Ricoh A571 User manual

ROLL FEEDER

(Machine Code: A571)

1. SPECIFICATIONS

Roll Paper Size: Width: 210 mm to 914 mm, 81/2" to 36"

Length: 150 meters

Diameter: Less than φ170 mm

Cut Size: –Preset Cut: 1189 mm, 841 mm, 594 mm,

420 mm, 297 mm

48", 36", 24", 18", 12"

46", 34", 22", 17", 11"

Up to 10 extra preset cut length can

be specified by SP23 ~ 32.

–Selected Length Cut: 245 mm to 2000 mm

(1 mm per step)

9.6" to 80" (0.1" per step)

Cutting Time: Within 0.80 second

Paper Transport Velocity: 50 mm/s

Repeat Quantity: 1 to 99

Control: Microprocessor

Power Source: +24 volts and +5 volts from the copier

Power Consumption: Maximum 110 W

Dimensions (W x D x H): 1,080 mm x 475 mm x 295 mm

42.71" x 18.70" x 11.61"

Weight: 29 kg, 63.8 lb

31 October 1994 SPECIFICATIONS

1

2. MECHANICAL COMPONENT AND DRIVE

LAYOUT

1. Paper Feed Motor 5. Paper Feed Rollers

2. Idle Pulley 6. Paper Roll Spool

3. Timing Belt 7. Paper Roll

4. Cutter Motor 8. Cutter Unit

5

4

3

2

1

76

8

5

6

7

MECHANICAL COMPONENT AND DRIVE LAYOUT 31 October 1994

2

3. ELECTRICAL COMPONENT DESCRIPTIONS

The index numbers refer to the electrical component layout on the reverse

side of the Point to Point (Water proof paper).

Name Function Index No.

Motors

Paper Feed Drives all mechanical components except the cutter unit

(DC Stepper Motor). 43

Cutter Drives the cutter (DC Reversible Motor). 39

Switches

Door Indicates "Door Open" on the operation panel and

disables the key operation. 38

Left Cutter Detects whether or not the cutter is at the left home

position. 40

Right Cutter Detects whether or not the cutter is at the right home

position. 33

Sensors

Paper End Detects when the roll paper runs out. 35

Leading Edge Misfeed detector. Also detects the leading edge of the

paper to start the paper length pulse count. 42

Humidity Detects humidity and turns on the RF antihumidity

heaters while copying is not being done (if the humidity

is lower than 45%).

34

Printed Circuit Board

RF Control Controls all roll cutter unit functions in accordance with

copier CPU. 37

Others

Upper RF

Antihumidity Heater Removes humidity from the roll paper 41

Lower RF

Antihumidity Heater Removes humidity from the roll paper 36

31 October 1994 ELECTRICAL COMPONENT DESCRIPTIONS

3

4. MECHANICAL OPERATION

4.1 BASIC OPERATION

The paper feed rollers [A], which are turned by the paper feed motor, feed

paper from the paper roll [B] through the cutter unit [C] to the paper leading

edge sensor [D] according to the signal from the copier. When the paper feed

motor starts, the copier CPU starts measuring the length of the paper. (The

paper length is measured by counting the number of steps as the paper feed

motor [stepper motor] turns.)

[C]

[A]

[B]

[D]

MECHANICAL OPERATION 31 October 1994

4

After the leading edge of the paper reaches the exit rollers [A], the paper is

directed to the copier registration roller [B]. The registration roller stops

rotating after the registration sensor [C] detects the leading edge of the copy

paper. The copy paper is fed to the registration roller and stops to wait for the

original. At the appropriate timing after the original registration sensor is

activated by the original, the registration roller and roll paper feed motor start

to rotate. The copy paper starts to be fed again. Just before the cut length of

copy paper is fed, the speed of the roll paper feed motor is doubled. A paper

buckle forms at the trailing edge of the copy paper. When the paper reaches

the proper length, paper feed motor stops and the cutter unit cuts the paper.

During the time that paper feed motor has stopped, the registration roller

continues to feed the copy paper forward. The paper is cut during the time it

takes for the paper buckle to be pulled straight. This allows for a neat cut.

