edc MU300 User manual

User’s Manual

Operating Instructions of Ultrasonic Flowmeter

Preface

Thanks for purchasing the product!

The User’s Manual covers functions, settings, wiring and troubleshooting methods of this flowmeter.

Please carefully read this manual before use.

After reading the manual, please keep it in a proper place for reference when you operate the flowmeter.

Notes

Any modifications concerning function update in this manual will not be notified.

This manual has been carefully checked, if you find anything improper or any errors, please contact the

vendor.

If there are any differences between the flowmeter and its descriptions in this manual, please take the final

product as standard.

DO NOT fully or partially reprint or reproduce this manual.

Version

Rev1.0 Oct20

Warnings

For your safety, please carefully read the following safety warnings before use.

MU300 Rev1.0 Oct20 Page 1 of 54

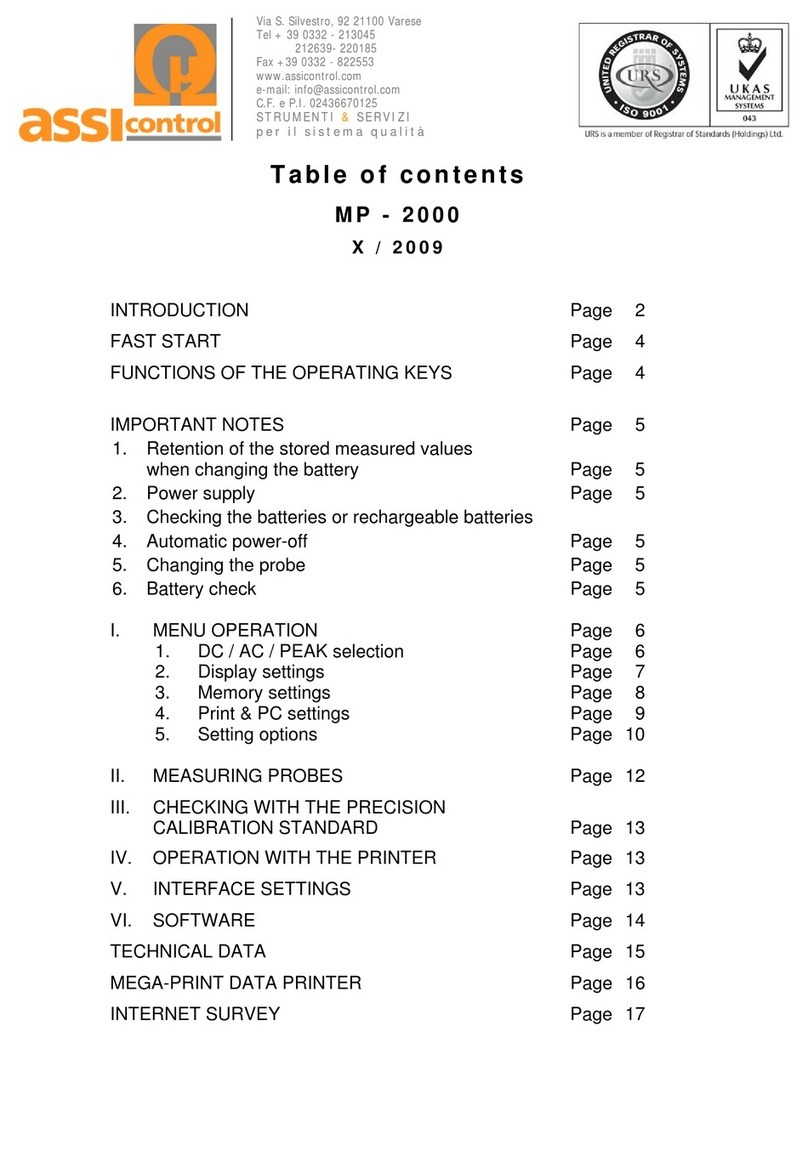

Contents

1.1 Product Liabilities and Quality Assurance..........................................................................3

1.2 Safety Instructions to Operators ........................................................................................4

Chapter II Descriptions of the Flowmeter...........................................................................................5

2.1 Delivery Scope ....................................................................................................................5

2.2 Measuring Principle............................................................................................................7

2.3 Application Scope ...............................................................................................................7

2.4 Nameplate ..........................................................................................................................8

3.3 Connecting electrical cables .......................................................................................9

3.4 Transmitter Connections..................................................................................................10

Chapter IV Operation Panel and Quick Start .....................................................................................11

