Eddystone Short Wave User manual

SHORT WAVE RECEIVERS AND TRANSMITT

EDDYSTONE

SHORT WAVE MANUAL

No. 5

All the sets and equipment described in this Manual have been subjected to thorough tests and trials and can

be relied upon to give excellent results, if built exactly to the instructions given. Should difficulties be ex-

perienced, other than from faulty construction or the substitution of different components, we shall be glad to

help, but to avoid lengthy correspondence, we ask constructors to make a careful check of the equipment before

writing us. Finding out the cause of one's own troubles is, moreover, not only a reason for self-satisfaction

but is also highly instructive.

" Eddystone " components are available through selected Registered Retailers in most areas. In case of any

difficulty, you are invited to write for the name and address of your nearest stockist.

CONTENTS

BAND -SPREAD ALL DRY FOUR RECEIVER .. Page i

V.H. FREQUENCY METER ..

. . I3

SIXTY MEGACYCLE. xs WATT TRANSMITTER ,.

R5

9 f

FIVE -TEN METRE. 5 -VALVE CONVERTER .. , f io

TWO VALVE PRE -SELECTOR .. .. .. ..91 ,xl

28 MEGACYCLE C.W. AND TELEPHONY TRANSMITTER.. .. is

COMPONENT LIST AND PRICES .. .. Inside Back Cover

INT. OCTAL .

VALVE BASE DATA

B 9 G. AM. 7 PIN.

OCTAL BASED VALVES.

MSHDGiG2G3AK

Metallising.

Shield.

Heater.

Diode.

Control Grid.

Screen Grid.

Suppressor Grid.

Anode.

Cathode.

Valve Pin 1234567

H

H

8

K

Top Cap

EF 36

EF 39 M

-

HAG2 G3 -GI

L63

EC31 HA-GI K-

EL35

EL37

6V6 MHAG2 GI H

GI

HG3

H

HG3

K(G3) ---

0VO4-20

DF33

HGI

H

K, G3, S G2 H.C.T. Connect to

Shield H

Cl

--

A

-

GI-

AG2 -

DAC32

DL35

HA-D

HAG2 G1

BRITISH 9 -PIN BASED VALVES.

Valve

EF 50

EF 54

EC 52

OVO4-7

1

H

H

H

H

2345 6

K

GI-

7

GI

S

--

GI

8 9

G2 A G3 S S

S

--

S

H

AG2 K, S. G3 S H

GI K.A -H

AG2 G2 SKH

AMERICAN 7 -PIN BASED VALVE.

Valve 123 4

I

5 6 7 Top Caps.

4074A HGI K

I

GI HA

2EDDYSTONE SHORT WAVE MANUAL

in the rear of the cabinet to allow the aerial to be

connected when cabinet and chassis are assembled.

WIRING.

The wiring throughout, except for the screened

lead to V3 and possibly the battery leads, may be

carried out with 20 s.w.g. tinned copper wire en-

closed in insulating sleeving. All R.F and detector

circuit wiring must be kept as short as possible and

this point applies very particularly to the top grid

of the DAC32 detector valve. Both the grid con-

denser C8 and the grid leak R5 should be soldered

extremely close to the top cap - otherwise static

hum and other undesirable effects may be en-

countered.

The top cap of Vi and the stator of CI are

connected to a tag on the midget insulator, from the

underside of which A. wire is taken through the

chassis to pin 4 of the coil base.

Similarly, the grid condenser C8 and the

stat9rs of both C2 and C3 are connected to the other

midget insulator and detector coil socket. All

tuning condensers are earthed with short leads from

the tags provided to tags fitted under the bracket

bolts.Resistors Rio and Rig and condenser Cm are

soldered to the group board and the associated inter-

connections made before the board is fixed to the

rear of the chassis. The other small components are

held in the wiring, 5 -way tag strips being fixed on

available projecting bolts, for anchoring purposes and

to enable H.T wiring, etc., to be commoned up.

C4 and Cie are soldered directly from the appro-

priate valve pins to an earth tag, and condensers

C5 and C7 similarly from the detector coil base.

The double pole switch connects the L.T and

H.T batteries simultaneously. If a non self -shorting

telephone jack is employed, be careful not to dis-

connect the telephones whilst the set is working.

L.T leads are taken up through the chassis from the

switch and a chassis earthing tag and H.T leads

from the switch and the right hand tag strip to the

batteries clipped to the rear of the chassis.

Fig. 2. Illustrating the lay -out of the receiver. Due

to the addition of side brackets, it is necessary to trans-

pose the positions of the batteries.

Fig. 3. Showing the mounting of components on the

underside of the chassis.

OPERATION.

Before connecting the H.T battery, ensure

that the correct voltage is shown across the filament

pins (2 and 7) of any one valve, to avoid possible

damage through an inadvertent error in wiring up.

On advancing the reaction control from mini-

mum, a point will be reached at which oscillation

commences, indicated by the usual slight increase

in noise. The receiver is most sensitive when just

oscillating - advancing the reaction control too

far will cause violent oscillation. The R.F tuning

condenser should be kept in tune with the detector

stage - signals will increase in 'strength consider-

ably at the proper setting.

The frequency ranges, band -spread of amateur

bands, etc., are set out in the table below and close

agreement will be found in a receiver built to the

layout and instructions given above. In the case

of the 6BB coils; oscillation ceases at approximately

28° on the band -set dial, due to the inductance

capacitance ratio becoming too low but there is

still an overlap with the 6LB coil, As will be seen,

the coverage is complete from approximately 35

Mc/s. to 990 Kc/s., using the six coils specified.

The amount of bandspread on each amateur band is

fully adequate and makes the receiver a pleasure to

handle. The noise level is extremely low and weak

signals can be tuned in, held and read with ease.

An earthing terminal, on the rear of the chassis,

will be an asset but, to be effective, the earth lead

itself must be short, particularly when the receiver

is being operated on the higher frequencies.

The aerial employed will, of course, depend upon

local circumstances. For general use, a wire of a

length between 5o and too feet, suspended as high

and clear as possible, connected directly to the aerial

socket, will prove very effective on all ranges. For

restricted frequencies, e.g., any one amateur band,

an aerial cut specially to the appropriate length and

fed to the receiver by either low or medium im-

pedance feeder will ensure particularly good recep-

tion on that particular frequency band, although

directional effects may be noticeable.

The consumption from the batteries is very

low - 25 amperes L.T and 8.5 milliamperes H.T.

EDDYSTONE SHORT WAVE MANUAL 3

PANEL OF FREQUENCIES.

Frequency Range Amateur Bands. Frequency Range Amateur Bands.

Coil. Coil.

Max. Min. Band Set Frequency Band Max. Min. Band Set Frequen Band

Mc/s. Mc/s. Dial. Kc/s. Spread Mc/s. Mc/s. Dial Kc/s. Spread

Dial. Dial.

6 BB 35.6 27.2 18° 30000 15° f6 It 8.8 3.65 13' 7300 30°

(28°) 28000 89° 7000 60°

6 LB 27:4 12 680 14400 15° 6 W 4.65 192 13' 4000 0°

14000 88° 3500 100'

6 Y I15:85 7.05 6 P 2.45 99 16° 2000 10°

1800 90°

CHART OF POSITIO

CHASSIS (looking at front).

Top Chassis Screen 5' high, 7' long plus 1"

fixing flange, mounted 64' from L.H.

side, 94' from R.H. side, fixing flange

on right.

Sub Chassis Screen 2" high, 7' long plus 1"

flange, mounted 710 from R.H. and 84'

from L.H. side.

Adjustable brackets all 24" from front

(fixing centres). R.F. condenser

bracket 2' from L.H. side, detector

bracket 3' from R.H. side, Band spread

bracket 14" to right of- s!*een (i.e.,

dead central). All condensers 24 up

from chassis top.

NS OF MAJOR COMPONENTS, DIMENSIONS, ETC.

V.4 valveholder

from front. lir from R.H. side, 34" R.F. Gain Control 6' from L.H. edge (2' dia.

hole).

V.3 valveholder

from front. 11- from R.H. side, If" Switch 31' to left of R.F. Control (1" dia.

hole).

V.2 valveholder

from front. 51' from R.H. side, ir Jack 31' to right of Reaction Control (

dia. hole).

V.1 valveholder

from front. 51' from L.H. side, 11" Aerial Socket 5" from L.H. side.

1 General Purpose Chassis Eddystone No. 641

1 General Purpose Cabinet .. 609

2 Metal Handles 8' .608

2 Microdensers, 100 pF (Cl. 3) .. 1130

1 Air Dielectric Trimmer, 15 pF (C2) 580

1 Full Vision S/M Dial

2 Precision S/M Dials, 2" Silver ..

2 6 -pin Coil Bases ..

