Ectron 451 User manual

INSTRUCTION MANUAL

MODEL 451

LVDT AND RVDT

SIGNAL CONDITIONER

The information contained in this manual is proprietary. Permission to reproduce all or

part must first be obtained in writing from this company.

Ectron Corporation reserves the right to make specification changes at any time.

LIFE-SUPPORT POLICY: Ectron products are not authorized for use in life-support

devices or systems without the express, written approval of the President of

Ectron Corporation.

Copyright 1998, revised October, 2009 Ectron Corporation

Ectron Corporation 8159 Engineer Road

All rights reserved San Diego, CA 92111-1980

858-278-0600

858-732-8159

Fax: 858-278-0372

www.ectron.com

All Ectron instruments are warranted against defects in material and workmanship for one year

from the date of shipment to the original purchaser. Ectron agrees to repair or replace any

assembly or components (except expendable items such as fuses, lamps, batteries, etc.) found to

be defective during this period. Ectron's obligation under this warranty is limited solely to

repairing or replacing, at its option, an instrument that in Ectron's sole opinion proves to be

defective within the scope of the warranty when returned to the factory or to an authorized

service center. Transportation to the factory or service center is to be prepaid by the purchaser.

Shipment should not be made without the prior authorization of Ectron. This warranty does not

apply to products repaired or altered by persons not authorized by Ectron, or not in accordance

with instructions furnished by Ectron. If the instrument is defective as a result of misuse,

improper repair, alteration, neglect, or abnormal conditions of operation repairs will be billed at

Ectron's normal rates. Ectron assumes no liability for secondary charges of consequential

damages as a result of an alleged breach of this warranty; and in any event, Ectron's liability for

breach of warranty under any contract or otherwise shall not exceed the purchase price of the

specific instrument shipped and against which a claim is made. This warranty is in lieu of all

other warranties, expressed or implied; and no representative or person is authorized to represent

or assume for Ectron any liability in connections with the sale of our products other than is set

forth herein.

If a fault develops, notify Ectron or its local representative, giving full details of the difficulty.

Include the model and serial numbers. On receipt of this information, a service date or shipping

instructions will be furnished. If shipment is indicated, forward the instrument, freight prepaid,

to the factory or to the authorized service center indicated in the instructions.

Instruments should be tested upon receipt. If there is any damage, a claim should be filed with

the carrier. A full report of the damage should be obtained by the claim agent, and that report

should be forwarded to Ectron. Ectron will advise the disposition to be made of the equipment

and arrange for repair or replacement. Please include model and serial numbers in all

correspondence.

