iv

Contents

Expansion Chassis Installation .........................................................................3-7

Placing The Keyboard .......................................................................................3-8

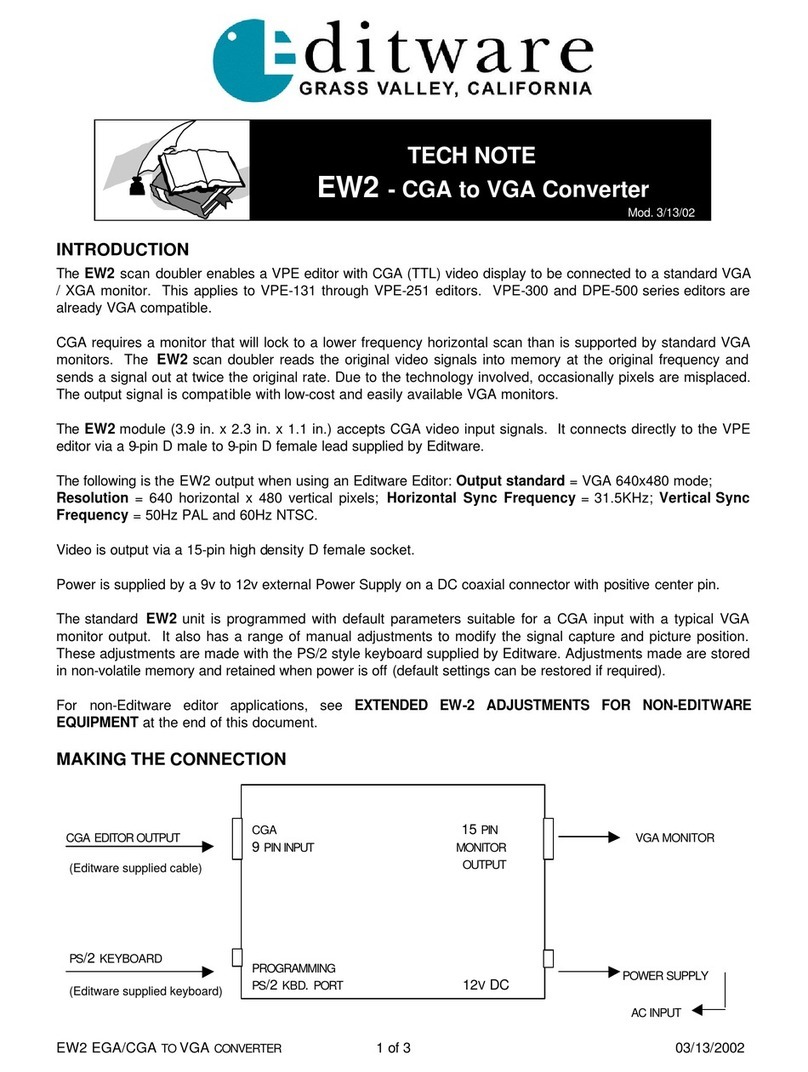

Making The Connections .........................................................................................3-9

Computing Chassis Connections .....................................................................3-9

Expansion Chassis Connections .......................................................................3-13

K5 Keyboard Connections ................................................................................3-14

The Start-up Sequence .............................................................................................3-15

Turning Power On .............................................................................................3-15

Menu Selection And Control ............................................................................3-16

Making Basic Checks ................................................................................................3-19

Machine Assignments .......................................................................................3-19

VTR Machine Assignments ........................................................................3-20

AUX and BLK Crosspoint Assignments ..................................................3-22

Fast Column Data Entry .............................................................................3-23

Other Machine Assignments .....................................................................3-24

Communications Testing ............................................................................3-25

Installation Troubleshooting ...................................................................................3-27

Front Panel Status Indicators ............................................................................3-27

Program Execution ............................................................................................3-28

SBC Switches .......................................................................................................3-28

SBC Jumpers .......................................................................................................3-29

Appendix A – System Differences

Appendix B – Port Availability With Options

Appendix C – K3 Keyboard Information

Introduction ...............................................................................................................C-1

K3 Keyboard New Features ....................................................................................C-1

Embedded Functions ...............................................................................................C-2

Embedded Alpha Character Keystrokes ...............................................................C-3

Keyboard Sensitivity Adjustment ..........................................................................C-4

Uploading/Re-uploading Keyboard Software ....................................................C-5

Troubleshooting After Downloading ....................................................................C-5

Internal Keyboard DIP Switch Settings .................................................................C-6

Appendix D – K2 Keyboard Information

Introduction ...............................................................................................................D-1

Manual Override of Jog Knob Automatic Mode .................................................D-1

Keyboard Sensitivity Adjustment ..........................................................................D-2

Appendix E – Interconnecting Diagrams

Appendix F – System Software Installation

Introduction .........................................................................................................F-1

Installing System Software ...............................................................................F-1