2 6 -pin Coils, 6BB

2 6 -pin Coils, 6LB

2 6 -pin Coils, 6Y

2 6 -pin Coils, 6R

2 6 -pin Coils, 6W

2 6 -pin Coils, 6P

1 R.F. Choke ..

2 Skirt Knobs 11'

3 Large Flexible Couplers

598639964959959959959959959

1010

2416

1009

R.F. coil base 54' from L.H. side, 34' from

front.

Det. coil base 54' from R.H. side, 31" from

front.

(Both are fitted with pins 1 and 4 to the

right).

Reaction control 6" from R.H. edge (1' dia.

hole). LIST OF PARTS.

3 Adjustable Insulated Brackets .. 1007

2 Midget Stand-off Insulators .. 1019

1 Valve type DF 33 (V1) Mullard

2 Valves type DAC 32 (V2, 3) .. Milliard

1 Valve type DL 35 (V4) Mullard

4 Octal Ceramic Valveholders.

1 Intervalve Transformer 3.5: 1 Niclet Varley

1 D.P.S.T. Toggle Switch, S.88 Bulgin

1Insulated Closed Circuit Jack .. Igranic

1 Aerial Socket type L373/Skt. Belling -Lee

1 Aerial Plug type L.373/P.8 Belling -Lee

3 Mica Condensers :001 mF (C4, 5, 13).

2 Mica Condensers -0003 mF (C7, 12).

1 Ceramic Condenser, 100 pF (C8).

1 Ceramic Condenser, 20 pF (C15).

1 Paper Condensers -5 mF (C11).

1 Paper Condenser -01 mF (C9).

PANEL.

Three 4' holes for dial bosses, plus two 4BA.

holes per dial, vertically above and

below large hole and 1 r apart. Holes

for jack, switch and potentiometers as

for chassis. Aerial socket and earth

terminal holes at rear of cabinet.

2 Paper Condensers -1 mF (C10, 14).

1 Electrolytic Condenser 8 mF (C6)

1 Resistor, 4 watt, 5,000 ohm (R3).

2 Resistors, 4 watt, 1,000 ohm (114, 12).

2 Resistors, 4 watt, 2 megohm (R5, 9).

1 Resistors, 4 watt, 50,000 ohm (R6).

2 Resistors, 4 watt, 20,000 ohm (R2, 8).

1 Resistor, 4 watt, 100,000 ohm (RIO).

1 Resistor, 4 watt, 10,000 ohm (R11)

2 Potentiometers, 100,000 ohm (RI, 7).

1 x 5 -way Group Board ; 3 x 5 -way Tag

Strips.

NOTE.-The stated values of resistance

are not critical and the nearest preferred

value, 20% tolerance, will be suitable.

V.H. Frequency Meter

INTRODUCTION.

Some method of measuring the actual operating

frequency is essential when working in the five metre

amateur band. The frequency meter described

below fulfils this function and it also has several

other uses which render it a valuable addition to any

amateur station. It illustrates one use of the small

diecast metal box - No. 65o - for which many

other applications can be found.

Basically, the instrument is of the absorption

type but with the addition of a valve and meter,

which combination gives a more positive and reliable

indication than is possible with the flashlamp bulb

usually employed. This latter method calls for

power to light the lamp and results in very flat tuning,

which drawbacks are absent in the present design.

CIRCUIT.

Referring to the complete circuitdiagram shown

in Fig. I, Li, CI, and C2 form the tuned circuit,

the 6o to 56 megacycle range being covered from 19

to 45 degrees of the dial. Coupling to it is accom-

plished by taking a lead from a point on the coil one

turn from the earthy end to a midget lead -through

4EDDYSTONE SHORT WAVE MANUAL

insulator, to the external terminal of which a short

pick-up rod is fitted.

Connection to the valve is made from an

approximate centre tap on the coil via a to pF

ceramic condenser, thus keeping the tuned circuit

loading low. The indicating meter, a Hobut minia-

ture type reading up to Soo micro -amperes, is shunted

across the valve with a Cat. No. tot I choke in series.

Two versions of the meter have been tested.

The one shown in the photograph, Fig. 2, utilises

a type 1T4 miniature 1-4 volt filament valve (Mullard)

used as a diode with all electrodes, other than the

filament, strapped together. The use of this valve

enables a small cell to be included within the box,

making the instrument completely self-contained.

The circuit employed is given in Fig. i(a).

Improved results are obtainable if a television

type diode (Mullard E.Ar5o) is substituted for, the

1T4, but in this case, it is not possible to include a

heater battery inside the box. Two terminals, one

insulated, are fitted to the lid of the box for con-

nection to an external L.T. supply which may con-

veniently be a 6.3 volt supply from a mains trans-

former indoors and three or four small dry cells in

series for use outdoors. The circuit in this case

becomes the one shown in Fig. t (b).

CONSTRUCTION AND WIRING.

Enclosing the instrument in: the Cat. No. 65o

metal box, which is complete with a close fitting

flanged lid, assists in the maintenance of frequency

stability and calibration and eliminates the effects

of body capacity and other unwanted external

influences. Because of the restricted space, the

components must be located with care, otherwise

the construction is straightforward.

The II" hole for the meter is located 1" from

the left hand side and t i" from the top, looking at.

the face of the box.

The tuning condenser requires a '4" hole 1" from

the right-hand side and t 14" from the top. The

switch is fitted to the left-hand top corner of the box,

near the lid, so that it is clear of the meter terminals.

Immediately below the meter is a midget insulator,

to a tag on which are anchored condenser C3, one

end of the RF choke and the wire to the valve anode.

FIG .I (a).

Circuit diagram of VHF Frequency meter employing

a 1T4 1.4 volt valve.

The aerial insulator is mounted through the top

side, 1" from both side and front, a -" hole being

necessary. The small index strip for the dial should

be fixed at an early stage in the construction. A

small metal strap holds in place the filament cell.

When all holes in the box have been made, first

fit the valve -holder in place. It is located 2i" from

each edge and as close to the face of the box as pos-

sible. Two I" 6 BA bolts with spacing pieces keep

the valve -holder away from the metal side. Loose

leads should be soldered to the valve pins (in the case

of the IT4, the GI, G2, and anode pins are corn-

moned) for connection to the appropriate points

later. The other components are then mounted,

leaving the coil until the valve and meter wiring has

been completed. The coil, directly across the pins

of which is connected C2, is soldered to one stator of

the variable condenser and to an earthing tag bolted

to the side of the box. Finally, C3 and the aerial

lead -through connections are completed.

CALIBRATION.

Before calibration, ensure that the lid is screwed

down and fit a 12" length of stiff copper wire to the

external terminal of the midget insulator. If

assistance is available from amateurs using trans-

mitters of known frequency, calibration can be

carried out quickly. Otherwise it will be necessary

to use an existing transmitter, or build a small

oscillator, with which to excite a Lecher wire system.

Space does not permit of a full description of this

method here and the reader is referred to the " Eddy-

stone " Ultra Short Wave Guide (published before

the War) and to the R.S.G.B. Amateur Radio Hand-

book. The frequency meter itself may be employed

to determine the position of the antinodes along the

Lecher wires.

When a number of dial readings against fre-

quencies have been secured, a graph should be drawn

and kept for use with the instrument.

USING THE FREQUENCY METER.

To measure the frequency of a transmitter, the

box, with its pick-up rod in position, is placed some

little distance from the output tank, and the dial

rotated slowly, since the tuning is quite sharp. If

Continued on page 9

-11C3 RFC

CI C2

TT 111LT

FIG.I (b).

VI

aim

74

Circuit diagram of instrument when using a

television type (6.3 v heater) diode.

EDDYSTONE SHORT WAVE MANUAL

60 Megacycle 15 Watt

INTRODUCTION. .

Several considera-

tions have been borne in

mind when designing a

transmitter for use in the -

6o megacycle amateur

band. Firstly, something

better than the simple .

self-excited oscillator, with

its inherently poor fre-

quency stability and liabil-

ity to frequency modula-

tion is definitely desir-

able. Secondly, too

elaborate a " line-up " hag

been avoided and the trans-

mitter described is capable

of giving good results without

adjustments.

A suitable modulator is included, together with

the necessary power supply for working off A.C.

mains, the whole forming a complete transmitter

on one chassis.

CIRCUITS.

The complete circuit diagram is given in Fig. 1.

The radio frequency circuits, of the balanced push-

pull type, are built around two type 4074A twin

triode valves, which are designed for use at very high

frequencies and are capable of realising high efficiency.

At the same time, the power requirements, both

L.T. and H.T. are economically low. The trans-

mitter is nominally rated at 15 to 20 watts input, the

R.F. output being between io and 12 watts.

