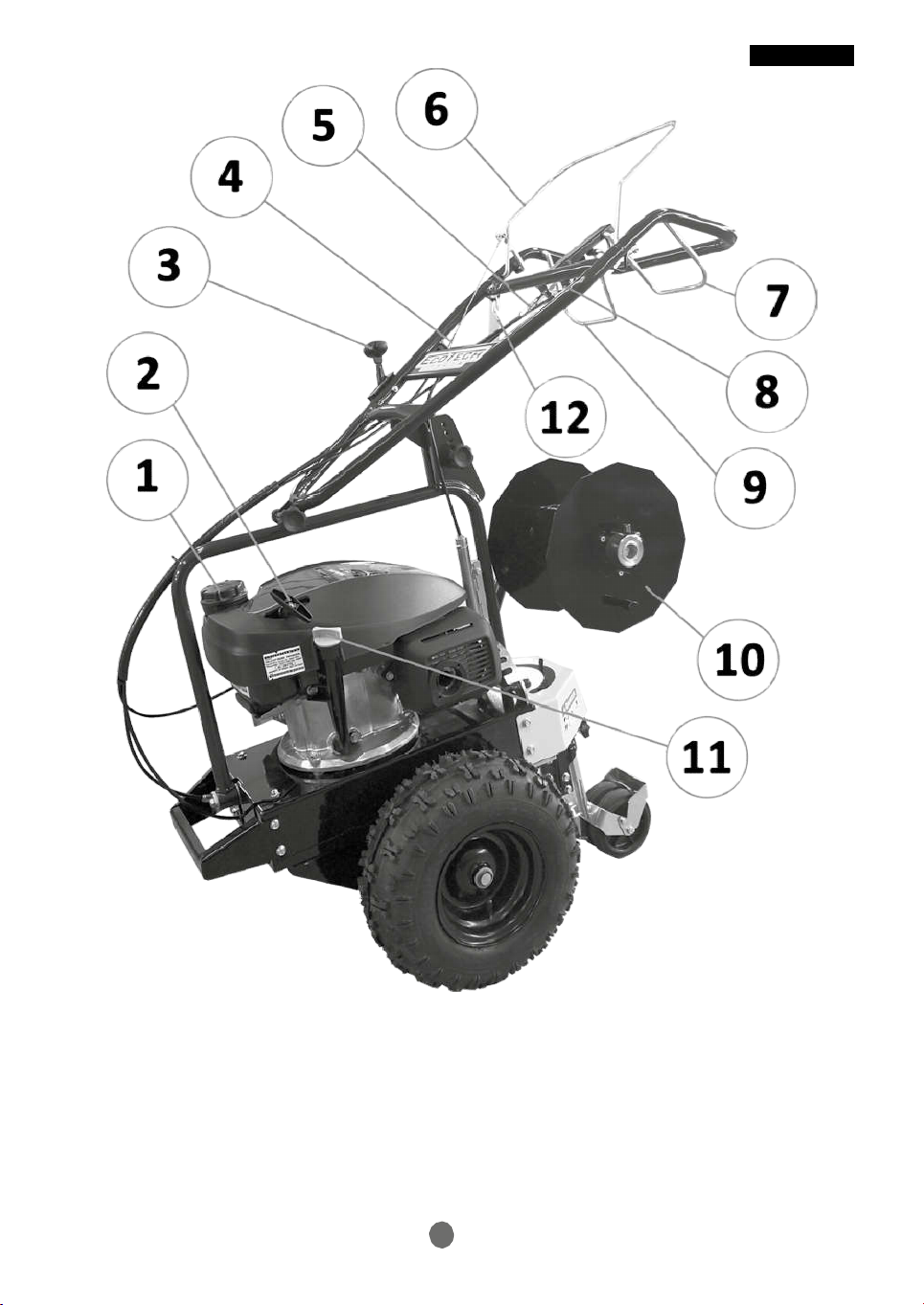

of the transmission box. This operation can severely damage the mechanical part

of the transmission. The forward lever (fig.1 n.9) must ALWAYS be pulled completely, i.e.

until it touches the handle.

