Page 2

E-EDCO-2MPH-0321

EQUIPMENT DEVELOPMENT CO., INC.

1•

800•

638•

SAFETY INFORMATION

•Engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects or other reproductive harm.

• 7LOWLQJ D JDVROLQH SRZHUHG PDFKLQH ¿WWHG ZLWK DQ

(3$DSSURYHGYHQWHGFKDUFRDO¿OWHUJDVFDSEH\RQG

20° can cause fuel leakage. If a leak occurs, do not

VWDUWRUUXQWKHHQJLQHXQWLOWKHOHDNLV¿[HG(OLPLQDWHDOORWKHULJQLWLRQ

VRXUFHVLQWKHLPPHGLDWHDUHDQRVPRNLQJÀDUHVVSDUNVRUÀDPHV

Use approved gasoline absorbing material to contain the fuel leakage.

Then use clean, non-sparking tools to collect absorbed materials then

GLVSRVHRIWKHVHFRQWDPLQDQWVSURSHUO\

•*DVROLQHLVH[WUHPHO\ÀDPPDEOHDQGSRLVRQRXV,WVKRXOG

RQO\EHGLVSHQVHGLQZHOOYHQWLODWHGDUHDVDQGZLWKDFRRO

engine.

• Small gasoline engines produce high concentrations of

FDUERQPRQR[LGH&2H[DPSOHD+3F\FOHHQJLQHRSHUDWLRQLQ

DQHQFORVHGFXIWDUHDZLWKRQO\RQHFKDQJHRIDLUSHUKRXU

LVFDSDEOHRISURYLGLQJGHDGO\FRQFHQWUDWLRQVRI&2LQOHVVWKDQ¿IWHHQ

minutes. Five changes of air in the same area will produce noxious

fumes in less than 30 minutes. Gasoline powered equipment should

QRWEHXVHGLQHQFORVHGRUSDUWLDOO\HQFORVHGDUHDV6\PSWRPVRI&2

poisoning include, head-ache, nausea, weakness, dizziness, visual

SUREOHPV DQG ORVV RI FRQVFLRXVQHVV ,I V\PSWRPV RFFXU JHW LQWR

IUHVKDLUDQGVHHNPHGLFDODWWHQWLRQLPPHGLDWHO\

• Never refuel a hot engine or an engine while it is running.

(QJLQHVDUHVKLSSHGIURPIDFWRU\ZLWKRXWIXHORLO

SAFETY MESSAGES

Indicates an imminent hazard which, if not avoided,

ZLOOUHVXOWLQGHDWKRUVHULRXVLQMXU\

Indicates an imminent hazard which, if not avoided,

FDQUHVXOWLQGHDWKRUVHULRXVLQMXU\

Indicates hazards which, if not avoided, could result in

VHULRXVLQMXU\DQGRUGDPDJHWRWKHHTXLSPHQW

•6DIHW\,QVWUXFWLRQVDUHSURFHHGHGE\DJUDSKLFDOHUWV\PERORI'$1*(5

:$51,1*RU&$87,21

GASOLINE / POWERED EQUIPMENT

DUST WARNING

(TXLSPHQW VKRXOG RQO\ EH RSHUDWHG E\ WUDLQHG SHUVRQQHO LQ JRRG

SK\VLFDOFRQGLWLRQ DQG PHQWDO KHDOWK QRWIDWLJXHG 7KH RSHUDWRUV

DQGPDLQWHQDQFHSHUVRQQHOPXVWEHSK\VLFDOO\DEOHWRKDQGOHWKHEXON

weight and power of this equipment.