4.1 Power on...........................................................................................................................11

4.2 Boot screen.......................................................................................................................11

4.3 Keyboard Operation .........................................................................................................13

Chapter V Installation.........................................................................................................................14

5.1 Installation, Storage and Prompts....................................................................................14

5.2 Pipe Design and Selection ................................................................................................15

5.3 Transducer Installation...................................................................................................18

Chapter VI Operation .........................................................................................................................25

6.1 Common Functions...........................................................................................................25

6.2 Description of Operation Menus......................................................................................30

6.3 Menu Configuration .........................................................................................................32

Chapter VIII Communication Interface and Communication Protocol..............................................47

MU300 Rev1.0 Oct20 Page 2 of 54

Copyrights and Data Protection

Content of this file has been carefully checked. We don’t promise that the content is totally correct and

completely identical with the latest version.

Content of this file and related products are under protection of China’s copyright laws. Without authorization in

writing of the Company, please DO NOT try to reproduce, transfer, transcribe or translate any parts of the

flowmeter including the source code to any languages or computer language in any forms or through electronic,

electromagnetic, optical or other means.

Without authorization in writing of the Company, please DO NOT reproduce, copy, reprint, translate or transfer

the manual or part of it to any electronic or readable media.

The designations and signs shown on the product are the registered trademark or trademark of the Company. All

other trademarks, product designations or company names quoted herein are only used for identification and

belong to the property of their respective owners.

Exception Clauses

The manufacturer shall bear no responsibilities for any consequences caused by the product in use, which

include penalties arising from any direct or indirect accidents or indirect losses.

The exception clauses shall be invalid if the manufacturer’s actions are intentional or the manufacturer has

culpable negligence. According to applicable laws, it is not allowed to confine implied warranties of the product,

or it is not allowed or it confines the compensation of some kind, and these rights are applicable to you, under

such cases, the above exception clauses or confinement may partially or completely inapplicable to you.

As for each purchased product, related product files and the manufacturer’s sales terms are applicable.

As for the content of these exception clauses, the manufacturer should reserve the right to make any corrections

in any form, at any time or for any reason with no need to issue any notifications in advance, and shall bear no

responsibilities in any forms arising from the corrections described herein.

MU300 Rev1.0 Oct20 Page 3 of 54

1.1 Product Liabilities and Quality Assurance

The purchaser should judge by himself whether the flowmeter is applicable or not, and shall bear related

responsibilities. The manufacturer would bear no responsibilities for any consequences arising from the

purchaser’s misuse of the flowmeter. The purchaser may lose the rights for quality assurance if the flowmeter or

the system is installed or operated in a wrong way. In addition, the corresponding “Standard Terms of Sale” is

also applicable and shall be the basic conditions of the Sales Contract.

Information about this file

To avoid any injuries or any damages to the flowmeter, please DO carefully read this file and DO comply with

local standards, safety rules and accident prevention rules.

If you can’t understand this file, please ask the manufacturer or the vendor for help. As for any property loss or

personal injury arising from your misunderstandings, the manufacturer would bear no related responsibilities.

With this manual, you could set up correct operating conditions of this flowmeter to ensure safety and efficiency

in use.

In addition, special notes and safety measures will be marked through the following symbols.

Convention of graphic symbols

The following symbols will help you better understand the file.

Warning!

This symbol indicates electrically related safety prompts.

Caution!

Please DO pay attention to this symbol. Any slight negligence may cause severe health hazard and

may damage the flowmeter or related equipment and facilities in operation.

Prompts!

The symbol indicates related important information for operation.

MU300 Rev1.0 Oct20 Page 4 of 54

1.2 Safety Instructions to Operators

Caution!

For your safety, please carefully read the following safety instructions before use. With this manual,

you could set up correct operating conditions of this flowmeter to ensure safety and efficiency in use.

Only certified personnel who have received related training are allowed to install, use, operate and

maintain this flowmeter.

Caution!

1. When using the flowmeter in inflammable media, please take measures to prevent from fire or

explosion.

2. When operating the flowmeter in hazardous environment, DO follow the correct operation

steps.

3. When removing the flowmeter, please follow the fluid OEM’s safety instructions to avoid

splashing.

4. Pay attention to the flowmeter’s probe. Even a minor scratch or incision would influence its

accuracy.

5. To get the optimum efficiency, the longest calibration period could not exceed two years.

MU300 Rev1.0 Oct20 Page 5 of 54

Chapter II Descriptions of the Flowmeter

2.1 Delivery Scope

Prompts!

