Edic FLOODBUSTER FB50 Owner's manual

Electronic

Service

Manuals

This electronic document is provided as a service to our customers.

We do not create the contents of the information contained in this

document. Should you have detailed questions pertaining to the

information contained in this document, you may contact Michco, or

the manufacturer which provided the original information in this

electronic deliverable. Michco’s only part in this electronic deliverable

was the electronic assembly process. By providing this manual online

we are not guaranteeing parts availability.

You may contact Michco through the following methods:

Phone (517) 484-9312

2011 N. High St. -- Lansing, Michigan -- 48906

Fax: (517) 484-9836

Website: www.Michco.Com

Order Parts online at:

www.Michco.Com

Directly to Parts & Service:

By Fax: (517) 484-9836

By Voice: (517) 484-9312

Serving the Cleaning Industry Since 1922

Notice: All copyrighted material remains property of original owners, all trademarks are property of respective owners.

Manuals are subject to Manufacturer’s reproduction limitations. Originals or reproductions were provided by manufacturers

through a request. We make no warranty as to the correctness of information provided in this document and you assume

all risk. By placing these manuals on line we are not declaring our corporation to be an manufacturer authorized dealer or

provider, please check our web site for authorized manufacturers we represent.

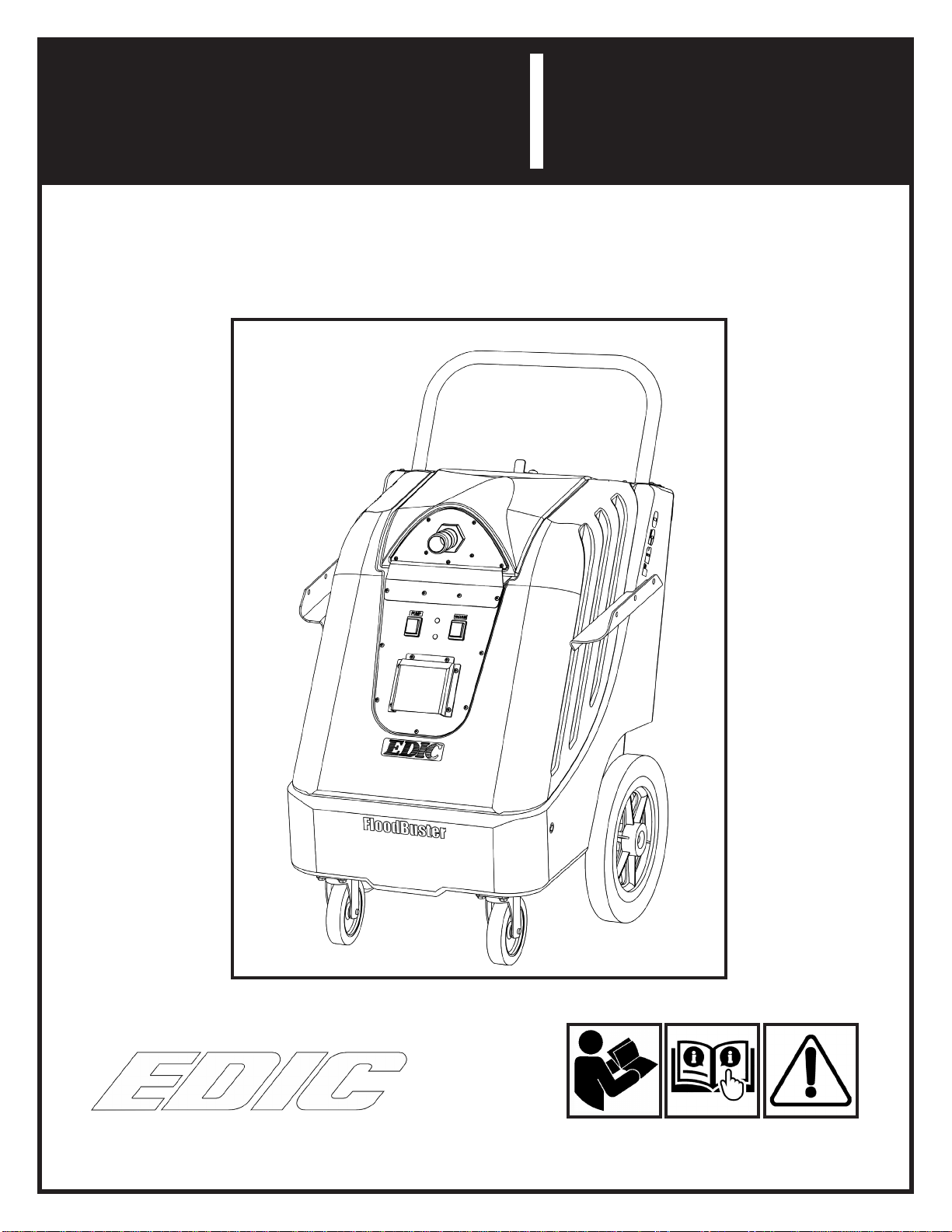

wFLOODBUSTER FB50

PROFESSIONAL

FLOOD EXTRACTOR

OWNER’S/OPERATOR’S MANUAL

PROUDLY DESIGNED AND MANUFACTURED BY

WWW.EDIC-USA.COM Edition 1

9-21-16

Intended for

commercial use only

2

RECEIVING AND UNPACKING YOUR NEW FB50.................................................

WARNINGS AND SAFETY..............................................................................................

ELECTRICAL INFORMATION.......................................................................................

GROUNDING INSTRUCTIONS......................................................................................

MAINTENANCE................................................................................................................

INCLUDED ACCESSORIES.............................................................................................

FB50 MACHINE OVERVIEW..........................................................................................

SPECIFICATIONS..............................................................................................................

SETTING UP THE MACHINE........................................................................................

OPERATION OF THE MACHINE.................................................................................

AFTER OPERATING THE MACHINE.........................................................................

TROUBLESHOOTING....................................................................................................