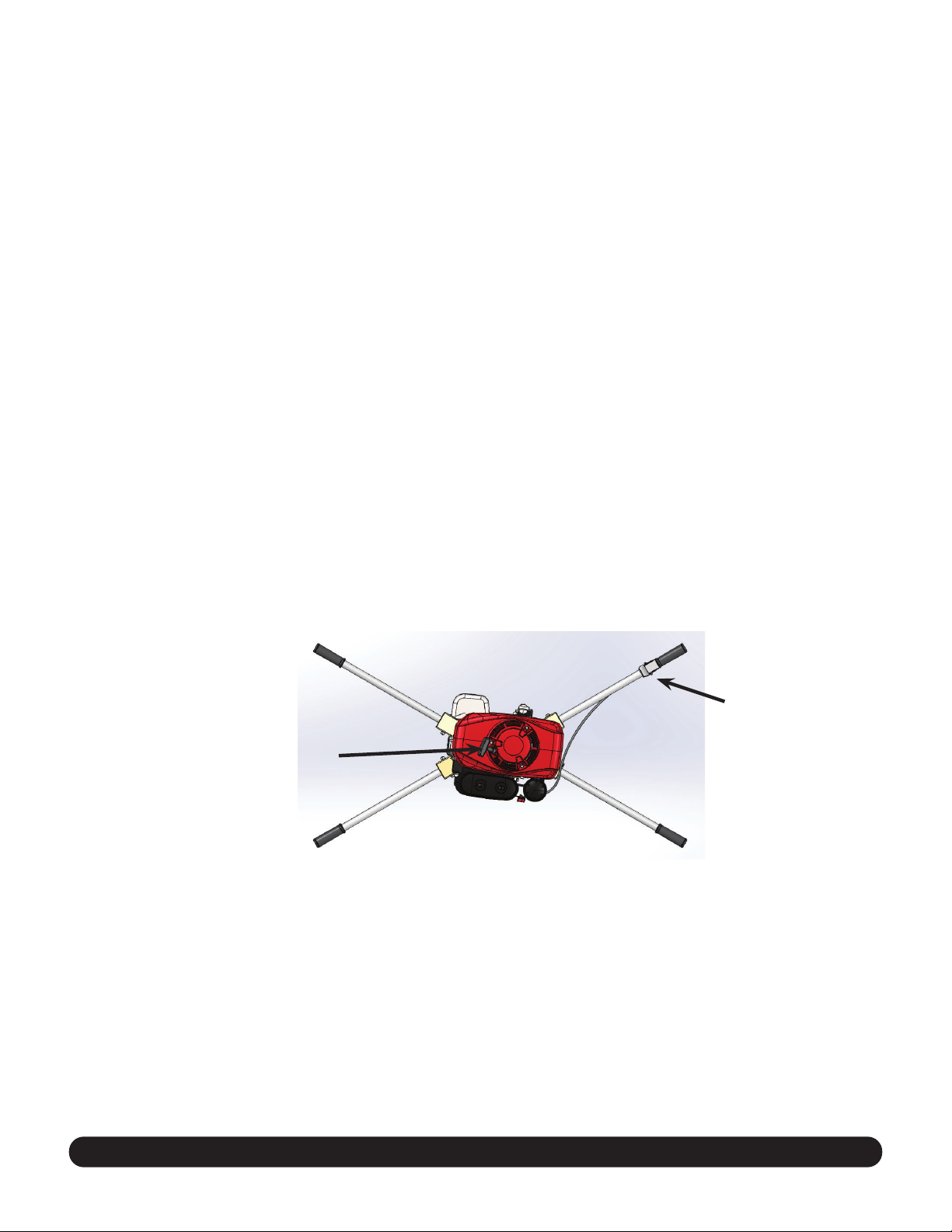

• This is a TWO person tool. Maintain a safe operating distance to other

personnel. It is the operators’ UHVSRQVLELOLW\ to keep other people (work-

HUVSHGHVWULDQVE\VWDQGHUVHWFDZD\GXULQJRSHUDWLRQ%ORFNRႇ

WKHZRUNDUHDLQDOOGLUHFWLRQVZLWKURSLQJVDIHW\QHWWLQJHWF

)DLOXUHWRGRVRPD\UHVXOWLQRWKHUVEHLQJLQMXUHGE\À\LQJGHEULVRU

exposing them to harmful dust and noise.

7KLVHTXLSPHQWLVLQWHQGHGIRUFRPPHUFLDOXVHRQO\

)RU WKH RSHUDWRU¶V VDIHW\ DQG WKH VDIHW\ RI RWKHUV DOZD\V NHHS DOO

guards in place during operation.

• Never let equipment run unattended.

3HUVRQDO3URWHFWLRQ(TXLSPHQWDQGSURSHUVDIHW\DWWLUHPXVWEHZRUQ

ZKHQRSHUDWLQJ WKLV PDFKLQHU\ 7KHRSHUDWRU PXVW ZHDUDSSURYHG

VDIHW\HTXLSPHQWDSSURSULDWHIRUWKHMREVXFKDVKDUGKDWDQGVDIHW\

VKRHV ZKHQ FRQGLWLRQV UHTXLUH +HDULQJ SURWHFWLRQ 0867 EH XVHG

ZKHQRSHUDWLRQDOQRLVH OHYHOVRIWKLV HTXLSPHQWPD\ H[FHHG GE

(\HSURWHFWLRQ0867EHZRUQDWDOOWLPHV

GENERAL INSTRUCTIONS

.HHSERG\SDUWVORRVHFORWKLQJDQGDFFHVVRULHVDZD\IURP

moving parts. Failure to do so could result in dismember-

ment or death.

