Eddystone 840C User manual

-DDYSIO

COMMUNICATIONS

RECEIVER

MODEL

The

EDDYSTONE

Model

840C

is

a

single

conversion

communications

superhet

receiver

covering

the

band

480

kc/s

to

30

Mc/s

in

five

overlapping

ranges.

Provision

is

made

for

the

reception

of

both

AM

and

CW

signals

and

although

the

receiver

is

not

designed

specifically

for

SSB

reception,

such

signals

can

be

received

with

careful

tuning.

The

receiver

has

a

built-in

power

unit

allowing

operation

from

all

standard

AC

and

DC

mains

supplies.

An

internal

loud-

speaker

is

fitted

and

provision

is

made

for

connection

of

an

external

speaker

unit.

Telephones

can

be

plugged

into

a

socket

on

the

front

panel

when

a

speaker

output

is

not

required.

Ease

of

operation

is

assured

by

the

logical

positioning

and

convenient

dimensions

of

the

major

controls.

The

high

grade

gear

driven

slow

motion

tuning

system

allows

extremely

fine

tuning,

while

the

flywheel

loading

permits

rapid

movement

from

one

end

of

a

range

to

the

other.

Dial

calibration

is

directly

in

terms

of

trequency,

the

scales

being

linear

and

easy

to

read.

A

calibrated

vernier

is

used

in

conjunction

with

a

special

logging

scale

so

that

dial

settings

can

be

recorded

for

future

use.

A

visual

tuning

indicator

is

fitted

as

a

further

aid

to

accurate

tuning.

Independent

manual

gain

controls

together

with

an

efficient

automatic

gain

control

circuit

allow

the

receiver

to

be

set

for

all

levels

of

input

signal

and

tone

can

be

adjusted

by

means

of

a

panel

control.

Advanced

design,

rugged

construction

and

high

quality

components

are

used

throughout;

the

receiver

is

of

a

most

convenient

size,

contemporary

in

appearance

and

suitable

for

continuous

operation

in

all

areas

under

extreme

climatic

conditions.

The

five

frequency

ranges

are

as

follows

:—

Range

|.

12-4

-

30

Me/s.

Range

2

5:2

—

12:9

Me/s.

Range

3.

2:5

-

6:1

Mejs.

Range

4.

1-12

—

2:58

Me/s.

Range

5.

480

—

1150

ke/s.

840C

CIRCUIT

DESCRIPTION

The

840C

is

an

eight

valve

model

and

can

be

used

on

all

AC/DC

mains

supplies

in

the

ranges

100/125V

and

200/250V.

It

has

a

single

stage

of

RF

amplification

using

a

high

gain

pentode

type

UAF42

(VI)

and

a

combined

Mixer

and

Local

Oscillator

V2.

This

stage

employs

a

UCH42

triode-hexode

in

which

the

triode

portion

functions

as

a

tuned

anode

oscillator.

Normal

ganged

tuning

is

employed

in

conjunction

with

a

switched

five

range

coil

unit

using

precision

wound

inductors.

The

IF

output

from

the

Mixer

Stage

is

at

450

kc/s

and

a

single

stage

of

amplification

is

provided

at

this

frequency.

Two

permeability

tuned

transformers

provide

excellent

selectivity

and

the

IF

valve

(V3)

is

a

UAF42.

The

diode

in

the

IF

valve

envelope

is

used

as

AGC

Rectifier

and

controls

the

RF,

IF

and

Mixer

Stages

on

Ranges

3,

4

and

5

while

on

Ranges

|

and

2

the

RF

and

IF

Stages

only

are

controlled

to

prevent

oscillator

pulling.

AGC

is

removed

from

all

stages

when

the

BFO

is

switched

in

and

it

should

be

noted

that

the

AGC

delay

is

affected

by

the

RF

Gain

control

which

should

always

be

set

to

maximum

when

AGC

is

in

use.

The

visual

tuning

indicator

V4

which

ts

a

miniature

DM70

is

controlled

by

the

Detector

Stage

and

is

therefore

operative

with

or

without

AGC.

V5

is

another

UAF42

serving

as

Signal

Detector

and

Ist

Audio

Amplifier.

The

detector

is

a

series

diode

type

and

the

pentode

portion

of

the

valve

is

fed

from

the

AF

Gain

control

which

forms

part

of

the

detector

load.

Output

from

the

pentode

is

resistance-capacity

coupled

to

the

following

valve

V7

(UL41l).

Negative

feed-back

is

applied

to

this

stage

and

the

high

quality

output

transformer

feeds

either

a

loudspeaker

or

low

impedance

telephones.

Tone

control

is

by

means

of

a

variable

resistor

(RV3)

in

series

with

a

capacitor

across

the

primary

of

the

output

transformer.

The

Beat

Frequency

Oscillator

(V6)

is

also

a

UAF42

and

employs

a

conventional

electron

coupled

circuit.

The

frequency

of

oscillation

is

variable

by

means

of

a

panel

control

to

permit

adjustment

of

the

pitch

of

the

note

when

receiving

CW

signals.

Two

gain

controls

are

provided,

the

RF

Gain

which

takes

the

form

of

a

variable

resistor

in

series

with

the

common

cathode

return

of

VI

and

V3

and

the

AF

Gain

which

is

a

potentiometer

control

in

the

output

of

the

signal

detector.

Provision

is

made

for

desensitising

the

receiver

when

it

is

not

required

but

must

be

available

for

immediate

use.

This

is

achieved

by

means

of

the

Standby

switch

which

applies

a

large

bias

to

the

RF

and

IF

stages

when

switched

to

‘

standby.’

HT

supplies

remain

on

all

stages

during

standby

periods

so

that

frequency

stability

is

maintained

when

the

receiver

is

not

in

use.

The

power

supply

circuitry

is

quite

conventional

and

includes

the

normal

half

wave

rectifier

V8

(UY41),

the

smoothing

circuit

and

the

ballast

resistor

which

feeds

the

series/parallel

connected

heater

chain.