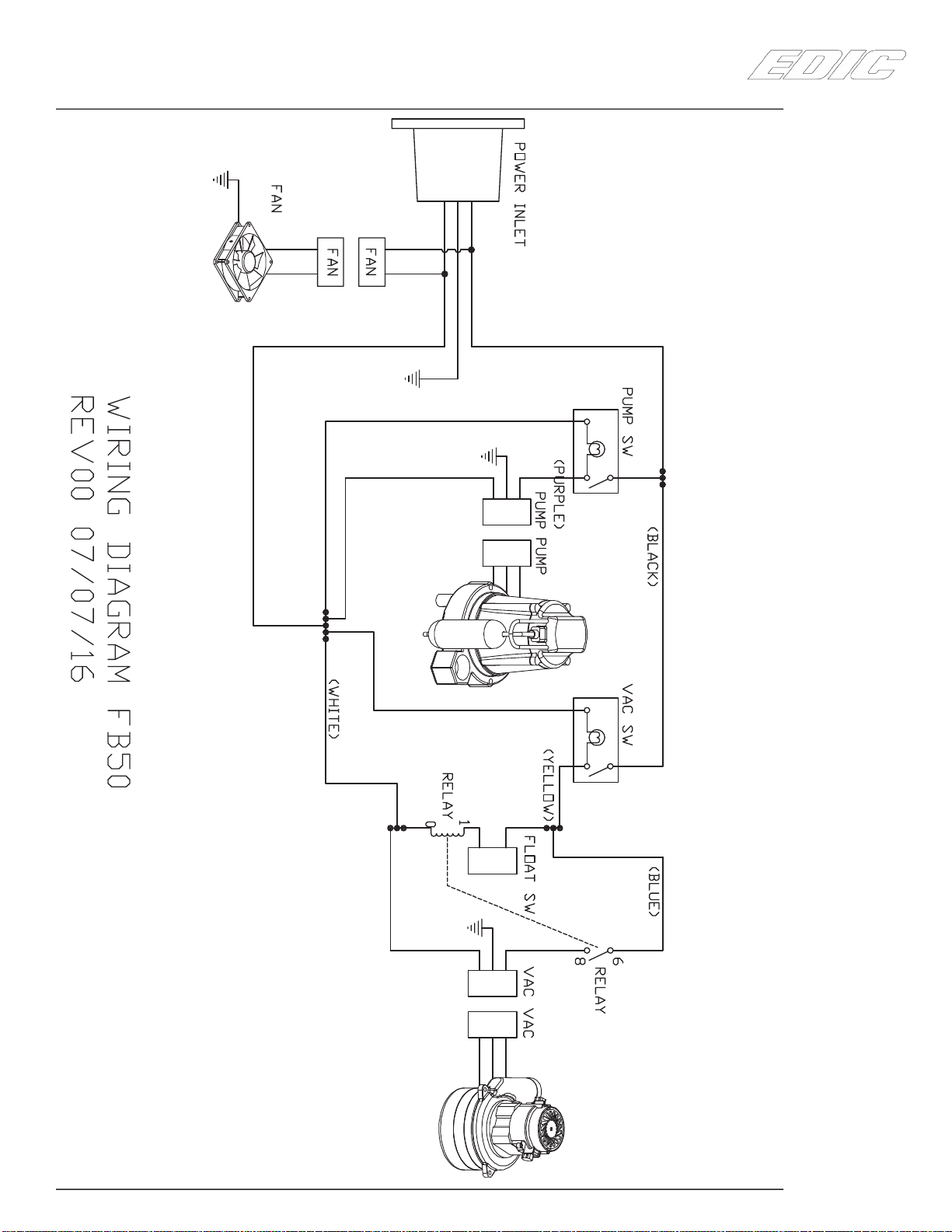

WIRING DIAGRAM.........................................................................................................

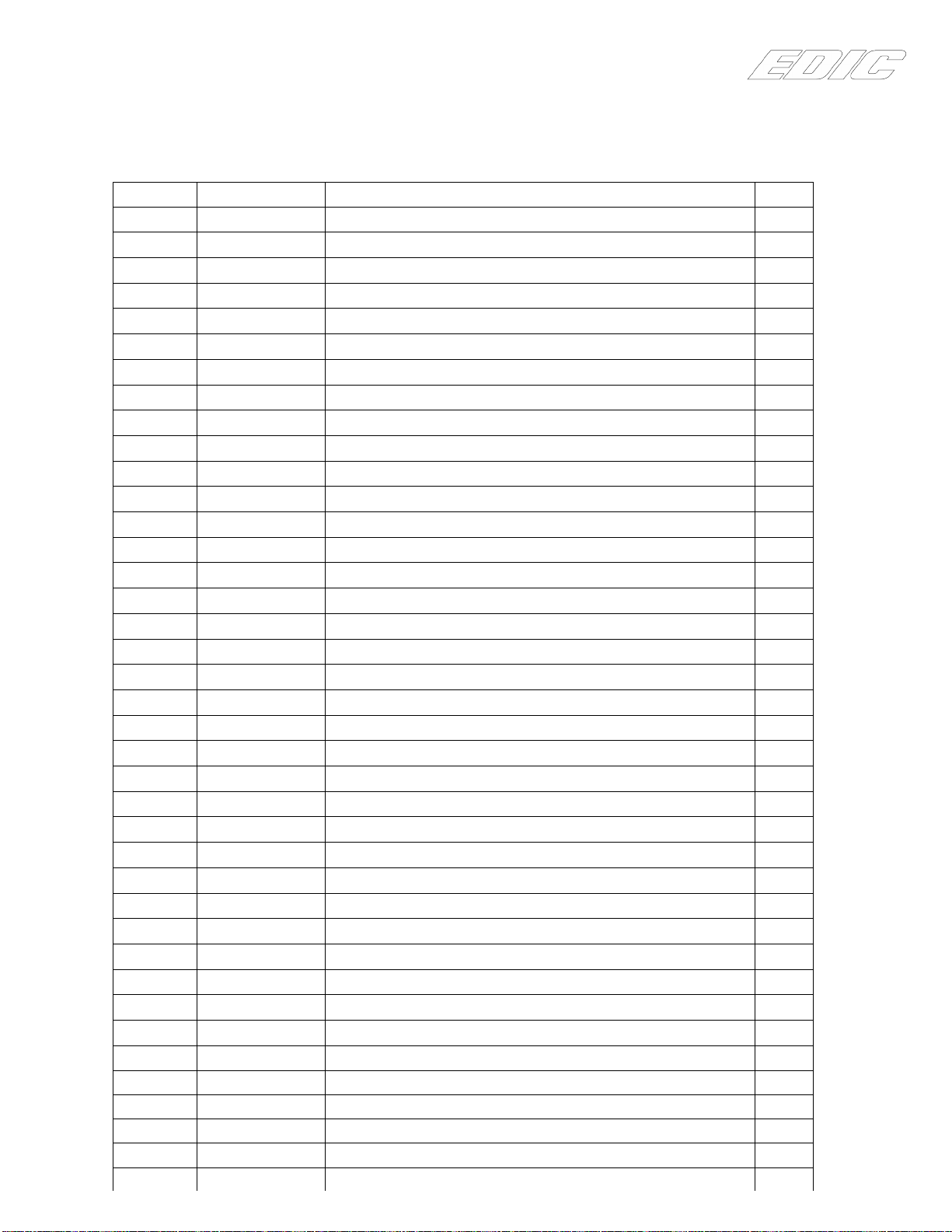

FB5O TANK BREAKDOWN..........................................................................................

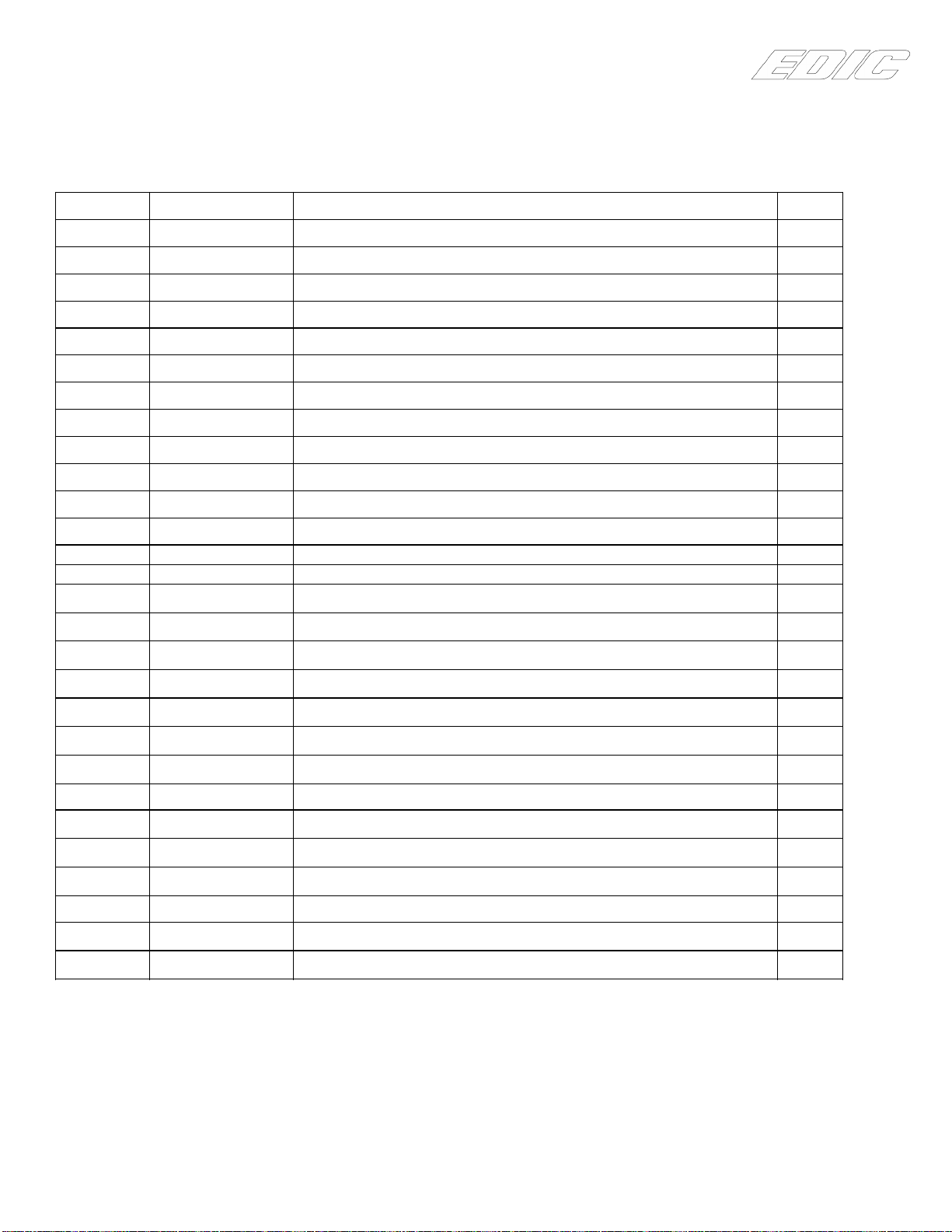

FB50 BASE BREAKDOWN..............................................................................................