GENERAL

PROCEDURE FOR SERVICE

DAMAGE IN TRANSIT

®

TABLE OF CONTENTS

PAGE

Warranty

Inside Front Cover

Section I, Description

General 1-1

Modes of Operation 1-1

Other Features 1-2

Enclosures 1-2

About This Manual 1-2

Section II, Specifications

Input 2-1

Dynamic Response 2-1

Output 2-1

Excitation 2-1

Input Power 2-1

Calibration and Alignment 2-1

Environment 2-2

Physical Parameters 2-2

Compatibility 2-2

Notes 2-2

Section III, Operation

General 3-1

View Angle 3-1

Connections and Enclosures 3-1

Controls 3-2

Updating Memory 3-3

Time Out 3-3

Power On 3-3

Operating Screens 3-3

Operation Scheme and Main Menu 3-4

First Screen 3-4

Gain-mode Setup 3-5

Example-mode Setup 3-5

Scale-mode Setup 3-7

Autozero 3-8

Zero Setup 3-9

i

Filter Setup 3-9

Cal 3-9

Other 3-10

Secondary Menu 3-10

Excitation Setup 3-10

Units of Measure 3-11

Reset System 3-12

Align 3-12

System Info 3-12

Other Exit 3-12

ENCLOSURES

Model R418-7 3-13

Models 4001 and 4005 3-14

Model E408-6 3-16

Model R408-14 3-17

Section IV, Applications

General 4-1

Selecting the Operation Mode to Use 4-3

Determining the Active Mode 4-4

Crosstalk 4-5

Output Noise 4-5

Phase Control 4-5

Ground Connections 4-5

Emi Protection 4-6

Vehicle Applications 4-6

Response Time 4-6

Update Rate 4-7

Output Polarity 4-7

Null Improvement 4-7

Section V, Theory of Operation

Analog Input 5-1

Firmware 5-1

Gain Mode 5-1

Scale Mode 5-2

Example Mode 5-2

Calibration 5-2

PAGE

Table of Contents

Model 451

ii

Section VI, Alignment

General 6-1

Equipment Required 6-1

Procedures 6-1

Output Alignment 6-1

Input Alignment 6-3

Section VII, Parts Lists

Names of Manufacturers 7-1

Model E408-6 Enclosure 7-2

Model R408-14 Enclosure 7-3

Model R418-7 Series Enclosure 7-4

Model R418-M1028C Enclosure 7-5

Figures

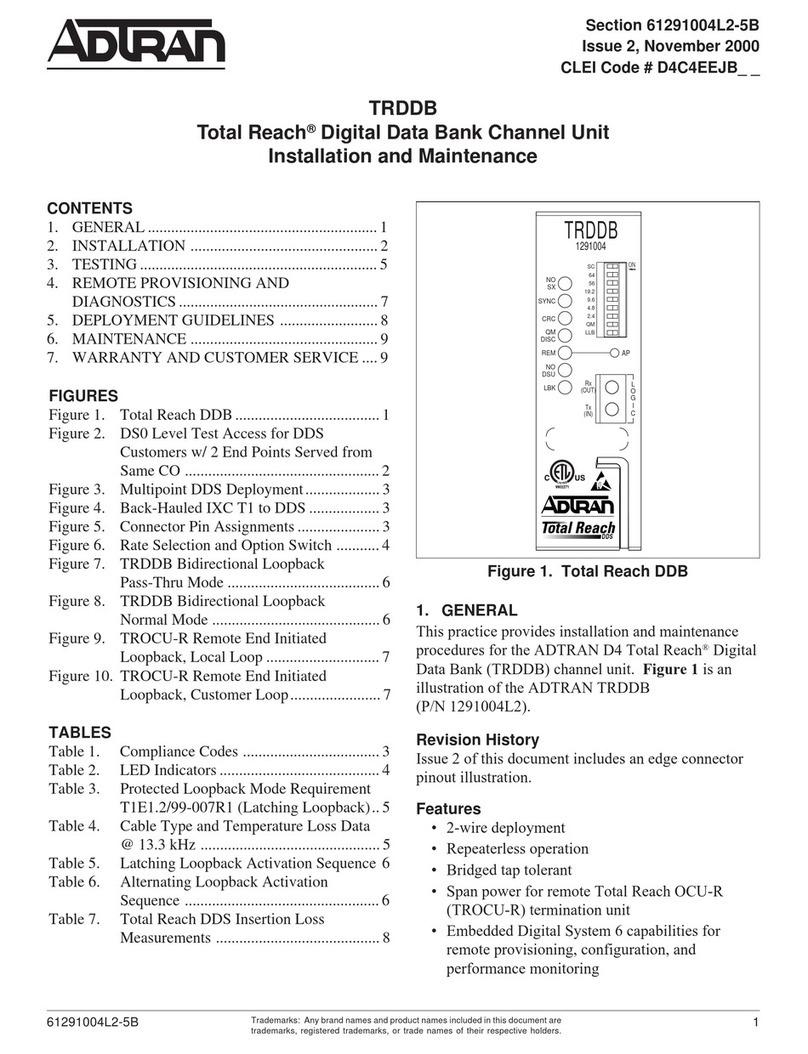

Model 451 1-1

Figure 3-1, Typical LVDT Connection to the Model 451 3-2

Figure 3-2, Main Menu 3-4

Figure 3-3, Secondary Menu 3-11

Figure 4-5, Typical Output Filter 4-5

Figure 6-1, Output Alignment 6-2

Figure 6-2, Input Alignment 6-3

Tables

Table 3-1, Connections 3-1

Table 3-2, Transducer Sensitivity Ranges

(mV/V/Unit of Displacement) 3-5

Table 3-3, Adapting Ectron Enclosures for

Model 451 Operation 3-13

Table 3-14, Model R418-7 14-Channel Enclosures 3-14

Table 7-1, List of Manufacturers 7-1

Schematics and Drawings

Model E408-6Y (Internal-12-V-dc Power Supply) 408-600

Model E408-6X (Internal-28-V-dc Power Supply) 408-601

Model R408-14Y (Internal 12-V-dc Power Supply 408-605

Model R408-14X (Internal 28-V-dc Power Supply 408-606

Model R418-7 Series Rack-mount Enclosure 418-627

Model R418-7-M1028C Rack-mount Enclosure 419-605

Model 451 Outline Dimensions 451-900

Model 451 Operational State Diagram

PAGE

Model 451

Table of Contents

iii

Table of Contents

Model 451

iv

Section I

Description

GENERAL

The Model 451 LVDT signal-con-

ditioner produces an analog volt-

age that represents the

displacement of the shaft of an

LVDT (linear variable displace-

ment transformer). This voltage

and the displacement, in either

milli-inches, millimeters, or de-

grees, are displayed on a backlit

front-panel display. There are three

independent modes of operation

making it the most versatile LVDT-

signal conditioner produced today.

MODES OF OPERATION

The Model 451 is always in one

of three modes of operation:

GAIN

,

EXAMPLE

, or

SCALE

.

To activate an inactive mode, the

user simply dials the the knob until

the desired mode is displayed and

answers

YES

to a screen prompt.

The unit then guides the user

through the setup for that particular

mode.

In the

GAIN

mode, the desired

gain of the Model 451 and the

