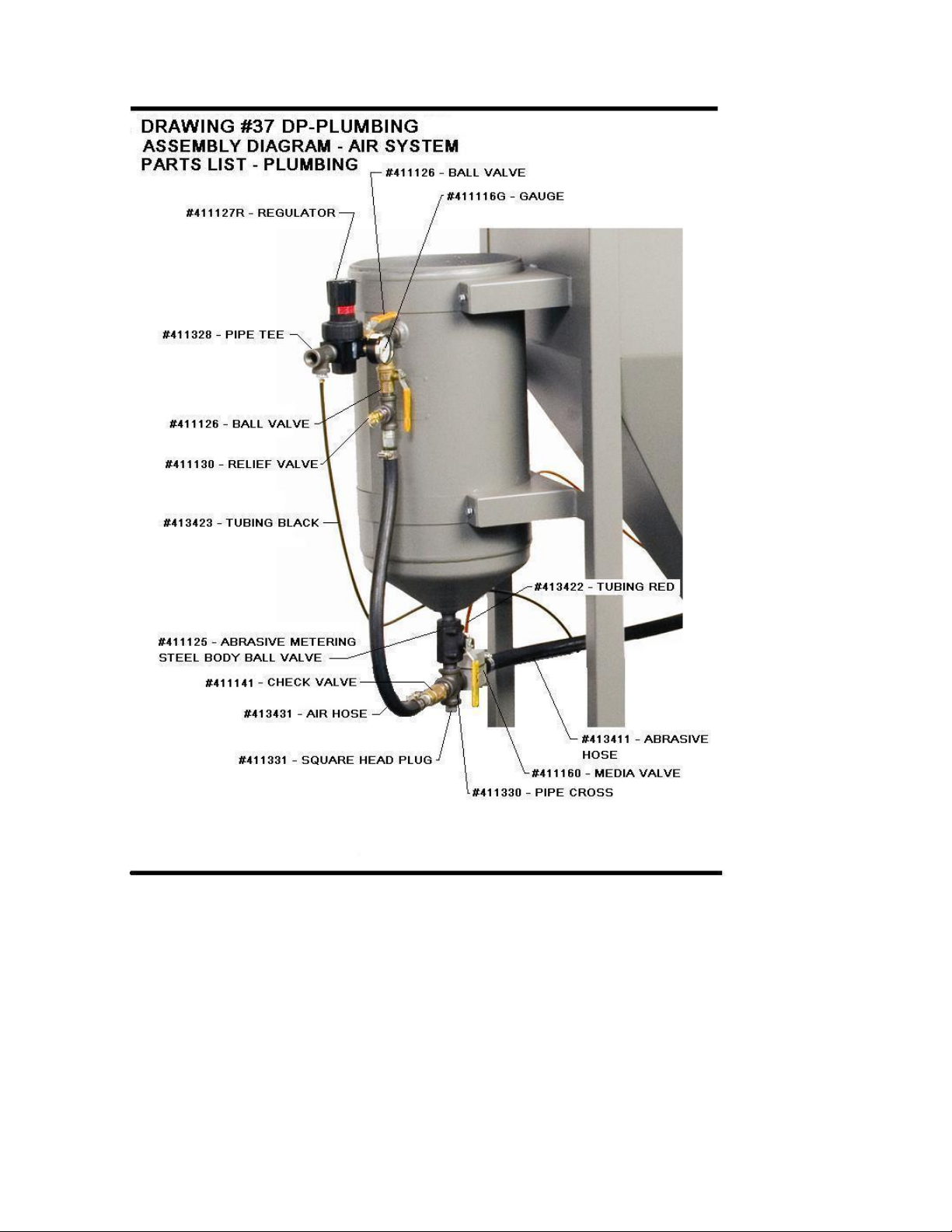

PARTS LIST FOR AIR SYSTEM – PLUMBING

DESCRIPTION PART NO.