FB50 LID BREAKDOWN................................................................................................

WARRANTY INFO............................................................................................................

3

3, 4

4

4

4

5

6

7

7

8

8

8

9

10-12

13, 14

15

16

TABLE OF CONTENTS

RECEIVING AND UNPACKING YOUR NEW

FLOODBUSTER FB50:

When your package is delivered, check the carton care-

fully for signs of rough handling. If the FLOODBUSTER

FB50 is damaged, notify the carrier immediately and

request an inspection. Be sure to keep the carton, pack-

ing inserts, packing lists and carrier’s receipt until the

inspector has veried your claim.

EDIC’s liability ceases when the carrier picks up the

shipment. However, our customer service sta will be

happy to furnish any information needed in connection

with the claim and will attempt to expedite a resolution.

PLEASE READ BEFORE OPERATING YOUR

NEW FLOODBUSTER FB50:

Read the manual carefully and completely before at-

tempting to operate the unit. is manual has important

information for the use and safe operation of the ma-

chine. Keep this manual handy at all times.

is equipment has been engineered and manufactured

to provide excellent performance and service. To ensure

that your equipment will continue to perform as intend-

ed:

• Maintain equipment regularly- following the sug-

gested maintenance schedule provided.

• Use only original EDIC parts when servicing.

• Operate equipment with care.

If additional information is needed, please contact EDIC

All information and specications printed in the man-

ual are current at the time of printing; however because

of EDIC’s policy of continual product development, we

reserve the right to make changes at any time without

notice.

is machine was designed for removing ooded wa-

ter on carpet, oor and upholstery as per instructions

and recommendations written in this manual. Any de-

viation from its proper use or purpose that may cause

consequential damages is the sole responsibility of the

end user. Failure to comply with the following warning

instructions will void the warranty.

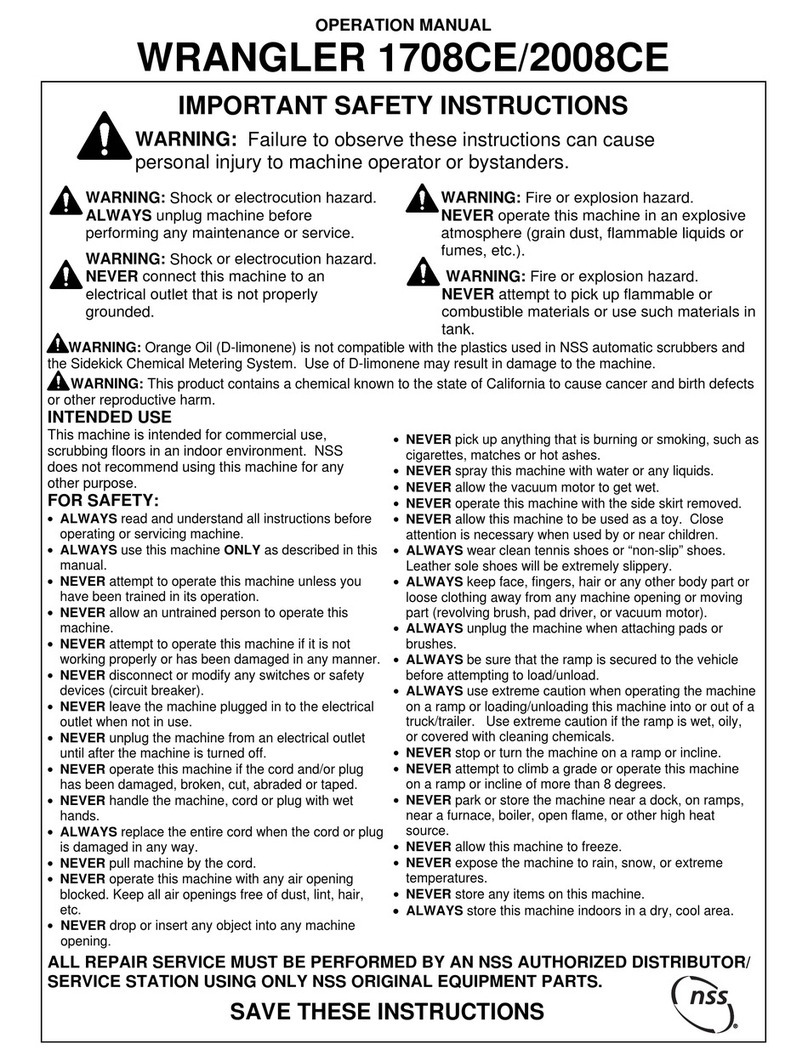

• Make sure the machine is plugged into an electrical

outlet with the same voltage and frequency rating as

shown on the nameplate of the machine. Do not at-

tempt to plug a 115 volt machine into a 230 volt outlet.

• Do not immerse or use this machine in standing wa-

ter. Such use can cause electric shock.

• Do not use to pick up ammable or combustible liq-

uids such as gasoline or use in areas where they may

be present.

• Do not expose machine to freezing temperatures.

• To avoid electric shock, do not expose the unit to rain.

Store indoors only.

• Connect to a properly grounded outlet only. See

“Grounding Instructions.”

• Turn o all controls before unplugging.

• Turn o all controls and disconnect power cord from

the twist-lock power inlet at the lower back of the ma-

chine before servicing.

• Do not use without lter basket in place.

• Do not put any object into openings. Do not use with

any opening blocked; keep free of dust, lint, hair and

anything that may reduce air ow.

• Do not pick up anything that is burning or smoking,

such as cigarettes, matches or hot ashes.

• Do not use machine for dry vacuuming. is machine

is not outtted with a ne dust lter and it will dam-

age the vacuum motor.

• Do not pull machine by hoses or power cords. doing

so will stress or damage these components.

• All servicing of EDIC equipment should be performed

only by EDIC authorized service centers.

• Keep hair, loose clothing, ngers and all parts of the

body away from openings and moving parts.

• Use extra care when near stairs.

• Do not use replacement parts other than those spec-

ied in the parts list. Proper maintenance of the ma-

chine could be aected if substitutions are made.

• Follow maintenance schedule strictly.

• Keep the top lid open during storage

• Make sure discharge hose is rmly attached to the dis-

charge port tting at the back of the machine every

3

time the machine is used. Failure to do that may cre-

ate a ood around the machine.

• Do not leave dirty water inside the tank, pump or hos-

es aer each operation of the machine. Run clean wa-

ter through the pump. Rinse the tank and completely

drain the vacuum and discharge hoses. Run vacuum

motor for three minutes minimum so that the inside

of the vacuum turbine is free of residual moisture.

• Monitor vacuum system to prevent ooding.

GROUNDING INSTRUCTIONS:

is piece of equipment must be grounded. Should an

electrical malfunction occur, grounding provides a path

of least resistance for electrical current, reducing the risk

of electric shock. is piece of equipment is furnished

with a cord that has a grounding conductor and ground-

ing plug. e grounded plug must only be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordi-

nances.