The first 4o74A valve is employed as a self-

excited master oscillator in a somewhat uncon-

ventional circuit which requires only one tuning

control and which, in practice, functions well. The

frequency stability is good, sufficiently so in fact,

to enable the use of C.W. in a particular manner,

of which details are given later. The full high

tension voltage is not required on the first stage

and the surplus is dropped through R5. A closed

circuit jack (J3) enables a meter to be plugged in to

read the anode current of this stage. The master

oscillator produces more R.F. voltage than is

necessary to excite the power amplifier, and this

factor enables the loading to be kept low, with a

consequent improvement in frequency stability.

The second 4074A valve acts as a balanced push-

pull Class C power amplifier with a somewhat

higher L/C ratio in its anode circuit than is employed

in the master oscillator. A o/too "Millimeter is

permanently wired in the anode circuit. Neutralisa-

tion is effected by Cat. No. 481 Neutralising Con-

densers, mounted symmetrically in easily accessible

positions.

Bias for the M.O. valve is obtained through

separate resistors and for the P.A. valve through a

RFC.I

4

1.1 v --1J3

412 C

RI R3

c;IL

`T .T

calling for critical

RS

nG.1.

Transmitter

RI2 18

.T

s.

SI

R2 C 2 0

.T

combination of resistors. Whilst not essential, a

certain amount of fixed bias, obtained from a battery,

is advisable on the P.A. valve and the jack (J2) may be

employed for the connection of this additional bias.

This jack is primarily included to enable measure-

ment of grid current to be made, this being necessary

when neutralising the transmitter. The resistor in

the cathode circuit of the P.A. valve is normally

shorted out when the transmitter is functioning

properly but it is included for use during tuning

operations and for the,' special method of C.W.

operation.

The modulator conforms to standard practice

and, as shown in Fig. 1, is intended for use with a

crystal type of microphone. If a moving coil micro-

phone is employed, a suitable coupling transformer

must be included. If a carbon microphone is used,

the second valve may be omitted, in which case of

course, the anode of the first valve will be coupled to

the grid of the output valve.

The first two stages in the modulator use triode

valves, the first a medium impedance type and the

second a low impedance type. The beam power

output valve is capable of giving up to 8 watts audio

output, which is sufficient for full modulation of a

16 watt carrier. The switch S3 cuts off H.T. to the

modulator valves when C.W. is being used. The

correct output Toad of the EL35 valve is 2,500 ohms

and this is matched into the P.A. anode impedance

of approximately 5000 ohms by a multi -ratio. trans-

former.With the modulator and R.F. stages all on one

chassis, precautions are necessary to avoid R.F.

getting back into the modulator. Adequate filtering

is included so that no difficulty should be experienced

from this trouble.

The power supply also follows normal practice.

It uses the Mullard type FW4/5oo rectifier since the

total H.T. current consumption is in the region

of 15o milliamperes. When the transmitter is in

operation, all heaters are allowed to run contin-

EDDYSTONE SHORT WAVE MANUAL

uously and S2, which breaks the H.T. centre tap

to earth, is employed as a transmit/standby control.

GENERAL CONTRUCTION.

The transmitter is built on a standard chassis

Cat. No. 617, with a 8r front panel and two side

angle brackets, the whole forming a rigid unit of

pleasing appearance. Placing the transmitter,

modulator and power supply all on the one chassis

means that little space is wasted but no undue con-

structional difficulties will be experienced if the wgrk

is carried out in proper sequence.

The photographs Figs. 2, 3 and 4, show clearly

the lay -out which has been adopted, whilst the

chart, page 9, gives details of the spacings between

various components. It is suggested that a dummy

chassis top and panel are cut out of stiff cardboard

and all the components; screens, etc., laid out there-

on and the positions carefully marked. The card-

board pieces may then be used as templates for

marking out accurately the actual chassis and panel.

The Retailer from whom the items are pur-

chased may be in a position to assist the constructor

in the work of making the larger holes, otherwise the

help of a local metalworker should be engaged.

Note that the jacks and switches are fitted to the

front of the chassis and i" holes to give clearance are

required in the front panel. Two jacks (J2 and J3)

and two switches (S t and S2), being those which are

less frequently used, are mounted at the rear of the

chassis. The smoothing condensers take the form

of a three -in -one block, manufactured by British

Insulated Cables Ltd. This block mounts con-

veniently below the chassis to the rear, thereby saving

top space.

THE RADIO FREQUENCY STAGES.

Tandem construction, with the valves in a

horizontal position, permits an efficient lay -but with

an absence of long leads. To reproduce the excellent

Fig. 2. Top view illustrating the lay -out of the

transmitter.

Fig. 3. Close-up view of oscillator stage.

results given by the prototype this layout should be

followed closely, for which purpose a close-up view

of the master oscillator stage is shown in Fig. 3.

The M.O. valveholder is fitted to its bracket'

with the cathode pin at the top. To each top corner

of the bracket is fitted a midget stand-off insulator,

employed as a lead -through to hold the grid con-

densers and associated wiring firmly in place. The

grid R.F. chokes are similarly held rigid by two

further insulators on the chassis, leads being taken

from the undersides to the grid resistors. The M.O.

tuning condenser is fitted to an adjustable bracket

and its associated tuning coil soldered directly on the

end lugs on the stator sections. One end of the

anode R.F. choke is soldered to the centre of the coil,

the other being taken to the top of a Cat. No. 564 red

lead -through insulator. The timing condenser

rotor is connected to the cathode pin of the valve

via a short piece of thick copper braid.

A 6" square brass screen holds the P.A. valve -

holder and the neutralising condensers, which are

themselves fitted to miniature stand-off insulators.

Two holes in the screen are necessary to enable

the grid connections to pass through to the neutralis-

ing condensers. The P.A. tuning condenser is

mounted on an adjustable bracket in a position which

brings it close to the valve top caps. As before, the

coil is soldered directly across the condenser and the

R.F. choke from the centre of the coil is held by a

midget insulator, from which a lead is taken to the

meter. Another red lead -through insulator carries

the H.T. supply through the chassis, an R.F. choke

(RFC2) and by-pass condenser (C7) being fitted as

closely as possible to this insulator to prevent stray

R.F. being carried below the chassis.

As a result of keeping the wiring short, the

insertion of the valves is a little difficult but this is no

real disadvantage since it is unlikely that the valves

will require changing over long periods. The valves

should initially be fitted in their holders before the

EDDYSTONE SHORT WAVE MANUAL

adjustable brackets are fixed in place and should it

become necessary at any time to change a valve,

the nut holding the tuning condenser should be

slackened off and the condenser itself gently lifted

sufficiently to give clearance for the removal of the

valve and the insertion of a new one.

Aerial coupling is effected by a single turn coil

of 18 s.w.g. wire, enclosed in sleeving and looped

around the centre of the P.A. coil. The ends of the

loop are soldered to a Belling -Lee coaxial aerial

socket, fitted to a brass bracket which, in turn, is

mounted on the angle bracket opposite the coil.

MODULATOR AND POWER SUPPLY.

The modulator valves are grouped together

near the master oscillator and the associated com-

ponents are arranged on group mounting boards

fitted beneath the chassis near the appropriate

valveholders. The power supply components and

the modulation transformer are fitted at the rear of

the chassis and mounting of them should be left to

the last, to allow the chassis to be easily handled for

wiring up. Details of this part of the construction

are clearly shown in the photographs.

WIRING.

To begin with, the M.O. and P.A. radio fre-

quency stages should be wired, followed by the group

boards and audio circuits and finally the power

supply circuits.

The cathode, one heater and the two blank pins

on the M.O. valveholder are all soldered to a tag

bolted on to the brass bracket. Condenser C4 is

soldered directly across the heater pins and a flexible

lead from the " live " heater taken through a hole in

the chassis. The other components associated with

this stage are then wired up.

The silver plated tuning coil, a Cat. No. 602 of

four turns, is soldered to the condenser lugs nearer

the M.O. valveholder and to the same lugs are soldered

stiff pieces of wire from the grid lead -through

insulators. Anode caps on short flexible leads are

soldered to the other condenser lugs. Note that the

anode connections are crossed over so that the grid

condenser goes from the grid of one triode section

to the anode of the other. The valve will otherwise

fail to oscillate.

The P.A. stage wiring is very similar. In this

case, an additional condenser is soldered across the

cathode pin and earth tag, and leads through the

chassis are required both for the cathode and live

heater connections. The tuning condenser rotor

is not earthed but is allowed to " float." The tuning

coil is one of five turns. It is again necessary to

cross over the connections between the anodes of

the P.A. valve and the neutralising condensers.