A

thermistor

is

incorporated

in

this

circuit

to

reduce

the

current

surge

at

‘switch-on’

and

this

prolongs

the

life

of

the

valves

used

in

the

receiver.

No

indicator

lamp

is

fitted

since

this

function

is

effectively

performed

by

the

visual

tuning

indicator

which

exhibits

a

blue

glow

when

the

receiver

is

operative.

CONSTRUCTION

The

chassis

assembly

in

the

840C

is

totally

isolated

from

the

panel

and

cabinet

and

complies

with

the

relevant

standards

with

regard

to

safety

from

shock

applicable

to

AC/DC

equipment.

Specially

fabricated

insulating

pieces

are

employed

at

all

fixing

points

between

the

chassis

and

the

remainder

of

the

unit

and

when

correctly

installed

the

cabinet

and

panel

are

directly

earthed

and

the

internal

chassis

is

totally

inaccessible.

All

the

fixing

arrangements

for

control

knobs,

switches,

etc.

are

either

fully

insulated

by

virtue

of

their

inaccessibility

or

are

directly

earthed

to

the

panel.

Aerial

connections,

etc.

are

also

completely

safe.

The

chassis

assembly

is

made

up

in

three

parts.

These

are

the

central

coil

unit

which

is

an

aluminium

diecasting,

the

IF/AF

chassis

and

the

Power

Unit

chassis.

The

IF/AF

chassis

is

made

from

brass

and

is

mounted

to

the

right

of

the

coil

unit.

The

Power

Unit

is

built

on

a

rustproofed

steel

chassis

and

occupies

the

same

relative

position

as

the

[F/AF

chassis

but

to

the

left

of

the

coil

unit.

The

panel

is

an

aluminium

diecasting

having

four

fixing

holes

for

attachment

of

the

coil

unit.

At

the

extreme

ends

of

the

panel

are

the

two

steel

chassis

support

plates

which

make

direct

contact

with

the

panel

but

are

insulated

from

the

chassis

which

they

support.

Fixing

to

the

panel

is

by

means

of

the

four

screws

which

secure

the

chromium

plated

panel

handles.

These

handles

make

for

ease

in

lifting

the

receiver

and

also

allow

it

to

be

placed

*

face-down’

when

removing

the

cabinet.

Ample

clearance

is

provided

to

avoid

damage

to

the

panel

controls

when

the

receiver

is

placed

in

this

position.

The

high

flux

64”

speaker

unit

is

mounted

on

the

left-hand

chassis

support

plate

and

precautions

have been

iaken

to

avoid

undesirable

cabinet

resonance.

The

cabinet

is

stoutly

made

from

rustproofed

steel,

is

provided

with

adequate

ventilation

areas

and

a

loudspeaker

grille

:

apertures

at

the

rear

allow

connection

to

the

aerial.

external

speaker,

etc.

The

cabinet

is

easily

removed

after

taking

out

the

four

large

screws

at

the

back.

All

external

connections

with

the

exception

of

the

telephone

socket

are

located

on an

insulated

panel

positioned

at

the

rear

of

and

extending

the

full

width

of

the

chassis

assembly.

It

is

attached

to

the

chassis

support

plates

and

serves

to

support

the

rear

of

the

coil

unit

and

the

sub-chassis

which

make

up

the

complete

chassis

assembly.

Plan

view

of

receiver

INSTALLATION

Mains

Voltage

Adjustment

The

Model

840C

can

be

operated

equally

well

from

either

AC

or

DC

mains

supplies.

No

adjustment

is

necessary

when

changing

from

AC

to

DC

but

it

is

important

to

check

that

the

voltage

selector

at

the

rear

of

the

receiver

is

set

to

suit

the

local

mains

voltage

before

making

connection

to

the

supply.

When

despatched

from

the

factory,

the

selector

is

placed

in

the

230V

position

which

is

correct

for

operation

from

mains

voltages

in

the

range

225-250V.

If

the

local

mains

supply

is

between

200-22S5V

the

selector

plug

should

be

withdrawn

from

the

230V

socket

and

plugged

into

the

200V

position.

The

110V

socket

is

suitable

for

mains

supplies

in

the

range

100-125V.

Mains

Connections

and

Earthing

The

mains

input

is

taken

via

a-small

plug

and

socket

at

the

rear

of

the

cabinet,

the

plug

being

ready

wired

with

six

feet

of

three-core

mains

cable.

One

end

of

the

cable

is

lett

free

so

that

the

user

can

fit

a

plug

of

a

type

suitable

for

connection

to

the

local

mains

supply.

If

the

existing

cable

proves

too

short,

it

can

easily

be

disconnected

from

the

plug

and

replaced

by

a

longer

length.

In

most

cases

the

existing

length

will

be

adequate

and

this

is

coded

as

follows

:—

Red:

Live

(Positive

DC),

Black:

Neutral

(Negative

DC),

Green

:

Earth.

When

it

is

necessary

to

fit

a

two-pin

mains

plug

in

lieu

of

the

more

usual

three-pin

type,

the

green

lead

should

be

cut

off

short

and

pressed

back

into

the

cable

covering

so

that

there

is

no

chance

of

it

shorting

to

the

other

leads.

With

three-pin

plugs

the

green

lead

should

be

connected

to

the

thicker

of

the

three

pins.

Inside

the

set

the

green

lead

is

connected

directly

to

the

cabinet

and

panel

and

if

the

mains

earth

is

reasonably

short

there

will

be

no

need

to

connect

an

earth

at

socket

‘

E.”

However,

if

the

mains

earth

is

rather

long,

improved

reception

may

be

obtained

if

socket

‘E”

is

connected

to

a

more

direct earth.

It

is

important

to

note

that

in

cases

where

there

is

no

con-

nection

to

socket

*E,’

the

plug

supplied

must

still

be

in

position

to

complete

the

earth

to

the

internal

chassis.

Leaving

the

plug

out

will

reduce

the

sensitivity

of

the

receiver

especially

when

using

single

wire

aerials.

When

there

is

no

connection

to

the

green

earth

lead

an

earth

must

be

connected

to

socket

‘

E.’