When the selected cut length is between 245 mm and 309 mm, the roll cutter

unit cuts the paper after the first rotation of the roll paper feed roller [D], as

the paper reaches the selected length before the registration roller starts to

rotate again. After the registration roller stops rotating, the roll paper feed

motor continues to rotate and a paper buckle forms at the trailing edge of the

paper. When the selected cut length is between 309 mm and 410 mm, the

roll cutter unit cuts the paper after the second rotation of the roll paper feed

roller. The paper buckle forms after the first rotation of the roll paper feed

motor, because the paper feed roller is still rotating after the registration roller

has stopped. The registration roller brake ensures that the very stiff types of

paper will not rotate the registration rollers when the paper buckles while it is

stopped at these rollers.

[C]

[B]

[A]

[D]

31 October 1994 MECHANICAL OPERATION

5

4.2 CUTTER UNIT OPENING AND CLOSING MECHANISM

The gear [A] from the paper feed motor disengages from the cutter unit gears

[B] when the roll cutter unit is unlocked from the lower position and lifted up.

At this time, the cutter unit is locked at the upper position by the lock lever

[C], and the wheel [D] on the right side can be rotated manually to position

the leading edge of the roll paper.

[B]

[A]

[C]

[D]

MECHANICAL OPERATION 31 October 1994

6

4.3 CUTTER OPERATION

The cutter unit uses a sliding rotary cutting blade [A] which is pulled past a

fixed blade by a drive wire. The rotary cutting blade allows the cutter unit to

cut paper in both directions. There are home position switches [B] at both

ends of the cutter unit. The cutter motor turns off, stopping the cutting action,

when the rotary cutting blade knob plate [C] turns off one of these switches.

[C]

[B] [C] [A]

31 October 1994 MECHANICAL OPERATION

7

5. SERVICE TABLES

5.1 TEST POINTS

Function TP No.

GND TP903

VA(24 V) TP901

VC(5 V) TP902

5.2 BLOWN FUSE CONDITION

Component Unit Symptom

F901 (250V/1.0A) RF Main board The AC line for the

R/F antihumidity

heaters is cut. The

heaters are not

turned on.

SERVICE TABLES 31 October 1994

8

6. INSTALLATION PROCEDURE

Roll Feeder (A571)

CAUTION: Unplug the copier power cord before starting the

following procedure.

Check the accessories and their quantities according to the following list:

Harness Cover .............................................................................2 pcs

Angle Bracket ...............................................................................1 pc

Spacer ..........................................................................................1 pc

Small Cap .....................................................................................1 pc

Screws - M4x8 .............................................................................8 pcs

Screws with Spring Washer - M4x8..............................................2 pcs

NOTE: When the Roll Feeder is installed on the copier, the table (A714) is

required.

31 October 1994 INSTALLATION PROCEDURE

9

1. Lower the feet [A] so that the table does not move while the roll feeder is

being installed on the table and the copier.

NOTE: Do not place the roll feeder unit [B] onto the floor roughly, to

prevent the left and right covers from being damaged.

2. Remove the shipping tapes [C] and shipping cushions [D].

3. Remove the left and right covers [E and F] (3 screws each).

4. Remove the front cover [G] (2 screws) and lower the front cover arms [H]

to the down position.

[A]

[H]

[E] [G]

[H]

[F]

[B]

[C]

[C] [C]

[D]

INSTALLATION PROCEDURE 31 October 1994

10

5. Open the copier paper path section and remove the copier left lower

cover [A] (2 screws), lower right front cover [B] (2 screws), lower right

middle cover [C], toner collection bottle [D], and rear cover [E] (2 screws).

6. Remove the small caps [F] from the copier rear cover using cutting pliers.

7. Remove the table rear cover [G] (4 screws).

[A]

[E]

[B] [C] [D]

[F]

[G]

31 October 1994 INSTALLATION PROCEDURE

11

NOTE: Take care not to drop the manual feed table when removing the

bracket [A].

