M102 REV. A (OCT. 2002)

- 2 -

MODEL 625 OPERATING AND ADJUSTING INSTRUCTIONS

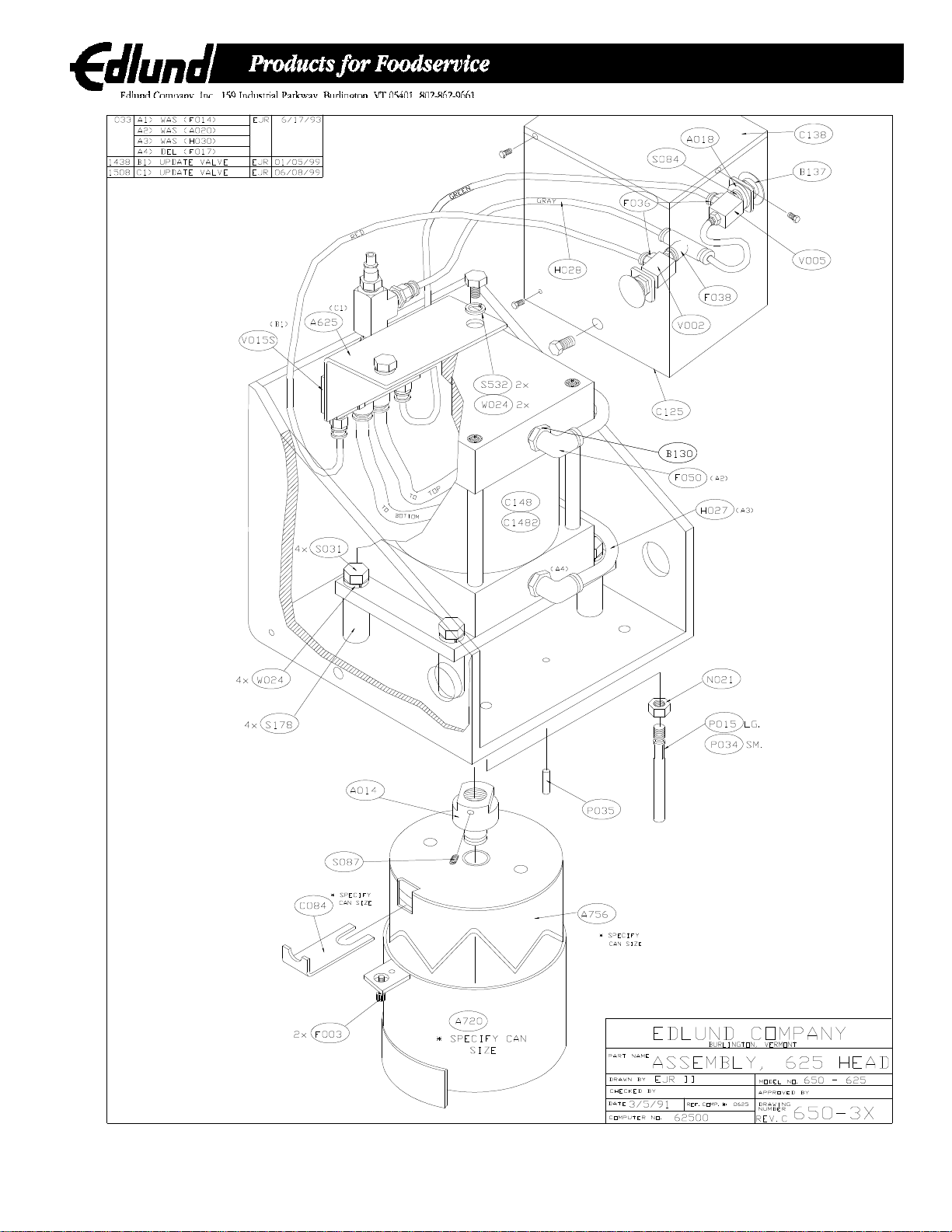

The Edlund Model 625 Pneumatic Can Opener operates at a minimum pressure of 75 PSIG. Lubrication is

not necessary but clean, dry air will prolong the units.

The opener may be connected to the air line using the quick disconnect coupling furnished and a length of

air hose.

The opener is simple to operate using the following procedure:

1. Connect air line and set inlet pressure to 75 PSIG minimum.

2. Place can to be opened on base against tab on guard ring. The can will be aligned with can guard

at the top of the opener.

3. Press both red buttons on sides of head at the same time. Hold until cylinder completes its

downward stroke and then release both buttons. Crown punch will retract to its starting position.

4. Remove can and repeat steps 2 and 3 as required.

The Model 625 opener is factory adjusted to open a standard #10 can or the particular size can ordered.

The crown punch should penetrate the can just far enough to cut off the cover but not so far as to cause

excessive splashing of liquid in can. If an adjustment is required to improve operation of the opener, the

following procedure will be used:

CAUTION: To avoid personal injury, disconnect air line before making any adjustment to opener.