Please carefully check whether the packing case is damaged or loaded/unloaded in an improper way

or not. If it is damaged, please notify the delivery man and the manufacturer or the consignor and

describe the damage in details.

Prompts!

Please check the goods you received with the packing list.

Prompts!

Please check the flowmeter’s nameplate and conform whether the scope of supply is identical with

your order. Check whether the power information on the nameplate is correct or not; if not, please

contact the manufacturer or the dealer.

MU300 Rev1.0 Oct20 Page 6 of 54

Accessories

1. Carrying Case*1pc.

2. Transmitter (Electronic)*1pc.

3. Transducer (Sensor) *1 pair.

4. Mounting track *1 set DT

5. Pipe straps *2 pairs.

6. Coupling compound (Grease)*1 pc, Battery charge*1pc, Output cable*1pc and Tapeline*1

Structural Configuration of Ultrasonic Flowmeter

MU300 Rev1.0 Oct20 Page 7 of 54

2.2 Measuring Principle

This series of ultrasonic flowmeter is an industrial time-difference type ultrasonic flowmeter. It applies the latest

industrial-level PFGA 700-thousand-gate-array chip, which extremely improves the signal sampling frequency and

bubble tolerance rate; the self-developed TGA technology makes it be capable of dealing with more complex

logic and calculation to provide more accurate and faster measurements, and ensures the flowmeter could

endure non-continuous bubbles or impurities within 5 sec. In addition, it could be installed and operated in a

convenient way with no need to break the pipe or cut off the fluid or stop work.

Time-difference type ultrasonic measurement indicates determining the fluid flow along the average velocity

with the time difference between two ultrasonic signals transmitting downstream or upstream in the same

stroke.

2.3 Application Scope

In which,

v Fluid velocity

M Ultrasonic reflections

D Pipe diameter

θIncluded angle between ultrasound signal and fluid

Tup Time that downstream transducer sends signal to

upstream

Tdown Time that upstream transducer sends signal to

downstream

△T =Tup-Tdown

It mainly applies for measuring the flow of homogeneous medium fluid in the following fields:

Domestic wastewater flow measurement, crude oil flow measurement, cementing slurry flow

measurement, oily sewage flow measurement in oil fields, water injection flow measurement in oil wells,

raw water flow measurement in rivers and reservoirs, tap water flow measurement, process flow

measurement of petrochemical products, industrial circulating water flow measurement, water

consumption measurement in production, mineral slurry flow measurement, pulp flow measurement,

chemical flow measurement, circulated cooling water flow measurement, generating coil cooling water

flow measurement (super small diameter), juice flow measurement, milk flow measurement, and so on.

MU300 Rev1.0 Oct20 Page 8 of 54

Ultrasonic Flowmeter

2.4 Nameplate

Prompts!

Please check the nameplate and confirm whether the goods are identical with your order or not.

Check whether the power supply on the nameplate is correct or not. The following shows

information on the nameplate:

Model:

Max. Operating

Temperature

℃

Specification Pressure Rating Mpa

Power Supply VDC Meter Factor

Accuracy Class

Measuring Range

Output Product No.

MU300 Rev1.0 Oct20 Page 9 of 54

3.3 Connecting electrical cables

Warning!

Signal cables and power cables must be connected while the power is off.

Warning!

As specified, the meter must be connected to the protective ground terminal to protect

operators from electric shock.

Warning!

As for the meters to be used in hazardous areas, please pay attention to the safety and

technical prompts as specified in the professional explosion-proof instructions.

Caution!

Please strictly obey the local occupational health and safety regulations. Only trained

personnel are allowed to operate on electrical equipment.

Warning!

Voltage difference is not allowed between the measuring transducer and the housing

or protective ground cable of the electronic system.

The measuring transducer must be well grounded according to related standard

DESIGN CODE OF INSTRUMENT GROUNDING (HT/T 20513-2014).

The ground conductor shall not transmit any disturbance voltage.

The ground conductor is not allowed to connect other electrical equipment.

MU300 Rev1.0 Oct20 Page 10 of 54

3.4 Transmitter Connections

3.4.1. Power supply

Please pay special attention to the power supply. Please connect related power supply

according to the symbols of connecting terminals.

3.4.2. Transmitter connections

Once the flowmeter is installed at the designated place as required, you can start

connections.