transducer sensitivity are entered,

and it is ready for use.

In the

EXAMPLE

mode, the user places the shaft of the LVDT at a position and “captures”

that point and assigns a voltage to it. This is done a second time for another position, and

after the transducer sensitivity is entered, the unit is ready for use.

In the

SCALE

mode, the user keys in two desired displacement points and corresponding

voltage points, and like the other two modes, after the transducer sensitivity is entered, the

unit is ready to use.

OTHER FEATURES

In addition to the mode of operation, the Model 451 offers complete control over a wide

variety of functions to truly make it unique.

Zero

Two means of controlling zero are provided: manual

and autozero. In manual zero, the user can dial in the

Model 451

LVDT Signal Conditioner

1-1

amount of offset desired and either view the amount of

offset or view the total offset (zero offset plus offset

due to input signal) at the output. When zero is “on,”

the user simply presses the display once to go directly

to autozero so that the unit can be quickly autozeroed.

If zero is not “on,” pressing the display once, turning

the encoder until autozero is displayed and pressing the

display again will turn zero on and initiate the autozero.

Filter

Four input-filter positions are provided to aid in eliminating

undesired signals. They are 1, 10, and 100 Hz in addition

to wideband (WB), which is approximately 300 Hz.

Cal

Both input (in terms of displacement) and output (in

terms of voltage) cals are provided.

Excitation

Two voltages and five frequencies are provided.

Units of Measure

Three units of measure are provided: milli-inches and

millimeters for linear measurements and degrees for ro-

tational measurements.

Alignment

Means to completely align the Model 451 are provided.

ENCLOSURES

Ectron manufactures several enclosures for its product line of ruggedized signal conditioners

and condtioner-amplifiers. These include the Models E408-6, R408-14, R418, 4001, and

4005. The Model 451 as well as the Models 352, 418, T418, 428, and 441A will operate

side by side in any of these enclosures.

ABOUT THIS MANUAL

The following sections are in this manual:

Specifications

This is a complete technical description of the

Model 451 and the performance that is guaranteed.

While the performance specifications are the best in

LVDT signal conditioning, they are conservative. The

user may find that a particular unit will perform well

beyond specification.

Operation

Here the user will find complete instructions to use the

Model 451. An operational-state diagram enhances the

discussion. Also discussed are the various enclosures

available for the Model 451 and other 352 and 400

Series units.

Applications

Because the Model 451 is designed as a universal

LVDT-signal conditioner, it would be impossible to

address every possible use for this product. Rather,

this section is written to help the user get the most

from the data resulting from using the Model 451.

Concerns about cabling, shielding, common-mode

voltage, etc. are addressed.

Description

Model 451

1-2

Theory of operation

Because the Model 451 is an encapsulated unit, repair

in the field is strongly discouraged. Therefore, a de-

tailed circuit analysis is foregone in this manual.

However, theory at the block-diagram level as well

as a discussion of internal software is presented to

further aid the user in operating the frequency-to-

voltage converter for best performance.

Calibration

Step-by-step instructions are given to align the

Model 451.

Parts Lists

Parts list for several enclosures are given to aid in any

field repairs.