1. Disconnect air line to unit.

2. Place can to be opened under can guard.

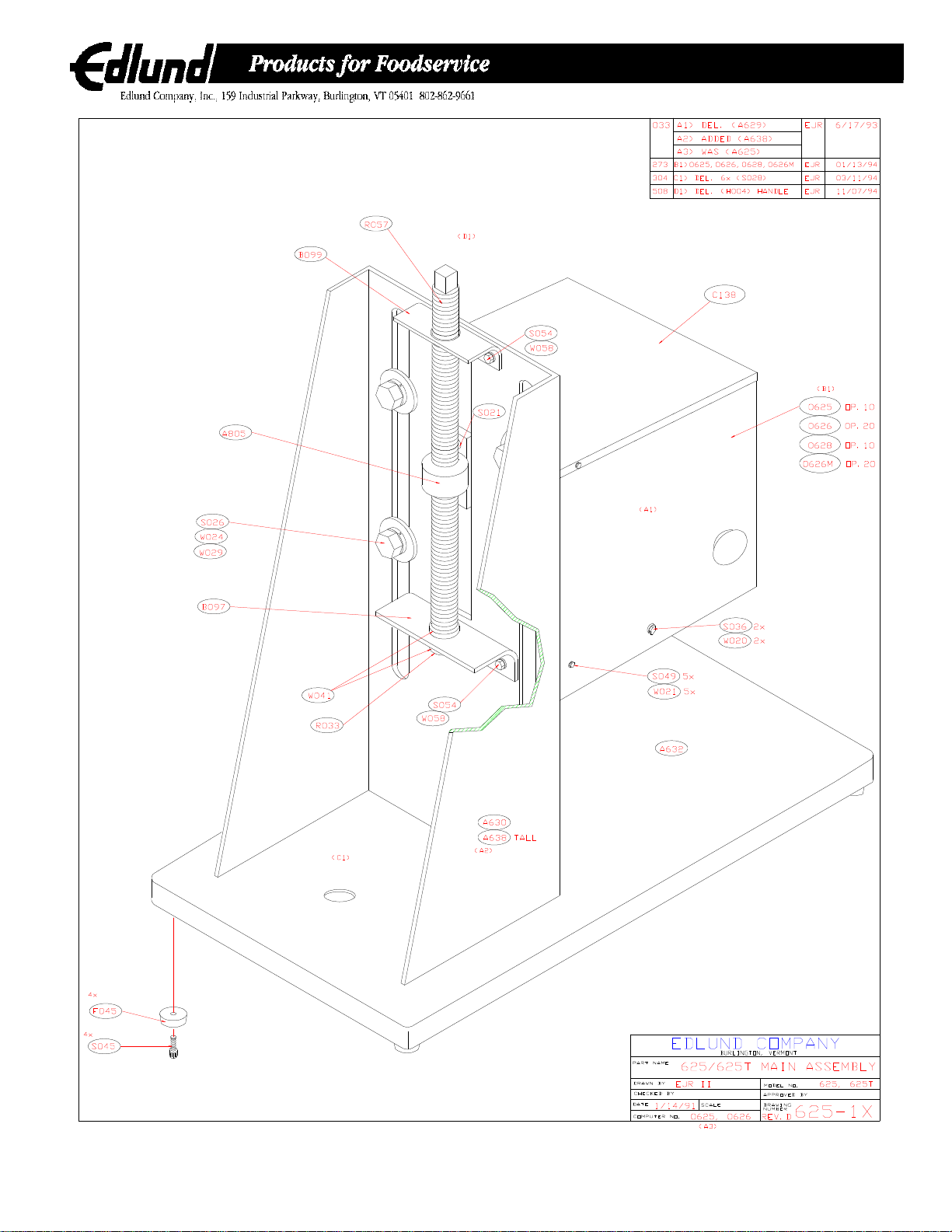

3. Loosen the four nuts or bolts at the rear of the vertical (see drawing) and raise or lower the head as

desired, keeping the can and can guard aligned and level.

4. Tighten fasteners and close interlock door. Operate according to operating instructions.

If a new size can is required to be opened, the following procedure will be used:

1. Disconnect airline to unit.

2. With one hand, hold up on the knife guard ring and with the other hand unscrew the two thumb

screws. (A flathead screwdriver may be needed to start the screws.) Let the guard ring down and

place to the side. Now hold up on the knife with one hand (being careful of any sharp parts of the

knife), and with the other hand, pull the blade clip straight out. (You may have to wiggle the knife to

loosen the blade clip.) Let the knife down. Place knife and clip with guard ring. Do not let knife fall

in the deck.

3. Install desired crown punch and can guard onto opener.

4. If can knockout pin does not align with holes in crown punch rotate crown punch or remove pin and

use proper size pin in alternate location.

5. Place can to be opened under can guard. If new can is taller than former size can, loosen the four

nuts or bolts at rear of vertical (see drawing) and raise head so can will fit.

6. Place ¼ inch to 5/16-inch thick shim between can and can guard.

7. Level and align head and tighten fasteners at rear of vertical.

8. Operate according to preceding instructions.

The knife, guard and clip should be removed after every use for cleaning. To remove any

preservatives or brine from the unit clean with mild soap and water. For disassembly see #2 above.

The entire machine may be hosed down inside and out.