1. Regulator 411127

2. Pipe Tee 411328

3. Inlet Ball Valve 411126

4. Air Hose ½” I.D. 413431

5. Choke Ball Valve 411126

6. Abrasive Metering Valve 411125

7. Pipe Cross 411330

8. Square Head Pipe Plug 411331

9. Gauge 411116G

10. Abrasive Hose (8’ required) 413411

11. Media Valve 411160

12. Pressure Relief Valve 411130

14. Check Valve 411141

15. Foot Pedal Valve 411131

15A. Foot Pedal – Complete 201719YW

16. Tubing (black) 413423

17. Tubing (red) 413422

Not shown - Gasket Closure 3” dia. – red 411427

PLEASE READ

For optimum performance, we have included two

different media valve diaphragms.

Installed in the media valve is our high-pressure

diaphragm part #411157.

If the media valve does not shut off immediately upon

releasing the foot pedal, you may need to change the

diaphragm.

For lower pressure uses we recommend installing the

low-pressure diaphragm part #411164

Whenever the media does not shutoff, you should first

inspect the diaphragm for wear.

TROUBLESHOOTING TIPS

PROBLEM POSSIBLE SOLUTION

Surging of blast flow?

Air pressure too low------------------- See “Lack of Air”

Too much media----------------------- Adjust media valve

Excessive media consumption?

Media valve open too far------------- Close slightly

Air pressure too low------------------- Check pressure gauge

Clogging and plugging of blast flow?

Debris in media------------------------ Purge & screen

Media size too large------------------- Use smaller grit size

Nozzle plugs---------------------------- Use larger nozzle

Nozzle plugs---------------------------- Adjust media valve

Wet media------------------------------- Dry media, drain water from air

Moisture in abrasive media?

Wet media------------------------------ Change or use dry media

Water in air----------------------------- Drain water from air lines

Water in tank--------------------------- Empty, dry out and refill

Humid weather?

Moderate humidity-------------------- Keep media dry as possible

Moderate humidity-------------------- Use dryer or moisture separator

High humidity ------------------------- Avoid usage if possible

Overtaxed compressor?

Compressor too small ---------------- Restrict time used

Nozzle size too large ---------------- Use smaller size

Too many leaks in plumbing ------- Seal and tighten plumbing

Holes in abrasive hose---------------- Replace

Air filter on compressor-------------- Clean

Lack of air pressure?

Compressor too small ---------------- Use smaller nozzle

Supply valves not on full position--- Open valves

Nozzle size too large ---------------- Use smaller size

Leaks in plumbing--------------------- Seal & tighten plumbing

Holes in abrasive hose----------------- Replace hose

Air filter on compressor plugged----- Clean filter

Urethane gasket worn or dirty-------- Clean or replace gasket

Lack of abrasive flow?

Blaster tank empty--------------------- Fill tank

Moisture in media---------------------- Dry media

Not enough air pressure--------------- Check system

Abrasive hose kinked ----------------- Straighten

Debris in media------------------------- Clean or screen media

WARRANTY

ECONOLINE

THIS PRODUCT HAS BEEN MANUFACTURED AND ENGINEERED TO THE

HIGHEST STANDARDS.

FIVE YEAR WARRANTY

ECONOLINE ABRASIVE PRODUCTS GUARANTEES ITS BLAST CABINETS

AGAINST DEFECTS IN MATERIAL AND WORKMANSHIP FOR A PERIOD OF FIVE

YEARS FROM THE ESTABLISHED PURCHASE DATE. ECONOLINE WILL REPAIR

OR REPLACE, FREE OF CHARGE, ANY DEFECTIVE PARTS DETERMINED TO BE

COVERED UNDER THIS WARRANTY BY OUR FACTORY SERVICE PERSONNEL.

THE PARTS MUST BE RETURNED TO THE FACTORY, FREIGHT COLLECT, WITH A

LETTER OF EXPLANATION. ON ACCEPTANCE OF CLAIM ECONOLINE WILL

REPLACE DEFECTIVE PART.