Open the case, you can see the connecting terminals on the power board from left to

right as follows:

Power

Power switch

Output

4-20mA or RS485

UP

DN

Charge

Warning!

Please ensure that the flowmeter is connected with the power off and ensure that it

has been reliably grounded before use.

3.4.3 Power on

When switching the power on for the first time, the flowmeter will run automatically

according to the parameters you put last time (the meter is calibrated before leaving

factory). After the flowmeter is installed and powered on, you can check its status in

M04 menu; if it displays “*R”, it indicates that the flowmeter is running normally.

If you use the flowmeter in a new environment, you need to input related parameters.

Any parameters you input would be kept in its memories forever till you correct them

again. If you need to adjust its installation position or the position of the transducer,

you need to input and set related parameters again of the flowmeter to ensure normal

use.

DO always finish all tasks when running. No matter in any displays, tasks including

measurement and output should be finished as usual.

MU300 Rev1.0 Oct20 Page 11 of 54

]

Flow Total

NET

POS

NE

Net

POS

NEG

Flow Total

Chapter IV Operation Panel and Quick Start

4.1 Power on

Warning!

Please check the meter is correctly installed or not before power on, including:

Connecting the power supply as specified.

Please check the electrical connection of the supply power is correct or not.

4.2 Boot screen

The flowmeter is composed of the measuring transducer and the signal converter. And the

delivery product is ready for putting into use. All operating parameters and settings have been

set according to your order requirements.

(1) Boot screen

In normal display, press [ and [ ] keys to switch among NET Total, POS Total and NEG Total.

Go on pressing [ ] to enter 01 menu to display the flow rate, total flow and transient flow. The

following shows how to switch between the flow rate and the total flow.

Prompts!

"*R" indicates that the flowmeter is running normally; “D” indicates that the flowmeter is

carrying out gain setting; “E” indicates that the flowmeter can’t receive any ultrasound signals.

Flow Rate

Flow Rate

G

MU300 Rev1.0 Oct20 Page 12 of 54

Heat

Heat

Cool

Cool

Energy meter display function

Note:

It is a function of energy meter and only the ultrasound heat meter has this function.

Press [Menu] key and digital key [2], i.e.: Menu + 2, to enter 2 heat display interface shown as

follows:

Transient heat quantity and temperature automatically switch and display for 6s, and it only

displays the inlet temperature and temperature difference. Press ENTER to stop switching, and

continuously refresh the display items; press ENTER again to recover.

Press [Menu] key and digital key [3], i.e.: Menu + 3, to enter 3 cold display interface shown as

follows:

Transient cold quantity and temperature automatically switch and display for 6s, and it only

displays the inlet temperature and temperature difference. Press ENTER to stop switching, and

continuously refresh the display items; press ENTER again to recover display.

Note:

When using the heat function, the temperature difference displayed is positive, while using the

cold function, the temperature difference displayed is negative.

MU300 Rev1.0 Oct20 Page 13 of 54

4.3 Keyboard Operation

4.3.1 Descriptions

Use digits [0~9] and [ . ] to input digits or menu number.

[ ] key is used for left backspace or deleting the characters on left.

[ ] and [ ] keys are used for entering the previous or next menu; the key is plus or minus when

inputting digits.

[Menu] key is used for choosing menus. Press the key and then input menu number to enter

related menu.

[Enter] key is used for entering the edit mode and confirm the corrections.

4.3.2 Keyboard Operation Methods

The flowmeter menu is divided into six modules according to the functions and field demands.

You can directly input the menu number to enter the menu and you also can switch through [ ]

and [ ] keys.

If you need to correct the flowmeter parameters, please firstly switch to related menu, find out

the parameter you want to correct and then press [Enter] to confirm; input the data and then

press [Enter] to confirm your corrections.

MU300 Rev1.0 Oct20 Page 14 of 54

Chapter V Installation

5.1 Installation, Storage and Prompts

Prompts!

Please carefully check whether the packing case is damaged or loaded/unloaded in an

improper way or not. If it is damaged, please notify the delivery man and the

manufacturer or the consignor and describe the damage in details.

Prompts!

Please check the goods you received with the packing list.

Prompts!

Please check the nameplate and confirm whether the goods are identical with your

order or not. Check whether the power supply on the nameplate is correct or not; if

not, please contact the manufacturer or the vendor.

Storage!

•Please store the flowmeter in a dry and dust-free place;

•Avoid long-term direct sunlight;

•Keep the flowmeter in the original packing case;

Prompts!