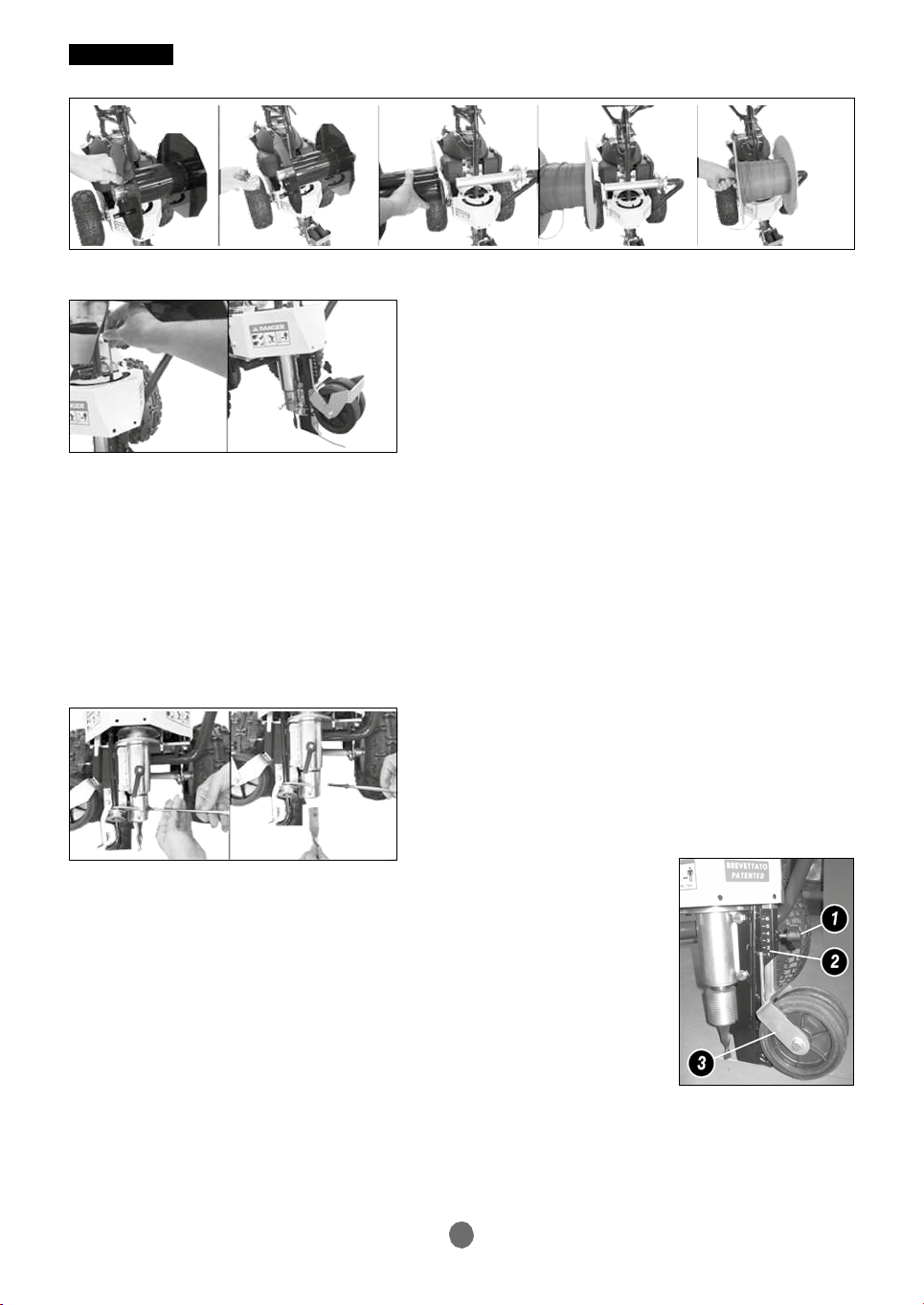

HOW TO ADJUST THE HEIGHT OF THE HANDLEBAR

The handlebar of the machine can be adjusted on five heights. To adjust

the height, loosen counter-clockwise the rear handle of

the handlebar (fig.10 n.2) until the knob (fig.10 n.1) can be removed, select

the height of interest, then fit back the knob in the new hole, rotate

clockwise and tighten completely the handle.

Fig.10

HOW TO ADJUST THE HANDLEBAR INCLINATION

In case of works under hedges, projecting branches, posts or any

type of obstacle, it is possible to tilt the handlebar from the opposite side

of the obstacle (fig. 11). To adjust the inclination, pull completely the lever placed

on the lower left side of the handlebar (fig.1 n.7) and position

the corresponding pin in one of the nine holes located on the rack at the bottom

of the handlebar. The machine allows four inclination levels

on the right and four on the left.