CONDITIONS

THIS WARRANTY DOES NOT APPLY IF THE UNIT HAS BEEN MISUSED,

ALTERED, OR USED FOR ANY PURPOSE OTHER THAN IN ACCORDANCE WITH

THE OPERATING AND ASSEMBLY INSTRUCTIONS PROVIDED.

THIS WARRANTY DOES NOT COVER TRANSPORTATION, INTERIOR OR

EXTERIOR FINISHES, HOSE ASSEMBLIES, NOZZLES, AIR JETS, WINDOWS,

FILTERS, LAMPSHIELDS OR MEDIA VALVE.

OPERATION OF THIS UNIT WITH NATURAL

SAND SHALL RENDER THIS WARRANTY NULL

AND VOID.

WARNING

DO NOT USE SAND OR ANY ABRASIVE CONTAINING SILICA. USE

OF COMPOUNDS CONTAINING SILICA IS A HEALTH HAZARD.

FREE SILICA WHEN INHALED CAN LEAD TO SERIOUS,

PERMANENT, DISABLING AND DEADLY DISEASE (SILICOSIS).

Table of contents

Popular Industrial Equipment manuals by other brands

Mec

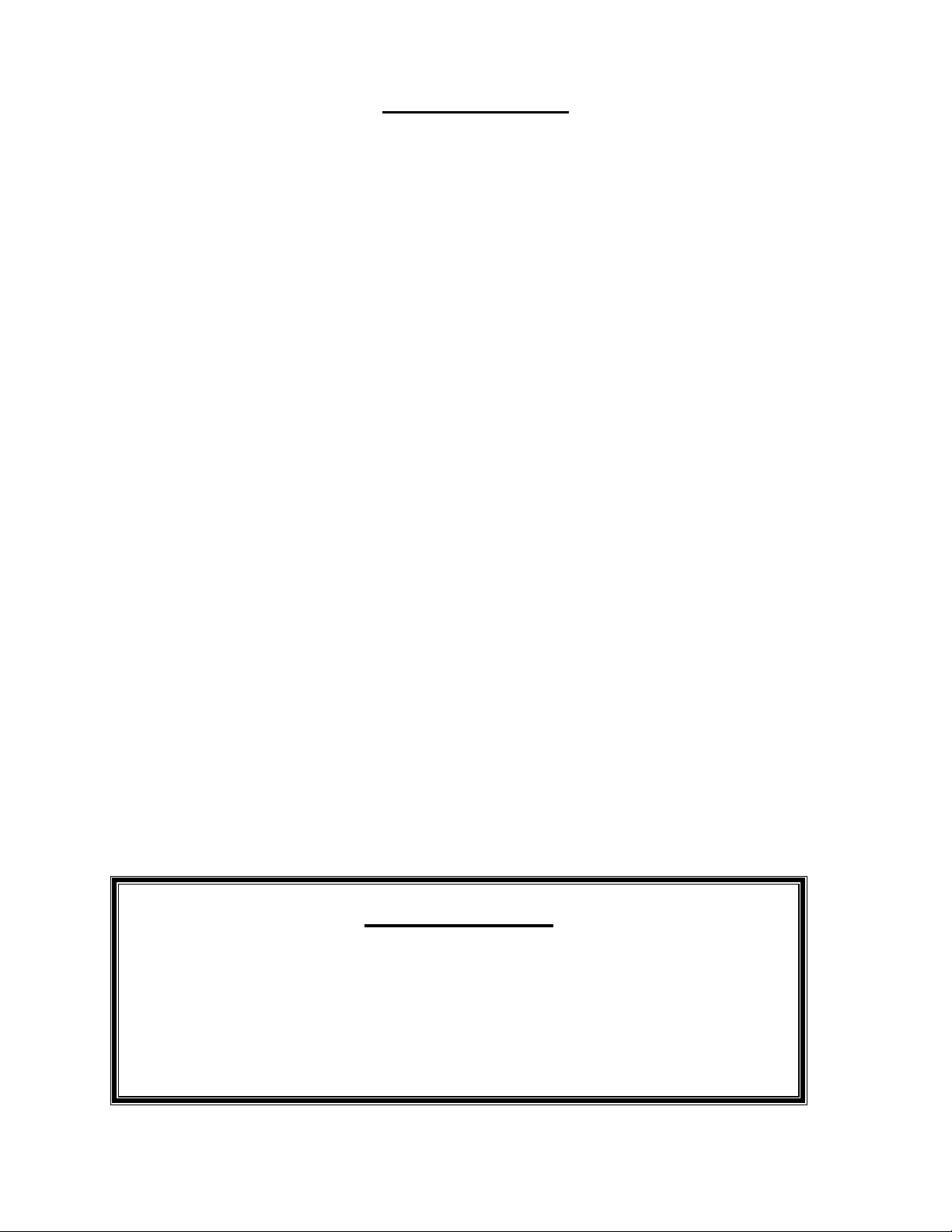

Mec TURBO-FLO LE ME806 Series Installation and operating instructions

VALLEY CRAFT

VALLEY CRAFT F88565C7 instruction manual

OP

OP TUBOMATIC H79 EL Use and maintenance manual

ABB

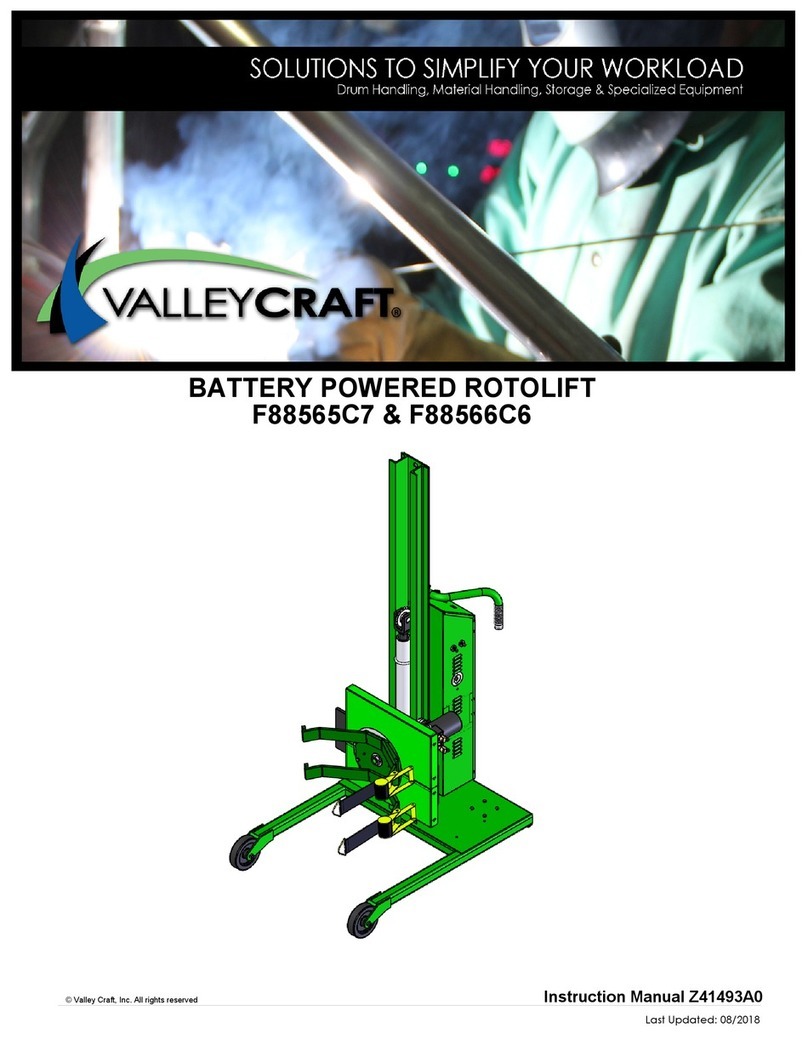

ABB HT569272 Operation manual

Gis

Gis GKU 1250 Translation of the original instruction manual

Festo

Festo KSK Series operating instructions