WARNING:

Connecting the equipment to an improperly grounded

outlet can result in an increased risk of electric shock. A

qualified electrician should be consulted if you are un-

sure that the outlet is properly grounded. Do not modify

the plug provided with the equipment. If it will not fit

the outlet, have a proper outlet installed by a qualified

electrician.

is appliance is designed for use on a 120-volt circuit.

e grounding plug provided looks like the plug illus-

trated in Figure 1. Replace the power cord if the ground-

ing pin is damaged or broken.

Extension cords connected to this machine should be

12 gauge, three-wire cords with three-prong plugs and

outlets. DO NOT use extension cords more than 25 feet

(7.6 m) long.

DAILY MAINTENANCE:

e FLOODBUSTER FB50 is engineered and built to

require minimum maintenance. But like any machine,

it does require some care to keep it in optimum work-

ing condition. Careful attention to these maintenance

instructions will give you maximum operating perfor-

mance and life expectancy of the machine.

CAUTION: Disconnect the power cord from the out-

let before doing any clean up or maintenance on the

machine

1. Keep the equipment and accessories, inside and out,

clean and dry including lid, lter strainer, waste tank,

hoses.

2. Vacuum motor: It is very important that the vacuum

motor is internally free of moisture when not used.

Run the vacuum motor with the lid and hose o for

3 minutes aer every operation.

3. Pump motor: Periodically hose o the surface of the

pump so that no debris may remain on the surface

and opening of the pump. Such debris may cause

pump damage in time.

Servicing:

In the event that your equipment requires service, please

contact EDIC at:

800-338-3342

Do not attempt repairs yourself. EDIC will assist you in

locating an indepedent service contractor.

Storage:

1. Store in a clean, dry location.

2. Store with the lid o the machine

Purchase record:

Fill in the blanks and keep for future reference.

Model #:

Serial #:

Distributor name:

Distributor contact:

4

Figure 1

5

INCLUDED ACCESSORIES

1

2

3

4

5

1. J00616-25: 1.5” X 25’ VACUUM HOSE

2. J14056A: 1.5” X 25’ DISCHARGE

HOSE

3. K11192 SQUEEGEE HEAD

4. K007001 SCALLOP TOOL

5. D03386-1 TWO PIECE WAND

6

G

D

H

A

B

F

C

E

A A

B B

C C

D D

E E

F F

G G

H H

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DO NOT SCALE DRAWING

FLOOD_BUSTER_FULL_ASSEMBLY

SHEET 3 OF 3

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:4

WEIGHT:

REV

DWG. NO.

E

SIZE

TITLE:

ENGINEERING DIVISION

1753 BLAKE AVENUE

LOS ANGELES, CA 90031

NAME

DATE

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/32

ANGULAR

.5

TWO PLACE DECIMAL

.02

THREE PLACE DECIMAL

.005

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

EDIC. ANY REPRODUCTION IN PART OR

AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF EDIC IS PROHIBITED.