On

AC

supplies

when

a

three-pin

plug

is

in

use,

the

red

lead

should

be

connected

to

the

pin

that

engages

with

the

right-hand

socket

of

the

wall

fitting.

This

is

true

on

the

assumption

that

the

wall

fitting

is

wired

correctly

but

if

as

is

sometimes

the

case

the

wall

fitting

is

wired

incorrectly,

it

may

be

found

that

an

objectionable

hum

appears

in

the

output

from

the

receiver.

Reversing

the

connections

to

the

plug

will

remove

the

hum.

Two-pin

AC

plugs

should

be

reversed

if

a

hum

is

present

and

can

then

be

marked

to

indicate

the

correct

orientation.

On

DC,

the

receiver

will

function

only

if

the

polarity

of

the

supply

is

correct.

Thus,

if

the

set

fails

to

operate

after

the

normal

warming

up

period,

reversal

of

the

plug

will

clear

the

trouble.

The

Aerial

The

Model

840C

is

an

extremely

sensitive

receiver

and

will

give

a

good

account

of

itself

even

on

poor

indoor

aerials.

For

best

possible

reception

an

outside

antenna

is

a

worthwhile

investment.

This

can

be

any

length

up

to

some

100

feet

or

so,

well

insulated

and

situated

clear

of

all

local

obstructions

especially

those

of

a

metallic

nature.

Single

wire

aerials

of

this

type

are

connected

at

the

right-hand

socket

labelled

*

A.’

The

shorting

plug

must

be

in

position

between

the

other

‘A’

socket

and

earth.

For

improved

reception

over

restricted

frequency

bands

(or

when

local

noise

is

a

problem)

a

dipole

cut

to

the

correct

length

is

probably

the

most

suitable

arrangement.

Aerials

of

this

type

have

a

‘

T”

formation

with

a

twin

balanced

feeder

which

helps

to

reduce

noise

pick-up

on

the

lead-in.

When

using

a

dipole

aerial,

the

shorting

plug

is

removed

and

the

two

feeder

wires

are

connected

to

the

two

‘A’

sockets.

Other

advantages

of

the

dipole

are

that

the

feeder

can

be

of

any

length

so

allowing

the

aerial

proper

(the

top

portion

of

the

‘T')

to

be

placed

in

the

most

suitable

position,

while

the

feeder

can

be

run

close

to

obstructions

without

adverse

effect

on

the

performance.

A

disadvantage

of

the

dipole

is

that

performance

is

only

optimum

over

the

band

for

which

it

is

designed.

Improved

performance

can

sometimes

be

obtained

on

frequencies

for

which

the

dipole

is

not

resonant

if

the

twin

feeders

are

strapped

together

and

connected

to

the

right-hand

*

A’

socket.

In

this

case,

the

shorting

plug

should

be

in

position

since

the

aerial

is

effectively

a

single

wire

arrangement.

The

overall

length

of

a

dipole

is

calculated

by

dividing

the

frequency

in

Mc/s

into

468.

The

result

will

be

in

feet

and

some

idea

of

actual

lengths

can

be

obtained

from

the

figures

for

the

amateur

communication

bands which

are

listed

below.

Band

(Metres)

160

80

40

20

15

10

Freq.

(M¢/s.)

i

oR

7

14

21

28

Length

(tft.)

264

+132

66

33

22

16-5

Connecting

an

External

Loudspeaker

An

external

loudspeaker

can

be

connected

after

taking

out

the

internal

speaker

plugs

at

the

rear

of

the

set

(labelled

L.S.

—

2:5

ohms).

The

external

speaker

should

be

fed

with

standard

twisted

flex

terminated

with

suitable

plugs.

No

transformer

is

required

and

the

speaker

should

be

a

standard

2-5/3

ohm

type.

Both

speakers

can

be

operated

simultaneously

if

their

leads

are

connected

in

parallel

but

there

will

be

some

drop

in

the

volume

level

of

each

speaker.

OPERATION

Once

the

receiver

has

been

correctly

installed

it

can

be

switched

on

by

rotating

the

tone

control

in

a

clockwise

direction

to

operate

the

mains

switch

which

is

ganged

to

it.

A

short

period

will

elapse

during

which

the

valve

heaters

will

reach

operating

temperature

prior

to

the

receiver

becoming

fully

operative.

A

check

should

be

made

that

the

standby

switch

is

in

the

down

position.

The

AGC/BFO

switch

should

be

set

to

*

AGC’

for

telephony

reception

or

‘

BFO’

if

CW

reception

is

required.

In

the

case

of

telephony,

best

AGC

action

will

be

obtained

if

the

RF

Gain

is

fully

advanced.

Under

these

conditions

the

volume

level

is

controlled

by

means

of

the

AF

Gain

at

the

extreme

right-hand

side

of

the

panel.

For

CW

reception

the

AF

Gain

should

be

advanced

and

the

RF

Gain

turned

down

to

prevent

over-

loading

of

the

receiver

on

strong

signals.

A

little

practice

will

result

in

a

natural

balance

being

found

in

the

settings

of

the

two

controls.

The

BFO

Pitch

control

permits

adjustment

of

the

audible

beat

obtained

when

receiving

CW

signals.

The

control

will

normally

be

offset

slightly

to

provide

a

note

of

about

1000

cycles

for

maximum

readability.

The

same

beat

can

be

obtained

at

two

settings

of

the

control

and

it

may

be

found

that

one

setting

gives

less

interference

than

the

other.

If

the

receiver

is

not

required

but

must

be

ready

for

instant

use,

the

standby

switch

should

be

placed

at

standby

(up

position).

Frequency

stability

is

held

within

close

limits

during

standby

periods

since

the

local

oscillator

remains

in

operation

at

all

times.

The

setting

of

the

tone

control

may

be

decided

by

the

quality

required

or

alternatively

by

the

type

of

interference

and

type

of

signal

being

received.

Some

experimentation

with

the

adjustment

of

this

control

will

be

found

invaluable.

In

cases

where

loudspeaker

reception

is

not

convenient,

telephones

can

be

connected

at

the

socket

on

the

panel.