8. Remove the lower front cover [B] (2 screws), reinforcement plate [C] (1

screw), bracket [A] (4 screws) (which is changed by the harness), and the

manual feed table [D].

[D] [B]

[A]

[C]

INSTALLATION PROCEDURE 31 October 1994

12

9. Mount the roll feeder unit on the copier (hook the mounting arms [A] on

both sides into the mounting rail [B]).

NOTE: Lift the unit by holding the plate [C] just under the size marks.

10. Install the angle bracket [D] and spacer [E] (4 screws).

11. Install the small cap [F] (2 screws).

[A]

[B]

[D]

[E]

[F]

[C]

31 October 1994 INSTALLATION PROCEDURE

13

NOTE: To ensure grounding, tighten the screws for the ground wire until the

spring washers [A] are flattened.

12. Secure the grounding wire [B] (1 screw with spring washer) to the inside

of the table.

13. Run the roll feeder harness [C] and roll feeder heater harness [D] through

the holes in the table rear cover (right [E] and left [F])

14. Connect the roll feeder harness to the copier main board {2 connectors

[G] and 1 grounding wire [H] (1 screw with spring washer)}.

15. Connect the roll feeder heater harness connector [I] to the copier ac drive

board connector.

16. Install the harness covers [J] (1 screw each).

17. Reattach all the covers and manual feed table excluding the roll feeder

right cover.

[F] [E]

[B]

[A]

[D]

[C]

[H]

[J]

[G]

[I]

[A]

INSTALLATION PROCEDURE 31 October 1994

14

18. Plug in the power supply cord and turn on the main switch.

19. Press the following keys on the operation panel:

Clear Modes key [A]

+ key [B]

- key [C]

Clear/Stop key [D]

20. Press the Clear/Stop key again and hold it down for longer than 3

seconds. The roll paper end and call service indicators will blink (SP

mode).

21. Select 40 using the + and - keys. Enter "1" by pressing the following keys.

Function Select key [E]

+ key

RF Select key [F].

22. Input values into SP modes 42 to 47 in accordance with the decal that is

attached to stuck on the right side plate.

23. Press the Clear Modes key 3 times to leave the SP mode.

24. Reattach the roll feeder right cover.

25. Check the roll feeder operation.

[B]

[A]

[D]

[F][E]

[C]

300 PRG.

No. 1100 PRG.

No.

NORMAL XX 42 XX 45

HIGH (VELLUM) XX 43 XX 46

LOW (FILM) XX 44 XX 47

Length

Temperature

31 October 1994 INSTALLATION PROCEDURE

15

7. REPLACEMENT AND ADJUSTMENT

7.1 EXTERIOR COVER REMOVAL

7.1.1 Front Cover Removal

1. Remove the front cover [A] (2 screws).

NOTE: If the screw holes for the front cover become worn by the screws,

extra holes are provided next to the original screw holes.

7.1.2 Left and Right Cover

NOTE: Be careful not to drop and damage the lower front cover [B].

1. Remove the left and right covers [C and D] (3 screws each).

NOTE: When reattaching the left and/or right covers, unlock and lift the

cutter unit for easier assembly.

[A]

[C]

[C]

[B]

REPLACEMENT AND ADJUSTMENT 31 October 1994

16

7.2 CUTTER UNIT REMOVAL

1. Remove the roll feeder left and right covers.

2. Remove the 4 screws [A] of the cutter unit.

3. Take out the cutter unit [B] (1 connector [C]).

NOTE: When reinstalling the cutter unit, attach the cutter unit cover [D]

with the cutter unit.

[C] [D]

[A]

[A]

[B]

31 October 1994 REPLACEMENT AND ADJUSTMENT

17

7.3 PAPER FEED ROLLER REPLACEMENT

1. Remove the cutter unit.

2. Unlock and lift the paper feed roller unit [A] using the release lever [B].

3. Remove the release lock lever [B] (2 screws).

4. Remove the feed roller guide plate [C] (6 screws).

5. Replace the paper feed roller [D] (2 allen screws [E], 1 gear [F], 1 snap

ring [G], 2 bushings [H], and 1 retaining ring [I]).