To ensure reliable installation, DO take the following measures:

Before installing the flowmeter, DO consider of the flowmeter’s diameter,

pipe size and installation position. Correct installation could ensure accurate output

signals, less maintenance and maximum performance.

MU300 Rev1.0 Oct20 Page 15 of 54

5.2 Pipe Design and Selection

The following should be considered when selecting a pipe:

5.2.1 Installation Environment

It is better to install the flowmeter indoors; if you have to install it outdoors, you should take

measures to avoid direct sunlight or rainwater.

The flowmeter shall be installed away from high temperature, thermal radiation from equipment

or corrosive gas.

Ultrasonic flowmeters cannot be installed nearby motors, transformers or other power sources

that are easy to cause electromagnet interference. DO NOT install ultrasonic flowmeters nearby

frequency converters or DO NOT connect it with the distributing cabinet of frequency converters

to avoid interference.

In convenience for installation and maintenance, keep sufficient space around the flowmeter.

5.2.2 Support of Flowmeter

Avoid installing the flowmeter on pipes with mechanical vibrations. If you must install it there,

DO take shock absorption measure. You could install a hose for transition or set support points

with absorbing pads on the pipe at 2DN in both upstream and downstream of the flowmeter. Try

not to install the flowmeter on the longer overhead pipes because the sagging of pipes would

cause leakage between the flowmeter and the flanges. If you have to do it, you must set support

points on the pipe at 2DN in both upstream and downstream of the flowmeter.

5.2.3 Requirements on Liquid-receiving Material

The ultrasonic flowmeter could measure single-medium liquid flow; The same medium could be

divided into three specifications (low temperature, high temperature and superhigh

temperature), different flowmeters should be used for different temperatures.

5.2.4 Dangerous Conditions

You could select the flowmeter with an explosion-proof housing, and intrinsic safety explosion-

proof flowmeter with intrinsic safety design circuit to ensure its safety and flame-retardant

operation. Each flowmeter should have a nameplate clearly identifying its certifications. Please

DO install and use the flowmeter according to the explosion-proof grade and protection grade as

shown on the nameplate.

MU300 Rev1.0 Oct20 Page 16 of 54

General conditions

Install after the elbow

Caution:

DO ensure that the flowmeter is filled. DO NOT make the liquid flow downwards

vertically, or it may have bubbles.

5.2.4 Requirements on the front/rear straight pipe sections

DO ensure a straight pipe section at least ten times of the pipe diameter (D) in the

upstream of the flowmeter and at least five times of the pipe diameter (D) in the

downstream of the flowmeter. The nominal accuracy depends on the pipe diameters in

the upstream; according to the interference, insufficient front/rear straight pipe

sections may cause about 0.5% deviation.

To ensure measurement accuracy of the flowmeter, try to satisfy the following

requirements on the length of straight pipe sections installed nearby the flowmeter:

upstream >20D, downstream>10D.

Try not to disturb the upstream flow distribution. Ensure no valves, elbows or triplets;

try to install the control devices or throttles in the downstream if any, so as to ensure

sufficient pipe flow at the measurement point, details are shown below:

MU300 Rev1.0 Oct20 Page 17 of 54

5.2.5 Requirements on Transducer Installation Angle

When being installed on horizontal pipes, the transducer should be installed at 3

o’clock or 9 o’clock, i.e. on both sides of the pipe. It’ not recommended to install it on

top or at bottom of the pipe because it’s easy to cause bubbles at the top and

accumulate sands or impurities at the bottom.

Pipe top Pipe top

3 o’clock 3 o’clock

direction direction

Pipe cross

Pipe cross

9 o’clock

9 o’clock

section

direction

section

direction

Pipe bottom Pipe bottom

The measurement point should be in the pipe section with relatively new inner wall

with no or relatively less scaling. The pipe must be made of compact material. When

selecting the installation point, DO ensure no welding seams or other gaps.

Install after valves

Install on diameter-reduced pipe

Install on diameter-expanded pipe

MU300 Rev1.0 Oct20 Page 18 of 54

5.3 Transducer Installation

Handling and unpacking

It’s better not to unpack it before installing it to designated location to avoid damage.

DO NOT heavily throw the flowmeter or press heavily on it, especially the probe

surface, or the sealing surface may be damaged.

After unpacking, protect the probe and converter. DO NOT place the probe at free will

on the floor with no cushions or other unsmooth surface.

