STAUFF FT Series Operational manual

Translation of the original

Operating Manual

Flat face threaded couplings series FT

Designation: QRC-FT-…

Old designation: FT…

Contents

1. Preliminary remarks ....................................................................................................... 2

2. Before coupling .............................................................................................................. 2

3. Connecting the coupling halves...................................................................................... 2

4. Checking the connection................................................................................................ 3

5. During operation............................................................................................................. 4

6. Separating the connection.............................................................................................. 4

7. Replacing the seal.......................................................................................................... 5

R0.1_en

2 /5

www.stauff.com

1. Preliminary remarks

First, please read the operating manual for the flat face threaded couplings from the FT series

carefully.

The coupling series for the individual application always has to be selected by qualified

personnel with regard to the operating conditions (pressure, temperature, media).

Coupling halves have tobe checked for damage and corrosion before initial installation or after

prolonged storage.

Safety-relevant warnings are set in bold type in this manual.

The threaded couplings QRC-FT… are operated with high internal pressures. Therefore,

incorrect maintenance as well as improper use can result in injury, damage or impaired

function.

For this reason, compliance with the information in these instructions aswell as regular

maintenance checks are absolutely mandatory. Replace damaged or worn parts.

2. Before coupling

Remove any dust caps and screw into the dust cap of the other coupling half. This protects

both dust caps against dirt. Carry out a visual check of both coupling halves for cleanliness,

damage and completeness.

Use suitable products to clean the coupling halves if they are soiled. Use lint-free cloths and

never use products that could corrode the seals or metallic surfaces of the couplings.

Do not allow foreign substances, such as cleaning agents, water or dirt, to enter into the

hydraulic system during cleaning. For this reason, never direct high-pressure cleaners directly

onto the valves of the coupling halves.

Replace damaged couplings. Replace coupling halves on which individual parts have

become detached. Always replace the components in pairs.

3. Connecting the coupling halves

Place the loose half (female coupling) onto the fixed half (male coupling) so it sits straight,

push the threaded sleeve towards the coupling connector and screw it onto the coupling

connector.

Ensure that the female coupling is not under pressure during coupling. The maximum

permissible residual pressure on the coupling connector is 250 bar. Do not exceed

the residual pressure when coupling.

At the end of the coupling process, the connecting process becomes increasingly more difficult

due to the counteraction of the spring force. If necessary, we recommend the use of a face

3 /5

www.stauff.com

spanner. When tightening, use a second face spanner to counter against the base body of the

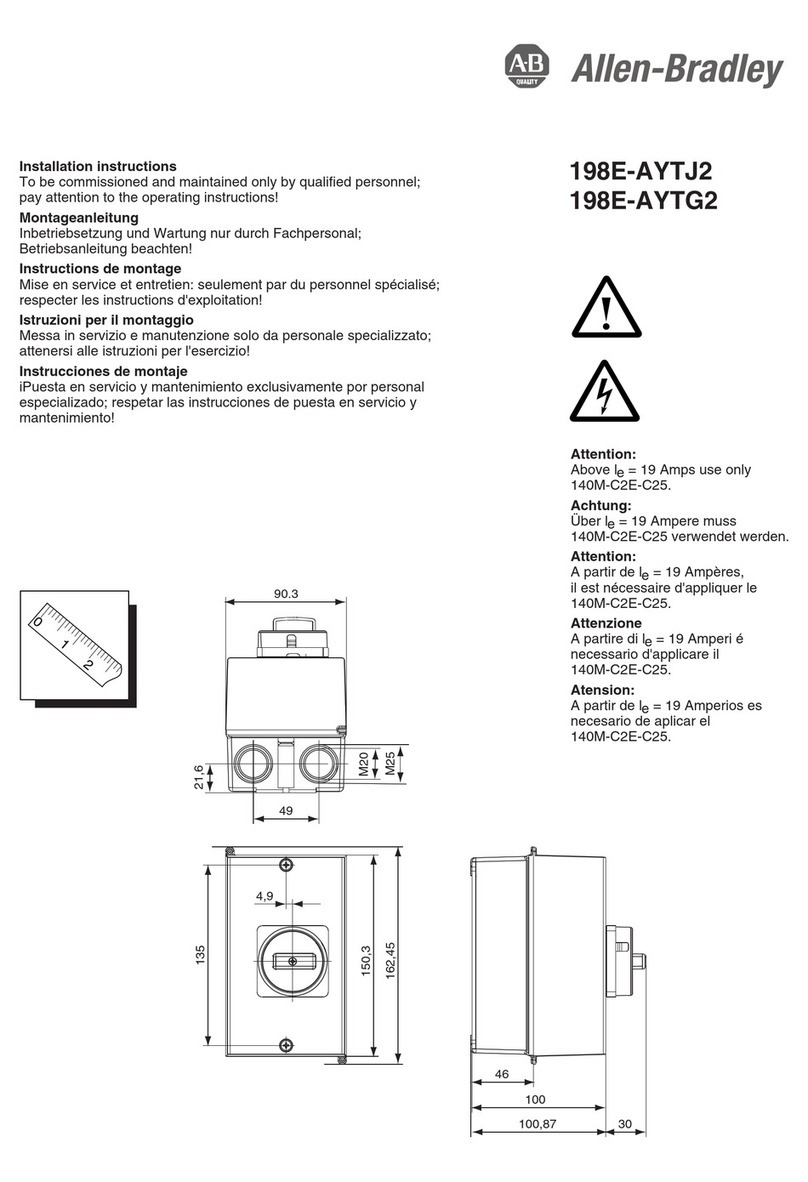

coupling connector [fig. 1].