The

speaker

is

automatically

cut

when

the

phone

plug

is

inserted.

All

standard

Broadcast

bands

are

marked

in

red,

Amateur

allocations

in

black.

Dial

settings

can

be

recorded

for

future

reference

by

combining

the

vernier

scale

reading

with

the

setting

on

the

bottom

logging

scale.

A

rar

©

Sit

Ste.

7

L41/C33

112/035

L13/C37

L14/C40 L15/C43

eee

ESS

i"

SHS

\

|

L6iC19 L7IC20

LBIC21

L9/C22

L10/C23

a

Si

NNN

jl

Stay

Lic4

L2icé6 L3/Cc7

L4/C8

LS/C9

U—FUSES

MAINS

L

VOLTAGE

SELECTOR

INPUT

SPEAKER

PLUGS

ul

EARTH

PLUG

Underside

view

of

receiver

SERVICING

INSTRUCTIONS

CAUTION.

The

Model

840C

is

a

universal

type

and

great

care

should

be

taken

when

carrying

out

tests

with

the

cabinet

removed.

When

running

from

AC

supplies

it

is

advisable

to

ensure

that

the

chassis

is

connected

to

the

neutral

pole

of

the

supply.

If

an

isolation

transformer

is

available

this

will

be

found

more

convenient

and

can

be

operated

at

an

output

voltage

of

110V

as

a

further

safety

precaution.

Should

the

receiver

fail

in

operation,

first

check

that

all

external

connections

are

correctly

made

and

also

that

mains

voltage

is

available

at

the

supply

point.

Next

check

the

fuses.

These

are

located

in

insulated

holders

at

the

rear

of

the

receiver

and

are

easily

removed

without

risk

of

electric

shock.

Visual

inspection

will

reveal

whether

or

not

a

fuse

has

blown.

Replacements

should

be

standard

14”

cartridge

types

rated

at

500

mA

(4

Amp).

If

a

blown

fuse

is

changed

and

the

replace-

ment

burns

out

immediately

or

after

a

very

short

period

of

Operation,

it

is

an

indication

that

some

‘internal

component

is

faulty.

In

this

case

the

receiver

should

be

taken

to

the

nearest

EDDYSTONE

Agent

who

will

rectify

the

trouble

at

a

reasonable

charge.

If

it

is

necessary

to

take

the

receiver

to

an

engineer

who

is

not

familiar

with

Eddystone

equipment,

take

this

instruction

sheet

with

the

set.

It

contains

information

which

may

enable

him

to

clear

the

fault

more

rapidly

than

would

otherwise

be

the

case.

Valve

Replacement

All

the

valves

used

in

the

Model

840C

are

easily

accessible

when

the

cabinet

is

removed.

All

except

the

tuning

indicator

have

B8A

bases.

The

pins

on

these

bases

are

equally

spaced

and

correct

location

of

the

valve

in

relation

to

the

holder

is

achieved

by

means

of

a

small

glass

pip

on

the

side

of

the

envelope

base.

This

locates

with

a

retaining

slot

in

the

base

fitting.

Care

should

be

exercised

in

removing

and

replacing

valves

not

to

exert

any

sideways

strain

since

this

could

result

in

fracture

of

the

glass

envelope.

The

visual

tuning

indicator

has

a

miniature

B8D

base

and

is

retained

in

a

small

metal

clip.

_

The

indicator

can

be

removed

by

sliding

it

out

of

the

clip

after

freeing

it

from

the

base.

When

fitting

a

replacement

indicator

it

will

be

necessary

to

trim

the

four

long

lead-out

wires

to

the

same

length

as

the

four

shorter

ones.

The

leads

should

be

carefully

straightened

to

line

up

with

the

sockets

so

that

the

indicator

can

be

plugged

into

its

base.

When

sliding

back

into

the

clip,

make

sure

that

the

‘keyhole’

in

the

indicator

lines

up

with

the

aperture

in

the

scale

plate.

Pointer

Drive

Cord

Replacement

In

the

unlikely

event

of

the

drive

cord

either

breaking

or

slipping

out

of

the

pulley

grooves,

replacement

will

be

much

simplified

(even

when

the

original

cord

is

undamaged)

if

a

new

length

is

obtained.

This

can

be

made

longer

than

the

length

actually

required

(3’

82”)

and

will

therefore

be

easier

to

handle.

Replacement

will

present

no

problems

if

the

following

instructions

are

followed

carefully.

NOTE:

In

these

instructions,

left

and

right

are

as

viewed

from

the

rear

of

the

receiver.

1.

Remove

the

cabinet

after

taking

out

the

four

retaining

screws

at

the

rear.

Take

off

the

old

drive

cord

by

slackening

the

8BA

screws

let

into

the

drive

pulleys.

N

3.

Set

the

tuning

control

so

that

the

tuning

gang

is

fully

meshed.

4.

Secure

one

free

end

of

the

replacement

cord

to

the

8BA

screw

in

the

left-hand

drive

pulley.

Feed

the

cord

through

the

pulley

slot

and

into

the

groove

nearest

the

panel

(cord

leaving

pulley

from

right

to

left).

a

6.

Pass

the

cord

below

the

tuning

indicator,

clockwise

round

the

jockey

pulley

and

across

the

dial

between

the

pointer

guide

rods.

Sufficient

tension

should

be

applied

to

cause

the

jockey

pulley

to

take

up

a

position

one

quarter

of

an

inch

from

the

guide

rod

support

bracket.

7.

Move

the

pointer

to

the

right-hand

end

of

the

guide

rods

(nearest

to

speaker)

and

slide

the

cord

up

and

over

the

retaining

spring.

The

spring

may

be

depressed

slightly

to

simplify

this

operation.

8.

Take

the

cord

round

the

right-hand

guide

pulley

and

across

towards

the

right-hand

drive

pulley.

9.

Lay

the

cord

in

the

groove

nearest

to

the

panel

and

wind

three

complete

turns

in

an

anti-clockwise

direction.

Ensure

that

the

cord

lies

snugly

in

the

pulley

grooves

and

that

the

tension

is

maintained

at

the

jockey

pulley.