1

3

5

7

2

8

9

10

11

12

13

14

15 16

4

5

7 7

1

7

12

11

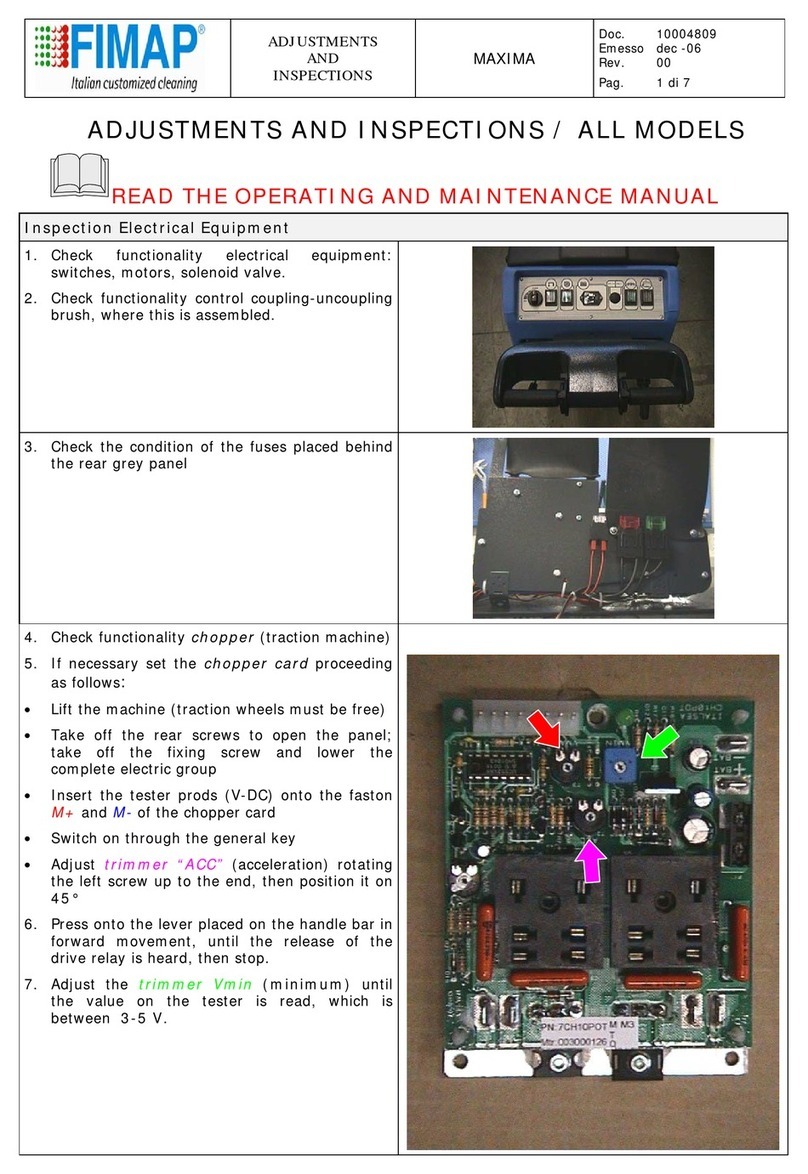

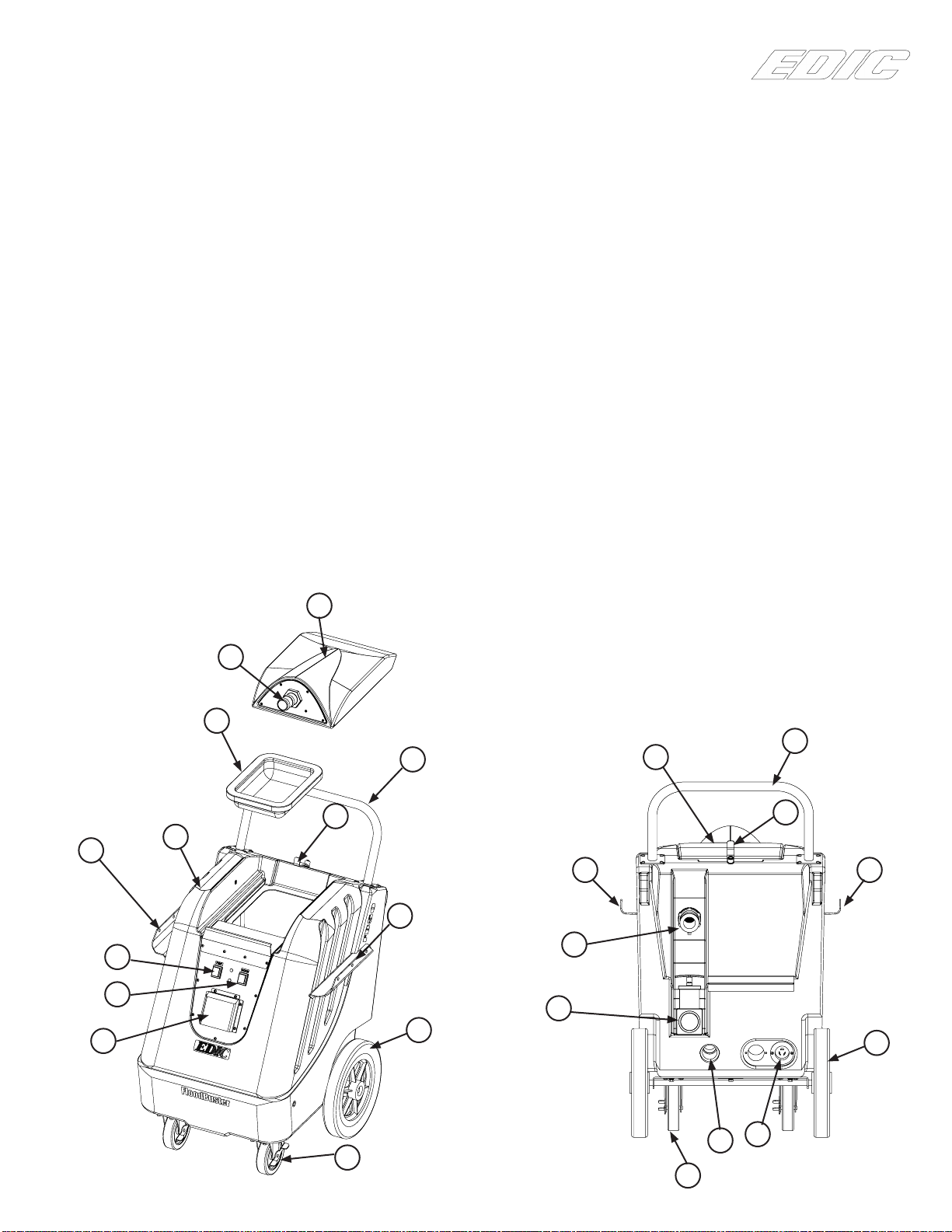

FB50 MACHINE LAYOUT OVERVIEW:

1. TANK LID: Provides seal for vacuum system when

closed and allows access to tank and debris basket

when removed.

2. VACUUM INTAKE BARB: Allows vacuum hose to

be attached to machine to pull in uid.

3. DEBRIS BASKET WITH GASKET: Removes larger

solids. from incoming water stream while gasket cre-

ates vacuum seal between tank and lid.

4. HANDLE: Used to maneuver and position equip-

ment.

5. LID LOCKING LATCH: Used to lock or release the

tank lid.

6. TANK: Houses pump and holds waste water

4

6

7. HOSE SUPPORT: Supports a hose when hose is

wrapped around machine. Has hook openings for

bungee cords. (Bungee cords not included)

8. PUMP SWITCH: Controls power to pump

9. VACUUM SWITCH: Controls power to vacuum

10. COLD AIR INTAKE: Cools vacuum motor.

11. FRONT LOCKING CASTERS: Allows machine to be

locked into place to prevent unwanted movement.

12. REAR WHEELS

13. DISCHARGE HOSE HOOKUP: Connects to pump

out hose.

14. WASTE WATER DUMP VALVE: Allows manual

dumping of waste water.

15. VACUUM EXHAUST PORT

16. TWIST LOCK POWER INLET: Hooks up to main

power cord

G

D

H

A

B

F

C

E

A A

B B

C C

D D

E E

F F

G G

H H

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DO NOT SCALE DRAWING

FLOOD_BUSTER_FULL_ASSEMBLY

SHEET 3 OF 3

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:4

WEIGHT:

REV

DWG. NO.

E

SIZE

TITLE:

ENGINEERING DIVISION

1753 BLAKE AVENUE

LOS ANGELES, CA 90031

NAME

DATE

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/32

ANGULAR

.5

TWO PLACE DECIMAL

.02

THREE PLACE DECIMAL

.005

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

EDIC. ANY REPRODUCTION IN PART OR

AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF EDIC IS PROHIBITED.

7

MACHINE SPECIFICATIONS

PUMP:

submersible, Epoxy-coated steel construction, Nylon Im-

peller, 50 GPM. Handles spherical solids up to ½”.

VACUUM:

5.7” 3 stage, high performance

AIR WATTS:

601

AIR FLOW:

110

WATERLIFT:

158”

VACUUM OVERFILL FLOAT SWITCH:

Yes, tilt type oat switch

LARGE TANK OPENING:

Ye s

HOSE DIAMETER:

1.5” vacuum, 1.5” discharge

REAR WHEELS:

12” Ball Bearing, Non-Marking

FRONT CASTERS:

5” Locking

POWER CORD:

Detachable 12 GA x 25 , Twist lock

POWER CONSUMPTION:

120V, 18 Amps

MACHINE WEIGHT:

106 lbs

SETTING UP THE MACHINE BEFORE

OPERATION:

1. Position the machine on a dry place away from the

ooded area. Lock in the casters so that machine does

not change position during operation.

2. Connect your discharge hose (#2 on page 5) to the

discharge hose hookup on the machine (#13 on page

6).

3. Position the end of the discharge hose in a safe drain-

age location. Check local laws and regulations for

proper waste water disposal.

4. Make sure the debris basket with gasket (#3 on page

4) is in place before you position the lid (#1 on page 4)

on the tank. Without the debris basket in position, the

vacuum motor will not create suction.

5. Make sure to tuck the lip on the lid under the metal

bracket

6. Turn the lid locking latch to the closed position.

7. Check on the drain valve and make sure it is fully

closed position.

8. Connect your vacuum hose (#1 on page 5) to the

vacuum intake barb (#2 on page 6).

IMPORTANT:

To ensure a secure lock on the lid:

1. Make sure the lip on the lid is tucked under the metal

bracket.

2. Pivot the lid locking latch (#5 on page 4) over the lid.

Note: To prevent the lid from being lost,

the above steps should also be followed when

transporting the equipment, especially in open air ve-

hicles or trailers.

OPERATION OF THE MACHINE:

1. Turn on both vacuum and pump switches. Vacuum

motor will turn on immediately and start pulling

water inside the tank. e pump will not start dis-

charging water until a certain level of water is reached

and the oat switch is activated.

2. For deep ooding, you may submerge the end of the

vacuum hose directly into the ooded area. Continue

extracting until the ooding is low enough to use the

appropriate hard oor or carpet tool.

3. For hard oors, attach the squeegee head to the wand

and vacuum hose. Use the wand to recover as much

uid as possible.

4. For carpets, connect the scallop tool to the wand and

vacuum hose. Use scallop tool and wand to recover as

much uid as possible.

5. Continue the operation until the task is complete.

Note: During operation, it is normal for both the

vacuum motor and pump are designed to start and stop

automatically as the oat switches regulate the level of

water in the tank.

AFTER OPERATION:

1. remove the hoses and run the vacuum motor for a

minimum of three minutes with only air moving

through the system. Doing so will ensure all mois-

ture is removed from the vacuum system. Residual

moisture in the system may damage the vacuum

motor.

2. Turn o the switches and unplug the power cord

from the machine power inlet and also from the wall

power outlet.

3. Dump the water remaining in the tank aer opera-

tion.

4. Rinse the tank with clean water.

5. Drain the tank completely.

6. Detach the hoses from the machine.

TROUBLE SHOOTING:

No user serviceable parts. Any inspection or service

should be conducted by a technician at an approved

service station.

Contact EDIC for assistance in locating an approved

service station.

PUMP DOES NOT DISCHARGE LIQUID:

• Machine is not plugged in.

• e switch is not on.

• e switch is bad.

• e oat has debris accumulated on it.

• Float or oat rod has obstruction.

PUMP DOES NOT SHUT OFF:

• e pump is air locked. Turn o the pump switch for

a minute and turn it on again. Repeat the procedure

until the air is completely out.

• Float or oat rod has obstruction.

• Impeller Inlet plugged. Have service station clean the

pump.

WEAK SUCTION FROM THE VACUUM

MOTOR:

• Lid is not completely closed.

• Debris basket is missing or not in proper position.

• Drain Valve is open.

• Wand is plugged.

• Vacuum Hose leaks.

VACUUM MOTOR DOES NOT TURN

ON:

• Machine is not plugged in.

• e vacuum motor switch is not on.

• e switch is bad.

• e vacuum oat switch is stuck in high position.

• Connection on the relay is bad.

VACUUM MOTOR DOES NOT SHUT

OFF:

• e vacuum oat switch is stuck in low position.

• Relay contact is stuck shut.