It should be possible to easily connect the coupling halves with a tool. If this is not the case,

check the following:

Has all pressure in the lines to be connected released or is the permitted residual

pressure in the lines exceeded?

Are the threads of the coupling halves not contacting straight?

Is there any damage/soiling?

Brake ring

[Fig. 1] Diagram of male and female connector. Left: Place female coupling on male

coupling. Right: Tighten to the stop with a tool.

4. Checking the connection

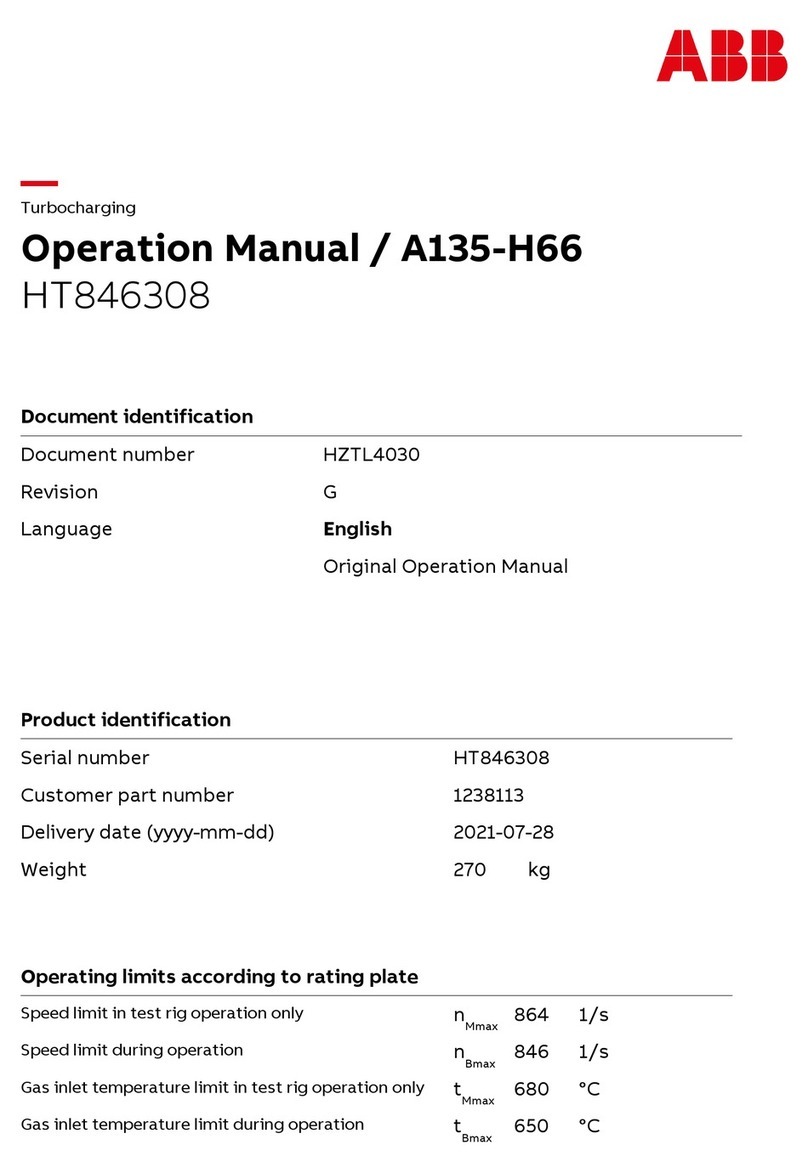

It is essential that the male and female connectors are screwed all the way to the stop during

the coupling process [Fig. 2]. This position is reached when the required torque increases

abruptly and when the brake ring (O-ring on the coupling connector) is fully covered by the

threaded sleeve of the female coupling, and when the threaded sleeve of the female coupling

rests against the base body of the coupling connector.

Check correct installation to the stop by positioning the tool once again.

Brake ring

Counter here

4 /5

www.stauff.com

[Fig. 2] Condition: coupled/screwed fully to the stop.

Incomplete connection of the coupling halves can result in the male and female

connectors (loose part and fixed part) separating during operation. Among other things,

this can destroy the seals and cause leaks on the coupling.

5. During operation

Before each start-up and regularly during extended work phases, check whether the coupling

halves are still fully connected and whether any damage is visible on them. If the coupling

halves are no longer connected correctly, re-establish the correct connection (chapters 2 - 4).

Replace damaged couplings.