The chart gives details of the components

which are fitted to the group boards, No. t being the

board mounted on the side of the chassis and the

others numbered reading outwards from this. The

small components are of course fitted to the boards

before the latter are bolted in place below the chassis,

using spacing washers to prevent any possibility

of short circuits occurring. The wiring of the R.F.

stages can then be completed. If a suitable power

supply is available (one giving between 15o and

25o volts will serve) it will be well to give the R.F.

stages a preliminary test as outlined below, to ensure

they are functioning correctly.

Next the audio stages may be completed. The

majority of the components are already in place on

the group boards but some, R9, Rio and RH for

example, are held in the wiring and should be con-

nected with very short leads. The electrolytic

by-pass condensers are connected between the

appropriate valve pins and the nearest chassis

earthing point. The lead from the underside of the

red lead -through insulator to the modulation trans-

former should be of screened cable and likewise the

lead from the modulation transformer to the anode

of V5. The H.T. connections for the three modulator

valves are brought to a common tag from which

a by-pass condenser is connected to earth. From

this tag also a lead is taken to S3 via a radio fre-

quency choke.

Tags t and 6 form the primary of the modulation

transformer and are connected to the anode of the

EL35 valve and to H.T. via the switch S3. The

secondary tags, connected in series with the H.T.

supply to the power amplifier, are 7 and to. It is also

necessary to connect up the following tags :-

2 tO 5 ; 7 to 9 ; and to to 12.

The audio circuits may now be tested but,

before doing so, connect a dummy load - a high

wattage resistor of 5,000 ohms or near - across the

modulation transformer' secondary winding.

Finally, it only remains to mount and wire up

the mains transformer and smoothing choke. The

safety fuse fitted in series with the primary of the

transformer is fixed to the rear of the chassis, between

the two switches, a t ampere fuse being adequate.

Fig. 4. Under chassis view of the Transmitter.

EDDYSTONE SHORT

COMPONENTS LIST.

2 Air Dielectric Trimmers, 25 pF x 25 pFEddystone Cat. No. 583

2 Neutralising Condensers, 4 pF 481

7 R.F. Chokes, V.H.F. 1011

1R.F. Choke .. 1010

2 Adjustable Mounting Brackets 1007

2 Slow Motion Precision Dials, 2" Silver 639

2 Flexible Couplers, Large Size 1009

9 Midget Stand off Insulators 1019

2 Red Lead Through Insulators 565

1 U.S.W. Coil, 4 turns 602

1 U.S.W. Coil, 5 turns 603

1 Instrument Knob, ir 1089

I Chassis .617

1Panel, 8i" .. 620

1Pair Angle Brackets 618

I Mains Transformer, Outputs 300-0-300 v. 150 mA

6.3 v. 3 amp. 4 v. 3 amp. .. Woden

1 Smoothing Choke, 20 H., 150 mA .. Woden type C.S.P.12

1 Modulation Transformer ...Woden type U.M.1.

2 Valves (VI, V2), 4074A *Standard Telephones & Cables Ltd.

1Valve (V6), F.W. 4/500 Rectifier Mullard

IValve (V3) L.63 Osram

1Valve (V4) E.C.31 Mullard

1Valve (V5), E.L.35 Mullard

2 Valveholders, American 7 -pin Ceramic S.T.C.

3 Valveholders, Octal Ceramlf

1Valveholder, British 4 -pin.

1 Smoothing Condenser Block, 3 x 8 mF, 550 v. B. I. Ltd.

1Milliameter, 100 mA, Moving Coil .Weston

1 Microphone, D.104, Crystal .. Rothermel

3 Switches, S.P.S.T., S.81 .Bulgin

1 Fuse Holder and Fuse (1 amp.), L.1045, C3 Belling Lee

1 Panel Light Holder and Bulb D.19 Bulgin

4 Telephone Jacks, Insulated, Closed Circuit Igranic

2 Electrolytic Condensers 50 uF, 12v. (C16, 18).

1 Electrolytic Condenser 25 uF, 25 v. (C15).

2 Ceramic Condensers, 10 pF (C9, 10).

2 Ceramic Condensers, 40 pF (C11, 13).

8 Mica Condensers 0003 uF (C5, 6, 7, 8, 13, 14, 20, 24).

2 Tubular Paper Condensers, -01 uF (C17, 19).

2 Resistors, watt, 5,000 ohms (R6, 7).

2 Resistors, 4 watt, 500 ohms (R2, 3).

1Resistor, I watt, 50,000 ohms (R18).

1Resistor, watt, 100,000 ohms (R17).

1Resistor, watt, 1,000 ohms (R14, 16).

1Resistor, watt, 2,000 ohms (R15).

2 Resistors, watt, 10,000 ohms (R11, 13).

1Resistor, watt, 1 Meg. (R15).

1Resistor, 1 watt, 200 ohms (R8).

1Resistor, I watt, 250,000 ohms (R11).

1Resistor, j watt, 100 ohms (R10).

1Resistor, k watt, 12 ohms (R9).

WAVE MANUAL 9

1Resistor, Variable, 2 Megohm (R20).

2 Resistors, 5 watt, 1,000 ohms (RI, R5).

1Resistor, 1 watt, 1,000 ohms (R4).

1Resistor, l watt, 500,000 ohms (R19).

4 5 -way Group Boards.

1Aerial Coaxial Socket, L.373/Skt.

1Aerial Coaxial Plug, L.373/P.8

1 Mains Connector, P.31

Belling Lee

Belling Lee

Bulgin

NOTE. ---The resistance values given are not critical. All may be

of 20% tolerance and the nearest preferred size will serve

if the actual value specified Is not obtainable.

CHART OF

CONSTRUCTIONAL DETAILS & DIMENSIONS.

Details of dimensions, spacings, etc., of screens and components

used in the transmitter. Distances are from valveholder, etc.,

centres or from fixing hole centres in the case of items such as

adjustable brackets, etc.

CHASSIS (looking at front).

M.O. Valve Bracket 2" wide, 3" high plus 4" flange. Valveholder

central 14" up. Fixed 2" from R.H. edge, centre 31" from front.

M.O. Condenser Adj. Bracket fixed 24" from front, 6" from R.H.

edge. Screen 6" by 6" plus 4" flange. Fixed 8" from R.H.,

9" from L.H. edge flush to panel. Valveholder central 2)"

up. Midget insulators 24' up each side of valveholder.

P.A. Condenser Bracket (adj.) 4" from L.H. side, 2)" from front.

Midget Insulators (M.O. grid chokes), 3" apart, 1" from R.H. edge.

Midget Insulators (P.A. grid chokes), 3" spart, 4" right of screen.

Red Insulators M.O., 4" from R.H. edge, 5" from front.

P.A. 64" from R.H. edge, 14" from front.

V3, V4 valveholders 14" from front, 14" apart.

V5 valveholder 74" from front, 2" from R.H. side.

Jack holes diam., switch holes 4" diam., all 3" apart,

1" up from lower edge.

Hole for Mains Connector at rear of chassis 14" .< 4".

PANEL (looking at front).

5" x r clearance holes for jacks, switches, etc., 1" up from lower

edge.

4" holes for dials - M.O. 5" from lower edge, 7" from L.H.

P.A. 5" from lower edge, 5" from R.H. edge.

Meter 24" hole, 24" from top edge, 84" from L.H. edge.

DETAILS OF COMPONENTS ON GROUP BOARDS.

No. I. R6, C14, R7, R5.

No. 2. R14, R12, R8, C17.

No. 3. C19, RI5, R18, R17, R16.

No. 4. RI, R13, C8, R2, R3.

The details given above represent the order in which the

components are mounted, reading left to right, looking at the

front of the inverted chassis.

V.H. Frequency Meter

Continued from

only a small, or perhaps no reading is obtained, the

instrument should be moved nearer but care should

be exercised to prevent damage to the micro -

ammeter.No meter reading will be possible when measur-

ing the frequency of a receiver but indication will

be given in the manner normal to absorption type

meters - that is, cessation of oscillation at resonance,

or diminution of quench noise.

The meter may be used to indicate neutralisation

of a power amplifier. With H.T. removed from the

P.A. and the tank circuit tuned to resonance, a small

reading should be obtained on the frequency meter

when it is placed near and tuned to the transmitter

frequency. Adjustment of the neutralising con-

denser, at the same time swinging the tank con-

denser slightly to maintain resonance, should be

made, until no meter reading is obtainable.

If a transmitter with a fair amount of power is

employed, the meter can be used to measure quali-

tatively the radiation from an aerial system and to

show the effect of various degrees of aerial coupling.

The polar diagram and back to forward ratio of a

Page Four.

beam array can be determined and the positions and

lengths of director and reflector elements adjusted

for optimum radiation in the desired direction.