10.

Holding

the

free

end

of

the

cord

reasonably

tight.

rotate

the

tuning

control

to

unmesh

gang.

Approximately

three

turns

of

the

control

will

be

required

and

this

Operation

will

place

the

tie-off

screw

in

the

drive

pulley

in

an

accessible

position.

Il.

Press

the

cord

into

the

pulley

slot,

round

8BA

screw

and

secure.

12.

Check

that

the

jockey

pulley

is

correctly

tensioned

and

then

cut

off

the

surplus

cord

at

the

right-hand

drive

pulley.

13.

Move

gang

to

tully

meshed

position

and

set

pointer

to

“O°

on

logging

scale.

Check

drive

for

free

and

normal

Operation

and

correct

vernier

tracking.

14.

Check

the

dial

calibration

against

a

suitable

frequency

standard.

15.

Replace

cabinet

and

fit

retaining

screws.

Cleaning

the

Scale

and

Scale

Window

1.

Locate

the

three

screws

disposed

vertically

at

each

end

of

the

rear

of

the

scale

plate.

Take

out

the

centre

screw

at

each

end

and

remove

the

small

side

castings

at

the

extremities

of

the

glass

window.

2.

Remove

the

four

countersunk

screws

along

the top

edge

of

the

panel

and

take

out

the

white

scale

suppor.

3.

The

glass

is

now

free

and

can

be

removed

by

lifting

up

and

tilting

back

slightly.

Re-alignment

—

General

In

the

unlikely

event

of

a

complete

re-alignment

being

necessary

the

following

instructions

should

be

followed

in

full.

In

the

more

usual

case

of

partial

alignment

required

to

compensate

for

ageing

components,

etc.

the

relevant

instructions

can

be

extracted

as

required.

It

should

be

stressed

that

alignment

adjustments

should

not

be

tampered

with

unless

there

is

a

clear

indication

that

re-

alignment

is

in

fact

required.

Adjustment

should

only

be

carried

out

by

fully

skilled

technicians

equipped

with

adequate

test

equipment.

Re-alignment

of

the

[F

Transformers

and

BFO

First

disable

the

local

oscillator

by

shorting

out

the

forward

section

of

the

tuning

gang

(Clic).

Set

the

Range

switch

to

5,

tuning

to

S00

kc/s

and

the

RF

and

AF

Gain

conirols

to

maximum.

The

Tone

control

should

be

rotated

fully

clockwise

and

the

AGC/BFO

switch

set

to

AGC

to

disable

the

BFO.

The

AGC

line

should

be

connected

to

chassis

either

at

S2a

or

at

Tl.

Connect

the

signal

generator

output

leads

via

0-01

mfd

isolating

capacitors

to

the

Mixer

section

of

the

tuning

gang

(Cl1b).

Unplug

the

internal

speaker

connections

at

the

rear

and

connect

an

output

meter

matched

to

2:5/3

ohms

in

their

place.

Allow

some

10

minutes

for

warming

up

and

then

tune

the

signal

generator

to

450

ke/s

with

modulation

at

a

depth

of

30%

(400

c/s).

Adjust

the

attenuator

for

a

convenient

output

and

then

peak

the

cores

in

Tl

and

T2

for

maximum

reading

on

the

meter.

It

should

be

noted

that

the

cores

in

TI

are

set

to

the

outer

peak

and

those

in

T2

to

the

inner

peak.

increase

the

attenuation

as

alignment

proceeds

and

ensure

that

on

completion

a

sensitivity

of

at

least

35uV

is

obtained

for

an

output

of

SOmW.

If

this

figure

cannot

be

achieved

some

improvement

may

be

forthcoming

if

V3

is

changed.

If

a

spare

UAF42

is

not

available

try

changing

with

V6.

Once

the

IF

transformers

are

peaked

to

the

generator

frequency,

cut

the

modulation,

reconnect

the

loudspeaker

and

place

the

AGC/BFO

switch

at

BFO.

Set

the

BFO

Pitch

control

so

that

the

white

index

line

is

at

“‘

12

o’clock’’

and

then

adjust

the

core

setting

of

L1I6

for

zero

beat.

The

link

connecting

the

AGC

line

to

chassis

can

be

left

in

place

so

that

the

receiver

can

be

operated

with

both

BFO

and

AGC

‘off’

(switch

at

AGC)

while

carrying

out

RF

alignment.

The

signal

generator

leads

should

be

removed

from

the

Mixer

section

of

the

tuning

gang

as

should

the

temporary

short

on

the

oscillator

section.

RF

Alignment

The

first

step

in

re-alignment

of

the

RF

Section

of

the

receiver

is

a

check

on

the

accuracy

of

the

dial

calibration

to

ascertain

whether

adjustment

is

required

in

the

oscillator

stage.

This

check

is

best

carried

out

using

a

crystal

controlled

harmonic

generator

or

frequency

meter

since

the

accuracy

of

the

average

signal

generator

is

less

than

the

scale

accuracy

of

the

receiver

(0-5%).

The

marker

signal

should

be

introduced

at

the

aerial

input

and

checks

made

at

100

kc/s

intervals

throughout

each

of

the

five

ranges.

If

the

indications

are

that

calibration

accuracy

is

outside

the

limit

quoted,

re-alignment

of

the

oscillator

tuned

circuits

will

be

required.

Standard

tracking

procedure

should

be

adopted

using

the

alignment

points

and

adjustments

listed

in

the

table

below.

Trimming

Padding

Frequency

|

Trimmer

|

Frequency

Core

28

Mc/s

14

Me/s

Cul

12

Mc/s

3-8

Me/s

L12

5-6

Mc/s

2:7

Mc/s

L13

2-4

Mc/s

1-25

Me/s

Li4

1060

ke/s

520

ke/s

The

oscillator

tracks

“‘

high’

on

all

ranges.

On

Ranges

|

and

2

it

may

be

possible

to

set

the

oscillator

on

the

low

side

of

the

signal

and

a

check

should

be

made

to

ensure

that

the

response

with

minimum

capacity

or

minimum

inductance

is

selected.