The flowmeter is kept unused for a long time

After the flowmeter is installed, try not to keep it unused for a long time; if you have to

do so, you must take the following measures:

A. Check the sealability of end covers and connection ports and ensure that no

dampness or water enters inside the converter. DO check it regularly and check each

measure mentioned above and the connection box at least once per year.

B. If the converter may be immersed in water (after a heavy rain or thunderstorm),

check the converter immediately.

Transducer installation spacing

Before mechanical installation of the ultrasonic flowmeter, please follow the way

described in Article [4.4 Quick Start] to set related parameters of the pipe and fluid,

and obtain value L of the installation spacing in M14 menu.

Installation spacing of the clamp-on transducer should be the distance between its two

end surfaces; while that of the insert-in transducer should be the distance between the

axis center of two transducers.

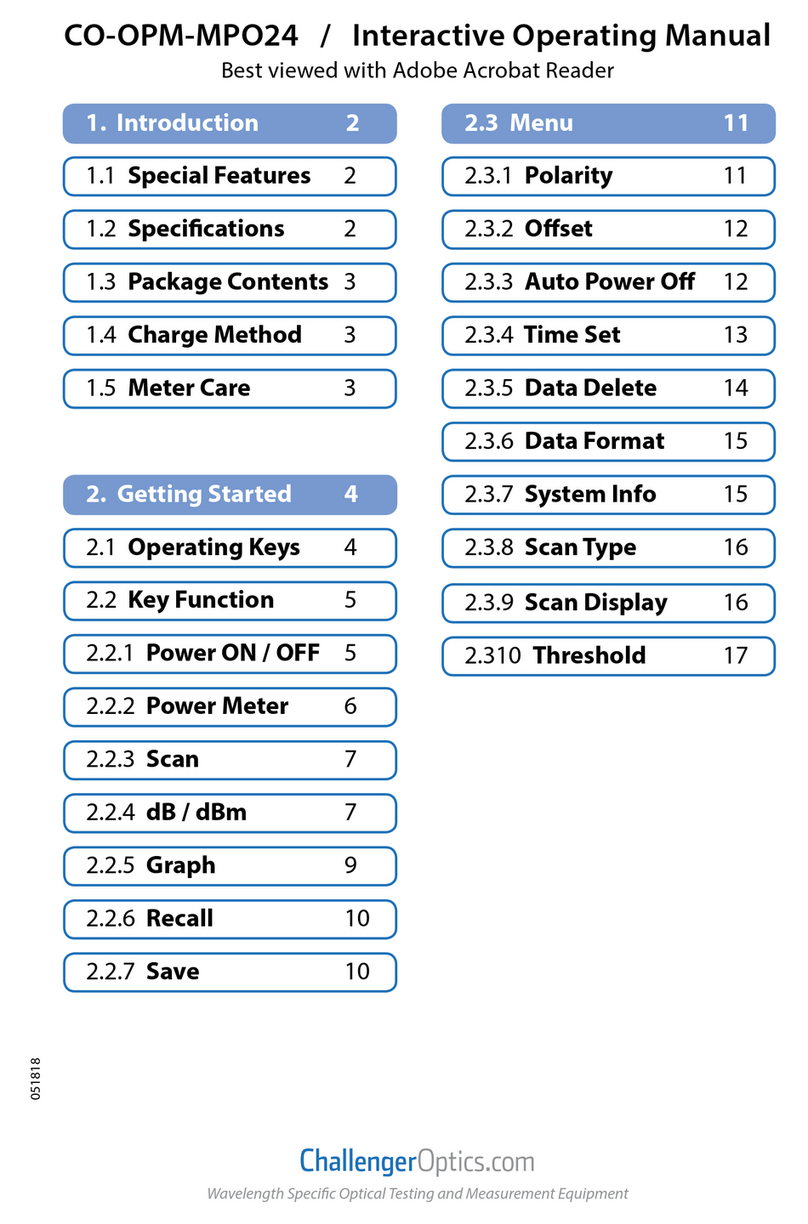

Table of contents

Other edc Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Challenger Optics

Challenger Optics CO-OPM-MPO24 Interactive operating manual

KEPCO

KEPCO BATCHtrol II Installing & operating manual

Brain Bee

Brain Bee AGS 200 Operation manual

Accu-Flo Meter Service Ltd.

Accu-Flo Meter Service Ltd. TM Series owner's manual

KEPCO

KEPCO 52U manual

AU Tool

AU Tool X50 Plus user manual