One further application of the frequency meter

is as a standing wave detector on open wire feeder

lines. If, on moving the aerial rod attached to the

meter along a feeder line, the meter reading fluctuates

considerably at regular intervals, it is a definite indi-

cation of the existence of standing waves along the

line. Further adjustments of matching, particularly

at the aerial end, should make it possible to reduce the

variations to a small amount - it will usually be

difficult to remove them completely.

COMPONENT

IAir Dielectric Trimmer 15 pF (CI )

1 Direct Drive, 2" Dial (Black) .

1U.S.W. Coil, 5 turns

1R.F. Choke (VHF) ..

1 Die-cast Metal Box with Lid

2 Midget Insulators ..

1Switch, SPST, type S.80

1 Meter 0-500 microamps

2 Ceramic Condensers, 10 pF (C2, 3)

1Mica Condenser -0003 mF (C4).

1Valve 1T4 or EA 50

1Valveholder,, as required.

1L.T. Cell, 1.5 volt.

LIST.

Eddystone Cat. No. 580595603

1011650

1019

Bulgin

IlobutErie

Mullard

10 EDDYSTONE SHORT WAVE MANUAL

Five Ten 3 -Valve Converter Unit

INTRODUCTION.

When used in conjunction

with ashort-wave receiver

(which may be either a T.R.F.

or superheterodyne, the very

high frequency converter des-

cribed below enables signals on

the 5 and to metre amateur

bands to be received. The

short-wave receiver may already

include the to metre band in its

coverage but it is likely that

both sensitivity and selectivity

may be poor at this extreme

range and the use of the' con-

verter will result in a much

better performance generally.

The super -regenerative type

of receiver has inherently low selectivity, is unable to

receive C.W. signals and is liable to cause serious

interference to other receivers and its use is therefore

deprecated. The converter unit suffers from none

of these defects and is capable of giving excellent

results with any type of shortwave receiver.

CIRCUIT.

The converter unit has been designed and built

around three modern valves, of a type which ensure

really good performance at very high frequencies.

As shown in the circuit diagram, Fig. 1, an EF54

(previously known 'as an RL7) single ended R.F.

pentode is employed as a tuned R.F. amplifier. It

will normally be operated at full gain but a variable

resistor (R2) is included to enable gain to be reduced

wren strong local signals are being received. This

system of gain control works quite well, even though

the EF54 valve is not of the variable -mu type. The

frequency changer is an EF5o, with suppressor

grid injection from the local oscillator, which employs

an EC52 (previously RLi6) triode. The tuned

circuit of the latter incorporates a fixed condenser in

parallel with the split -stator tuning condenser, which

arrangement results in adequate spreading of the

amateur bands. The R.F. and F.C. tuning con-

densers are ganged and controlled by a direct drive,

since tuning of these stages is not critical. Con-

versely, the oscillator tuning is sharp and a good slow

motion dial is essential.

Interchangeable coils are employed, three being

required for each band. The aerial input is arranged

for a coaxial feeder from a dipole aerial, although

other types may be used. The intermediate fre-

quency output, at 1.6 megacycles, is taken via a

short -length of coaxial feeder to the short-wave

receiver. An open wire should not be used or pick-up

of unwanted signals around 1.6 Mc/s. may occur.

CONSTRUCTION.

The converter is built on a diecast aluminium

chassis and enclosed in a metal cabinet. Very corn-

plete screening is essential and

therefore a certain amount of

metal work is unavoidable. As

shown in the photograph of

the top deck, Fig. 2, the

oscillator section is screened

off by apiece of metal

which should be as thick as

possible - preferably not thin-

ner than r8SWG -and arranged

to come flush with the front

of the chassis. The oscillator

condenser is mounted on a

metal bracket, the dimensions of

which, together with those of

other metal parts, is given in the

chart (page 12). The screen

beneath the chassis measures

9" by 2" and should be bent to shape and fixed so

that it screens off all components associated with the

R.F. stage from those of the other two stages.

Three small holes are required in this screen,

for connections to H.T., L.T., and the suppressor

grid of the EF5o. The latter hole should be made

immediately opossite the appropriate pin of the

EF5o valveholder, to enable the lead to be kept

separate from other wires.

The mounting of the gang condenser calls for

detailed explanation. It is not desirable to use in

this position a twin gang condenser with a common

spindle, since coupling between the R.F. and F.C.

stages will occur. Two Cat. No. 58o air dielectric

trimmer condensers are therefore employed, with a

medium size insulated flexible coupler. The con-

densers are held together by two brass rods, 4"

long and either Ar" or I" square, tapped 6 BA at

the ends and screwed to the spare holes in the

ceramic end plates. Two further tapped holes in

each rod enable the assembly to be fixed to the

chassis. Spacing pieces /98-" long are employed to

hold the condensers above the chassis, with the stator

plates uppermost. If tapping facilities are not

available, two 3" lengths of 6 BA screwed rod may be

used, with nuts and washers on both sides of the

ceramic plates. Small brass feet, for mounting

purposes, can then be located conveniently along the

rods and held in place with 6BA nuts.

The screen between the two condensers is

fixed to the rear condenser by the nut on the spindle

bush, two slots being cut out to take the brass rods.

The screen, which again should be of stout metal,

comes flush with the chassis. It projects slightly

over the edge on one side and is close against the

EF5o valve on the other side. Each coil holder

is fitted as close as possible to its associated condenser,

leaving a small clearance between the coil and the

condenser plates. The bracket holding the aerial

socket is fitted on the edge of the chassis and a single

EDDYSTONE SHORT WAVE MANUAL I

Fig. 1.

turn coupling of 18

the R.F. coil.

When fitting the chassis into the cabinet, it is

good plan to fit short extension spindles to the

flexible couplers, of a length to bring them level with

the gain control spindle. A spot of paint on the

end of each spindle will then leave an indication on

the inside of the cabinet front of the exact point at

which the appropriate holes should be drilled. A

hole I- diam. is required in the side of the cabinet

to give clearance to the aerial plug.

WIRING.

It is hardly necessary to say that in a V.H.F.

unit of this type, it is imperative to keep short all

R.F. wiring and particularly the wiring in the

tuned circuits. Also, loops in the wiring must be

avoided as far as possible - for instance, when

grounding several points, separate wires should be

used, each going to the same soldering tag on the

chassis, rather than one wire running from com-

ponent to component and thence to chassis.

To take the oscillator stage, the coil base is

lifted h-" above the chassis so that the soldering

tags come level with the condenser lugs. Short

wires through the chassis connect to the anode pin

and the grid condenser. The latter is supported on a

single insulated tag. R8 and C14 are soldered

directly across the appropriate valve pins, and C13

directly across the upper condenser lugs.

The frequency changer wiring calls for little

comment. The tag on the tuning condenser bush

is soldered to the " cold " end of the coil base and to

a tag fitted under the coil base fixing screw. The

positions of the other components associated with

this stage are clearly shown in Fig. 3.

The tag on the R F tuning condenser and the

cold end of the coil base are both soldered to a tag

bolted to the chassis. The other components are

grouped closely around the valveholder, insulating

tags being ..tmployed where necessary, to hold parts

rigid. Two R.F. chokes in series are necessary in

the anode circuit of the R.F. valve. The VHF choke

(RFCI) is held between the anode valveholder pin

and a single tag strip beneath RFC2 (which is visible

in the photograph) and is held by another tag strip,

to which R3 and C5 are also connected.

SWG wire is arranged close to

The power supply leads are brought together

to a tag strip bolted to the rear of the chassis. All

valve pins labelled " screen " and the tag on the

centre spring grip of the V2 valveholder are soldered

to a common earthing tag. In the case of Vi, the

screen is connected internally to the cathode and

the pins marked " screen " are left alone, but the

centre tag is earthed.

PUTTING THE CONVERTER INTO

OPERATION.

The converter requires 6.3 volts I amp. for the

valve heaters and 200/250 volts 3o mA (approx.)

H.T. supply. These may be obtained from the set

used with the converter (provided the mains trans-

former will not thereby be overloaded), from a

separate mains unit or from batteries. Smoothing

must be good, to prevent A.C. modulation of the

oscillator.

The output socket is connected to the aerial

input of the receiver, which should be tuned to 1.6

megacycles. If the receiver is a superhetrodyne

the B.F.O. will be used as usual for the reception of

C.W. whilst in a straight receiver, the detector stage

should be just oscillating. A suitable aerial system

should be connected to the aerial socket.

A low power oscillator, roughly calibrated, will

be found an asset in ascertaining that the converter

is working properly, particularly on the 6o Mc/s.

band, where, in some localities, signals may be rare.