Drawings

Schematic diagrams of several enclosures are included

to aid the user in instrumentation configuration. The

outline-dimension drawing for the Model 451 and its

operational state diagram are also provided.

Warranty

The warranty for this product is on the inside of the

front cover.

Model 451

Description

1-3

Description

Model 451

1-4

Section II

SPECIFICATIONS

INPUT

Configuration Differential.

Input Impedance 100 kΩ±5% each input.

Common-mode-voltage

Range 20 V dc or peak ac.

DYNAMIC RESPONSE

Gain Range 1 to 300, either polarity (automatically set in example

and scale modes). Gains of less than unity are not sup-

ported.

Frequency Response Selectable, 1, 10, and 100 Hz, and wideband (WB is

approximately 300 Hz).

Nonlinearity ±0.1% of full scale, maximum.

OUTPUT

Full Range ±10.5 V minimum.

Current 10 mA minimum.

Impedance 2Ωmaximum.

Zero-offset Range 10 V.

Offset/Zero Control There are three zeroing modes: autozero and two

manual-adjustment positions. (See Note 1)

EXCITATION

Voltage 1 or 3 V ac rms, ±1%.

Current 30 mA ac rms minimum at 2500 Hz.

Frequency Selectable 400 Hz, 1.0, 2.5, and 10 kHz.

Output Resistance 1.0 Ωmaximum at 2.5 kHz.

INPUT POWER

Voltage Range 10.5 to 32 V dc.

Current (nominal) 150 mA.

Over-voltage Protection Up to +60 V for 15 s, +32 V and −50 V continuous.

CALIBRATION AND ALIGNMENT

Calibration An internally generated calibration signal can be set from

−10 V to +10 V in 0.01-V steps, ±0.1% of full scale,

2-1

and from −10000 to +10000 mils, −250.0 to +250.0 mm,

and −60.00 to +60.00 degrees, ±0.1% of full scale. (See

Note 2.)

Ali

g

nment An extensive software-guided, self-calibration procedure

is available for the complete alignment of the instrument.

(See Note 3.)

Error Indicator Front-panel LED indicates errors. (See Note 4.)

ENVIRONMENT

Emi/rfi Internal rfi filters are provided on all connector leads.

Operatin

g

Temperature

Ran

g

e−25°C to +71°C.

Stora

g

e Temperature −40°C to +80°C.

Altitude No limit with adequate heat dissipation.

Static Acceleration Resis-

tance 200 m/s2(approximately 20 g) for 11 ms in any plane.

Shock Resistance 200 m/s2(approximately 20 g) for 11 ms in any plane.

Vibration Resistance 100 m/s2(approximately 10 g) in any plane.

PHYSICAL PARAMETERS (DRAWING 451-900)

Hei

g

ht (panel) 60.2 mm (2.37″).

Hei

g

ht (case) 50.8 mm (2.00″).

Width 27.9 mm (1.10″).

Depth 101.6 mm (4.00″) plus front panel, front-panel controls,

and connector.

Wei

g

ht 255 g (9 oz) nominal.

Connector DA-15P (mate DA-15S).

COMPATIBILITY

The Model 451 will operate in all standard Ectron enclosures designed for

conditioner-amplifier Models 352, 418, T418, and 428 and the Model 441A frequency-to-

voltage converter. See Table 3-2 for connection information.

NOTES

1. Zero Controls Three zeroing modes are available when using the

Model 451’s output-zero circuit. Automatic zeroing can

be commanded at any time, which will bring the output

to zero within ±5 mV. In addition, manual zeroing al-

lows the user to either view the amount of the offset

voltage or to view the amount of the offset voltage plus

output signal. The amount of offset in use can be ac-

Specifications Model 451

2-2

cessed and displayed on the front panel. The zero range

available is from −10 to +10 V in 0.01-V steps.

2. Calibration Since the calibration adjustment allows the output volt-

age to be set in 0.01-V steps from −10 V to +10 V

with an accuracy of better than ±0.1%, this output can

be used to check linearity of the instrumentation fol-

lowing the Model 451. The output voltage can be varied

also by varying the displacement reading while in the

displacement part of the calibration mode.