Fig.11

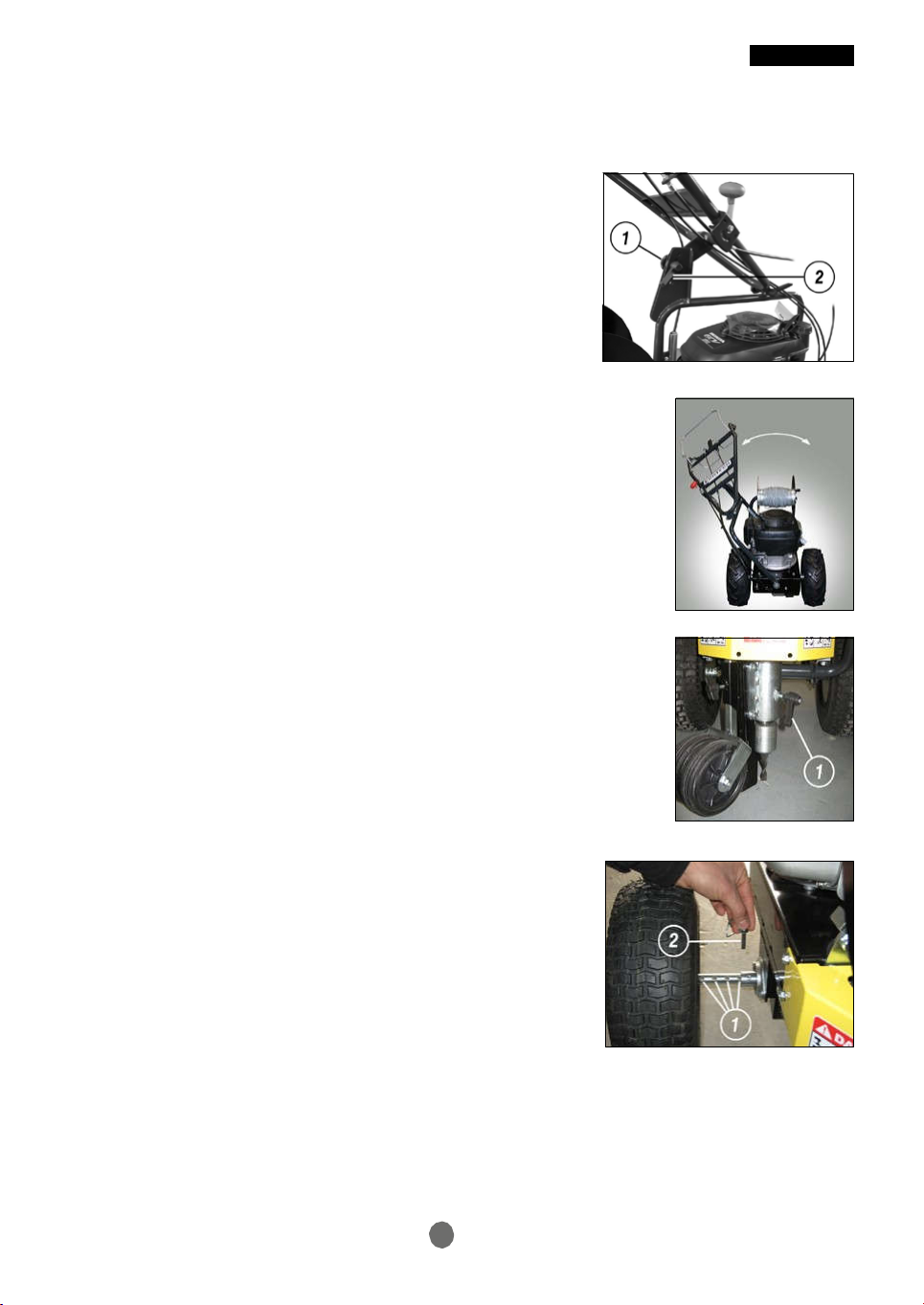

HOW TO LOCK THE SWIVELLING BLADE

When the cable has to be laid over long straight sections, it is

possible to lock the swivelling blade (fig.12) to ensure greater

precision of the machine direction. To lock the blade, it suffices to tighten the handle

placed on the right side of the support apparatus (fig.12 n.1).

Fig. 12

HOW TO ADJUST THE WIDTH OF THE WHEELS

Both wheels are equipped with 4-position adjustable drive shafts.

This system offers the possibility to position the cutter

at 25, 27, 29 o 31 cm from the adjustable edge.

(fig.13). This allows laying the cable at equal distance

from any edge, wall or hedge. To adjust this

distance, pull out the locking pin (fig.13 n.2), position it

in one of the 4 holes provided on the drive shaft (fig.13 n.1) and

lock back the safety spring.

HOW TO START WORKING

Fig.13

Once the cable is positioned and the cutter is mounted, fix the cable to the ground. To do so,

stick a bit or a stake into the ground and fasten to it the part of the cable that

comes out from the bottom of the blade. This operation has the purpose to ensure the cable

is laid on the furrow created by the cutter on the soil along the first few meters.