On the 6o Mc/s. band, 3 turn coils are plugged into

the R.F. and F.C. coil sockets and a 4 turn into the

oscillator coil socket. The actual oscillator range,

over the full dial, will be 53 to 63 Mc/s. The

oscillator may therefore be used either 1.6 Mc/s.

higher or lower than the signal frequency - in the

latter case, the coverage will be from 51-4 to 6o-5

Mc/s. and the amateur band (58.5 to 6o Mc/s.) will

occupy from 6o to 48 degrees. Future possible exten-

sions of the band are also covered.

Fig. 2. The oscillator is to the left of the metal screen.

Front right is the frequency changer and rear right the

R.F. stage.

12 EDDYSTONE SHORT WAVE MANUAL

Fig. 3. Under -chassis view of the Converter. RFC2

is shown near the potentiometer and beneath it, but not

visible is RFC'.

The left hand smaller dial controls the R.F. and

F.C. tuning condensers and the noise level will

increase at resonance. The dial reading will be 5o°

approx. at 6o Mc/s. Whilst not critical, the tuning

of these stages must be kept in step with the oscillator

or signals will be missed. The coils, condensers and

stray capacities associated with the first two stages

are all similar and ganging is therefore fairly good.

Fine adjustment can be carried out, with the aid of a

steady local signal, by opening out or closing up one

of the coils, but this coil must then be marked so that

it is always put back in the same coil socket.

For use on the 28 Mc/s. band, three to turn coils

are plugged in. In this case, the oscillator covers

28 to 35 Mc/s. and is set 1.6 Mc/s. lower than the

signal frequency, giving coverage of from 26.4 to

33.4 Mc's. The band of 28 to 3o Mc/s. is covered

from 78 to 44 degrees on the oscillator dial, the R.F./

F.C. dial setting being in the region of 90 degrees.

All settings are, of course, approximate but close

agreement will be found providing the layout shown

is accurately followed.

The aerial coupling coil should be very close

to the tuning coil and, on 28 Mc/s1, it may be found

an improvement with some aerials to use two turns

instead of one.

CHART OF CONSTRUCTIONAL DETAILS,

(Looking at Front.)

Central Brass Screen 4" high, 51" long, with mounting flange

fitted 5' from L.H. edge, 31" from R.H. edge.

Oscillator Condenser Bracket, 1.4" wide, 11" high, plus flange.

Fitted from front, spindle 21' from R.H. edge, 14" up.

V3 (OSC) Valveholder 2' from rear, r from R.H edge.

VI (RF) Valveholder 11" from front, 31" from L.H. edge.

V2 (FC) Valveholder It" from rear, 31" from L.H. edge.

Condenser Screen 3' high, 31" wide. Condenser spindle 1/" from

L.H. edge, 14' up.

L4 Coil Base behind C12.

LI Coil Base alongside RF Section of Condenser (fixing hole r

from L.H. side, 21" from front).

L3 Coil Base alongside FC Condenser section (i" from L.H. side,

4" from rear).

Aerial Socket Bracket ir long, 1" high, plus flange, fitted flush

with L.H. side, centre 11" from front edge.

Lower Screen 2" deep plus flange, 9" long, bent to fit.

6 Mica Condensers-, -0005 mF. (C3, 4, 5, 7, 9, 14).

1 Mica Condenser, .001 mF. (C8).

1 Mica Condenser, -0003 mF. (C10).

2 Ceramic Condensers, 10 pF. (C6, 13).

1 Ceramic Condenser, 50 pF. (C11).

1Resistor, 4 watt, 220 ohm (R1).

3 Resistor, watt, 500 ohm (R3, 5, 7).

2 Resistors, watt, 5,000 ohm (R4, 6).

1Resistor, watt, 30,000 ohm (R.8

1Resistor, watt, 20,000 ohm (R9).

1Resistor, Variable, 5,000 ohm (R2).

2 Coaxial Sockets, type L373/Skt. Belling Lee.

2 Coaxial Plugs, type L.373/P.8 Belling Lee.

1x5 -way, 3 x1 -way, 1 x 3 -way Tag Strips.

COMPONENTS LIST.

1Die-cast Chassis .. .. .. Eddystone Cat. No. 643

1 Metal Cabinet -.

644

2 Air Dielectric Trimmers, 15 pF .580

.

1 Air Dielectric Trimmers, 25 x 25 pF 583

1 Vernier Slow Motion Dial, Silver 637

.

1Direct Drive, 2" Dial, Silver 638

.

3 Flexible Insulated Couplers, Medium Size .. 529

3 U.S.W. Coil Bases .. .. 606

.. .

3 U.S.W. Coils, 10 turns 605

2 U.S.W. Coils, 3 turns 601

I U.S.W. Coll, 4 turns 602

1 VHF. Choke (RFC1) 1011

2 R.F. Chokes (RFC 2 and 3) 1010

I Instrument Knob 11" 1089

1Valve, type EF54 (V1) Mullard

1Valve, type EF50 (V2) Mullard

1Valve, type EC52 (V23) ...Mullard

3 Ceramic Valveholders, 9 -pin British with with Locking rings.

Belling Lee.

28 Meg. Transmitter. CHART OF POSITIONS AND DIMENSIONS. Continued front page 20.

TRANSMITTER TOP CHASSIS.

Crystal Holder, 6" from left hand edge, 21" from fear.

VI Valveholder, 8" from left hand edge, 21" from rear.

V2 Valveholder, 5" from right hand edge, 21' from rear.

L3 Insulators, 11" apart, from rera.

L4 Insulators, 11" apart, 11" from right hand edge.

C13 Bracket, 11" wide, 21" high with i" fixing flange.

Mounted 2" from front. Condenser mounted 1r up.

V3 Screen, 11" (overall) by 51" high, plus 4" flange. Valveholder

11" up, 21" from front.

L5 Insulators, 3" apart, 3" from left hand edge.

Coaxial Socket Bracket, 3" x 11" wide, fixed to Angle Bracket.

1" holes for leads to heater and G2 of V3.

r hole for leads to anode current meter.

4" hole for P.A. H.T. lead through insulator.

1" hole beneath Insulator for G.B. negative lead.

4" holes beneath L3 Insulators.

TRANSMITTER UNDER -CHASSIS AND PANEL.

Brackets for C3, C4 and C10, 2" wide, 11- high plus 4" flange.

Jack mounting holes, 4" diam., 3" apart at rear.

Hole for 10 -way Socket (4- x 11" centre 31" from right hand side.

In front : 4 \ 1" holes for Condenser drives and panel light (see

text) 14" hole for Jack (5 x1" holes in panel) ; 1x 2/"

hole for meter 8" from right hand side of panel, 2r from top.

POWER SUPPLY CHASSIS.

1x1" hole in front left for transmitter control switch.

1x1" hole in front right for red panel light.

1x r hole in centre for green panel light.

1 hole I I' x 1" at rear left for mains plug.

1x1" hole for mains switch, 3' to right of mains plug.

1x4" hole for modulator plug, 5" from righthand edge.

1 hole 11" x 1)", 2" from right hand edge.

1" hole in panel (above metal rectifier) for R.21.

3 x 1' holes in panel, to match items on front of chassis.

MODULATOR CHASSIS.

V9 Valveholder 11" from right hand edge, 2" from front.

V5 Valveholder 64" from right hand edge, 2" from front.

V6 Valveholder 21" to left of V5.

V7 Valveholder 1" from front 2' from left hand edgP

V8 Valveholder 21" to rear of V7.

1x1" hole for mains switch, front left.

1x1" hole for panel light, 3" to right of switch.

1x1" hole for gain control, 3" to left of panel light.

1X?a " hole for microphone jack, 3" to left of gain control.

4 x 4" holes in panel to match.

1x 21 hole in panel for meter, 9 from left hand edge (of panel)

1 hole 11" x i" at rear right for mains plug, 21" from top.

1x1 4" hole at rear left for ourput plug, 21" from side.

EDDYSTONE SHORT WAVE MANUAL 13

Two -Valve

INTRODUCTION.

Whether used in con-

junction with a straight or

superheterodyne type of

communications receiver, a

pre -selector confers a num-

ber of advantages. In the

first case, the considerable

R.F. gain given by the pre -

selector will enable reception

of signals otherwise practic-

ally inaudible and the addi-

tional adjacent channel select-

ivity will be greatly improved.

In the second case, using a

superhet, almost if not com-

plete freedom from image

interference is an additional

advantage. The pre -selector

described below is designed for use with a mains oper-

ated set, from which it should be possible to draw the

comparatively small power requirements. The unit

may be used with a battery receiver if facilities exist

for providing the H.T. and L.T. supplies, either

from batteries or from a small mains power pack.

Two additional tuned circuits are definitely advis-

able, to obtain optimum results, and therefore two

valves are used in the pre -selector.

CIRCUIT.