Care

should

be

taken

to

balance

any

interaction

between

the

trimming

and

padding

adjustments

which

should

-

be

repeated

at

least

twice

to

achieve

the

desired

accuracy.

Once

the

scale

calibration

has

been

checked

and

corrected

if

necessary,

alignment

of

the

RF

and

Mixer

circuits

can

be

commenced.

The

output

meter

should

be

connected

to

provide

a

Clearer

indication

of

maximum

output

than

is

possible

with

the

speaker

alone.

The

receiver

input

impedance

is

75

ohms

and

the

signal

generator

(modulated

30%

at

400

c/s)

should

be

arranged

to

match

this

impedance

when

connected

to

the

aerial

input

socket

at

the

rear.

Alignment

adjustments

are

made

at

the

following

frequencies

tuning

for

maximum

output

with

the

appropriate

trimmer

or

core.

As

with

oscillator

alignment,

each

adjustment

should

be

repeated

at

least

twice

to

reduce

errors

due

to

interaction.

Padding

Mixer

RF

|

Mixer

l

C19

14

Mc/s

Li

L6

2

2

Mc/s

C20

|

5:8

Mc/s

|

L2 L7

3

5-6

Mc/s

|

C7

|

C2L

|

2:7

Me/s

|

L3

L8

4

2-4

Mc/s

|

C8

|

C22

|

1-25

Mc/s}

L4

L9

5

!

1060

ke/s

|

C9

C23

520

kecfs

LS

LIO

TABLE

OF

VOLTAGE

VALUES

The

following

voltage

readings

will

be

of

use

during

servicing

Operations.

In

each

case,

the

first

reading

is

that

obtained

using

a

meter

of

20,000

ohms/volt

;

the

second

600

ohnis/volt.

A

variation

of

+5%

should

be

allowed.

|

Stage

Anode

Cathode

VI

li2v/tiov

|

67v/45V.

|

L-av/i-3v

Triode

|

90V/80V

=

cay

enacted

Sneie

titel

|

Hexode

|

tisvittov

|

saviov

|

Liv/tiv

vz.s«dsdisw/ttav.

|

62v/4sv.

|

L-sv/iav

|

V4

50V/15V

a

V5

asviiov

|

22v/10V.

|

1-3V/0-7V

V6

~~

62v/57V_

|

62V/57V

me

v7

10SV/105V

|

LISV/LISV

|

6-5V/6-0V_

V8

135V/135V"

it

7

AC.

All

other

readings

are

D€

taken

between

the

point

indicated

and

chassis.

Readings

taken

on

Range

S,

gains

at

maximum,

BFO

and

Standby

to

‘ON.’

Mains

240V.

HT

Voltage

..

LI5SV

Total

Current

280mA.

HT

Current

..

65mA

Manufacturers

:

Telephone:

PRIORY

2231/4

STRATTON

&

9,

ALVECHURCH

ROAD,

BIRMINGHAM,

31

Cables:

STRATNOID,

BIRMINGHAM

Ll

Ls

Princed

in

England

H.E.J.

6.61

‘

sl

cane

ry

|

L6/C19

L7/C20

L8/C21

L9/C22

L10/C23

L1ic4

L2/;C6

L3/C7 L4/C8

LS5/C9

i

L—FUSES

VOLTAGE

SELECTOR

\

EARTH

PLUG

SPEAKER

PLUGS

Underside

view

of

receiver

6

R.

F.

AMPLIFIER

UAF42

SHORTING

r--@E

PLUG

r----@E

ALL

SECTIONS

OF

$1

ARE

=>

+

SHOWN

AT

RANGE

2

CONNECTIONS

FOR

CONNECTIONS

FOR

ALL

TRIMMERS

ARE

3-30pF

UNBALANCED

INPUT

BALANCED

INPUT

ar

ais

C20

be

N

Cci2

see

-S'o>

Co75

VAL

I

ys

100p

L

yO

C21

R3

470k

a

Lf&

7

2

eae

Cj1i0:|Cila

1-5

=

20p

‘|

366p

1

e

'

‘

«

«

«

«

.

‘

‘

«

«

e

.

-005

CHASSIS

EDDYSTONE

840C

RESISTORS.

CABINET

R1

..

2:2

Megohms.

R2

..

2:2

Megohms.

R3

..

0:47

Megohm.

R4

..

47,000

ohms.

RS

..

1,000

ohms.

Ao

a

or

ohne.

45%.

ae

ys

hms.

TABLE

OF

VOLTAGE

VALUES

R8

|.

0:47

i

eeokns:

RI

..

~+47,000

ohms.

R10

..

22,000

ohms.

Stage

Cathode

R11...

1,000

ohms.

eT

at

Basel

¥

1-4V/1-3V

+.

4

ohms.

v1

_|

1lav/tiov

|

67Vv/4s

/

aa

Coenen

a

|_Teiode

|

90v/80v

=

Rie

1.

47,000

chs.

ps

TF

cc

caaen

ene

e

R17

..

22,000

ohms.

Hexode

LISV/110V

62V/40V

1-1V/1-1V

R18

..

330

ohms.

45%

POTS

Sect,

praca

R19...

0-47

Megohm.

V3

LISV/114V

|

62V/45V

1-5V/1-3V

R20

..

0:47

Megohm.

bee

Ae

Lt

aesiis.

a

oe

:

egohms.

v4

SOV/15V

R23:

0-4

Megohm.

4

ss

aA

"

V5

asv/iov

|

22v/10V

|

1-3V/0-7V

Ras

7.

O47

Mewonm.

——————_—-

———

R26

..

0-68

Megohm.

V6

62V/S57V

62V/57V

—_

R27...

22,000

ohms.

ae

|

ae

wi

vig

Hp

stig

V/LISV

|

6:5V/6-0

-

.000

ohms.

v7

10SV/105V

|

115V/I1

R30

et

ate

3

im

31...

10,000

ohms.

v8

135V/135V*

R32...

0-1

Megohm.

R33...

47,000

ohms.

FREQUENCY

CHANGER

I.

F.

