Please read thoroughly before operation and keep for future reference 9

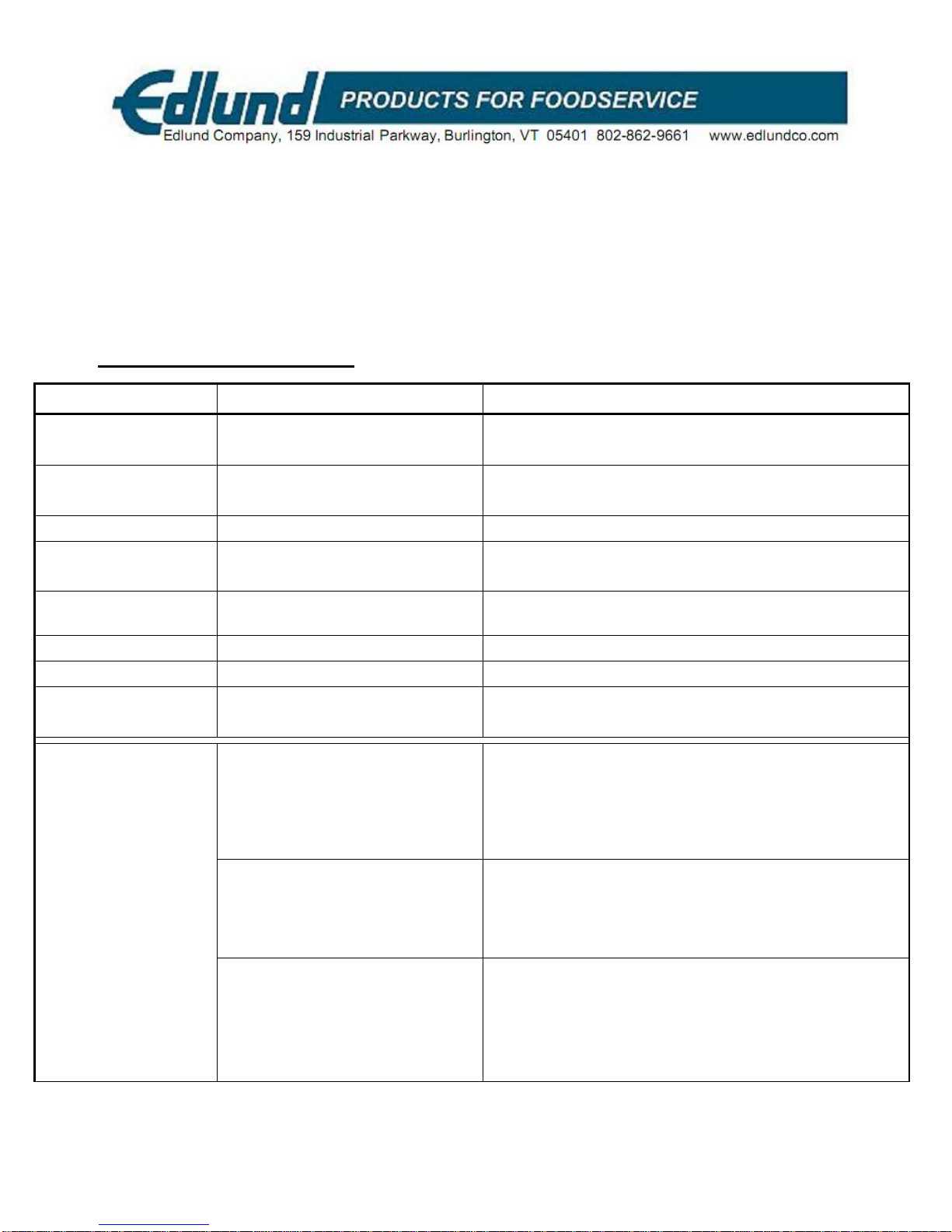

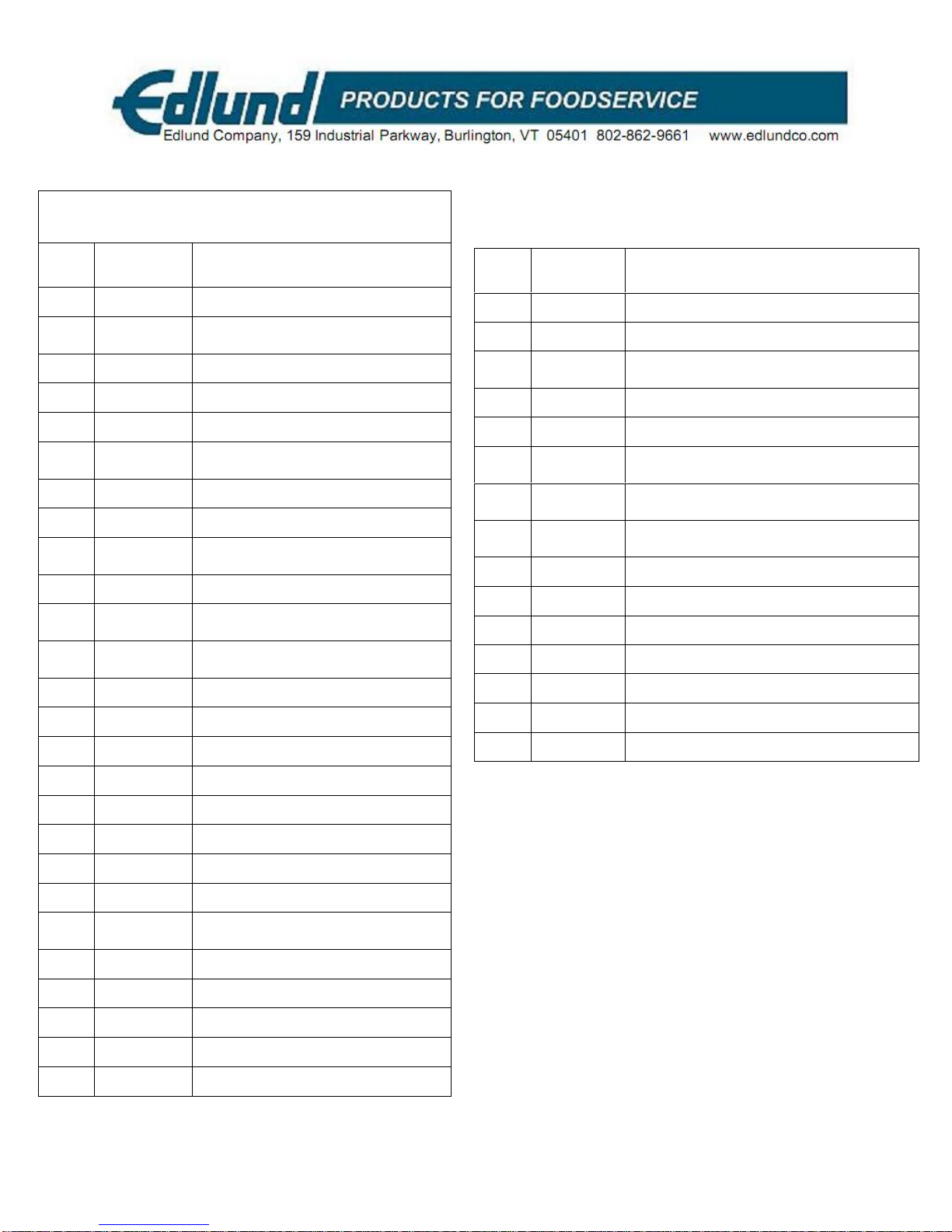

QTY PART

NUMBER DESCRIPTION

4S049 SCREW, #10-32 X 3/8, SS HEX HEAD

4S059 SCREW, #6-32 X .25, SS HEX HEAD

2S085 SCREW, #8-32 X 1/4 S/S RHM

SLOTTED

2S098 SCREW, #10-32 X 3/8 SHCS, SS

1S312 SWITCH, ROCKER--HI/LOW

1S314 SCREW, KNIFE HOLDER, KH LATCH

SHOULDER

1S316 SCREW, KNIFE HOLDER, RIGHT

SHOULDER

1S317 SCREW, KNIFE HOLDER, LEFT

SHOULDER