Fig. t, which gives the complete circuit diagram,

is practically self-explanatory. The R.F. pentode

valves employed are Mullard type EF39, giving

high gain with low noise level. The three types of

Eddystone plug-in coils give a continuous coverage

from 32 to 3.5 megacycles. The range may be ex-

tended to lower frequencies by means of additional

coils, but the advantages fall off below 3 Mc/s, unless -

a very small or badly screened aerial is used. The

tuned circuits are controlled by a single knob and the

full vision dial can, if desired, be directly calibrated

for each of the three ranges.

Variable gain control is fitted and at maximum

gain, on some frequencies, it may be found that

self -oscillation will occur. In point of fact, this

feature is somewhat advantageous, as the selectivity

is considerably increased when using regeneration

below the point of actual oscillation. With the gain

control backed off slightly, the pre -selector is quite

stable. Screened leads and top connectors to

the grid top caps of the valves will cure the self -

oscillation but the performance on the higher

frequency ranges will be affected by the losses

introduced thereby.

The stray capacities across each tuned circuit

are approximately equal and the Eddystone coils

are closely matched during manufacture. The

ganging therefore holds well over the whole range

and separate trimming condensers have been

found unnecessary.

Pre -SelectorCONSTRUCTION.

The pre -selector is built

on a diecast chassis, which,

in turn, is enclosed in a metal

cabinet. The appearance of

the complete unit is pleasing

and matches the excellent

performance.

As will be seen from

Figs. 2 and 3, which are

photographs above and below

the chassis, the construction

is fairly simple. Two metal

screens are required, their

dimensions, together with

other constructional details,

being given on page 14.

All necessary holes

should be made in the chassis

before any item is permanently mounted. When

fitting the chassis into the cabinet, the dodge mentioned

in the article on the Five -Ten Converter should be

employed. It consists of, where necessary, ex-

tending the spindles and putting a blob of paint on

the end of them. A clear marking is then obtained

on the inside of the cabinet of the correct point at

which holes should be drilled. Three holes are

required at the rear of the chassis, two for the input

and output sockets, and one for the power supply

cable. Note that two holes are required immediately

below the tuning condenser stators to enable con-

nections from the latter to be led through to the coil

bases.

WIRING.

Wiring up is quite straightforward and Fig. 3

clearly shows the details. C4, R2, C3, and RI, are

mounted on a 5 -way group board, which is bolted to

the side of the chassis close to the VI valveholder.

Similarly, R4, C6, C7, and R7, are mounted on

another group board, fitted close to the V2 valve -

holder. The other components are held in the

wiring, small mounting strips being used where

necessary.

The lead between the anode of VI and the second

CO *

11

R6 7

cr

3Cr- V2

56

TCs

L

C2

C9

C7

Fig. I. Shewing complete circuit diagram.

01-1T 4-

OLT&H

OLT +

14 EDDYSTONE SHORT WAVE MANUAL

Fig. 2. The first nined ' stage is to the front

and the second to the rear.

coil holder should preferably consist of a short

length of narrow diameter coaxial feeder, but if this

is not obtainable ordinary screened wire will serve.

The lead between C9 and the output socket should

be another short length of similar cable.

PUTTING THE CONVERTER INTO

OPERATION.

The two EF39 valves require 6.3 volts 6 amp.

foi the heaters and an H.T. supply of about 25o

volts, 15 milliamperes. The aerial input is trans-

ferred from the normal receiver to the left-hand

aerial socket on the pre -selector and the output

socket on the pre -selector connected to the receiver

by means of the shortest possible length of coaxial

feeder. Unscreened wire must not be employed for

connecting the pre -selector to the receiver as it is

liable to act as an aerial and pick up signals direct, and

may also interact with the proper aerial, so causing

instability.

Resonance of the pre -selector will be indicated

by an increase in noise level, and, as a guide to

the constructor, the following figures were obtained

when calibrating the prototype model :-

Coil 6LB 37045°

Coil 6BB o°Ioo°87-82°

Coil 6R o°oo°26-20°

3o Mc/s Amateur

28 Mc/s f Band

27 Mc/s

13 Mc/s

14 Mc/s

9 Mc/s

3.5 MO

7 Mc/s

Amateur

Band

Amateur

Band

It will be noticed that a gap . occurs between

9 and 13 Mc/s and listeners interested in short wave

broadcasting between these two frequencies can

eliminate the gap by employing two type 6Y coils.

Fig. 3. View beneath the chassis of the

Pre -Selector Unit.

CONSTRUCTIONAL DETAILS & DIMENSIONS.

Tuning condenser spindle, 44" from each edge.

Length of spindle projecting, reduce to r.

Front condenser holes 1 r from front of chassis.

VI valveholder 2 from right-hand edge and 14" from rear.

V2 valveholder 2" from right-hand edge and 2" from front.

First coil holder 2" from left-hand edge and 14" from rear.

Second coil holder 2" from left-hand edge and 2 from front.

Gain control central 1" up.

Input (aerial) socket 2" from left-hand side 1" up.

Output socket 2" from right-hand side 1" up.

Top screen 3" wide, 3r high, plus r flange, mounted centrally

between coils, flush with tuning condenser.

Lower screen 7' long, 2" deep, plus i" flange, centrally mounted.

COMPONENTS LIST.

1 Die Cast Chassis .. Eddystone Cat. No. 643

1 Small Metal Cabinet 644

26 -pin Coil Bases 964

26 -pin Coils 6BB 959

26 -pin Coils 6LB 959

26 -pin Coils 6R 959

1 R.F. Choke .. 1010

2 Midget Insulators 1019

1 Full Vision Dial 598

I Skirt Knob 11' 2416P

1 Flexible Coupler 1009

2 Valves Type EF39 (VI, V2) Mullard

2 Valveholders Octal Ceramic.

1 twin gang Condenser 100 pF per section .. Polar

2 Coaxial Sockets, type L.373/Skt. Belling Lee

2 Coaxial Plugs, type L.373/13.8 Belling Lee

2 5 -way Group Boards.

1 3 -way Tag strip.

2 1 -way Tag strips.

7 Mica Condensers 001 mF (C.3, C4, CS, C6, C7, C8, C10).

1 Mica Condenser .0003 mF (C9).

2 Resistors watt 300 ohm (RI, R4).

2 Resistors watt, 1,000 ohm (R3, 1(6).

2 Resistors, watt, 10,000 ohm (R2, R7).

1 Variable Resistor, 10,000 ohm (R5).

EDDYSTONE SHORT WAVE MANUAL 15

28 Megacycle C.W. & Telephony

INTRODUCTION.

The transmitter described below has been

specifically designed to meet present-day licence

conditions, particularly as they apply to the 28 to

3o Mc/s. band. At the same time, it is possible,

with minor modifications, to employ the transmitter

also on other high frequency bands.

Crystal control is employed and the number of

valves has been reduced to the minimum. No very

high voltage supply is required, yet the radio fre-

quency output is entirely adequate for long distance

communication.

A suitable modulator and power supply are

included in the design and the equipment as a whole

is recommended as a thoroughly efficient and up-to-

date transmitter for amateur use.

CIRCUIT DESCRIPTION.

As will be seen from the circuit diagram, Fig. r,

the transmitter proper utilises three modern valves.

The first of these (a 6V6) is employed in a tritet

circuit with a 7 megacycle crystal and the design is

such that abcplutely stable operation is assured.

The R.F. voaage required to drive the second valve

is low and the H.T. voltage on the 6V6 is corres-

pondingly low - actually 15o volts. One result of

this is that crystal curren t is small and heating

negligible.

The second valve (a QVo4-7) is a new type

recently introduced by Mullarch. It is fitted with a

9 pin glass base znd the short electrode leads and

general design enable exceptionally good efficiency

to be achieved at the higher tiequencies. In the

present design, this valve operates as a frequency

doubler and furnishes ample drive for the final

power amplifier valve, a Mullard QVo4-2o. The

latter is a double beam power tetrode, of similar

characteristics to the American type 815. The

driving power requirements are low, the overall

efficiency high and neutralisation has been found

unnecessary.

The modulator, which is capable of giving up to

3o watts output, follows normal practice. The first

valve is a high gain microphone amplifier, enabling

either a crystal or moving coil microphone to be used.

The circuit as shown in Fig. i(b) is intended for

use with a crystal microphone. If a moving coil

type is employed a matching transformer will be

necessary. The second valve, a medium impedance

triode, is transformer coupled to the two EL37 output

valves, which operate under Class AB' conditions.

A multi -ratio matching transformer is used to match

the required load of the output valves (approximately

5,000 ohms.) to the impedance presented by the R.F.

power amplifier stage (approximately 2,700 ohms.).

The modulator has its own power supply and can

therefore be switched off when not required. To

secure good regulation achoke input filter

C3 C4

Transmitter

CI6

J2

C13

systems employed and, because of the thorough

smoothing incorporated, the output is entirely free

from hum.