8

9

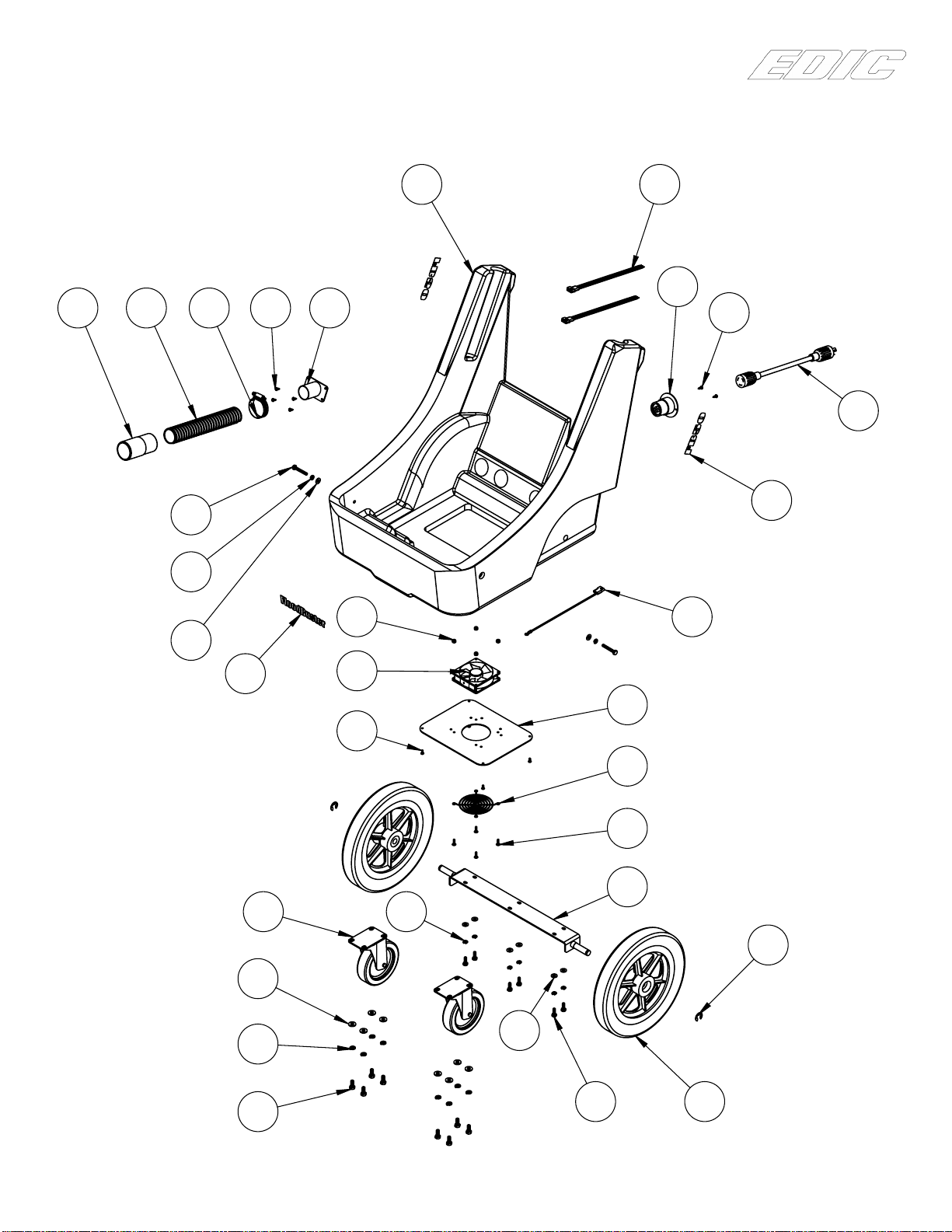

10

42

18

59

35

36

51

27

46

52

12

60

11

13

48

47

45

44

34

38

97

10

1

6

8

54

43

28

31

2

14

39

41

39

40

24

23

53

19

49

50

20

26

25 21

55

30 22

32

33

29

16

17

37

15

57

58

56

3

5

4

51

14

26

41

7

38

7

38

37

63

62

67

61

65

66

66

26

66

FB50 TANK

7/15/2016

11

FB50 TANK

7/15/2016

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

F13809

TANK

1

2

D13614

VACUUM PLATE

1

3

G13941

VACUUM MOTOR, 120V, 3-STAGE

1

4

D00424

EXTENSION TUBE

1

5

D13855

ALUMINUM SPACER

3

6

K00711

DRAIN VALVE

1

7

E11128

DRAIN VALVE GASKET

5

8

C00271

1 1/2" JAM NUT

1

9

K13925

DISCHARGE FITTING

1

10

A13893

CHECK VALVE 1 1/2" FPT

1

11

K13920

1 1/2" HOSE BARB

2

12

G13895

PUMP, 50 GPM

1

13

D13891

PUMP BRACKET

1

14

C13844

5/16-18 X 3/4" HEX BOLT, SS 6

15

K00672

1-1/2" PIPE

1

16

K00666

1-1/2" 90 DEGREE ELBOW

1

17

K00665-1

1-1/2" HOSE ADAPTER

1

18

D14032

L-BRACKET

1

19

D13609

SWITCH PANEL, REV. 04

1

20

D13877

VENT COVER

1

21 B02211-1

ROCKER SWITCH

2

22

E13982

SWITCH PLATE PAD

1

23

F13983

SWITCH PLATE PLUG

1

24

F13984

SWITCH PANEL PLUG BASE

1

25

C00310-12

#8-32 X 1/2" SCREW, BLACK OXIDE

6

26

C11236

#8-32 X 1/2" SCREW, SS

17

27

B13269

FLOAT SWITCH

1

28

D13943

SIDE RAIL, RIGHT

1

29

D13942

SIDE RAIL, LEFT

1

30

D14034

LID HOLDER

1

31

C11167

1/4-20 X 3/4" SCREW, SS

6

32

C00233-1

1/4" ID FLAT WASHER, SS

6

33

E13951

GASKET, FRONT TANK

1

34

D13948

LID LATCH

1

35

B11821

STRAIN RELIEF

2

36

B11832

STRAIN RELIEF NUT

2

37

J00618-1

1 1/2" WIRE REINFORCED HOSE

2

38

J00650

SCREW CLAMP #24 1.25 INCH

3

39

J00618

2" ID HOSE

2

12

FB50 TANK

7/15/2016

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

40

E13949

GASKET, SWITCH PANEL

1

41

J00639

2" ID HOSE CLAMP

4

42

J10744

1 3/4" SLIP-ON CUFF GREY

1

43

D13973

DRIP GUARD

1

44

C14049

SPRING, 1/2" ID X 1/2" L

1

45

C11491

#10-32 X 1" SCREW, SS

1

46

E13900

GASKET, INTAKE BASKET

1

47

D13887

U-HANDLE

1

48

C02290

#10-32 X 1/2" SCREW, SS

8

49

B13851

DIN RAIL

1

50

B13848

RELAY

1

51

C00238 1/4" ID SEALING WASHER

4

52

C13028

1/4-20 X 1" HEX BOLT, SS

2

53

B13956

WIRING HARNESS

1

54

C14053

1/4-20 X 1" SCREW, FH, SS

2

55

K13905

5/16" NYLON PLUG

2

56

C00295-1

#10 X 3/4" SHEET METAL SCREW, SS

2

57

H02574

PUMP SWITCH LABEL

1

58

H02576

VACUUM SWITCH LABEL

1

59

C02268

#10-32 X 3/8" SCREW, FLAT HEAT, SS

1

60

K13898

INTAKE BASKET

1

61

B13738

MOUNTING CARRIER LEVER

2

62

C00256

LOCKWASHER, #10, EXT. STAR

1

63

C14055

LOCKNUT, 1/4-20, NYLON, BRASS

2

64

K00710

ELBOW, DRAIN VALVE

1

65

H11831

LABEL, EDIC

1

66

C11955

WASHER, #10

11

67

C13120

#8-32 HEX NUT W/ LOCK WASHER

8

-

B02176

3-C MOLEX, FEMALE

2

-

B02179

MOLEX PIN, MALE

6

-

B00185-61

GROUND WIRE, 16GA

1

-

B00180-10-3

RING TERMINAL, #10

1

-

C00284

GROUND SCREW, 10-32 X 3/8"