3. Ali

g

nment The Model 451 includes extensive self-alignment capa-

bilities. The output stages are aligned with a voltmeter

while making two adjustments via the front-panel con-

trols. Similarly, the input stages are calibrated by ap-

plying an excitation voltage to resistive dividers

connected to the input and commanding the Model 451

to self-align. Once aligned, values are stored in non-

volatile memory. Section VI details the procedure for

aligning the Model 451.

4. Error Indication The Model 451 has a front-panel LED error indicator.

This LED lights for four types of error:

1. Data-entry error This type of error results

from a front-panel entry that the hardware can-

not support (such as gain beyond the range of

the analog circuitry). No data entry, by itself

can be invalid. However, when an entry and

another entry or entries together violate pre-

programmed limits, this error occurs. A simple

example is if the user attempts to enter the

same voltage for Point 1 and Point 2 volts in

the example or scale mode.

2. Output-overload error This error re-

sults from a situation that produces an output

outside of the ±10.5-volt range.

3. Input-overload error This error condition

results from an input signal that is beyond the

range of the unit, such as a large-scale input

when a high gain is requested.

4. Memory error This error occurs when-

ever the Model 451 detects an error in its

nonvolatile memory. When this occurs, an

alignment of input and output is required.

In each case, the Model 451 displays a screen describing

the error, and the LED remains lit as long as the error exists.

Model 451 Specifications

2-3

Specifications Model 451

2-4

SECTION III

OPERATION

MODEL 451

GENERAL

The Model 451 operates in three completely independent measurement modes: gain, example,

and scale, one of which is always active. When activating one mode, the other two are

automatically deactivated. All settings in each mode are retained in nonvolatile memory,

and none is used by the other two modes. For example, all three modes have a transducer-

sensitivity setting, so there are three settings retained in memory.

Additionally, the Model 451 allows the user to control zero, autozero, excitation, input filter,

cal, units of measure, and to perform a complete alignment, both input and output.

VIEW ANGLE

Because the temperature at which the Model 451 is operating can affect the display, the

ability to quickly adjust the view angle (contrast and brightness) has been incorporated into

the Model 451. When power is on, from any screen (even if the screen is blank or dark),

press and hold the display for more than two seconds. Then turn the encoder (clockwise to

darken, counterclockwise to lighten) until the screen is adjusted for best contrast and bright-

ness. Thirty degrees (encoder clicks) of control are provided. When it is right, press the

display. The Model 451 will not “time out” from this screen.

CONNECTIONS and ENCLOSURES

The Model 451 uses a “D” subminiature fifteen-pin connector for all input and output

connections. Table 3-1 summarizes these connections, and Figure 3-1 shows a typical LVDT

connection to the Model 451.

Table 3-1

Connections

Pin

Function

Pin

Function

Pin

Function

1

Plus input

6

---

11

Output low

2

Minus input

7&8*

Power

12

---

3

---

13

Case

4

Output high

9

Guard (shield)

14

Excitation

common

5

Remote

autozero

10

Excitation high

15

Power common

* Internally connected

3-1

CONTROLS

The Model 451 is operated using only the two front-panel controls: the display and the

encoder.

Display

In addition to displaying the various screens, the display

is used to accept the data, or settings, as they appear

on the screen when it is pressed and released. This is

always true, although in a few situations, the user is

asked to confirm his or her intentions with an additional

confirmation request. For instance, if the user answers

YES

to

RESET SYSTEM

, a confirmation will be

prompted so that the user will not accidentally erase

all

existing settings without intending to do so. Pressing

and holding the display for approximately two seconds

from any screen takes the user to the

VIEW ANGLE

ADJUST

screen so that the brightness and contrast can

be adjusted. This is because with changes in temperature,

the brightness and contrast are subject to variation.

Encoder

The encoder is used by either turning it or pressing it.

Both functions control the cursor (not always displayed)

on the screen. When the screen is a menu item such as

GAIN MODE SETUP

or

EXAMPLE MODE SETUP

,

a cursor is not displayed because the entire screen will

change when the encoder is rotated. In other words, the

entire screen is the item to be accepted, so there is no

need to display a cursor. When there are data points

that can be changed or yes-no questions to be answered

Figure 3-1 Typical LVDT Connection to the Model 451

Operation

Model 451

3-2

or both, the cursor is displayed. In these situations, ro-

tating the encoder changes the setting on the screen for

that data field or point. (Remember that only pressing

the display places the data on the screen in memory.)

Pressing the encoder will move the cursor from field

to field on a screen or from digit to digit within a field

on a screen.