6. Separating the connection

The operating temperature of the coupling can be above 100 °C/212 °F. For this reason,

ensure that it has cooled down sufficiently after operation before touching. If in doubt,

wear suitable gloves.

Before separating the connection, ensure that the line to be disconnected is not

in operation, i.e. that neither pressure nor media flow are present in the line.

Use the above tools to separate the halves. An excessive release torque can indicate a high

pressure in the connection. If this is the case, depressurise the line before disconnecting.

After the coupling halves have been separated, use appropriate products to clean them

(see also chapter 2), use dust caps to prevent them from becoming soiled and store them

so that they are protected against damage, e.g. from impact by other objects.

No gap

5 /5

www.stauff.com

7. Replacing the seal

Seal sets are available for the coupling connectors

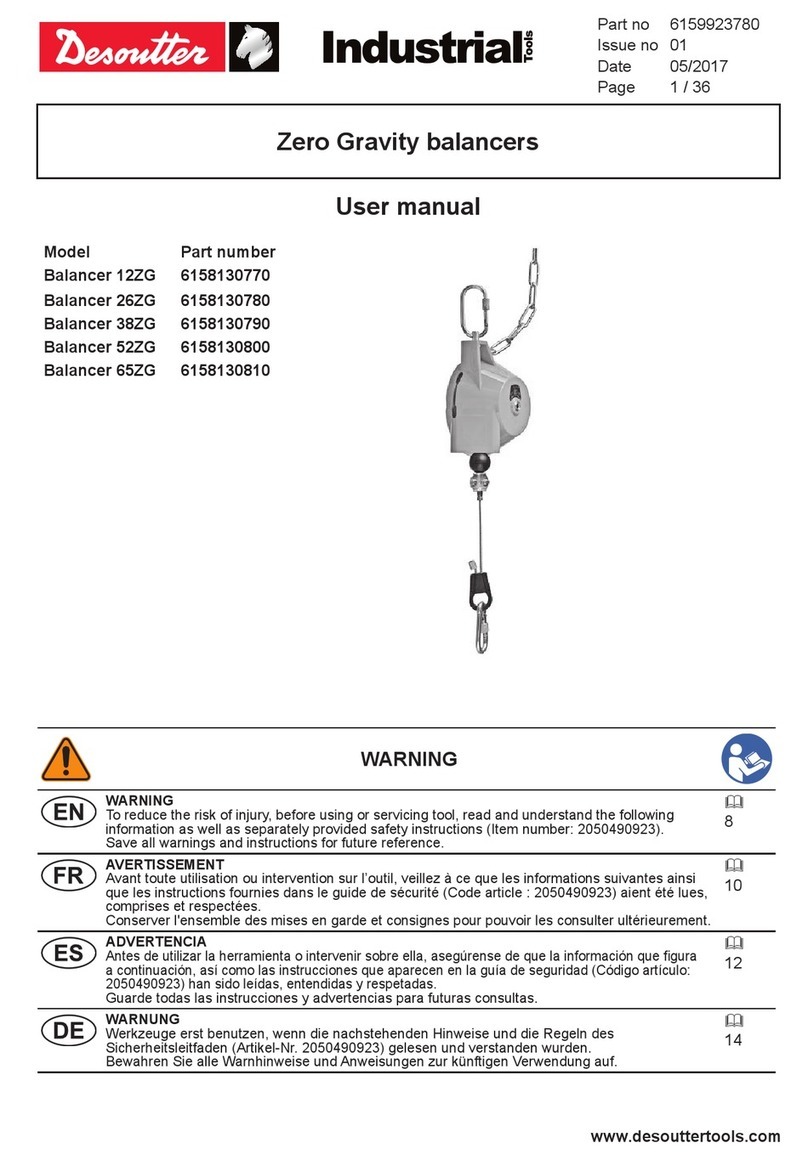

Lightly oil seals before installation. To replace the seal pack, use a blunt object to press the

plunger far enough into the connector until the seal pack or the groove are fully visible.

Then remove the damaged seal (fig. 3 on left). Ensure that the seal faces in thegroove are not

damaged. Then insert the two O-rings (fig. 3, middle) and then the profile seal into the groove

(fig. 3, right). Ensure that the profile seal is not damaged by bending.

[Fig. 3] Removing and installing the seal package

Note: Any dismantling of the individual coupling halves (male/female connectors)

will invalidate the warranty!

Walter Stauffenberg GmbH & Co. KG

Im Ehrenfeld 4

58791 Werdohl

Germany

T: +49 2392 9160

F: +49 2392 916 103

sales@stauff.com

www.stauff.com

Then install

the profile seal

Install the O-ring first

Brake ring

This manual suits for next models

3

Table of contents

Other STAUFF Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT846308 Operation manual

Amber

Amber AC2600 Setup guide

Desoutter

Desoutter Industrial Tools Balancer 12ZG user manual

Siemens

Siemens SIMATIC HMI KTP400 Basic quick start guide

Trox Technik

Trox Technik X-AIRCONTROL FAM-RD Installation and operating manual

WEISS ROBOTICS

WEISS ROBOTICS GRIPLINK manual