1

-

B00190

NYLON TIE, 4"

2

-

B00191

NYLON TIE, 11"

8

-

E12030

FOAM

2

13

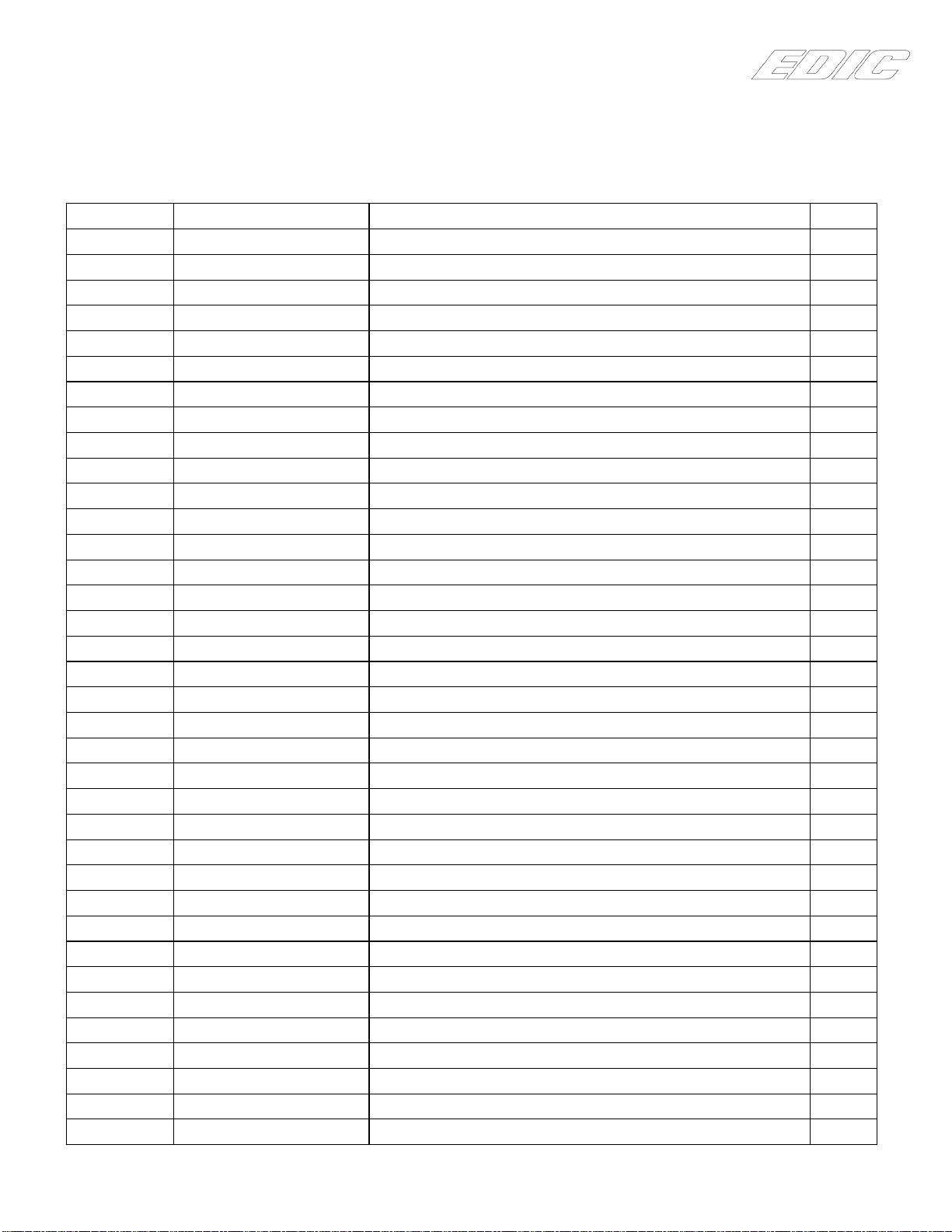

1

25

23

5

24

8

6

19

16

10

20

17

15

14

9

7

2

18

3

21

22 12 11 13

4

13

FB50 BASE

7/15/2016

26

19

16

27

29

28

14

FB50 BASE

7/15/2016

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

F13808

BASE

1

2

D13890

BASE BOTTOM PLATE

1

3

B13280

COOLING FAN

1

4

D13884

EXHAUST FLANGE REV.04

1

5

B13278

POWER INLET

1

6

D13888

AXLE

1

7

G13248

WHEEL 12 INCH

2

8

C13861

E-RING

2

9

G13897

CASTER, SWIVEL, 5"

2

10

D13281

FAN GUARD 92MM

1

11

J00650

SCREW CLAMP #24 1.25 INCH

1

12

J00618-1

HOSE 1.5 INCH

1

13

C00293

#8-32 X 0.5" PAN HEAD SCREW

6

14

C13844

1/4-20 X 3/4" HEX BOLT, SS

8

15

C00233

1/4" ID FLAT WASHER USS SAE

8

16

C00233-1

1/4" ID FLAT WASHER, SS

8

17

C00313

1/4-20 X 3/4" HEX BOLT

6

18

C00311

#8-32 X 3/8" SCREW

4

19

C00254

1/4" SPLIT LOCKWASHER

8

20

C10737

#8-32 X 5/8" TRUSS HEAD SCREW, SS

4

21

C02320

#8-32 NYLON LOCKNUT STAINLESS

4

22

J10744

1 3/4" SLIP-ON CUFF GREY

1

23

B13131

EXTENSION CORD 12/3 SJTW

1

24

-

COOLING FAN WIRE HARNESS

1

B02177

MOLEX, 3-C MALE

1

B02178

MOLEX PIN, FEMALE

3

B00185-61

GROUND WIRE, 16GA

1

B00180-10-3

RING TERMINAL, #10 CENTER

1

25

B13899

WIRING HARNESS 1

26

C02322

HEX BOLT, 1/4-20 X 1 3/4

2

27

C00251

SPLIT LOCK WASHER, 5/16"

8

28

H13672

LABEL, FLOODBUSTER

1

29

H13673

LABEL, FB50

2

-

B00190

NYLON TIE, 4"