The power supply for the transmitter provides

one high tension supply, which is applied to all three

stages in the transmitter, dropping resistors reducing

the voltage for the first two stages. Again the filter

is of the choke input type, used with a mercury

vapour rectifier valve. It is desirable to have an

independent supply available to provide grid bias

for the power amplifier valve. This will ensure that

no damage is caused to the P.A. stage, and will also

avoid the use of batteries. This supply, which

incorporates a metal rectifier, gives a higher maximum

voltage than is required for the present transmitter,

but it has been borne in mind, as with the design as a

whole, that the power supply may at a later date be

required for other purposes. All heaters are supplied

from a separate transformer, and control of the trans-

mitter is effected by a switch in the primary of the

H.T. transformer. This switch is mounted on the

panel of the power supply chassis, but, if desired, an

extension lead may easily be fitted.

Inter -connection between the transmitter and its

associated power supply is effected by a multi -way

cable, fitted with a plug at each end. Sockets to

match are fitted on the chassis. A separate 3 -way

lead is necessary between the modulator chassis and

the power supply chassis.

GENERAL CONSTRUCTION.

Each unit of the transmitter is built on a standard

chassis, the majority of the controls being brought

out to the front panels. On the transmitter chassis,

three of the jacks are fitted to the rear of the chassis,

the one on the front being the keying jack. If the

three units are mounted in four upright channels

(Cat. No. 615/642) the assembly as a whole will have

areally professional appearance and occupy a

minimum- of space. Whilst two meters only are

included in the design, the constructor may, of

course, include additional meters to read the currents

taken at various stages, and such meters could be

accommodated in the rack on special panels which are

available.

16 EDDYSTONE SHORT WAVE MANUAL

THE R.F. STAGES.

The photograph (Fig. 2) of the upper deck of

the transmitter conveys a good idea of the lay -out

adopted, and, while not critical, it will be well to

follow this lay -out as closely as possible, particularly

in the case of the power amplifier valve, which must

be well shielded to prevent instability.

The holder for the QVo4-2o valve is mounted in

a metal screen, which is 43" high, 5/" wide and

extended as shown in the photograph for another 5/".

By mounting the valve horizontally irr this way good

screening is achieved between the input and output

circuits, the anode caps are brought near the tuning

condenser, and wiring in the final tuned circuit is

reasonably short. The butterfly type condenser,

Cat. No. 584, which is used to tune the grid circuit

is fitted to a brass bracket, mounted close to the

valve holder. The dimensions of this and other

brackets are given later. The screen grid -by-pass

condenser is screwed directly to the metal screen,

close to the valveholder. Two miniature insulators,

fitted with valve sockets instead of the usual 4BA

screws, serve as coil holders and are mounted on the

chassis to the right of the grid tuning condenser.

A third insulator acts as a lead -through from the

centre tap on the coil to the grid bias supply.

It is necessary to clamp around the metal ring

at the base of the QVo4-2o valve a metal strap, from

the fixing bolt of which a connection should be made

the valveholder fixing bolt, using a very short

length of copper braid for the purpose.

The tuning condensers for the other stages are

all mounted below the chassis, but are controlled

from the front by flexible drives. Condensers C4

and Cro are insulated from their brackets by paxolin

washers, and as the rotors of these condensers are at

low R.F. potential, no losses are introduced. Con-

denser C3 need not be insulated. Note that, whilst

these condensers are centrally mounted in the

brackets, the relative holes in the front of the chassis

(and in the front panel) are made r r from the lower

.1 1.2

Fig. 2. View of top' of the transmitter chassis.

edge, but otherwise in line with the condenser

spindles, to allow easy fitting of the index strips used

with the dials. The discrepancy in alignment is

easily taken up by the flexible driving shafts. Fig.

3 shows the positions occupied by C3, C4, and Cro

and their associated drives, which are variable in

length between 41." and 6".

The tuning coil L3, which is also mounted on

midget insulators is above the

chassis, to enable it to be link -coupled to L4. Holes

are therefore required beneath the insulators to take

leads through to the valve, etc. Coils Li and L2

are fixed to the chassis with small brass angle pieces.

All the by-pass condensers are screwed directly to

the chassis, the other components being held in the

wiring, tag strips being used where necessary.

An American 5 pin yalveholder is used to hold the

crystal.Condenser C16 is lifted above the chassis

by a +"metal pillars, to bring the stator plates

more in line with the valve top

caps and with the stand-off insulators.

6

J3

R

RIO

R9 a

CI7 .n tr!ce

Fig. ra. Circuit of radio frequency sections.

--eel° 4

090 3

2

A IV hole is required midway between

the latter to take aCat. No. 564

insulator, which carries the high tension

supply through the chassis. At the rear

of the chassis -&" holes are required

for jacks I, 3 and 4, and also a hole

f" by it" for the ro way socket. A

hole " diameter, fitted with a rubber

grommet is required near the front

of the chassis to take the leads from the

milliameter. On the front panel 2r hole

is necessary to take the meter, and

clearance holes for the panel light and

the jack. The holes for the tuning

condenser controls are all t" diameter,

and should be fitted with metal bushes.

Small holes, to give clearance to 6BA,

1" above the spindles, are necessary

for fixing the_ dial index strips.

EDDYSTONE SHORT WAVE MANUAL 17

Fig. 3. Under -chassis lay -out of the 28 McIs. trans-

mitter.

TUNING COILS.

Coils Li and L2 are wound on 1" ribbed formers,

Cat. No. 646. Li is close wound with 9 turns of

22 SWG enamelled wire and L2 has 12 turns 20

SWG wire, space one wire diameter. L3, of 8 turns,

is wound with 14 SWG wire. It is self-supporting

and has an outside diameter of t f", the length being

adjusted to 1", and the ends, spaced t"apart, made

to fit into the valve sockets on the stand-off insulators.

L4 is similar to L3 but has io turns, occupying II".

A thin flexible wire is soldered to an approximate

centre tap on this coil. The link winding between

L3 and L4 consists of a length of 16 SWG wire,

enclosed in sleeving formed into loops at each end,

with the centre portion twisted. L5 is 2" outside

diameter, and has 6 turns, spaced to occupy t /".

It should preferably be made of i" silverplated

copper tubing but, if unavailable, No. io or 12 SWG

wire will serve. Output coupling to L5 is effected by a

single turn of 16 SWG wire, enclosed in sleeving,

soldered to a Belling -Lee coaxial socket which is

mounted opposite the centre of the coil on the angle

bracket.

WIRING.

The wiring should be commenced with the sub -

chassis wiring of VI. To ensure good electrical

connection the tag on the rotor plates of C3 should be

connected to an earthy tag fitted beneath one of the

crystal holder bolts, to which also is soldered one

end of Li. The resistor R3 is important and should

be mounted directly on the valve pin. A value of

to ohms is recommended, but this may be varied

up to 20 ohms. A miniature insulator mounted

near the VI valveholder assists in holding securely

condenser C7, and the anode wiring.

Leads are brought down through the chassis

from the midget insulators holding L3 to the

variable condenser and associated components.

The remainder of the sub -chassis wiring is clearly

illustrated in Fig. 3. The wiring may be carried out

with i8 SWG tinned wire, enclosed in insulating

sleeving, except in the case of heater wiring which

should be of somewhat heavier gauge.

Pins 3, 5 and 6 of the QVo4-2o valveholder

are connected to a soldering tag, mounted under one

of the valveholder fixing bolts. Pins i and 8 are

connected together and a lead from them taken down

through the chassis for connection to L.T. Another

lead through the chassis carries H.T. to the screen

grid (pin 4) and in series with this lead is the de -

coupling resistor R9, mounted very close to the valve -

holder. One end of C15 is connected to pin 4 of the

valveholder, and one end to the earth tag.

POWER SUPPLY.

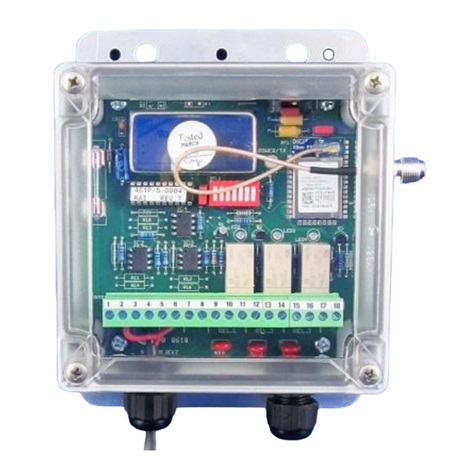

The photographs of the power unit Figs 4 and 5

have been annotated to indicate the various com-

ponents and no difficulty should be experienced in

following the lay -out and construction.