AMPLIFIER

AND

AGC

UCH42

UAF42

R9e

C26

c32884400p

47k

=

Tos

2s

L,

ences

34312

jon

Sif

Oo.

C25

C34

883625,

=

%

nCaTlp

1638]

ro

1

100p

aL

=H

Sy

od

)

13

eat

10p

C36

WE1625p

BnC40[y

[cai

914

Cu

20p

Cl24:|Ci11b

C39

881200p

i

S15

-

BnC43)y

[c44

ga

lg

P|

36°?

|

saccao

3

15

Bu

Sie

10p

+

|

366p

:|

(c

‘|

AGC

‘|

le

C42n™

400p

cag

|cs0

sR18

=

R14

:

:

“05

220

‘|

s2ay

‘O05

|-25

}330

%*

GANGED

TO

TONE

CONTROL

MAINS

*

MAINS

R34...

0-1

Megohm

1

watt.

rans

R35

..

2:2

Megohms.

OR

R36

..

0:47

Megohm.

R37

..

150

ohms.

200/250V

R38

..

550

ohms.

tapped

at

100

ohms.

“SA

VOLTAGE

and

350

ohms.

0-2

amps.

*%*

MAINS

EARTH

SELECTOR

R39

..

100

ohms.

45%

4

watts.

R40

..

CZ1

Thermistor.

R41...)

8

ohms.33

watts.

NOTE.

All

resistors

are

10%

4

watt

unless

stated

otherwise.

POTENTIOMETERS.

C1S..

0:05

mfd.

Metallised

Paper

+20%

250V.

DC

wkg.

RV

C16...

20

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

a

a%

Eg

a

carbon.

CAT

na

6

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

Rua

en

'hoo

a

ge

;

ci8

..

6

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

as

A

ohms

carbon

with

double

pole

switch.

C19

..

3-30

pf.

Air

Trimmer.

20

..

3-30

pf.

Air

Trimmer.

CAPACITORS.

C21

1.

3-30

pf.

Air

Trimmer.

CT

as

1800

pf.

Disc

Ceramic

Isolacor.

C22...

3-30

pf.

Air

Trimmer.

G2

2a

1800

pf.

Disc

Ceramic

lsolator.

C23

..

3-30

pf.

Air

Trimmer.

C3...

0-005

mfd.

Disc

Ceramic

900V.

OC

wkg.

C24

..

12

pf.

Tubular

Ceramic

410%

350V.

DC

wkg.

G4

an

3-30

pf.

Air

Trimmer.

C25...

100

pf.

Tubular

Ceramic

410%

350V.

DC

wkg.

CS

acs

10

pf.

Silvered

Mica

410%

350V.

OC

wkg.

C26

..

0:05

mfd.

Mecallised

Paper

+20%

250V.

DC

wkg.

C6:

3-30

pf.

Air

Trimmer.

C27

..

0-05

mfd.

Metallised

Paper

+20%

250V.

DC

wkg.

oe

—

3-30

pf.

Air

Trimmer.

C28...

100

pf.

Tubular

Ceramic

£10%

350V.

DC

wkg.

C8

as

3-30

pf.

Air

Trimmer.

C29...

100

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

CP

as

3-30

pf.

Air

Trimmer.

C30

..

0-01

mfd.

Tubular

Ceramic

+10%

350V.

DC

wkg.

C10...

20

pf.

Silvered

Mica

+10%

350V.

OC

wkg.

C31

..

0:05

mfd.

Metallised

Paper

+20%

250V.

DC

wkg.

C11

..11-5-366

pf.

Three

Gang

Tuning

Capacitor.

C32

..

4400

pf.

Silvered

Mica

+1%

350V.

DC

wkg.

C12...

100

pf.

Tubular

Ceramic

+10%

350V.

OC

wkg.

C33

..

3-30

pf.

Air

Trimmer.

C13...

0:05

mfd.

Metallised

Paper

+20%

250V.

DC

wkg.

C34

..

3625

pf.

Silvered

Mica

+1%

350V.

DC

wkg.

C14...

0-05

mfd.

Metallised

Paper

+20%

250V.

DC

wkg.

C35...

3-30

pf.

Air

Trimmer.

TUNING

INDICATOR

DM71

DETECTOR

AND

AUDIO

UAF42

C68

R27

22k

BEAT

OSCILLATOR

UAF42

C66

|C67

-O1

|-O1

R32

100k

R28

220k

2

4

|

6

If

ele

7

@

mw

1

8

qh

le

ele

aye

oye

le

oye

HE

AF

GAIN

in

ole

ate

pe

ape

C56

RV1

R24

-Lcé62

R29

RF

GAIN

-O1

=e

|S

2Qk

25

22k

RV2

470

470

500k

k

k

v8 v2

vi

V3

V4

R39

R40

R38

‘

100

¢cZ1

200

110,

|

_

rey

a.

Gan

2509

i.

91200V

is

$

j

100Q

V7

v6

v5

‘

*-[-%_

230v

C36...

1625

pf.

Silvered

Mica

+1%

350V.

DC

wkg.

CS7

..

0-01

mfd.

C37...

3-30

pf.

Air

Trimmer.

C58

0-05

mfd.

C38

..

10

pf.

Silvered

Mica

+10%

350V.

DC

wkg.

C59

8

mfd.

C39'..

1200

pf.

Silvered

Mica

+1%

350V.

DC

wkg.

C60

500

pf.

C40.

3-30

pf.

Air

Trimmer.

C61

3

pf.

C41...

20

pf.

Silvered

Mica

+10%

350V.

DC

wkg.

262

25

mfd.

C42

400

pf.

Silvered

Mica

+1%

350V.

OC

wkg.

C63.

100

pf.

C43

3-30

pf.

Air

Trimmer.

Cé4

3-11

pf.

C44

20

pf.

Silvered

Mica

+10%

350V.

DC

wkg.

C65

100

pf.

C45

10

pf.

Tubular

Ceramic

+10%

350V.

OC

wkg.

C66

0-01

mfd.

C46

100

pf.

Silvered

Mica

+2%

350V.

DC

wkg.

C67

0-01

mfd.