1S318 SHIM, SS, 0.005 THK

1S318T SHIM, .015 X .335 X.438

1S338 SPACER, ACTUATOR LEVER

2W010 WASHER, FLAT, #10 SS

4W018 WASHER, #10 LOCK, PLATED

4W022 WASHER, #6 LOCK, SS

2 W023 WASHER, #8 LOCK, SS

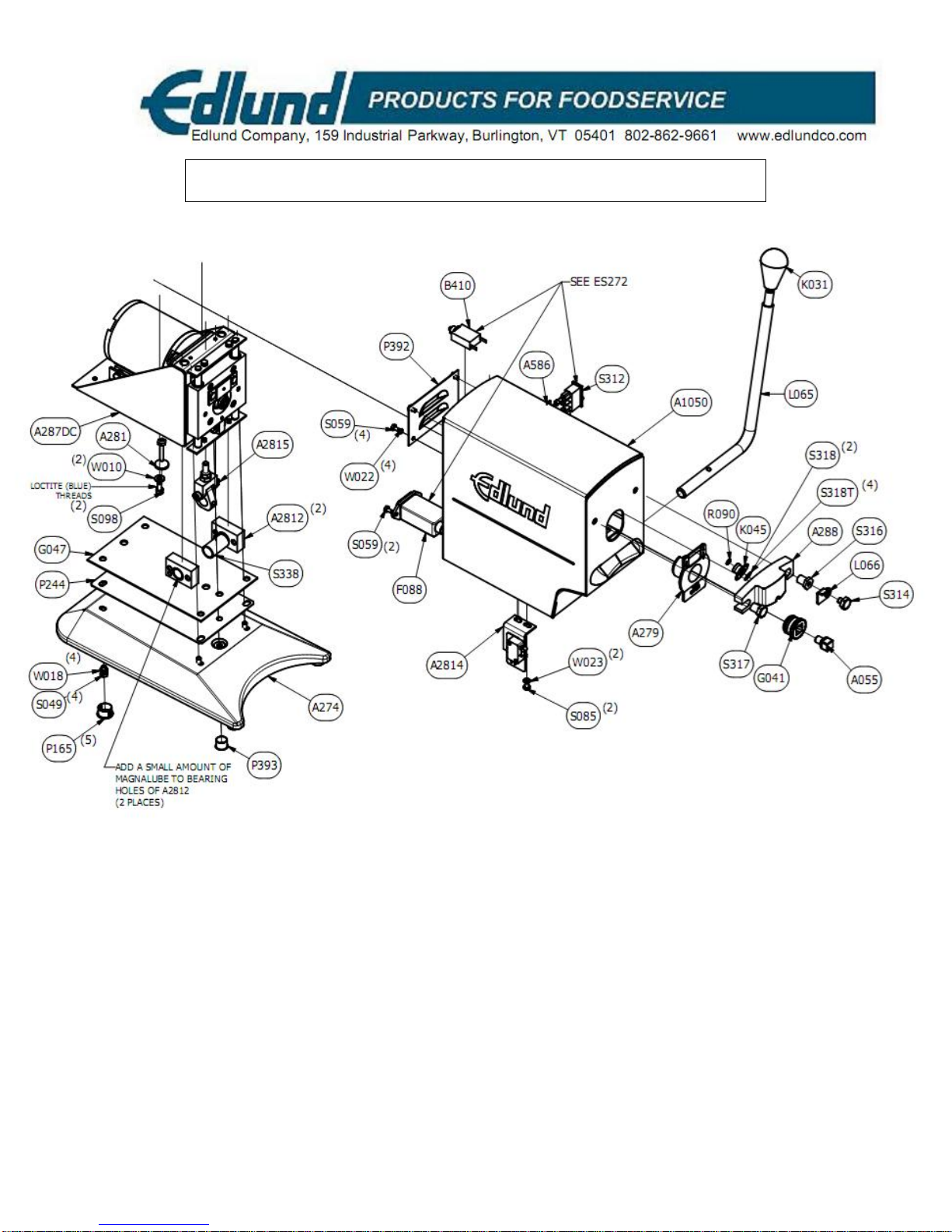

270 ASSEMBLY AND PARTS LIST--

115V

QTY PART

NUMBER DESCRIPTION

1A055 ADAPTER, DRIVE GEAR

1A273C WELDMENT, HOUSING

ASSEMBLY

1A274 WELDMENT, BASE

1A279 ASSEMBLY, GEAR SHIELD

1A281 ASSEMBLY, SWITCH ACTUATOR

2A2812 ASSEMBLY, LEVER ARM

BEARING MOUNT

1A2814 ASSEMBLY, ROLLER SWITCH

1A2815 ASSEMBLY, LEVER CAM

1A283DC ASSEMBLY, 270 FRAME,

MOTOR/GEAR TRAIN, 115V

1A288 ASSEMBLY, KNIFE HOLDER

1A586 ASSEMBLY, SPEED CONTROL

DIODES

2A641 ASSEMBLY, CORD W/

CONNECTORS

1B410 BREAKER, THERMAL, 1.2 A

1G041 GEAR, CAN DRIVE

1G047 GASKET, BASE

1K031 KNOB, LEVER ARM

1K045 KNIFE

1L049 LABEL, NSF

1L065 LEVER, ACTUATOR ARM

1L066 LATCH, KNIFEHOLDER

1L073 RATING LABEL, 270, POWER

MOTOR, 115V

1L087 CAUTION LABEL, RED, 270

5P165 PLUG

1P244 PLATE, GASKET

1P392 PLATE, LOUVER COVER

1P393 PLUG