1

Content

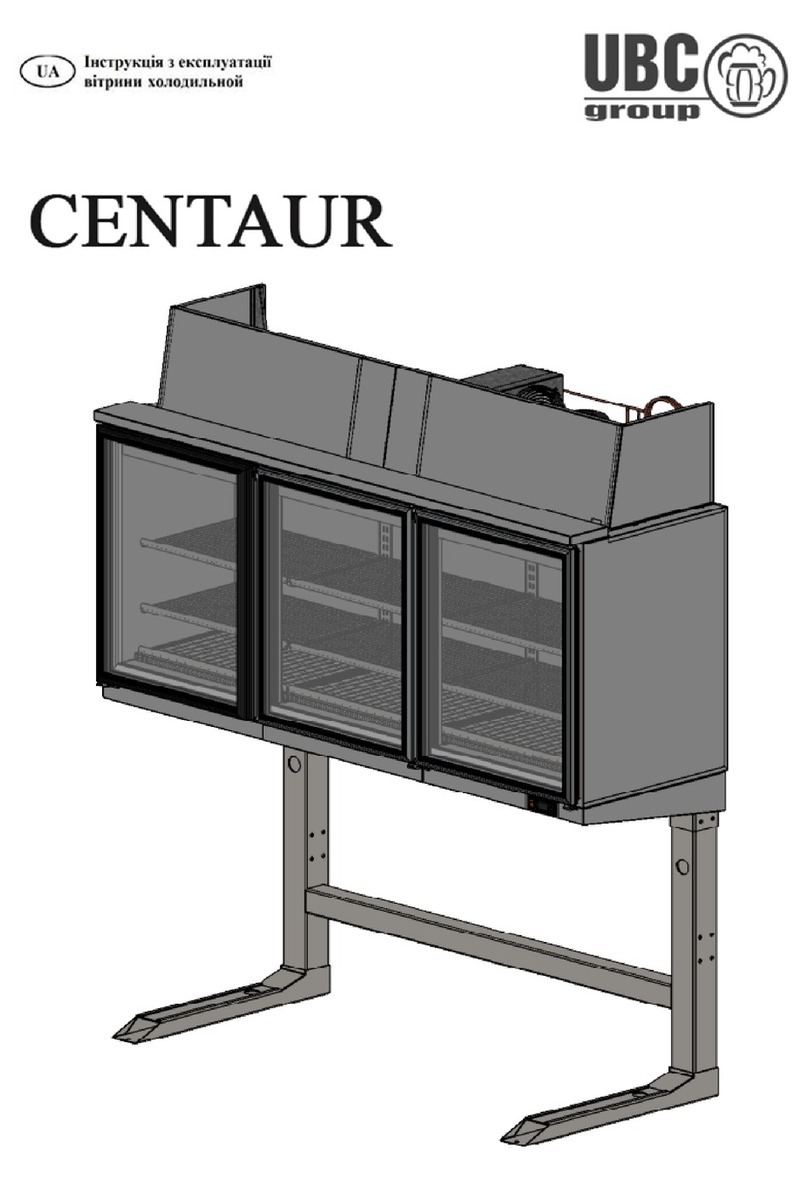

Model type.....................................................................................................2

Security .....................................................................................................3

Explanation symbols......................................................................................3

General information.......................................................................................4

Manufacturer's responsibility .........................................................................4

General safety instructions and warnings........................................................5

Safety techniques for operating equipment with refrigerant R -290 (propane).7

Instruction .....................................................................................................9

1. Standards and directives.............................................................................9

2. Rating plate................................................................................................9

3. Unpacking, installing and connecting.......................................................11

5. Temperature control.................................................................................12

6. Temperature regulator..............................................................................13

6.1. Mechanical thermostat.......................................................................13

6.2. Eliwell electronic temperature controller ...........................................14

6.3. Regulation of the temperature range ..................................................15

7. Loading ...................................................................................................15

8. Maintenance, defrosting and cleaning.......................................................16

8.1. Service..............................................................................................16

8.2. Defrosting and cleaning.....................................................................17

9. Storage.....................................................................................................19

10. Disposal.................................................................................................19

11. Possible malfunctions and recommendations for them elimination..........20