When at the operating screen, which is normally alter-

nating between displaying the voltage out and the input

displacement, the user can select either screen full time

by pressing the encoder when the desired operating

screen is displayed. If the user wants to view only the

input displacement, pressing the encoder when the dis-

play has alternated to the input displacement will keep

the display screen in this mode. Pressing it again will

return the operating screen to the alternating mode.

UPDATING MEMORY

As stated above, memory is updated when the display is pressed and released, capturing the

information as it was. This is always true. However, if a screen does not require in user

confirmation with a

N

or

NO

or

Y

or

YES

, then memory is updated as the data on the

screen is changed. An example of this is zero offset. The zero offset actually changes as

the user turns the encoder.

TIME OUT

When there has been no activity for twenty seconds at a screen, the Model 451 will revert,

or “time out,” to the operating screen

without having made any updates to memory from

that screen

. This is true for all screens except error screens, alignment-required screens, and

several other screens only when certain conditions exist. These screens are maintained so

that the user will know that action is required to return the Model 451 to a fully operational

state, or it recognizes that the user probably intends to make a change.

POWER ON

When power is applied to the Model 451, diagnostics are run to ensure proper start-up. This

is normally invisible to the user. However if an memory error occurs or if alignment is

required, a screen other than the operating screen will appear. If the

ALIGN REQ’D

screen

appears, the Model 451 must be recalibrated. If the

MEMORY ERROR

screen appears,

turn the unit off and back on. If the

MEMORY ERROR

screen still appears, return the

unit for repair. If, however, the unit goes to the

ALIGN REQ’D

screen, recalibrate the unit

before using it.

OPERATING SCREENS

There are two operating screens for the Model 451, and they normally alternate every three

seconds. One displays the analog output of the unit in volts; and the other displays the

LVDT output in units of displacement, either milli-inches (

MIL

), millimeters (

MM

), or degrees

(

DEG

) for RVDT’s. (The transducer output is accurate only when the transducer sensitivity

for the particular mode of operation has been set.)

Model 451

Operation

3-3

Either screen can be set on all the time by pressing the encoder when the desired screen is

displayed. The operating screen selected will stay on until either the encoder is press again

or the display is pressed taking the user to the main menu or beyond. When the Model 451

is returned to the operating screen in this situation, it will be alternating.

OPERATING SCHEME AND MAIN MENU

Although the Model 451 has more than one hundred screens, it is easily operated when the

overall scheme of the screen layouts is understood.

The Model 451 normally displays the operating screen. By pressing the display from the

operating screen, the main menu is displayed. On this menu are

GAIN MODE SETUP

,

EXAMPL

MODE SETUP

,

SCALE MODE SETUP

,

AUTOZERO

,

ZERO SETUP

,

FIL

-

TER

,

CAL

,

RETURN TO OPERAT

, and

OTHER

. By selecting

OTHER

, a secondary

menu of less frequently changed items is activated. All menus have a screen that allows the

user to exit to the previous menu. Each

OTHER

menu item, when selected, goes to a menu

for setting the parameters for that area of operation.

FIRST SCREEN

When the display is pressed from the operating screen, and zero is not on, the active mode

will be the first screen displayed. For instance, if the active mode is example, then

EXAMPL

MODE SETUP

will be displayed. When zero is on,

AUTOZERO

will be the first screen

Figure 3-2 Main Menu

Operation

Model 451

3-4

Table of contents

Popular Network Hardware manuals by other brands

ADTRAN

ADTRAN Total Reach TRDDB Installation and Maintenance

Gridstore

Gridstore GS-1000-2 user guide

jacarta

jacarta interSeptor Pro-XP user manual

Ackcio

Ackcio BEAM-DG manual

IgniteNet

IgniteNet MetroLinq ML2.5-60-35 quick start guide

ZyXEL Communications

ZyXEL Communications NSA-220 Series quick start guide

Spirent

Spirent DLS 6700 operating manual

MB Connect Line

MB Connect Line mbNET MDH 810 manual

Comtrol

Comtrol InterChangeVS 1000 Installation reference guide

Cisco

Cisco ASA 5506-X Hardware installation guide

Buffalo

Buffalo LinkStation HD-HG160LAN Setup guide

Dell

Dell MC SD-WAN Edge 3400 Advanced Activation guide