2

-

H02548-2

LABEL, WARNING, POWER CORD

1

-

B12915

CABLE TIE, VELCRO

1

15

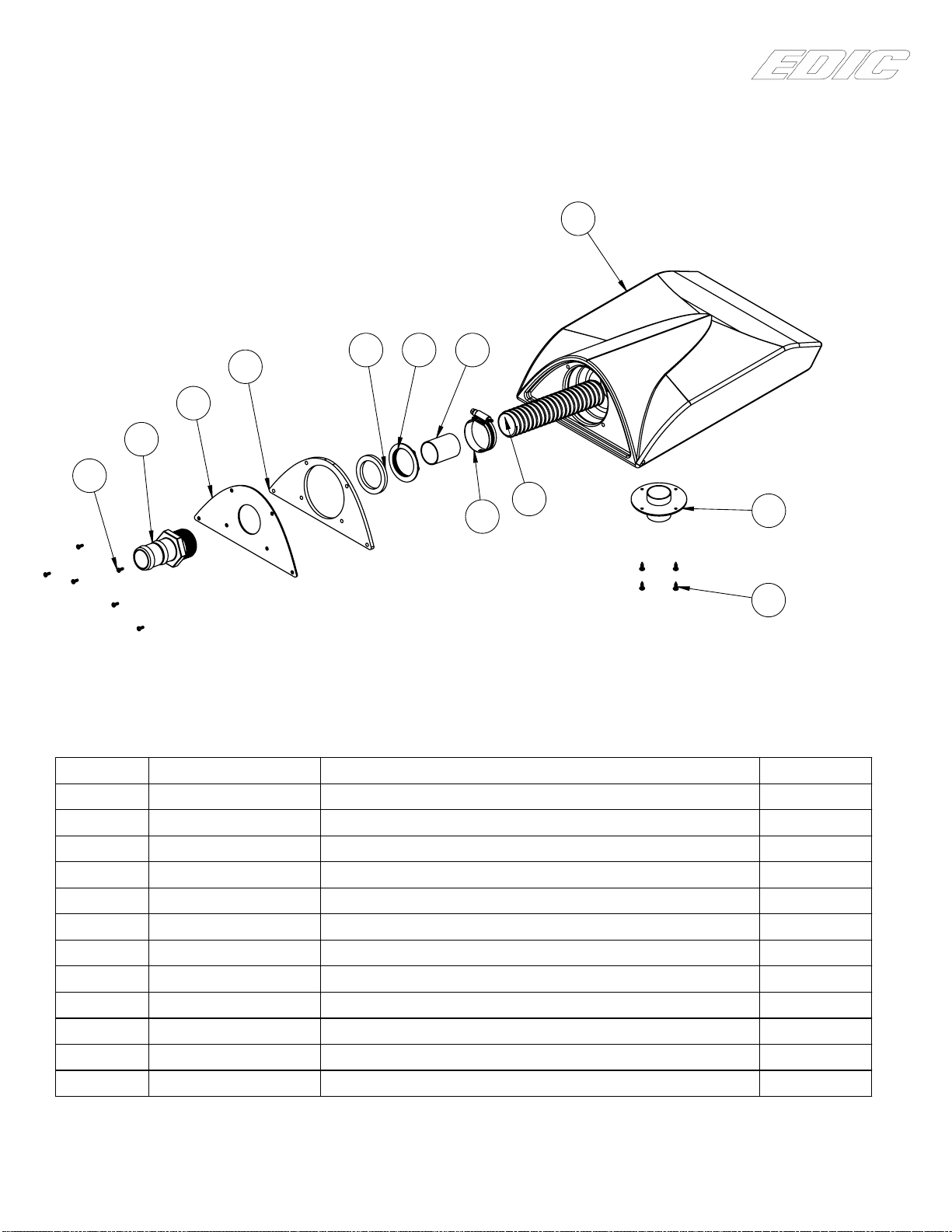

5 6 7

1

8

9

4

3

2

10

11

12

FB50 LID

7/15/2016

FB50 LID

7/15/2016

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

F13810

LID

1

2

E13904

INTAKE PANEL GASKET

1

3

D13608

INTAKE PANEL

1

4

K13920

1 1/2" HOSE BARB

1

5

E11128

DRAIN VALVE GASKET

1

6

C00271

1 1/2" JAM NUT

1

7

D14054

1-1/2" ID EXTENSION TUBE

1

8

J00618-1

1 1/2" WIRE REINFORCED HOSE

1

9

C00324-38

#6-32 X 3/8" SCREW RH

6

10

D14019

AIR GUIDE FLANGE

1

11

C00293

#8-32 X 0.5" PAN HEAD SCREW

4

12

J00650

SCREW CLAMP #24 1.25 INCH

1

16

LIMITED WARRANTY POLICY

To register your product warranty, visit our website at: www.edic-usa.com/warranty-registration/

LIFETIME on rotationally molded polyethylene tanks

2 YEARS on service labor, and all other parts not covered by the LIFETIME terms

EDIC REPLACEMENT PARTS LIMITED WARRANTY PLAN

All parts sold as replacement parts for out-of-warranty EDIC products have the following Limited Warranty, with no warranty on labor: 30

DAYS

Your product is warranted to be free of defects in material and workmanship for the period set forth above, aer the date of delivery to the

retail purchaser, when operated in normal service and used in accordance with the operating and maintenance instructions in the Owner’s

Manual. is warranty is limited to and provides at no cost to the retail purchaser repair or replacement of parts determined to be defective,

at EDIC’s option, and labor, if provided for above, to replace or repair the parts (“service labor”) according to EDIC’s Standard Rates, during

the warranty period set forth above. is warranty excludes transportation charges unless authorized in writing by EDIC. No warranty

returns for refund or credit will be permitted. In the event of a defect, these are your exclusive remedies. Warranty claims must be made in

writing to EDIC prior to returning the product and no products will be accepted for repair or replacement without prior authorization by

EDIC. Use of parts not approved by EDIC in EDIC products will void this warranty. Warranty repair or replacement shall not extend the

original warranty period of the product, and replacement parts used for in-warranty repairs will only be warranted for the remainder of the

original warranty and not from their installation date. Any parts or product replaced under this Limited Warranty will become the property

of EDIC.

EXCEPTIONS AND EXCLUSIONS FROM THE WARRANTY. is Limited Warranty only covers product issues caused by defects in ma-

terial or workmanship during normal service. It does not cover product issues from any other cause, including but not limited to (a) trans-

portation damages; (b) alteration by unauthorized persons; (c) unauthorized use, unreasonable use, misuse, or abuse (including the use of

incompatible or corrosive chemicals or overloading of capacity); (d) failure caused by lack of proper maintenance and cleaning; (e) normal

wear on items such as cords, belts, hoses, switches, bumpers, gaskets, seals, carbon brushes, squeegees, harnesses, valves, cams, extraction

brushes, bearings, handle grips, lters and nishes; (f) acts of God; or (g) modication of or any part of the product. is Limited Warranty

does not cover EDIC products sold AS IS and WITH ALL FAULTS. is Limited Warranty is valid only in the United States and Canada.

We suggest that you complete and return the enclosed product registration card promptly to facilitate verication of the date of the origi-

nal purchase. However, return of the product registration card does not eliminate the need for the retail purchaser to maintain the original

proof of the purchase in order to obtain the warranty benets. In the event that you do not have proof of purchase date, the purchase date

for purposes of this warranty will be the date of manufacture.

For specic information on how to obtain warranty services for your product, please write to: EDIC/Warranty Department 1753 Blake Ave.

Los Angeles, CA 90031

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF THIS STATEMENT. THERE IS

NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY USE ON THESE GOODS.

NO IMPLIED WARRANTY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, APPLIES TO THE PRODUCT AFTER THE APPLICABLE PERIOD OF THE EXPRESS LIMITED WARRANTY STATED

ABOVE, AND NO OTHER EXPRESS WARRANTY, EXCEPT AS MENTIONED ABOVE, GIVEN BY ANY PERSON OR ENTITY WITH

RESPECT TO THE PRODUCT SHALL BIND EDIC. EDIC SHALL NOT BE LIABLE FOR ANY FORM OF ACTION FOR ANY DAM-

AGES, WHETHER DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR INDIRECT, TO PROPERTY OR PERSON, INCLUDING

BUT NOT LIMITED TO, DAMAGE OR LOSS OF INCOME, LOSS OF PRODUCTION, OR LOSS OF PROFITS DUE TO MALFUNC-

TIONING OF ANY PRODUCT, REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED. IN NO EVENT SHALL

RECOVERY OF ANY KIND AGAINST EDIC BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT SOLD

BY EDIC, AND CAUSING

THE ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, YOU ASSUME ALL THE RISK AND LIABILITY FOR LOSS,

DAMAGE OR INJURY TO YOU AND YOUR PROPERTY AND TO OTHERS AND THEIR PROPERTY ARISING OUT OF USE OR

MISUSE OF, OR INABILITY TO USE, THE PRODUCT NOT CAUSED DIRECTLY BY NEGLIGENCE OF EDIC. THIS LIMITED WAR-

RANTY STATES YOUR EXCLUSIVE REMEDY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how long an implied

warranty lasts, so the above limitations or exclusions may not apply to you. is Limited Warranty gives you specic legal rights and you

may have other rights which vary from state to state (or province).

Table of contents

Other Edic Scrubber manuals

Popular Scrubber manuals by other brands

Kärcher

Kärcher KM 130/300 R LPG Original instructions

Abicor Binzel

Abicor Binzel xFUME FLEX operating instructions

Weller

Weller FT12 operating instructions

Floorwash

Floorwash 1400 Manual for use and maintenance

Cleanfix

Cleanfix Sparrow Safety, operation & maintenance manual

Trident

Trident NM14 Use and maintenance manual