[A]

[B]

[C]

[I]

[H]

[D]

[H]

[G]

[E]

[F]

[E]

REPLACEMENT AND ADJUSTMENT 31 October 1994

18

7.4 PAPER FEED MOTOR TIMING BELT TENSION

ADJUSTMENT

If the timing belt tension for the paper feed motor is not correct, the paper cut

length varies for each copy paper. Readjust the timing belt tension for the

paper feed if this occurs.

1. Remove the small cap [A] (2 screws).

2. Loosen the screw [B] and re-tighten it.

[A]

[B]

31 October 1994 REPLACEMENT AND ADJUSTMENT

19

Table of contents

Other Ricoh Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Littelfuse

Littelfuse Industrial Shock Block SB5000 Series manual

Plymovent

Plymovent DRAFTMAX BASIC ULTR A Installation and user manual

ABB

ABB HT576624 Operation manual

Cumberland

Cumberland 40 Series Operation and installation manual

Jenex

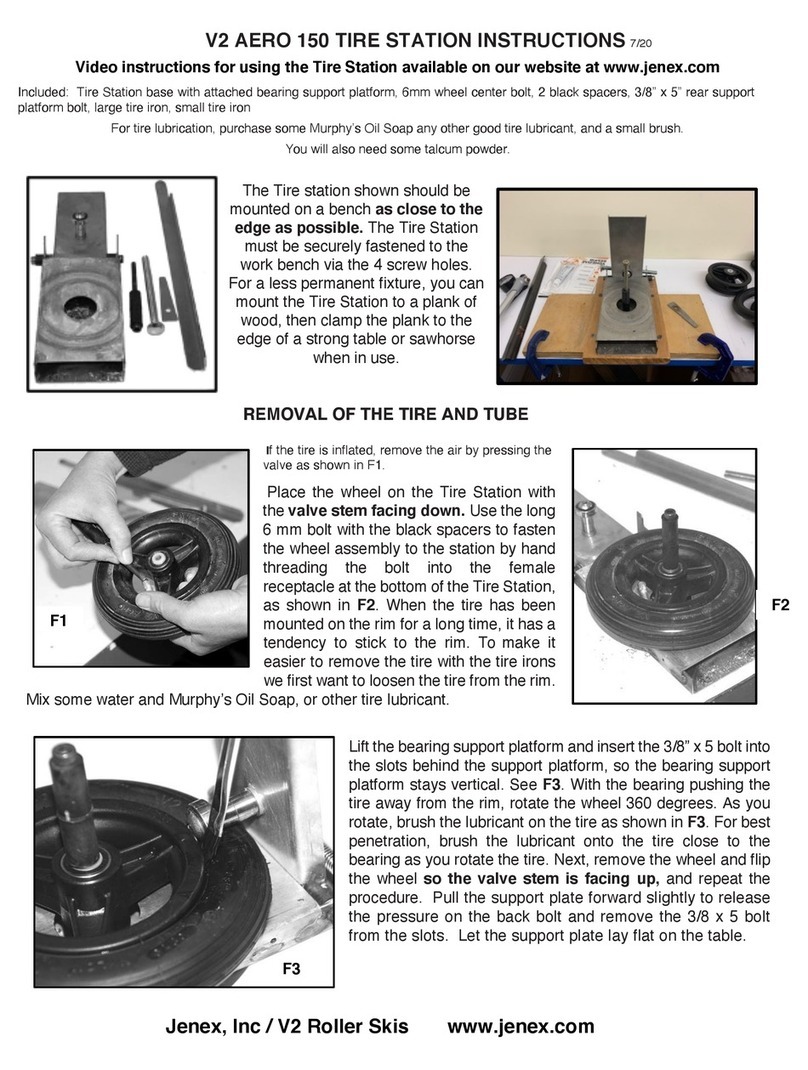

Jenex V2 AERO 150 instructions

Desoutter

Desoutter Industrial Tools SD Series Servicing and operating instructions