C47

100

pf.

Silvered

Mica

2%

350V.

DC

wkg.

C68

0-01

mfd.

C48

..

0-05

mfd.

Metallised

Paper

+20%

250V.

DC

wkg.

Cé9

0-05

mfd.

C49

..

0:05

mfd.

Metallised

Paper

+20%

250V.

OC

wkg.

C70

0-05

mfd.

CSO

..

0-25

mfd.

Metallised

Paper

+20%

150V.

DC

wkg.

C71

0-1

mfd.

Cs1

100

pf.

Silvered

Mica

+2%

350V.

DC

wkg.

C72

0-01

mfd.

C52

100

pf.

Silvered

Mica

+2%

350V.

DC

wkg.

C73

ee

25

mfd.

C53

20

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

C74...

1800

pf.

C54

100

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

C75

..

32+32

mfd.

CSS

....

100

pf.

Tubular

Ceramic

+10%

350V.

DC

wkg.

C76-..

0-005

mfd.

C56

..

0-01

mfd.

Tubular

Paper

+20%

150V.

DC

wkg.

C77

..

0-005

mfd.

STANDBY

AUDIO

OUTPUT

UL41

HT

RECTIFIER

UY41

150

Tubular

Ceramic

+20%

350V.

DC

wkg.

Metallised

Paper

+20%

250V.

OC

wkg.

Tubular

Electrolytic

275V.

DC

wkg.

Moulded

Mica

+10%

350V.

DC

wkg.

Tubular

Ceramic

+4

pf.

350V.

DC

wkg.

Tubular

Electrolytic

25V.

DC

wkg.

Silvered

Mica

+10%

350V.

DC

wkg.

Air

Spaced

Variable.

Silvered

Mica

+10%

350V.

DC

wkg.

Tubular

Ceramic

+20%

350V.

DC

wkg.

Tubular

Ceramic

+20%

350V.

DC

wkg.

Tubular

Ceramic

+20%

350V.

DC

wkg.

Metallised

Paper

+20%

250V.

DC

wkg.

Mecallised

Paper

+20%

250V.

DC

wkg.

Metallised

Paper

+20%

600V.

DC

wkg.

Tubular

Ceramic

+20%

350V.

DC

wkg.

Tubular

Electrolytic

25V.

DC

wkg.

Disc

Ceramic

lsolator.

Tubular

Electrolytic

350V.

DC

wkg.

Disc

Ceramic

900V.

DC

wkg.

Disc

Ceramic

900V.

DC

wkg.

Table of contents

Other Eddystone Receiver manuals

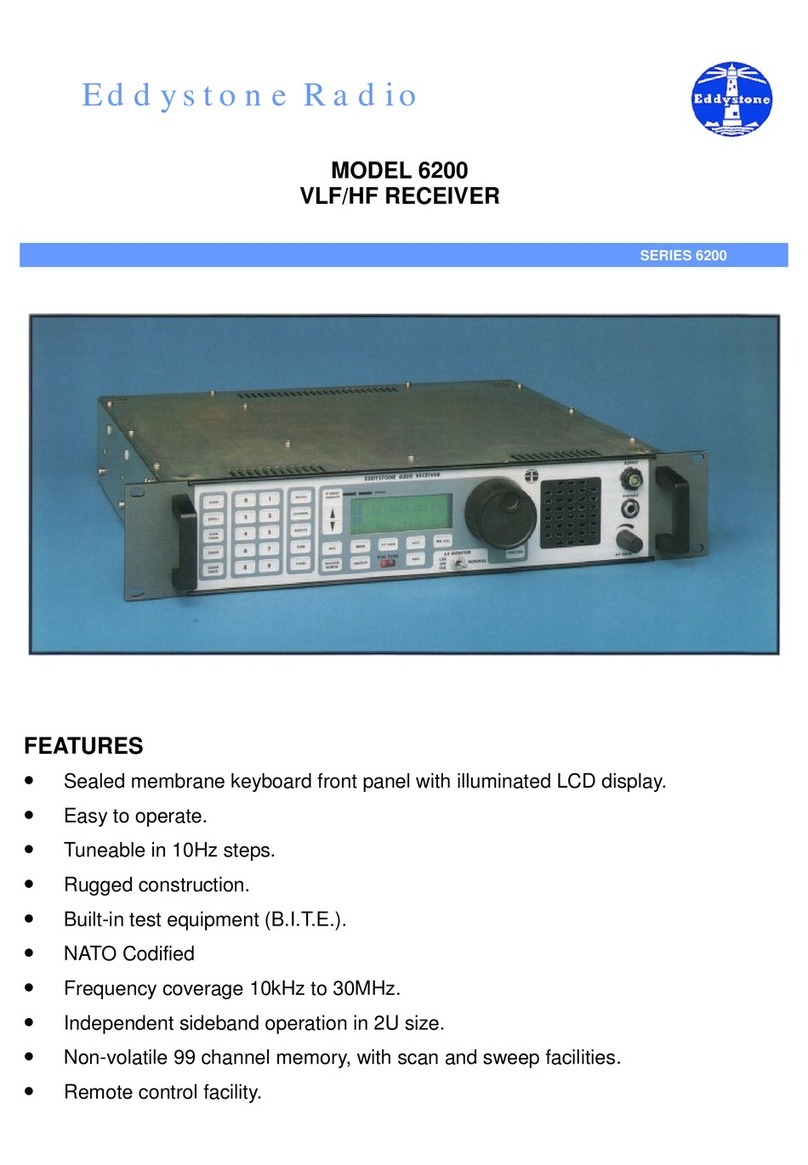

Eddystone

Eddystone 6200 Owner's manual

Eddystone

Eddystone 770R User manual

Eddystone

Eddystone 990R User manual

Eddystone

Eddystone 6200 User manual

Eddystone

Eddystone 1990R/2-S User manual

Eddystone

Eddystone 990R User manual

Eddystone

Eddystone 659 User manual

Eddystone

Eddystone Short Wave User manual

Eddystone

Eddystone 880 User manual

Eddystone

Eddystone 1590 User manual