WWW.EDELBROCK.COM

©2007 Edelbrock Corporation

Brochure #63-70216 Page 7 of 16

Catalog #70216

Rev. 5/07 - DC/mc

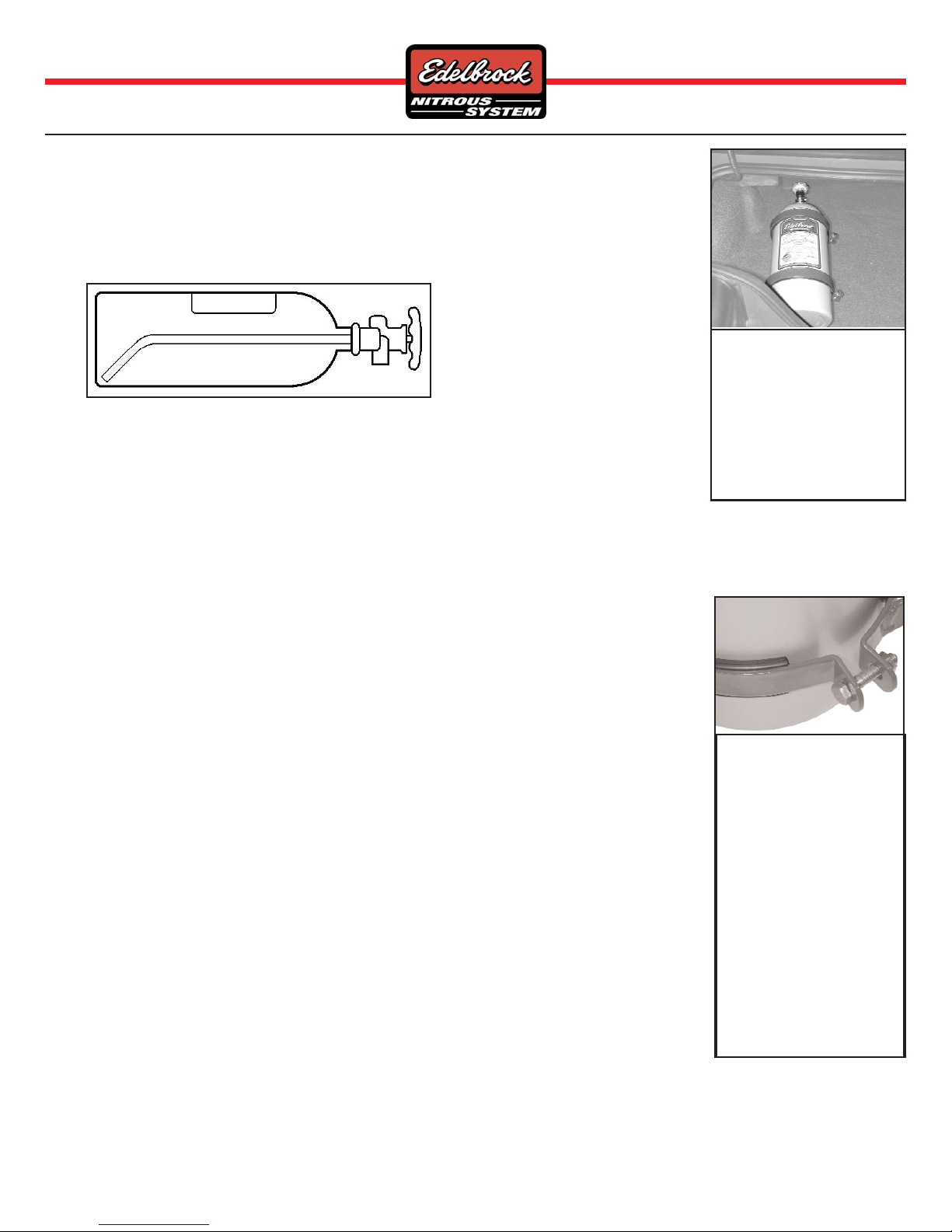

2.2 Bottle Orientation

Accurate calibration of your nitrous system depends on the bottle remaining at a stable

temperature. Choosing the proper location and orientation for your bottle can greatly affect the

overall opeation of the nitrous system. Please read the entire bottle mounting instructions section

before making your final bottle location decisions.

Bottle placement is critical to the

performance of your nitrous system. It is

important to understand how the bottle

valve and siphon tube are assembled to

properly orient the bottle in your vehicle

and ensure that it picks up liquid nitrous

while undergoing acceleration. All nitrous bottles are assembled so that the bottom of the siphon

tube is at the bottle of the bottle, opposite the bottle label (as pictured above).

An Edelbrock nitrous bottle cannot be mounted upside-down. Edelbrock does not offer a

non-siphon tube bottle for automotive use. If the bottle must be mounted parallel to the

axles of the vehicle (sideways), the label must be angled at approximately 45° towards the

rear and pointing to the lower rear-facing quadrant of the bottle. All of this positioning information is critical to system

operation. It is most important to draw as much liquid nitrous as possible. The siphon tube cannot do this unless positioned

correctly.

2.3 Nitrous Bottle Installation

After you have determined the location and orientation of the nitrous bottle, use the following

procedure to install the nitrous bottle:

1. Disconnect the vehicle’s battery.

2. Determine the location of the bottle within the confines of the rear of the vehicle.

3. Once a mounting location has been determined, raise the vehicle (following all safety

practices involved in working on a vehicle from under the vehicle) and verify that there are

no fuel lines, fuel tank(s), brake lines, emissions equipment, or structural members in the

way of potential mounting bolt locations.

4. Install the rubber insulators within the bottle brackets.

5. Install the bottle in the bottle brackets.

6. Using the mounting bracket bolt holes as templates, mark an area for each of the brackets

with chalk, scribe, or marking pen to locate the bottle placements for drilling.

7. Drill two 3/8” mounting holes for each bracket making absolutely sure that you are not

drilling into anything dangerous or critical to the safety of the vehicle.

8. If a bottle heater blanket is going to be used, be sure that brackets are installed 8½” apart

from each other.

9. Install the bottle mounting brackets using “Grade 8” bolts, nuts and flat washers (not

included with the kit). Use fender washers underneath the vechile for sheet metal mounting.

10. Tighten the mounting bolts using a thread locking compound.

Optional Blowdown Tube (PN 72960) Installation

11. If you are using a safety blowdown tube, mock this up on the bottle to decide where the tube

will go through the floor.

12. Mark the floor where the tube will go and using a ½” drill bit, drill through the floor on the mark.

13. Install the Safety Tube on the bottle and cut off any excess tube so that only 1”to 2” are protruding through the vehicle.

The most efficient mounting

method is the lay-down

position with the valve handle

towards the front of the

vehicle. This position allows

the greatest amount of liquid to

be used before the siphon tube

begins to pick up gaseous

nitrous oxide.

Shown here is a bottle with

a bottle bracket properly

installed with the rubber

insulator. The distance

between the bottle brackets

is somewhat adjustable.

Remember, mount the short

bottle bracket at least 1”

from the bottom of the

bottle, and never cover any

of the bottle labels with the

bottle bracket.

Do not attempt to install the

bottle in the bracket

without the rubber

insulator.