'RQRWPRGLI\WKHPDFKLQH

6WRSPRWRUHQJLQHZKHQDGMXVWLQJRUVHUYLFLQJWKLVHTXLSPHQW0DLQWDLQ

DVDIHRSHUDWLQJGLVWDQFHIURPÀDPPDEOHPDWHULDOV6SDUNV

IURPWKHFXWWLQJDFWLRQRIWKLVPDFKLQHFDQLJQLWHÀDPPDEOH

materials or vapors.

$OZD\VFRQWDFW\RXUDSSURSULDWHORFDODJHQFLHVWR

determine exact locations of all buried utilities and

VXEVXUIDFHKD]DUGV,IWKH('&23+FRPHVLQ

FRQWDFWZLWKDQ\VXEVXUIDFHKD]DUGSURSHUW\GDP-

DJHDQGRUSHUVRQDOLQMXU\ZLOORFFXU

5HDGDQGIROORZDOOVDIHW\GHFDOVDQGODEHOV

• Maintain a safe operating distance to other personnel.

%HIDPLOLDUZLWKDOODVSHFWVRIWKHPDFKLQH¶VRSHUDWLRQDQGFRQWUROV

EHIRUHDSSO\LQJSRZHUWRWKHHTXLSPHQW

8VHWKHFRUUHFWDFFHVVRU\IRUWKHMREEHLQJSHUIRUPHGDQGPDWHULDO

EHLQJUHPRYHG0DNHVXUHDFFHVVRULHVDUHPRXQWHGFRUUHFWO\

1HYHU RSHUDWH WKLV PDFKLQH ZKLOH XQGHU WKH LQÀXHQFH RI GUXJV RU

alcohol, while taking medications that impair the senses or reactions,

RUZKHQH[FHVVLYHO\WLUHGRUXQGHUVWUHVV

• Follow the instructions in the operator’s manual and exercise caution.

&RPSO\ZLWKDOOORFDOVDIHW\DQGKHDOWKUHJXODWLRQVDVZHOODV(3$DQG

26+$UHJXODWLRQV

5HDG0DLQWDLQDFRS\RIWKHHTXLSPHQW¶VRSHUDWRU¶VPDQXDODQGWKH

HQJLQHPRWRU PDQXIDFWXUHV RSHUDWRUV PDQXDO ZLWK WKH PDFKLQH IRU

reference at all times.

%HVXUHDOOGHFDOVRQWKHPDFKLQHFDQEHFOHDUO\UHDGDQGXQGHUVWRRG

5HSODFHZRUQPLVVLQJGHFDOVLPPHGLDWHO\

6RPHGXVWFUHDWHGE\SRZHUVDQGLQJVDZLQJ

grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth

defects, or other reproductive harm. Materials being removed can be

toxic or hazardous. A breathing respirator is required to help protect

the operator.

6RPHH[DPSOHVRIWKHVHFKHPLFDOVDUH

• Lead from lead-based paints.

&U\VWDOOLQHVLOLFDIURPEULFNVFRQFUHWHDQGRWKHUPDVRQU\SURGXFWV

Your risk of exposure to these chemi cals varies depending on how

RIWHQ\RXGRWKLVW\SHRIZRUN7RUHGXFH\RXUULVNZRUNLQDZHOO

YHQWLODWHGDUHDXVHDGXVWFRQWUROV\VWHPVXFKDVDQLQGXVWULDOVW\OH

YDFXXPDQGZHDUDSSURYHGSHUVRQDOVDIHW\HTXLSPHQWVXFKDVD

GXVWSDUWLFOHUHVSLUDWRUGHVLJQHGWR¿OWHURXWPLFURVFRSLFSDUWLFOHV

• See more on the importance of dust prevention and silica warnings

DWRVKDJRYVLOLFD

• More concrete and silica dust supression training and educational

PDWHULDOVDYDLDEOHDWHGFRLQFFRPVLOLFDVWDQGDUGV

:ULWWHQH[SRVXUHSODQVDUHSURYLGHGDWKWWSZZZHGFRLQFFRP

ZULWWHQH[SRVXUHFRQWUROSODQVGHIHFWVRURWKHUUHSURGXFWLYHKDUP

Materials being removed can be toxic or hazardous.